Method for promoting enzymolysis saccharification of lignocellulose

A lignocellulase and lignocellulose technology is applied in the field of promoting lignocellulosic enzymatic hydrolysis and saccharification, which can solve the problems of poor enzyme activity, difficult operation, low saccharification rate, etc., so as to ensure activity, avoid loss, and reduce thermal inactivation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Select wool from the hair, wash the wool with deionized water to remove surface impurities, dry it, and then soak the wool with a solid-to-liquid ratio of 1:1 (mg / mL) in 30% (v / v) acetic acid solution. Treat at 85°C for 30 minutes. Use ammonia water to neutralize excess acetic acid until the pH value is 6, filter, and dry the filtrate at 40°C for 2 days to obtain protein powder. Seal the obtained hair protein powder in a polyethylene bag and store at 4°C for future use.

[0043] 2) Select corn stalks for lignocellulosic biomass. First, take a certain amount of corn stalks, pick out foreign matter, crush and sieve the selected stalks (40 mesh), soak the sieved straw powder in deionized water, solidify The liquid ratio is 0.5:1 (mg / mL), and then irradiated with gamma rays at a dose of 1kGy for 10min.

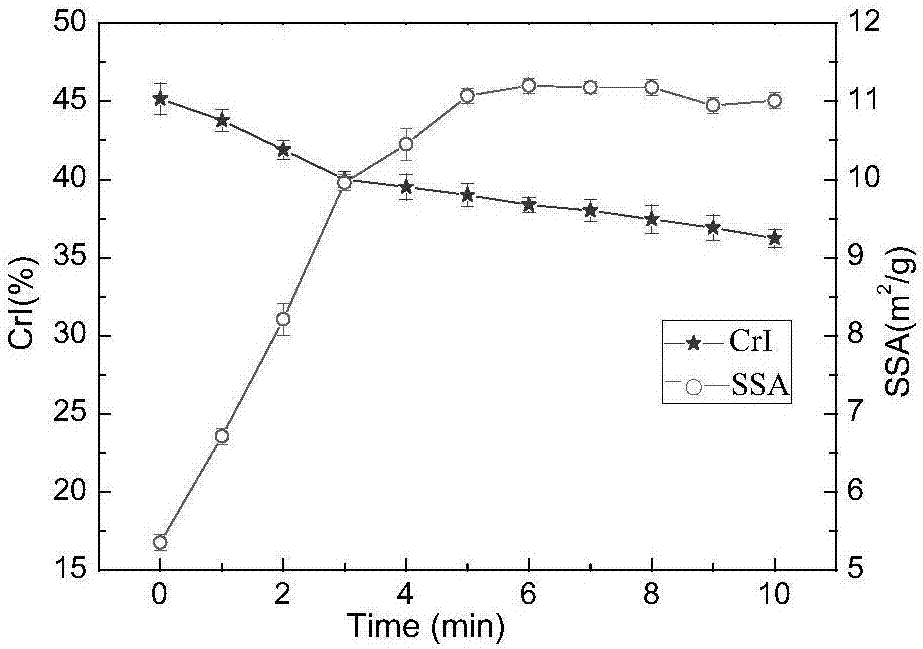

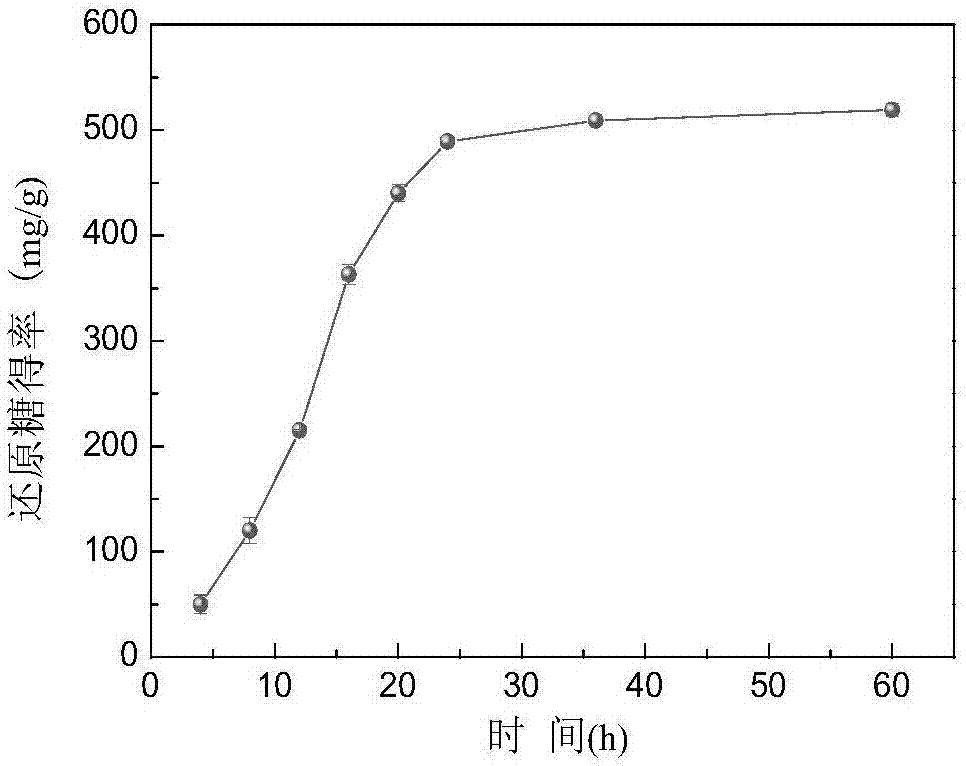

[0044]3) Take 0.5g of the pretreated sample in (2) and place it in a 50mL flask, add 2mL of 0.075mol / L (pH4.8) citric acid-sodium citrate buffer solution into it and mi...

Embodiment 2

[0051] 1) Select wool from the hair, wash the wool with deionized water to remove surface impurities, dry it, and then soak the wool with a solid-to-liquid ratio of 1:2 (mg / mL) in 35% (v / v) acetic acid solution. Treat at 88°C for 35 minutes. Use ammonia water to neutralize excess acetic acid until the pH value is 6.3, filter, and dry the filtrate at 45°C for 2 days to obtain protein powder. Seal the obtained hair protein powder in a polyethylene bag and store at 4°C for future use.

[0052] 2) Select corn stalks for lignocellulosic biomass. Firstly, take a certain amount of corn stalks, pick out foreign objects, crush and sieve the selected stalks (50 mesh), soak the sieved straw powder in deionized water, solidify The liquid ratio is 1:1 (mg / mL), and then irradiated with gamma rays at a dose of 3kGy for 20min.

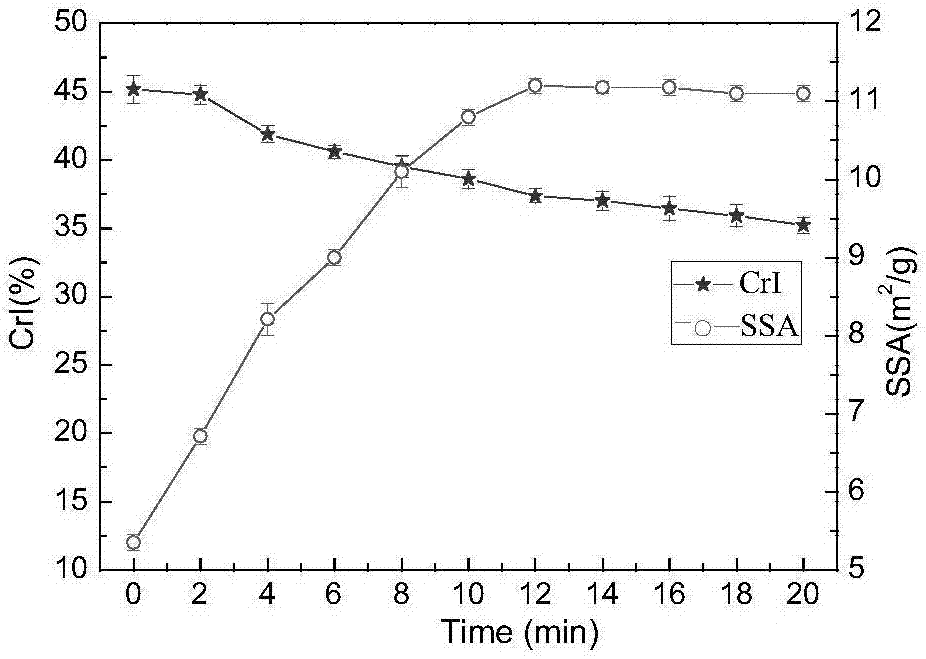

[0053] 3) Take 0.5g of the pretreated sample in (2) and place it in a 50mL flask, add 2.5mL of 0.075mol / L (pH4.8) citric acid-sodium citrate buffer to it and mix wel...

Embodiment 3

[0060] 1) Select wool for hair, wash the wool with deionized water to remove surface impurities, dry it, and then soak the wool with a solid-to-liquid ratio of 1:3 (mg / mL) in 40% (v / v) acetic acid solution. Treat at 90°C for 40 minutes. Use ammonia water to neutralize excess acetic acid until the pH value is 6.6, filter, and dry the filtrate at 50°C for 2 days to obtain protein powder. Seal the obtained hair protein powder in a polyethylene bag and store at 4°C for use.

[0061] 2) Select corn stalks for lignocellulosic biomass. First, take a certain amount of corn stalks, pick out foreign matter, crush and sieve the selected stalks (60 mesh), soak the sieved straw powder in deionized water, solidify The liquid ratio is 1.5:1 (mg / mL), and then irradiated with gamma rays with an irradiation dose of 6kGy for 30min.

[0062] 3) Take 0.5g of the pretreated sample in (2) and place it in a 50mL flask, add 3mL of 0.075mol / L (pH4.8) citric acid-sodium citrate buffer solution into it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com