Method for degelatinizing hemp fiber with biological enzyme degelatinizing method combined with chemical degelatinizing method

A hemp fiber and bio-enzyme technology, which is applied in fiber treatment, fiber chemical post-treatment, plant raw materials, etc., can solve the problems of long chemical degumming process, poor product quality stability, and difficult control of degumming quality. Bleaching process requirements, cost green and environmental protection, and the effect of expanding the hemp production chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

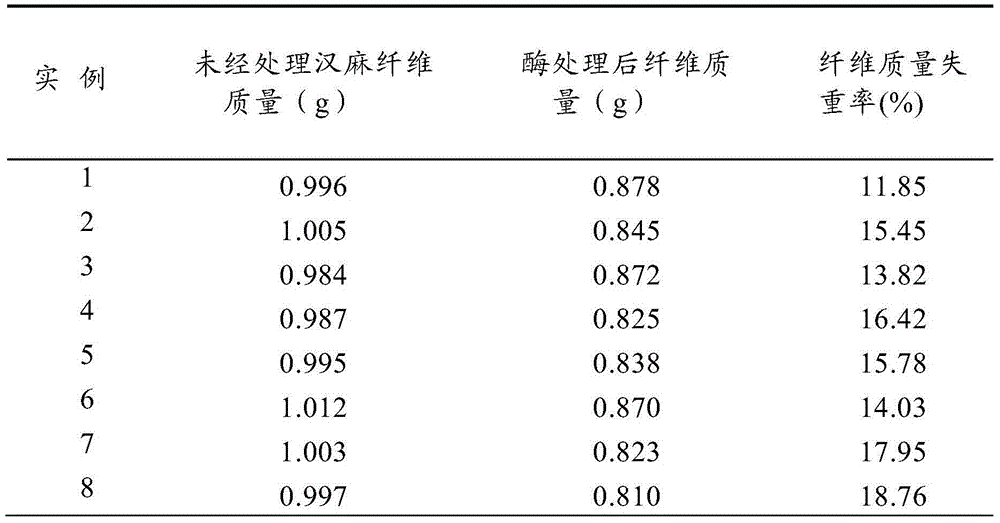

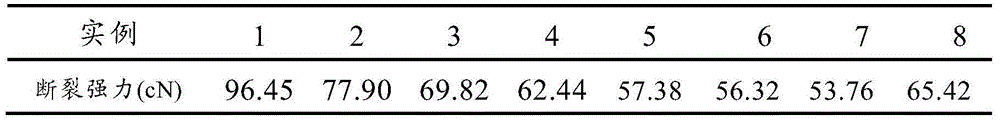

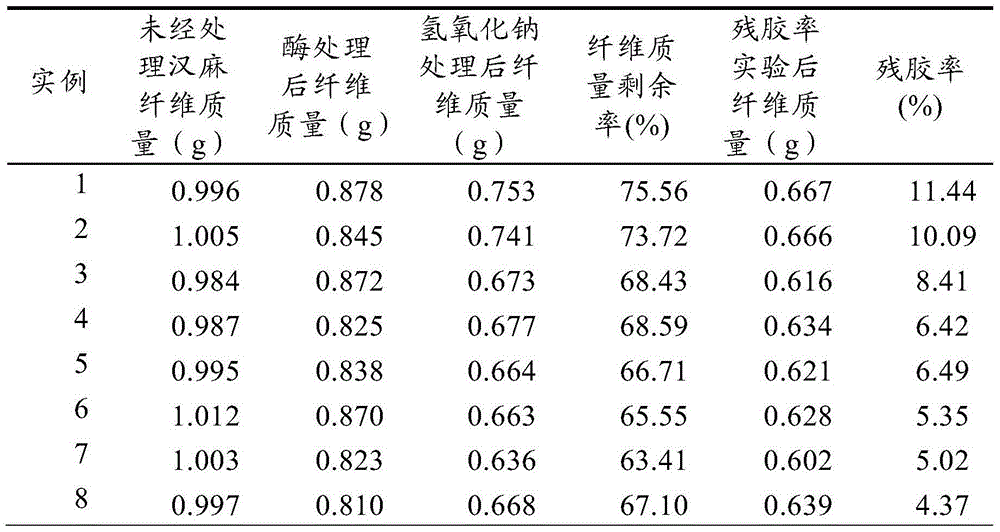

Embodiment 1

[0029] Combined degumming process of hemp fiber with bio-enzyme chemical method

[0030] (1) Weigh 0.996g of untreated hemp fiber and place it in a 50ml beaker, add 30ml of deionized water, and bathe in a 50°C water bath for 10min. Fibers were removed after 10 min. Put the dried hemp fiber in a 50ml beaker, with a bath ratio of 1:30, add 30ml of citric acid-sodium citrate buffer solution with a pH of 3.6 in the beaker, weigh 0.06g of pectinase, Put 0.09g of xylanase in a beaker to make the concentrations 2.0g / L and 3.0g / L respectively, place the beaker in a water bath at 40°C for 30min, then take out the fibers, wash them in cold water at 15°C, and dry them after washing. Dry and weigh.

[0031] Put 0.878g of enzyme-treated hemp fiber into a 50ml beaker of known mass, and add 26.34ml of deionized water at a liquor ratio of 1:30. Add 0.04g of sodium carbonate, 0.053g of sodium silicate, and 0.08g of sodium sulfite to the beaker to make the concentrations respectively 1.5g / L,...

Embodiment 2

[0033] Combined degumming process of hemp fiber with bio-enzyme chemical method

[0034] Weigh 1.005g of untreated hemp fiber and place it in a 50ml beaker, add 30ml of deionized water, and bathe in a 50°C water bath for 10min. Fibers were removed after 10 min. Put the dried hemp fiber in a 50ml beaker, the bath ratio is 1:30, add 30ml of citric acid-sodium citrate buffer solution with a pH of 4.6 in the beaker, weigh 0.09g of pectinase, Put 0.12g of xylanase in a beaker to make the concentrations 3.0g / L and 4.0g / L respectively, place the beaker in a water bath at 50°C for 60min, then take out the fiber, wash it in cold water at 15°C, and dry it after washing. Dry and weigh.

[0035] Put 0.845 g of enzyme-treated hemp fiber into a 50-ml beaker of known mass, and add 25.35 ml of deionized water at a liquor ratio of 1:30. Add 0.038g of sodium carbonate, 0.05g of sodium silicate, and 0.076g of sodium sulfite to the beaker to make the concentrations respectively 1.5g / L, 2.0g / L,...

Embodiment 3

[0037] Hemp fiber biological enzyme degumming

[0038] Weigh 0.984g of untreated hemp fiber and place it in a 50ml beaker, add 30ml of deionized water, and bathe in a 50°C water bath for 10min. Fibers were removed after 10 min. Put the dried hemp fiber in a 50ml beaker, the bath ratio is 1:30, add 30ml of citric acid-sodium citrate buffer solution with a pH of 5.6 in the beaker, weigh 0.03g of pectinase, Put 0.15g of xylanase in a beaker to make the concentrations 1.0g / L and 5.0g / L respectively, place the beaker in a water bath at 60°C for 90min, then take out the fibers, wash them in cold water at 15°C, and dry them after washing. Dry and weigh.

[0039]Put 0.872 g of enzyme-treated hemp fiber into a 50 ml beaker of known mass, and add 26.16 ml of deionized water at a liquor ratio of 1:30. Add 0.039g of sodium carbonate, 0.052g of sodium silicate, and 0.078g of sodium sulfite to the beaker to make the concentrations 1.5g / L, 2.0g / L, and 3.0g / L respectively, and then add 0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com