Fresh-cut vegetable processing method

A vegetable processing and vegetable technology, applied in the fields of fruit and vegetable preservation, heating preservation of fruits/vegetables, food preservation, etc., can solve the problems of loss, pH increase, fresh-cut vegetables sour taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

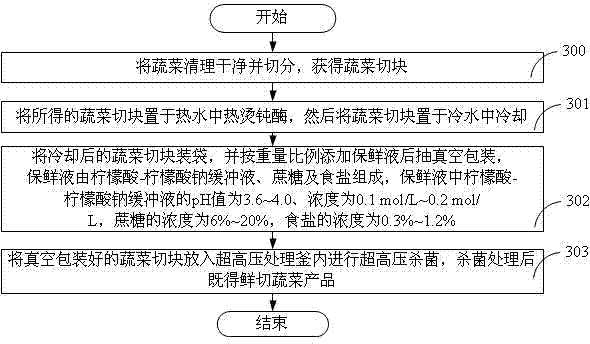

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The preparation of fresh cut green pepper

[0023] (1) Wash and cut the green pepper into slices, put the obtained green pepper slices into hot water to blanch the inactivated enzyme, and then place it in cold water to cool. The blanching temperature is 94-96° C., and the blanching time is 110 seconds.

[0024] (2) pack the chilli slices after cooling into bags, and vacuum pack after adding preservative solution in a weight ratio of 5:5. The concentration of citric acid-sodium citrate buffer solution is 0.1 mol / L, and the pH value of the buffer solution is is 3.8. The sucrose concentration in the preservation solution is 9%, and the salt concentration in the preservation solution is 0.5%. The vacuum degree of vacuum packaging is 0.095 MPa. The flexible packaging material can be a composite nylon bag.

[0025] (3) Put the vacuum-packed pepper slices into the ultra-high pressure treatment kettle, add water as the pressure transmission medium, then close t...

Embodiment 2

[0027] Embodiment 2 The preparation of fresh cut carrot

[0028] (1) Peel the carrots, wash them, and cut them into slices. Put the obtained carrot slices into hot water to blanch the inactivated enzyme, and then place them in cold water to cool. The blanching temperature is 94-96° C., and the blanching time is 90 seconds.

[0029] (2) Pack the cooled carrot slices into bags, add preservative solution in a weight ratio of 5:4, and then vacuum pack. The concentration of the citric acid-sodium citrate buffer solution is 0.2 mol / L, and the pH value of the buffer solution is 4.0. The sucrose concentration in the preservation solution is 18%, and the salt concentration in the preservation solution is 1%. The vacuum degree of vacuum packaging is 0.09 MPa. The flexible packaging material can be a composite nylon bag.

[0030] (3) Put the vacuum-packed carrot slices into the ultra-high pressure treatment kettle, add water as the pressure transmission medium, then close the ultra-h...

Embodiment 3

[0032] Embodiment 3 The preparation of fresh-cut rapeseed

[0033] (1) Wash and cut the rapeseed into slices, put the obtained rapeseed slices into hot water to blanch the inactivated enzyme, and then place them in cold water to cool. The blanching temperature is 94-96° C., and the blanching time is 60 seconds.

[0034] (2) Pack the cooled rapeseed slices into bags, add preservative solution in a weight ratio of 5:2, and then pack in a vacuum. The concentration of the citric acid-sodium citrate buffer solution is 0.2 mol / L, and the pH value of the buffer solution is 3.6. The sucrose concentration in the preservation solution is 18%, and the salt concentration in the preservation solution is 1%. The vacuum degree of vacuum packaging is 0.1 MPa. The flexible packaging material can be a composite nylon bag.

[0035] (3) Put the vacuum-packed rapeseed slices into the ultra-high pressure treatment kettle, add water as the pressure transmission medium, then close the ultra-high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com