Maize straw pretreatment process adopting multi-hydrogen-bond-donor deep-eutectic solvent and recycling method of multi-hydrogen-bond-donor deep-eutectic solvent

A technology of deep eutectic solvent and corn stalks, which is applied in the field of chemical engineering, can solve the problems of low toxicity and biodegradability, and achieve the effect of process economy, less three wastes, and good pretreatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

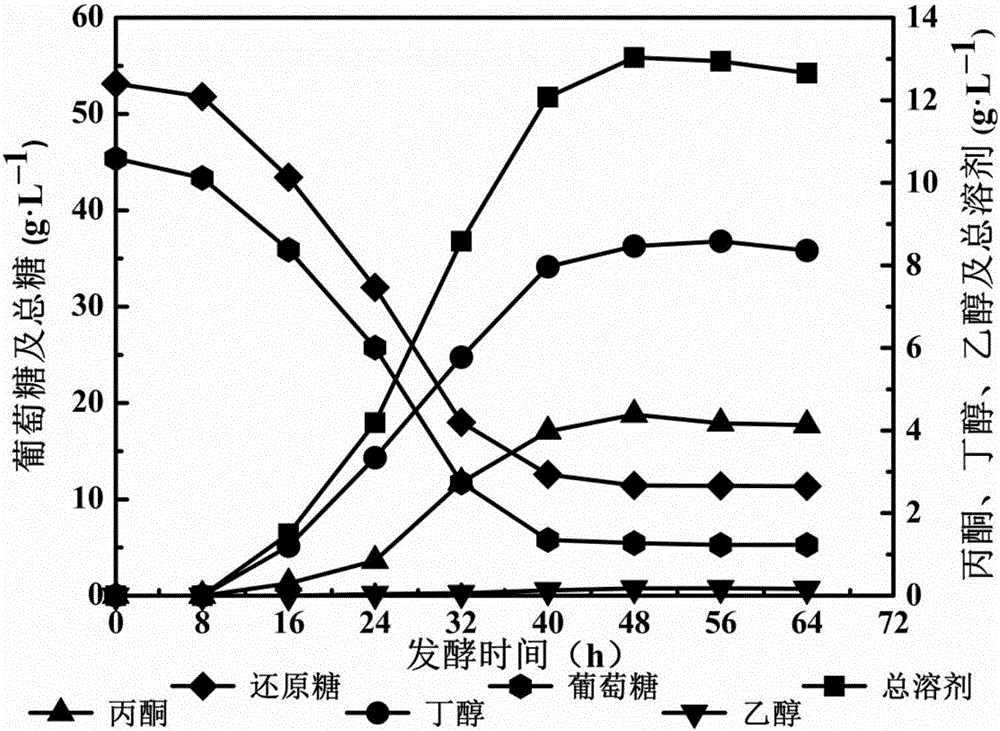

Image

Examples

Embodiment 1

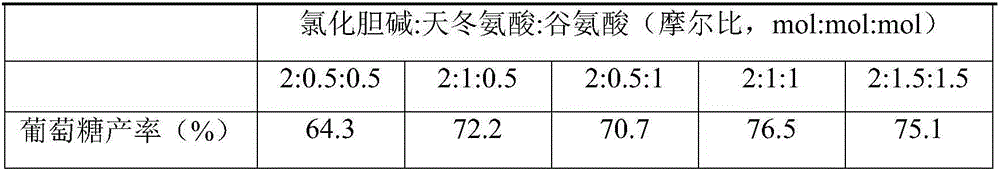

[0014] Example 1 Choline chloride, aspartic acid and glutamic acid pretreated corn stalks in different molar ratios

[0015] Get the choline chloride of 100g different molar proportions: aspartic acid: glutamic acid (2:0.5:0.5,2:1:0.5,2:0.5:1,2:1:1 and 2:1.5:1.5 ), adding 5 g of corn stalks, stirring at 130° C. for 2 h, then centrifuging the mixture, and washing the precipitate with deionized water for 3 times. Add pH 4.8, 50mM citric acid-sodium citrate buffer to the dried precipitate to form a mixed system, the final mass concentration of corn stalks is 10%, add The cellulase was used for enzymolysis, and the enzymolysis was carried out on a water bath shaker at 50°C and 150rpm for 72 hours, and the glucose yield was measured. The results are shown in Table 1.

[0016] Table 1 The optimization results of the molar ratio of choline chloride, aspartic acid and glutamic acid

[0017]

Embodiment 2

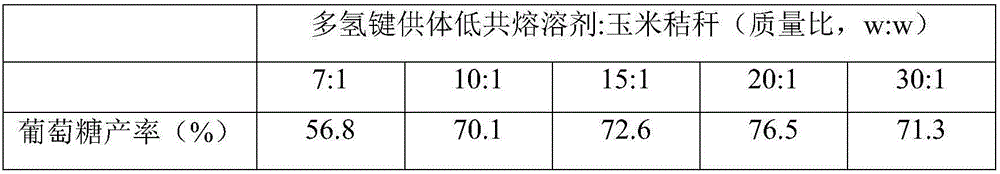

[0018] Example 2 Optimization of the Mass Ratio of Multi-Hydrogen Bond Donor Deep Eutectic Solvent and Corn Stalk

[0019] Get 100g of choline chloride with a molar ratio of 2:1:1: aspartic acid: glutamic acid, add corn by mass ratio 7:1, 10:1, 15:1, 20:1 and 30:1 respectively The straw was stirred at 130° C. for 2 h, then the mixture was centrifuged, and the precipitate was washed 3 times with deionized water. Add pH 4.8, 50mM citric acid-sodium citrate buffer to the dried precipitate to form a mixed system, the final mass concentration of corn stalks is 10%, add The cellulase was used for enzymolysis, and the enzymolysis was carried out on a water bath shaker at 50°C and 150rpm for 72h, and the glucose yield was measured. The results are shown in Table 2.

[0020] Table 2 Optimization results of the mass ratio of multi-hydrogen bond donor deep eutectic solvent to corn stover

[0021]

Embodiment 3

[0022] Example 3 Recovered multi-hydrogen bond donor deep eutectic solvent pretreatment of corn stalks

[0023] Take 100g of choline chloride:aspartic acid:glutamic acid with a molar ratio of 2:1:1, add 5g of corn stalks, stir at 130°C for 2h, then centrifuge the mixture, take the supernatant, and add corn stalks Straw (the mass ratio of supernatant to corn stalk is 20:1), stirred at 130° C. for 2 hours, and the above steps were repeated. All precipitates were washed 3 times with deionized water. Add pH 4.8, 50mM citric acid-sodium citrate buffer to the dried precipitate to form a mixed system, the final mass concentration of corn stalks is 10%, add The cellulase was used for enzymolysis, and the enzymolysis was carried out at 50°C and 150rpm on a water bath shaker for 72h. The choline chloride recovered four times: aspartic acid: glutamic acid pretreated corn stalks had a glucose yield of 65.4%. The results are shown in Table 3.

[0024] Table 3 Results of pretreatment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com