Graphite powder for negative electrode of lithium ion secondary cell and manufacturing method thereof

A secondary battery, graphite powder technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem of high material cost, achieve the effect of improving safety performance and reducing price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

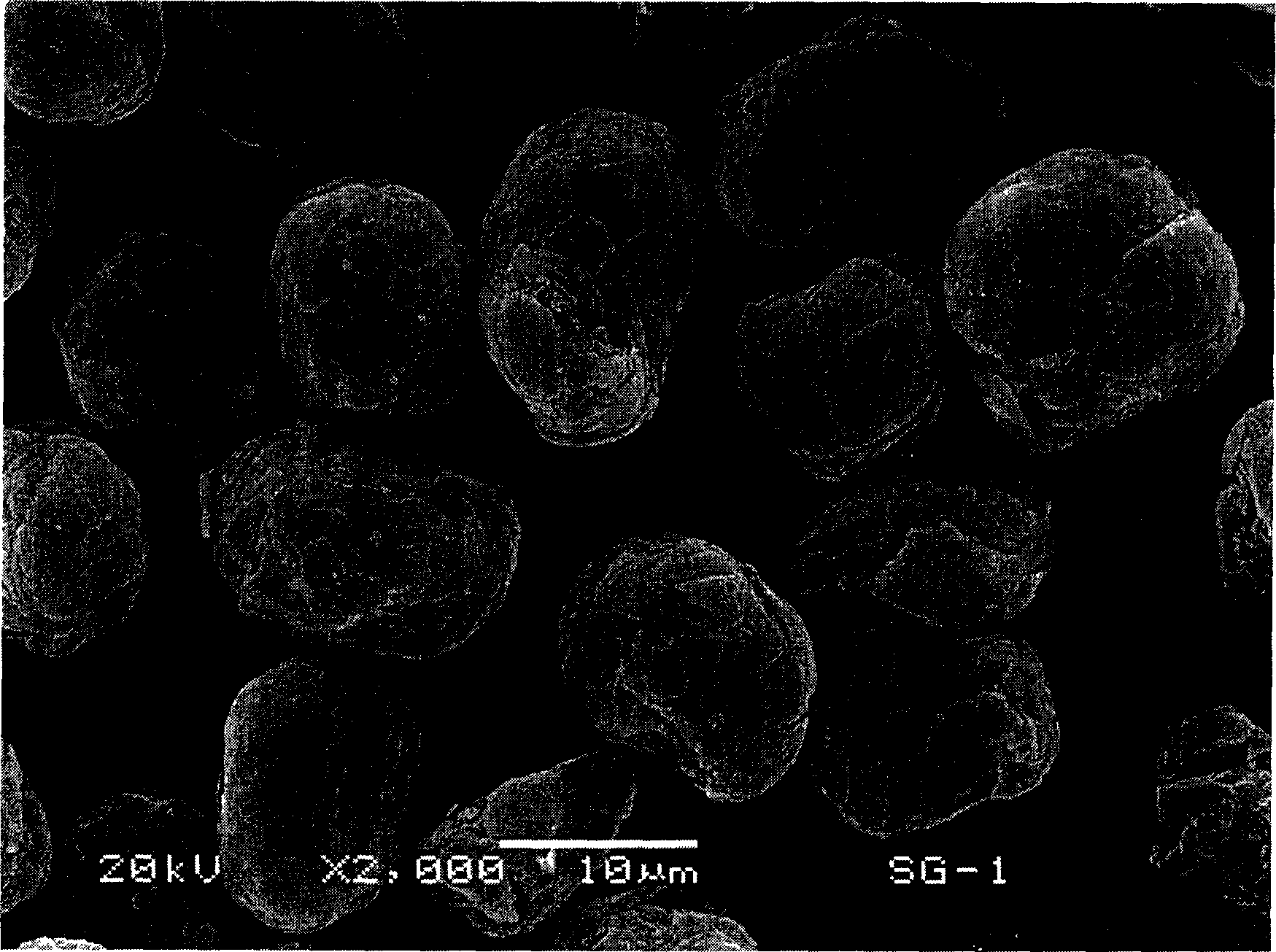

Image

Examples

Embodiment 1

[0030] Embodiment 1, the graphite powder with the surface closed end structure of the present invention is prepared through the first process. Take natural graphite 32 mesh 200kg, use a high-speed pulverizer, a kind of rotary high-speed pulverizer with 16 or 24 hammers, pulverize it at a rotation speed of 6000rpm for 10 minutes, and then use a low-speed impact ball to pulverize the graphite powder generated. The pulverizer was processed at a rotation speed of 3000rpm for 40 minutes, and the generated graphite powder was sorted to positive 5um and negative 75um by a classifier and used to make electrodes. The size distribution of the sieved graphite powder was measured using a laser diffraction / scattering size distribution analyzer. The average particle diameter of graphite powder in each batch is about 25um. The graphite powder prepared in each batch was used to produce electrodes as follows, mixing 90 parts by weight of graphite powder and 10 parts by weight of vinylidene fl...

Embodiment 2

[0031] Embodiment 2, the graphite powder with the surface closed end structure of the present invention is prepared through the first process. By getting natural graphite 200 order 200kg with a high-speed pulverizer a kind of rotary high-speed pulverizer that has 16 or 24 hammers, pulverized 20 minutes under the rotation speed of 5500rpm. The graphite powder that generates is processed 60 minutes under the rotating speed of 2500rpm with low-speed impact ball mill again. The generated graphite powder is sorted to positive 5um and negative 63um by a classifier and used to make electrodes. The size distribution of the sieved graphite powder was measured using a laser diffraction / scattering size distribution analyzer. The average particle diameter of graphite powder in each batch is about 23um. After the pulverized graphite powder was sorted to plus 5um to minus 63um, it was used to make electrodes for testing in the same manner as described in Example 1. The discharge capaciti...

Embodiment 3

[0032] Embodiment 3, the graphite powder with the surface closed end structure according to the present invention is prepared through the first process. By getting natural graphite 325 order 200kg with high-speed pulverizer, a kind of rotary high-speed pulverizer with 16 or 24 hammers, pulverized 30 minutes under 5000rpm rotating speed. The graphite powder that generates is processed 80 minutes under the rotating speed of 2000rpm with low-speed impact ball mill again. The generated graphite powder is sorted to positive 6um and negative 60um by a classifier and used to make electrodes. The size distribution of the sieved graphite powder was measured using a laser diffraction / scattering size distribution analyzer, and the average particle diameter of the graphite powder in each batch was about 21 um. After the pulverized graphite powder was sorted to plus 6um to minus 60um, it was used to make electrodes for testing in the same manner as described in Example 1. The discharge c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com