Composite solid electrolyte, and preparation method and applications thereof

A technology of solid electrolyte and solid electrolyte layer, applied in electrolytes, circuits, electrical components, etc., can solve problems such as liquid electrolyte leakage, decrease in bulk ionic conductivity, narrow electrochemical window, etc., to achieve inhibition of lithium dendrite growth, Ease of industrial production and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

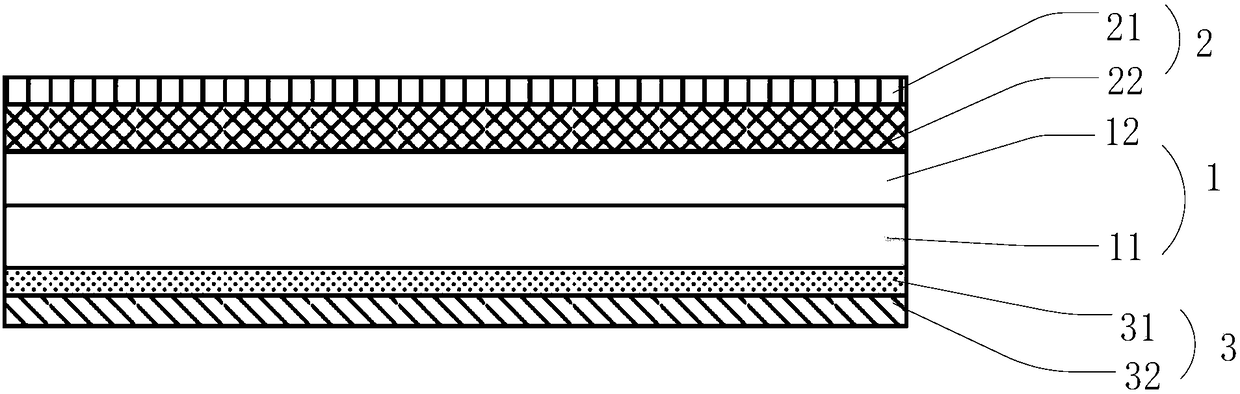

[0056] As an optional technical solution, the preparation method of the composite solid electrolyte includes the following steps:

[0057] (a) Add the polymer matrix and the lithium salt to the solvent and disperse to obtain the first mixed solution; the dispersion can be carried out by stirring to obtain a uniformly dispersed solution, such as mechanical stirring, magnetic stirring, etc.;

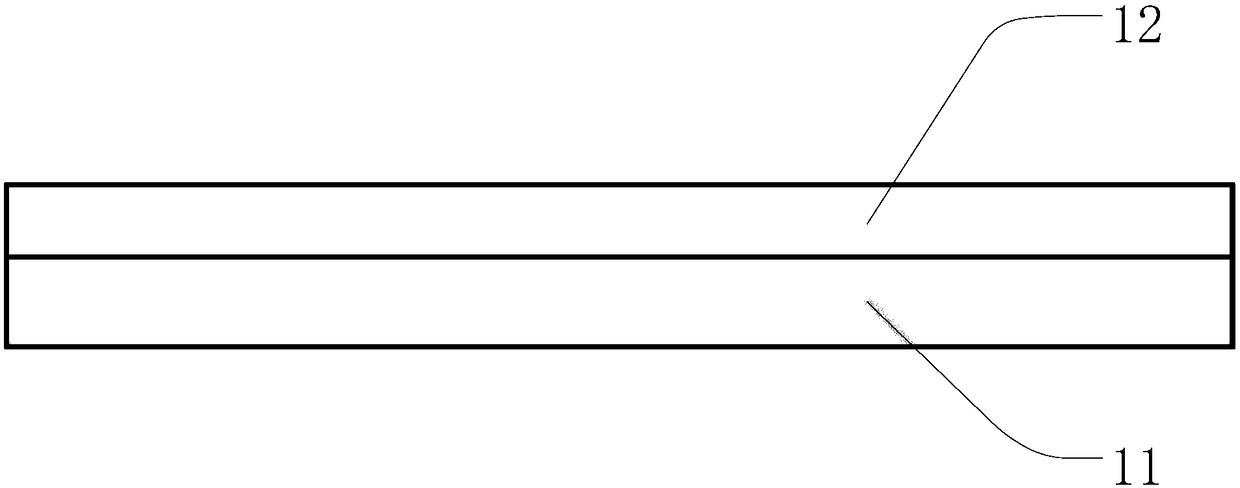

[0058] (b) adding part of the first mixed solution to the mold, volatilizing the solvent in vacuum, heating and vacuum drying to obtain the first solid electrolyte layer;

[0059] (c) Add an inorganic solid electrolyte to a part of the first mixed solution and disperse to obtain a second mixed solution; the dispersion can be carried out by stirring to obtain a uniformly dispersed solution, such as mechanical stirring, magnetic stirring, etc.; the inorganic solid electrolyte is usually in powder form Join, and disperse evenly;

[0060] (d) Pour the second mixed solution into the mold, evaporate the...

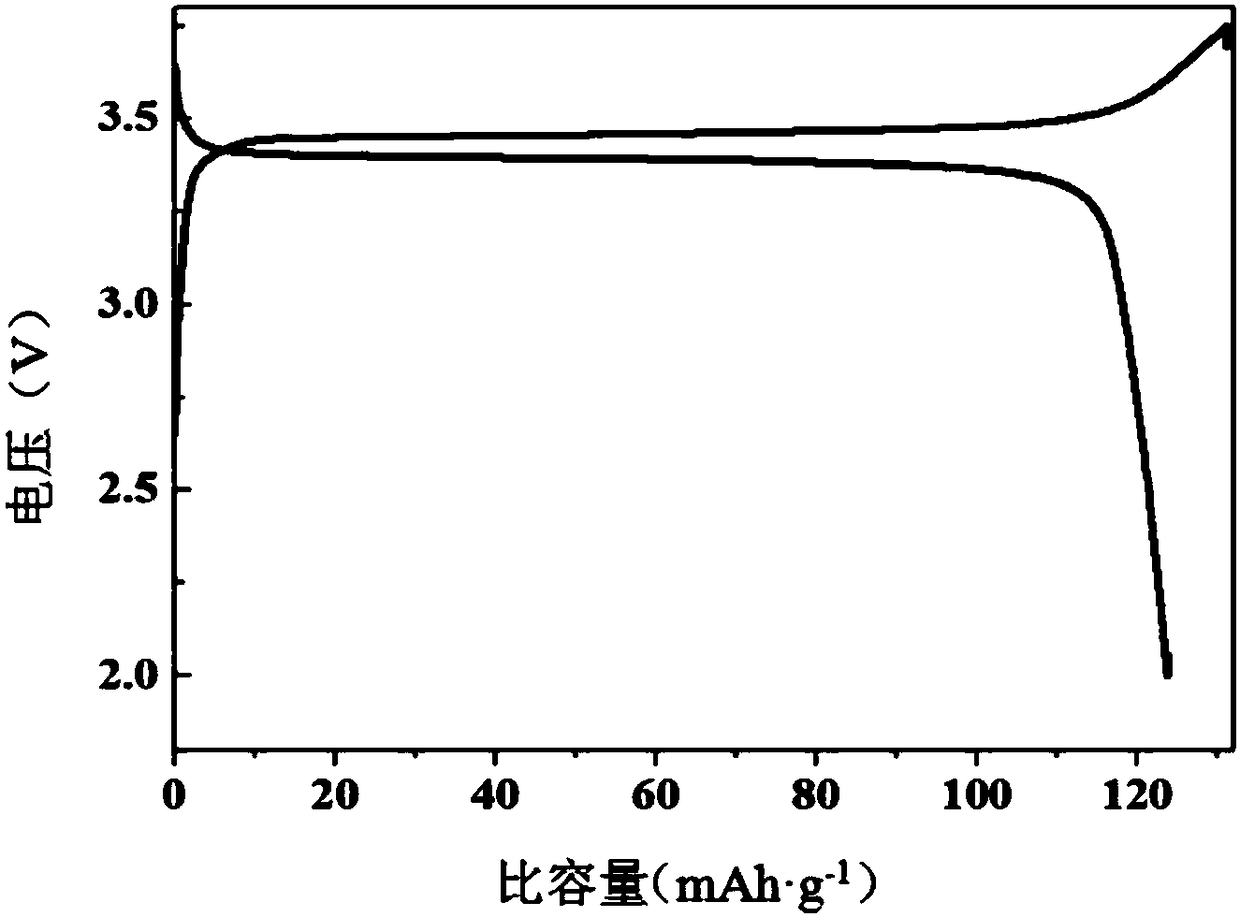

Embodiment 1

[0070] Select polyethylene oxide as the polymer matrix, and lithium bistrifluoromethanesulfonimide as the lithium salt, in which the mass ratio of the polymer matrix to the lithium salt is 0.5:1;

[0071] The polyoxyethylene and lithium bistrifluoromethanesulfonimide were dried at 50°C and 120°C for 24 hours, respectively, and then the polyoxyethylene and lithium bistrifluoromethanesulfonimide were dissolved in acetonitrile and dispersed uniformly to obtain the first A mixed solution;

[0072] The prepared first mixed solution is poured into a polytetrafluoroethylene mold to volatilize the acetonitrile solvent in a vacuum, and dried under vacuum at 50° C. to obtain a first solid electrolyte layer with a thickness ranging from 10 to 50 μm.

Embodiment 2

[0074] Highly selective polypropylene oxide is the molecular matrix, and lithium hexafluorophosphate is selected as the lithium salt, and the mass ratio of the two is 1:1;

[0075] For the preparation method of the first solid electrolyte layer of this embodiment 2, refer to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com