Modified phenolic foam and preparation method thereof

A phenolic foam and modification technology, which is applied in the field of preparation of phenolic foam, can solve the problems of difficulty in maintaining mechanical properties and flame retardancy, decreased fire resistance of phenolic foam, and poor thermal stability of flexible segments, etc., to achieve pulverization Low rate, low water absorption, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

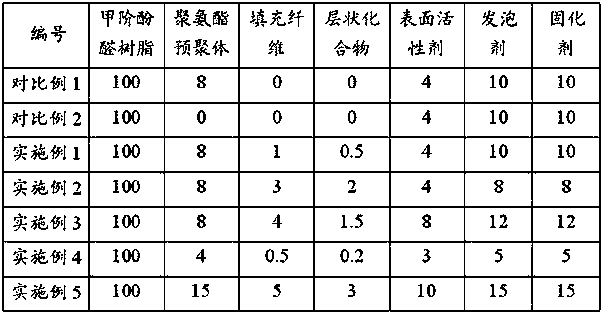

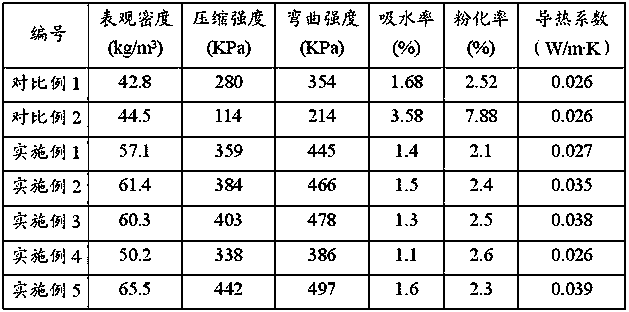

Examples

Embodiment 1

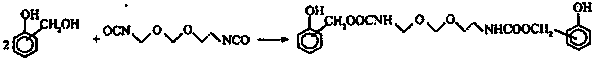

[0039] Preparation of toughening modifier: Add polyethylene glycol 1000 to toluene diisocyanate according to the ratio of -NCO / -OH substance ratio of 3:1, stir and react at 50°C for 1h, then raise the temperature to 80°C Continue to stir for about 2.5 hours to obtain a toughening modifier-polyurethane prepolymer.

[0040] Preparation of layered compound: After mixing sodium montmorillonite and dodecyltrimethylammonium bromide in a mass ratio of 1:2, add it to distilled water according to the solid mass: liquid volume ratio of 1g: 100ml , heated and stirred at 80°C for 24 hours, then centrifuged, washed with distilled water until there was no foam, and dried to obtain a layered compound - organically modified sodium-based montmorillonite.

[0041] The curing agent used in this embodiment is a mixed acid curing agent made of 40% toluenesulfonic acid, 20% phosphoric acid, and 40% distilled water by mass percentage.

[0042] Preparation of Modified Phenolic Foam:

[0043] (1) At...

Embodiment 2

[0048] Preparation of toughening modifier: Add polyethylene glycol 800 to diphenylmethane diisocyanate according to the ratio of -NCO / -OH substance molar ratio of 2.5:1, stir and react at 70°C for 0.5h, then raise the temperature Continue stirring at 80°C for about 2 hours to obtain a toughening modifier-polyurethane prepolymer.

[0049] Preparation of layered compound: After mixing iron-based montmorillonite and dodecyltrimethylammonium bromide in a mass ratio of 1:1, add it to distilled water according to the solid mass: liquid volume ratio of 1g: 80ml , heated and stirred at 90 °C for 18 hours, then centrifuged, washed with distilled water until there was no foam, and dried to obtain a layered compound - organically modified iron-based montmorillonite.

[0050] The curing agent used in this embodiment is a mixed acid curing agent made of 35% toluenesulfonic acid, 40% phosphoric acid, and 25% distilled water by mass percentage.

[0051] Preparation of Modified Phenolic Foam...

Embodiment 3

[0057] Preparation of toughening modifier: Add polyethylene glycol 1500 to polymethyl polyphenylene isocyanate according to the ratio of -NCO / -OH substance molar ratio of 2:1, stir and react at 70°C for 0.5h, then raise the temperature Continue stirring at 80°C for about 2 hours to obtain a toughening modifier-polyurethane prepolymer.

[0058] Preparation of layered compound: After mixing nickel-based montmorillonite and dodecyltrimethylammonium bromide in a mass ratio of 1:2, add it to distilled water at a solid mass:liquid volume ratio of 1g:80ml , heated and stirred at 70°C for 30 hours, then centrifuged, washed with distilled water until there was no foam, and dried to obtain a layered compound - organically modified nickel-based montmorillonite.

[0059] The curing agent used in this embodiment is a mixed acid curing agent made of 30% toluenesulfonic acid, 15% phosphoric acid, and 55% distilled water by mass percentage.

[0060] Preparation of Modified Phenolic Foam:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com