Preparation method of novel KH-560 modified phenolic foam

A KH-560, phenolic foam technology, applied in the chemical industry, can solve the problems of high brittleness, poor toughness and low mechanical strength of phenolic foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 Novel KH-560 modified phenolic foam

[0020] 1. Preparation of modified phenolic resin

[0021] 1) Add formaldehyde / phenol molar ratio of 1.8:1 to a 2000ml three-necked round-bottomed flask equipped with a stirrer, condenser, and thermometer. Formaldehyde is 270ML, phenol is 180ML, and the water bath is heated to 40°C under stirring at 200rpm. Add Adjust the pH to 9-10 with about 20ML of 20% (wt) NaOH, continue to heat up to 60°C, and react for 30 minutes;

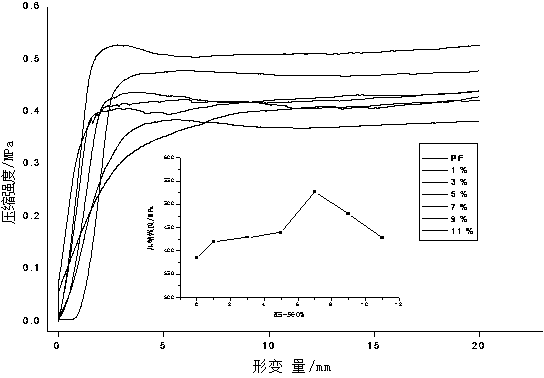

[0022] 2) Add mass fractions of 1%, 3%, 5%, 7%, 9%, and 11% silane coupling agent KH-560 (mass fraction is relative to the mass of phenol participating in the reaction, the mass of phenol is 190g, and the relative density is 1.0576 ), and then heated up to 95°C at a heating rate of 2°C / min, and reacted for 50 minutes; after the reaction was completed, it was cooled rapidly; the pH was neutralized to about 7 with 6mol / L hydrochloric acid. Then use a rotary evaporator to distill under reduced pressure t...

Embodiment 2

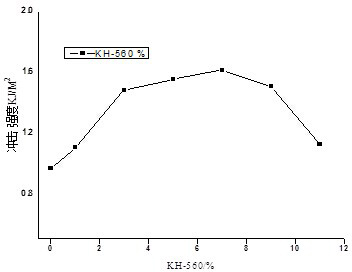

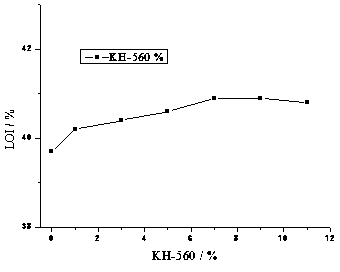

[0025] Example 2 Effect of different silane coupling agent KH-560 content on phenolic foam performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com