Preparing method for hyaluronic acid or salt particles of hyaluronic acid and obtained product

A technology of hyaluronic acid and salt particles, applied in the field of hyaluronic acid granulation, to achieve the effect of not easy to disperse and pulverize, control dust flying, and facilitate storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

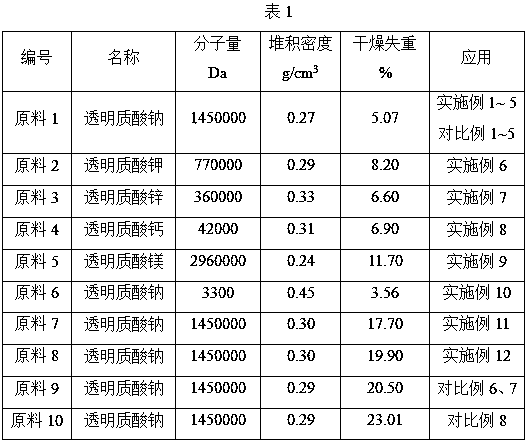

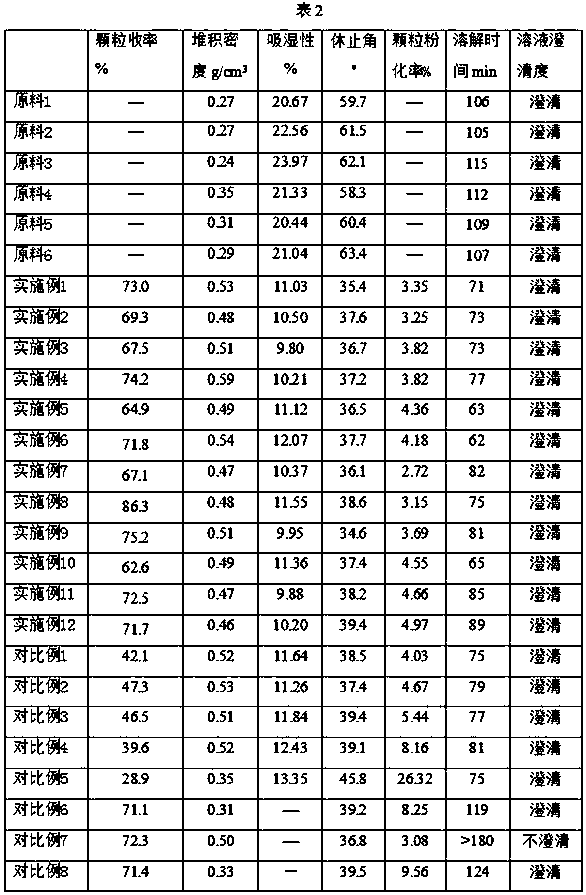

[0026]Pass sodium hyaluronate powder (raw material 1) through a 60-mesh vibrating sieve. Put the powder under the sieve into the dry granulator for granulation. The granulation conditions were set as follows: feed rate 40 r / min, roller speed 5 r / min, roller pressure 12 MPa, fine granulation speed 80 rpm, and the particle size of the screening system was set at 10 mesh and 40 mesh. The powder under the sieve is fed into the pressing roller at this feeding speed, pressed into thin slices, and then crushed into coarse particles. After fine granulation and two-stage sieving, the obtained coarse particles are discharged to obtain sodium hyaluronate particles.

Embodiment 2

[0028] Pass sodium hyaluronate powder (raw material 1) through a 60-mesh vibrating sieve. Put the powder under the sieve into the dry granulator for granulation. The granulation conditions were set as follows: feed rate 80 r / min, roller speed 12 r / min, roller pressure 15 MPa, fine granulation speed 80 rpm, and the particle size of the screening system was set at 10 mesh and 40 mesh. The powder under the sieve is fed into the pressing roller at this feeding speed, pressed into thin slices, and then crushed into coarse particles. After fine granulation and two-stage sieving, the obtained coarse particles are discharged to obtain sodium hyaluronate particles.

Embodiment 3

[0030] Pass sodium hyaluronate powder (raw material 1) through a 60-mesh vibrating sieve. Put the powder under the sieve into the dry granulator for granulation. The granulation conditions were set as follows: feed rate 30 r / min, roller speed 4 r / min, roller pressure 5 MPa, fine granulation speed 80 rpm, and the particle size of the screening system was set at 10 mesh and 40 mesh. The powder under the sieve is fed into the pressing roller at this feeding speed, pressed into thin slices, and then crushed into coarse particles. After fine granulation and two-stage sieving, the obtained coarse particles are discharged to obtain sodium hyaluronate particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com