Recipe and production process of artificial leather of thermoplastic polyurethane

A technology of thermoplastic polyurethane and artificial leather, which is applied in the formulation of artificial leather and its manufacturing field. It can solve the problems of artificial leather including toxicity, poor hydrolysis resistance, and harm to human health, so as to prevent sticking to metal wheel surfaces, reduce melting temperature, and reduce power consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The formulation of the thermoplastic polyurethane artificial leather of the present invention is further set forth below.

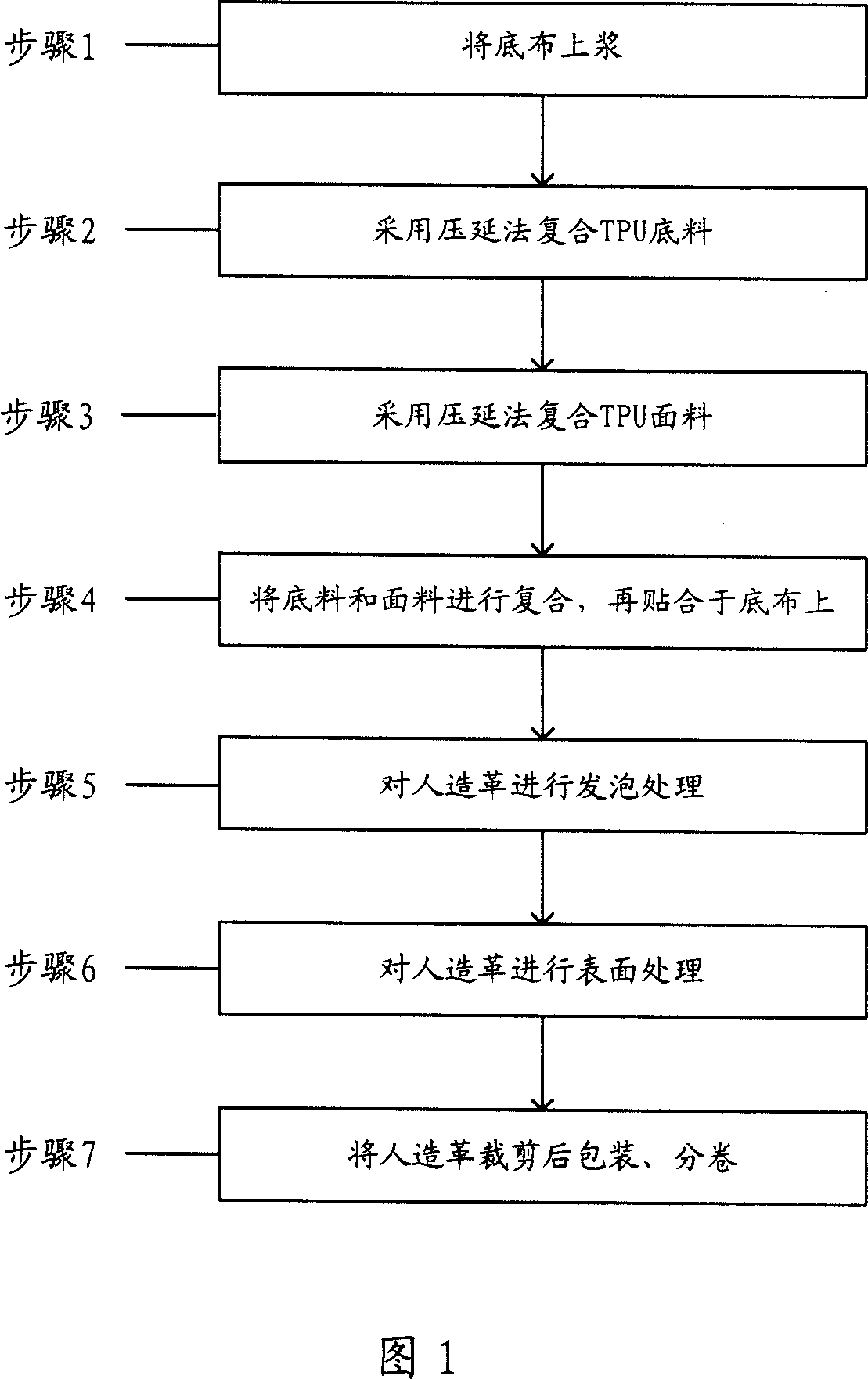

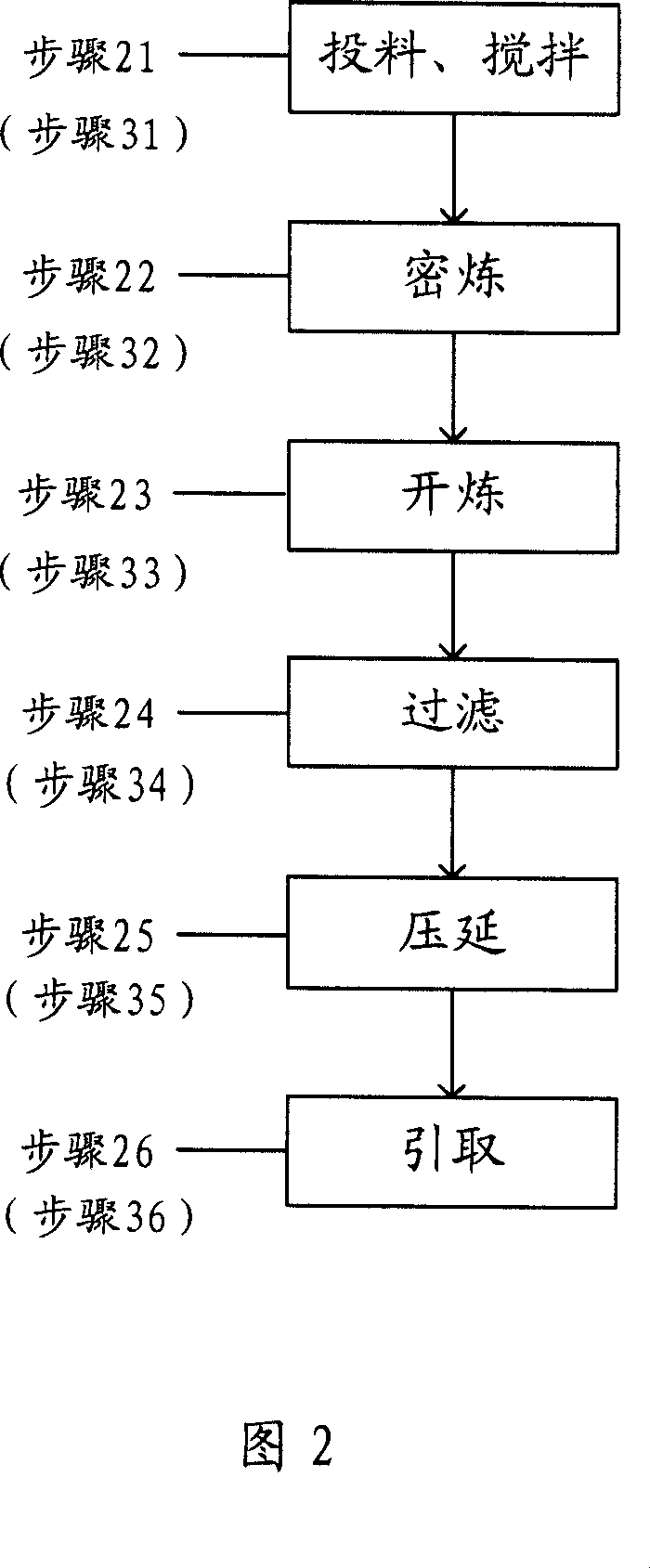

[0041] Artificial leather is made by laminating the calendered fabric and base material with the base fabric. The artificial leather fabric and base material are made of thermoplastic polyurethane resin as the main material, and the base material formula also includes auxiliary materials: plasticizer, foaming Stabilizers, foam control agents, reinforced filling materials; fabric formulations also include auxiliary materials: plasticizers, dispersants, reinforced filling materials, antioxidants, ultraviolet absorbers and colorants. In the present invention, plasticizer selects polyalcohol derivative plasticizer for use; Dispersant selects polymer fatty acid lipid dispersant for use; Foaming stabilizer selects Ba / Zn foaming stabilizer for use; Foaming agent selects foaming agent AC for use; Active light calcium carbonate can be selected as the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com