Anti-ageing matt polyurethane composition and preparation method thereof

A technology of polyurethane and composition, which is applied in the field of aging-resistant matte polyurethane composition and its preparation, and can solve the problems of poor long-term aging resistance, easy cross-linking or fracture, and poor long-term aging resistance of wires and cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

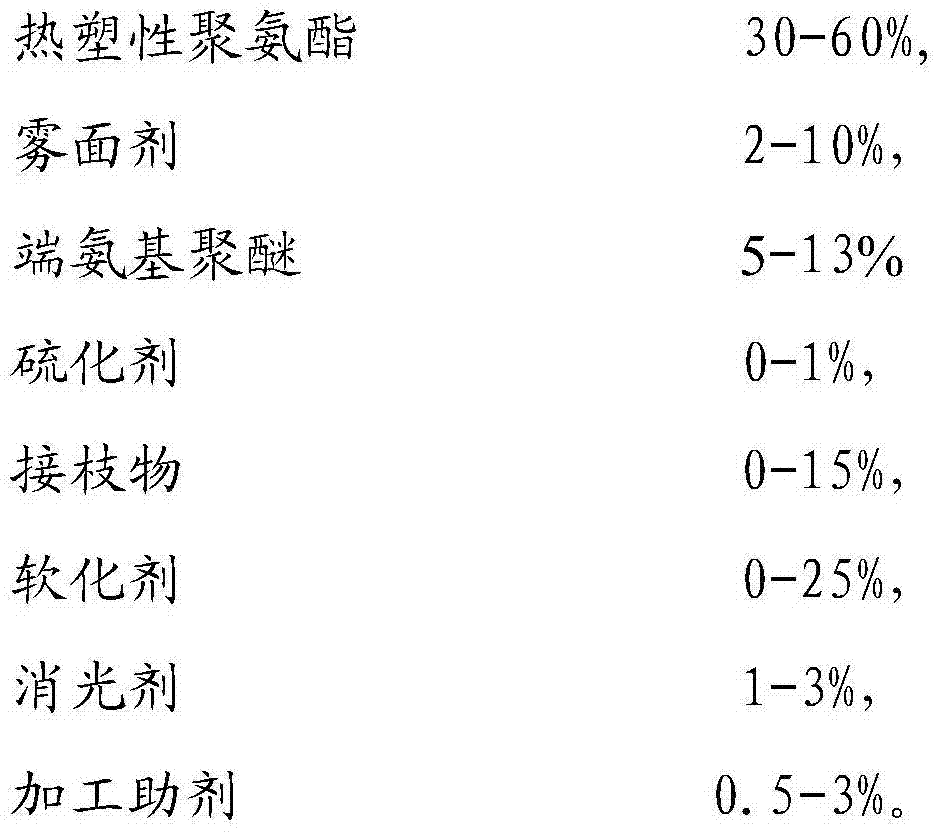

[0025] An aging-resistant matte polyurethane composition, comprising the following components in parts by weight:

[0026]

[0027] The thermoplastic polyurethane is polyester polyurethane.

[0028] The fogging agent is styrene block copolymer (SEBS).

[0029] The amino-terminated polyether is polyetheramine D-2000

[0030] The vulcanizing agent is sulfur.

[0031] The graft is an acrylate-maleic anhydride graft.

[0032] The softening agent is naphthenic rubber oil.

[0033] The matting agent is white carbon black

[0034] The processing aid is organosilicone.

[0035] The preparation method of described anti-aging matte polyurethane composition, comprises the steps:

[0036] 5) Weigh each component according to the formula and mix evenly;

[0037] 6) Put the mixture into a twin-screw extruder, melt and extrude at 160-180°C with a rotation speed of 350rpm, pelletize, and pack.

Embodiment 2

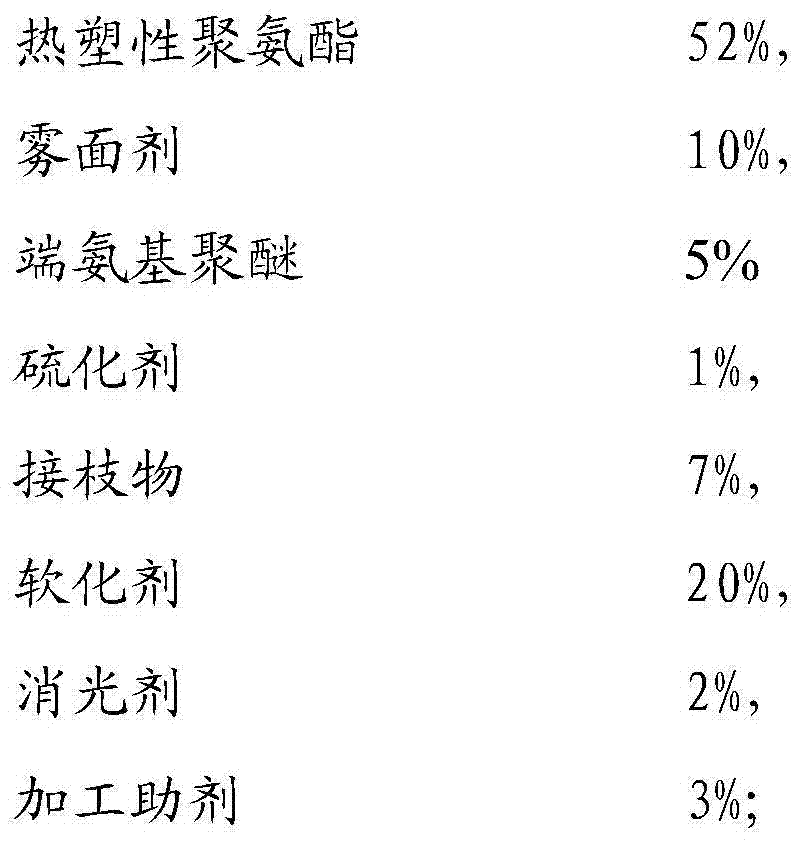

[0039] An aging-resistant matte polyurethane composition, comprising the following components in parts by weight:

[0040]

[0041]

[0042] The thermoplastic polyurethane is polyether polyurethane

[0043] The fogging agent is selected from styrene-ethylene-propylene-styrene block copolymers (SEPS).

[0044] The amino-terminated polyether is polyetheramine T-3000.

[0045] The graft is an acrylate-maleic anhydride graft.

[0046] Described softener is white mineral oil.

[0047] The matting agent is talcum powder.

[0048] The processing aid is a mixture of organic silicone and zinc stearate.

[0049] The preparation method of described anti-aging matte polyurethane composition, comprises the steps:

[0050] 7) Weigh each component according to the formula and mix evenly;

[0051] 8) Put the mixture into a twin-screw extruder, melt and extrude at 160-180°C with a rotation speed of 400rpm, pelletize, and pack.

Embodiment 3

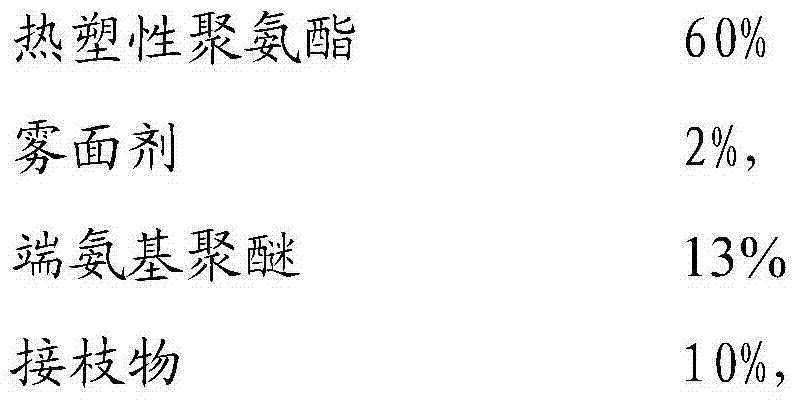

[0053] An aging-resistant matte polyurethane composition, comprising the following components in parts by weight:

[0054]

[0055] The thermoplastic polyurethane is polycarbonate thermoplastic polyurethane.

[0056] The matting agent is selected from acrylate rubber.

[0057] The amino-terminated polyether is polyetheramine T-3000.

[0058] The vulcanizing agent is sulfur.

[0059] The graft is an acrylate-maleic anhydride graft.

[0060] The softening agent is selected from paraffinic rubber oil.

[0061] Described processing aid is stearic acid.

[0062] The matting agent is calcium carbonate.

[0063] The preparation method of the non-aging matte polyurethane composition comprises the steps of:

[0064] 9) Weigh each component according to the formula and mix evenly;

[0065] 10) Put the mixture into a twin-screw extruder, melt and extrude it at 160-200°C with a rotation speed of 200-500rpm, pelletize, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com