Secondary structure masonry construction method

A construction method and secondary structure technology, applied in construction, building maintenance, building components, etc., can solve the problem of poor control of wall flatness and verticality, increased difficulty in quality control, and easy occurrence of cracks and hollows, etc. Problems, achieve the effect of reducing material and manual installation costs, good waterproof and anti-seepage effect, frost resistance, environmental protection and non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

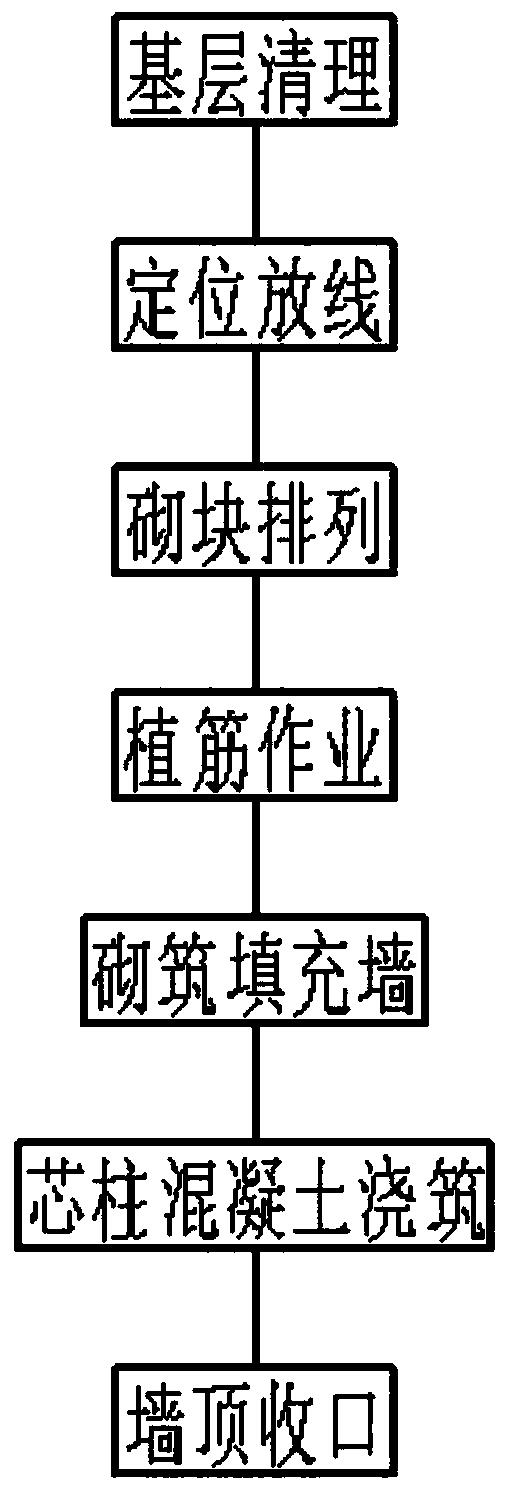

[0031] Example 1: Please refer to figure 1 , a secondary structure masonry construction method specifically comprises the following steps:

[0032] S1. Basic level cleaning: Clean up the debris at the construction site to avoid affecting the subsequent setting-out operation.

[0033] S2. Positioning and setting out: Level the foundation surface or the structural surface of the floor according to the elevation, release the edge line of the wall, the opening of the door and window, and the position line of the core column on the floor, and release the building +0.5m line on the wall and column of each floor, and mark it Door and window opening elevation control point. Construction according to the released line can effectively guarantee the construction quality, and there will be no door, window openings, and core columns being occupied, reducing rework and effectively ensuring the construction progress. After the positioning and setting out is completed, the quality inspectio...

Embodiment 2

[0040] Example 2: Please refer to figure 1, a secondary structure masonry construction method specifically comprises the following steps:

[0041] S1. Basic level cleaning: Clean up the debris at the construction site to avoid affecting the subsequent setting-out operation.

[0042] S2. Positioning and setting out: Level the foundation surface or the structural surface of the floor according to the elevation, release the edge line of the wall, the opening of the door and window, and the position line of the core column on the floor, and release the building +0.5m line on the wall and column of each floor, and mark it Door and window opening elevation control point. Construction according to the released line can effectively guarantee the construction quality, and there will be no door, window openings, and core columns being occupied, reducing rework and effectively ensuring the construction progress. After the positioning and setting out is completed, the quality inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com