V-shaped prestressed enclosure pile and its construction method

An enclosure pile and prestressing technology, applied in sheet pile walls, manufacturing tools, infrastructure engineering, etc., can solve the problems of complex manufacturing process, difficult mud discharge, pollution of the surrounding environment, etc., and achieve simple manufacturing process, light weight, The effect of occupying less storage yard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

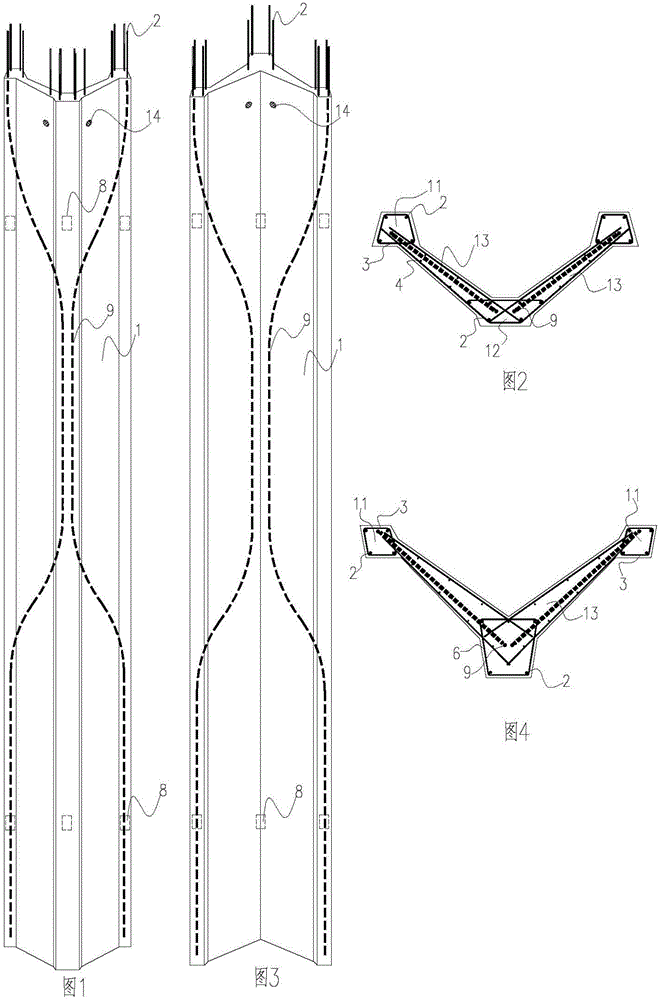

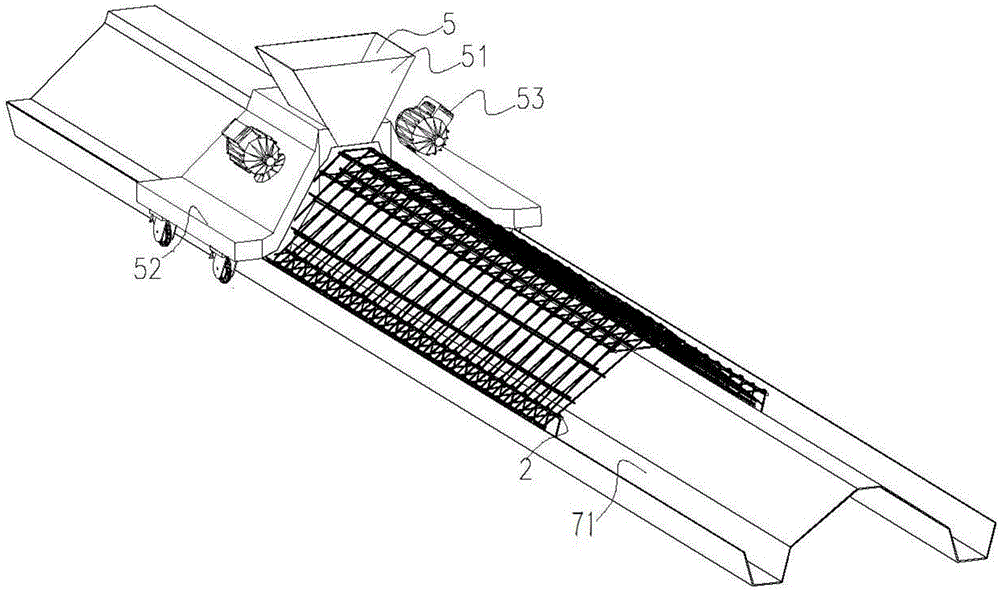

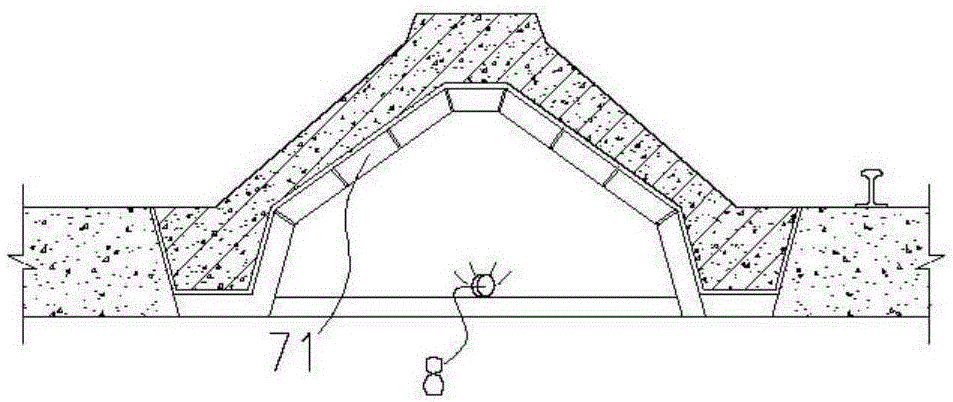

[0032] See Figure 1 to Figure 4 , The V-shaped prestressed enclosure pile provided by the present invention includes a pile body 1 and a steel strand 2 embedded in the pile body 1 as the main reinforcement. The pile body 1 is composed of an enlarged upper end 11 and a lower end 12 It is composed of a web 13 and a V-shaped cross-section. Stirrups 3 are embedded in the enlarged upper end 11, and a steel mesh 4 is embedded in the web. The steel strand 2 is longitudinally embedded in the enlarged upper end 11 and the lower end 12 . The pile body 1 adopts a V-shaped cross-section and its retaining surface is wide. It can be produced by the long-line method of the tire mold without supporting and removing the mold. The manufacturing efficiency is high and the cost is low. At the same time, the bearing capacity of the folded plate section is large. The enlarged upper end 11 is equipped with stirrups, which can strengthen the restraint of the stirrups on the concrete and improve the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com