Method for secondary grouting in equipment foundation construction process

A technology of equipment foundation and secondary grouting, which is applied in basic structure engineering, construction, etc., can solve the problems of inconsistent colors between the concrete base and the grouting layer, difficulty in ensuring the quality of the appearance process, and difficulty in installing and fixing the formwork, etc., so as to improve the appearance process , reduce the mold support process, and solve the effect of color inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

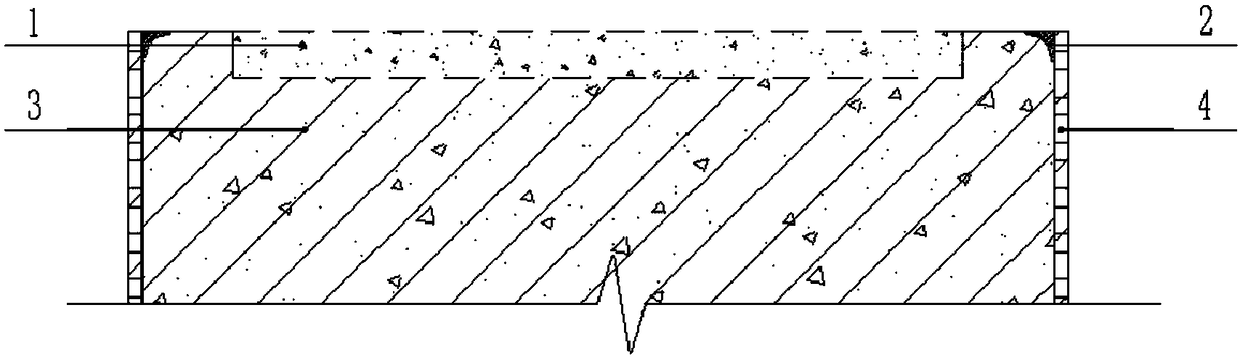

[0021] Such as figure 1 As shown, a method for secondary grouting in the process of equipment foundation construction, the specific steps are:

[0022] a. Conduct a comprehensive check on the construction drawings before construction to ensure that there are no errors in the construction drawings;

[0023] b. When constructing the equipment foundation 3 according to the requirements of the construction drawings, install the outer formwork of the equipment foundation 3 to the top elevation of the secondary grouting;

[0024] c. PVC corner line 2 is installed on the top plate of the outer formwork;

[0025] d. According to the grouting height required by the construction drawings, a groove is left on the inner side of the equipment foundation 3 as the equipment foundation grouting groove 1. The depth of the equipment foundation grouting groove 1 is 30-50mm lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com