Biaxially-oriented polypropylene (BOPP) pearlised film environment-friendly ink and preparation method thereof

An environmentally friendly, pearlescent film technology, used in the field of ink, can solve the problems of non-abrasion, non-rubbing, and poor gloss of the ink film, and achieve the effects of excellent performance, good blocking resistance and high color saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

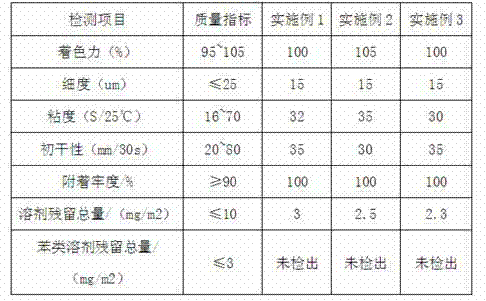

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of BOPP pearlescent film environment-friendly type benzene-free and ketone-free red ink of the present invention

[0037] Get 15 parts by weight of alcohol-soluble polyamide resin solution, 4 parts by weight of alcohol-soluble aldehyde and ketone resin solution, 4 parts by weight of alcohol-ester-soluble nitrocellulose resin solution, 4 parts by weight of maleic acid resin solution, 0.5 parts by weight of polyethylene wax, red organic 10 parts by weight of pigment, 0.5 parts by weight of anti-settling agent, 25 parts by weight of isopropanol, 9.5 parts by weight of n-propyl acetate, 0.5 parts by weight of TEXANOL ester alcohol, 0.5 parts by weight of acrylate, 7.5 parts by weight of ethyl acetate, absolute ethanol 15 parts by weight stand-by.

[0038]First mix absolute ethanol, ethyl acetate, and isopropanol in a mixing tank, and then mix alcohol-soluble polyamide resin, alcohol-soluble polyketone resin, nitrocellulose resin, maleic acid resin, ...

Embodiment 2

[0039] Example 2 Preparation of BOPP pearlescent film environment-friendly benzene-free and ketone-free blue ink of the present invention

[0040] 14 parts by weight of alcohol-soluble polyamide resin solution, 4 parts by weight of alcohol-soluble aldehyde and ketone resin solution, 4 parts by weight of alcohol-ester-soluble nitrocellulose resin solution, 4 parts by weight of maleic acid resin solution, 0.5 parts by weight of polyethylene wax, blue 12 parts by weight of organic pigments, 0.5 parts by weight of anti-settling agent, 25 parts by weight of isopropanol, 9.5 parts by weight of n-propyl acetate, 0.5 parts by weight of TEXANOL ester alcohol, 0.5 parts by weight of acrylate, 7.5 parts by weight of ethyl acetate, anhydrous 14 parts by weight of ethanol are for use.

[0041] First mix absolute ethanol, ethyl acetate, and isopropanol in a mixing tank, and then mix alcohol-soluble polyamide resin, alcohol-soluble polyketone resin, nitrocellulose resin, maleic acid resin, p...

Embodiment 3

[0042] Example 3 Production of BOPP pearlescent film environment-friendly benzene-free and ketone-free green ink of the present invention

[0043] 15 parts by weight of alcohol-soluble polyamide resin solution, 4 parts by weight of alcohol-soluble aldehyde and ketone resin solution, 4 parts by weight of alcohol-ester-soluble nitrocellulose resin solution, 4 parts by weight of maleic acid resin solution, 0.5 parts by weight of polyethylene wax, green organic 9.5 parts by weight of pigment, 0.5 parts by weight of anti-settling agent, 25 parts by weight of isopropanol, 10 parts by weight of n-propyl acetate, 0.5 parts by weight of TEXANOL ester alcohol, 0.5 parts by weight of acrylate, 7.5 parts by weight of ethyl acetate, absolute ethanol 15 parts by weight stand-by.

[0044] First mix absolute ethanol, ethyl acetate, and isopropanol in a mixing tank, and then mix alcohol-soluble polyamide resin, alcohol-soluble polyketone resin, nitrocellulose resin, maleic acid resin, polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com