Heterocyclic organic matter and polyhydric alcohol composite PVC (polyvinyl chloride) heat stabilizing agent and preparation method thereof

A technology of heterocyclic organic compounds and heat stabilizers, applied in the field of PVC heat stabilizers, can solve problems such as poor long-term thermal stability, achieve the effects of good thermal stability, simple preparation process, and increase long-term thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

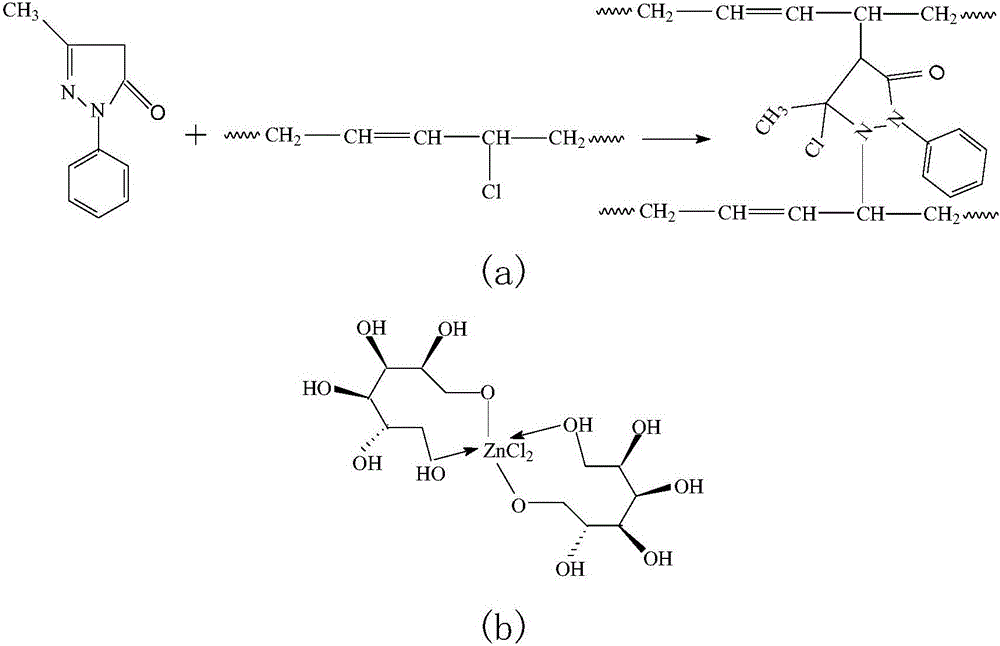

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the present invention is to put PVC, composite heat stabilizer, and calcium carbonate into a high-speed mixer and mix them evenly; carry out mixing on a double-roll mill at 170°C, fully mix and plasticize for 5 minutes, and then lower the sheet, the thickness of the lower sheet 1mm, then performance test.

[0024] The speed of the high-speed mixer used: 1440rpm, the temperature: 60-80°C, and the mixing time: 5min.

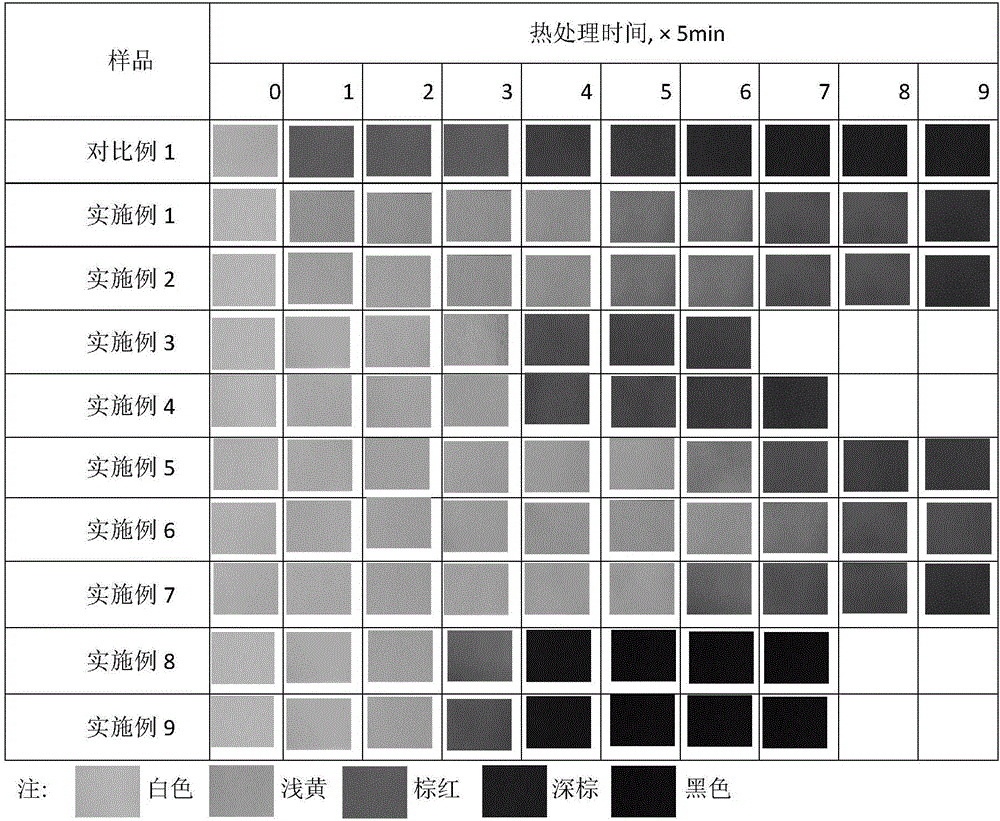

[0025] The performance test adopts the static heat aging method: cut the mixed PVC sample into 4cm×2cm samples, put them in a 180°C oven, take out a sample every 5 minutes, take pictures, record and compare the addition of different types of stabilizers The discoloration of PVC samples with aging time.

[0026] Performance test Congo red discoloration method: According to GB.T2917.1-2002, cut the prepared PVC sample into a granular sample with a size of 2mm×2mm×1mm, put it into a test tube, and the height of the sample is 50mm. Th...

specific Embodiment approach

[0033] Table 1 PVC composite heat stabilizer comparative example and embodiment

[0034]

[0035]

Embodiment 1

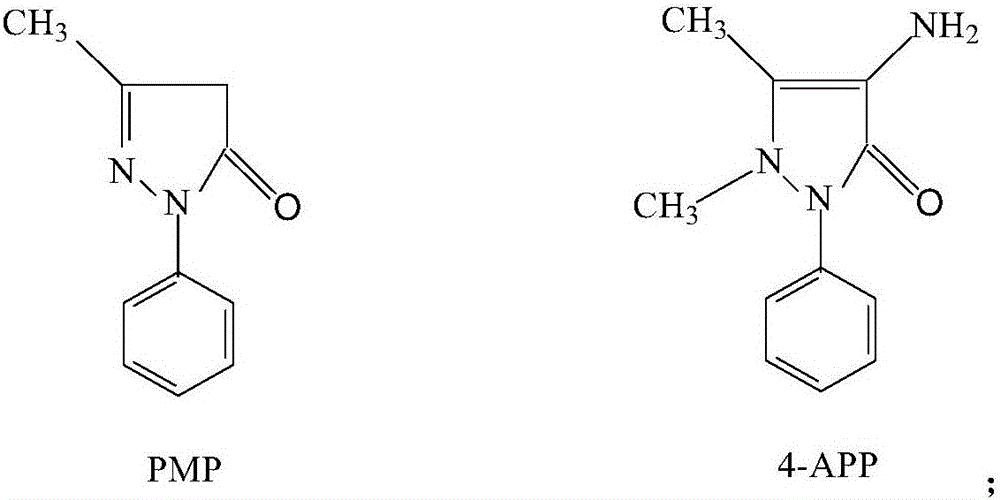

[0037] 1) Weigh 1000g PVC (SG-5), 150g superfine light calcium carbonate, 5g zinc stearate, 3g 4-amino-1,5-dimethyl-2-phenyl-3-pyrazolone , 5 g of sorbitol, and 16 g of polyethylene wax were plasticized on an open mill at 170° C. for 5 minutes and then released into sheets with a thickness of 1 mm.

[0038] 2) Mix the homogeneously mixed mixture in step 1) on a double-roll mill at 170°C, fully mix and plasticize for 5 minutes, and then release the sheet, the thickness of which is 1mm;

[0039] 3) Performance test: use the static heat aging method to test the discoloration of the sample with aging time, or use the Congo red discoloration method to test the thermal stability time of the sample.

[0040] Static heat aging results see figure 1 , Congo red discoloration time is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com