Crown-printing process for yarn tablecloth

A tablecloth and yarn technology, which is applied in the field of yarn tablecloth crown printing technology, can solve the problems of unable to meet consumers' pursuit of high-quality life, rigid pattern aging, oil spillage, etc., achieve good three-dimensional effect, improve product grade, Effect of reducing PVC components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

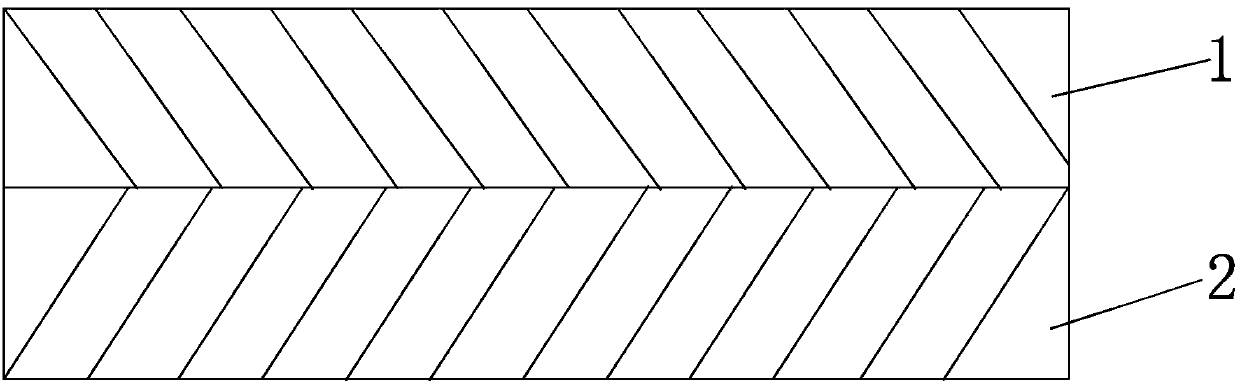

[0025] Embodiment 1: The present invention is a yarn tablecloth crown printing process, which includes making a PVC film layer 1 and a yarn layer 2. The yarn tablecloth is laminated by double-sided embossing of the PVC film layer 1 and the yarn layer 2 , printed and rolled.

[0026] The PVC film layer 1 includes the following components: 55 parts of dioctyl phthalate, 45 parts of PVC resin powder, 80 parts of active calcium, 2 parts of heat stabilizer, 0.01 part of pigment powder, and 0.01 part of titanium dioxide. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the gram weight of the active calcium is 180g / ㎡;

[0027] The production method of the PVC film layer 1 is as follows: adding each material of the above components in proportion to a polymerization reactor equipped with heavy oil as a solvent, raising the temperature to 195° C., stirring for 1 hour, filtering, and extruding to obtain the PVC film Layer 1: The oil content of the PVC film la...

Embodiment 2

[0035] Embodiment 2: The present invention is a yarn tablecloth crown printing process, which includes making a PVC film layer 1 and a yarn layer 2. The yarn tablecloth is laminated by double-sided embossing of the PVC film layer 1 and the yarn layer 2 , printed and rolled.

[0036] The PVC film layer 1 comprises the following components: 65 parts of dioctyl phthalate, 55 parts of PVC resin powder, 90 parts of active calcium, 3 parts of heat stabilizer, 0.16 part of pigment powder, and 0.15 part of titanium dioxide. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the grammage of the active calcium is 220g / ㎡;

[0037] The production method of the PVC film layer 1 is as follows: adding each material of the above components in proportion to a polymerization reactor equipped with heavy oil as a solvent, raising the temperature to 200° C., stirring for 1.5 hours, filtering, and extruding to obtain the PVC film layer 1. Film layer 1; the oil content of ...

Embodiment 3

[0045] Embodiment 3: The present invention is a yarn tablecloth crown printing process, which includes making a PVC film layer 1 and a yarn layer 2. The yarn tablecloth is laminated by double-sided embossing of the PVC film layer 1 and the yarn layer 2 , printed and rolled.

[0046] The PVC film layer 1 includes the following components: 60 parts of dioctyl phthalate, 48 parts of PVC resin powder, 85 parts of active calcium, 2.6 parts of heat stabilizer, 0.10 part of pigment powder, and 0.10 part of titanium dioxide. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the gram weight of the active calcium is 200g / ㎡;

[0047] The production method of the PVC film layer 1 is as follows: adding each material of the above components in proportion to a polymerization reactor equipped with heavy oil as a solvent, raising the temperature to 198° C., stirring for 1.3 hours, filtering, and extruding to obtain the PVC film layer 1. Film layer 1; the oil content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com