Environment-friendly copper-aluminum composite cable and production method thereof

A copper-aluminum composite and manufacturing method technology, applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problem of high cable production cost, cable burning and releasing a large amount of harmful substances, cable not having water blocking ability, Problems such as low cable recycling rate, to achieve the effect of reducing material cost, light weight and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

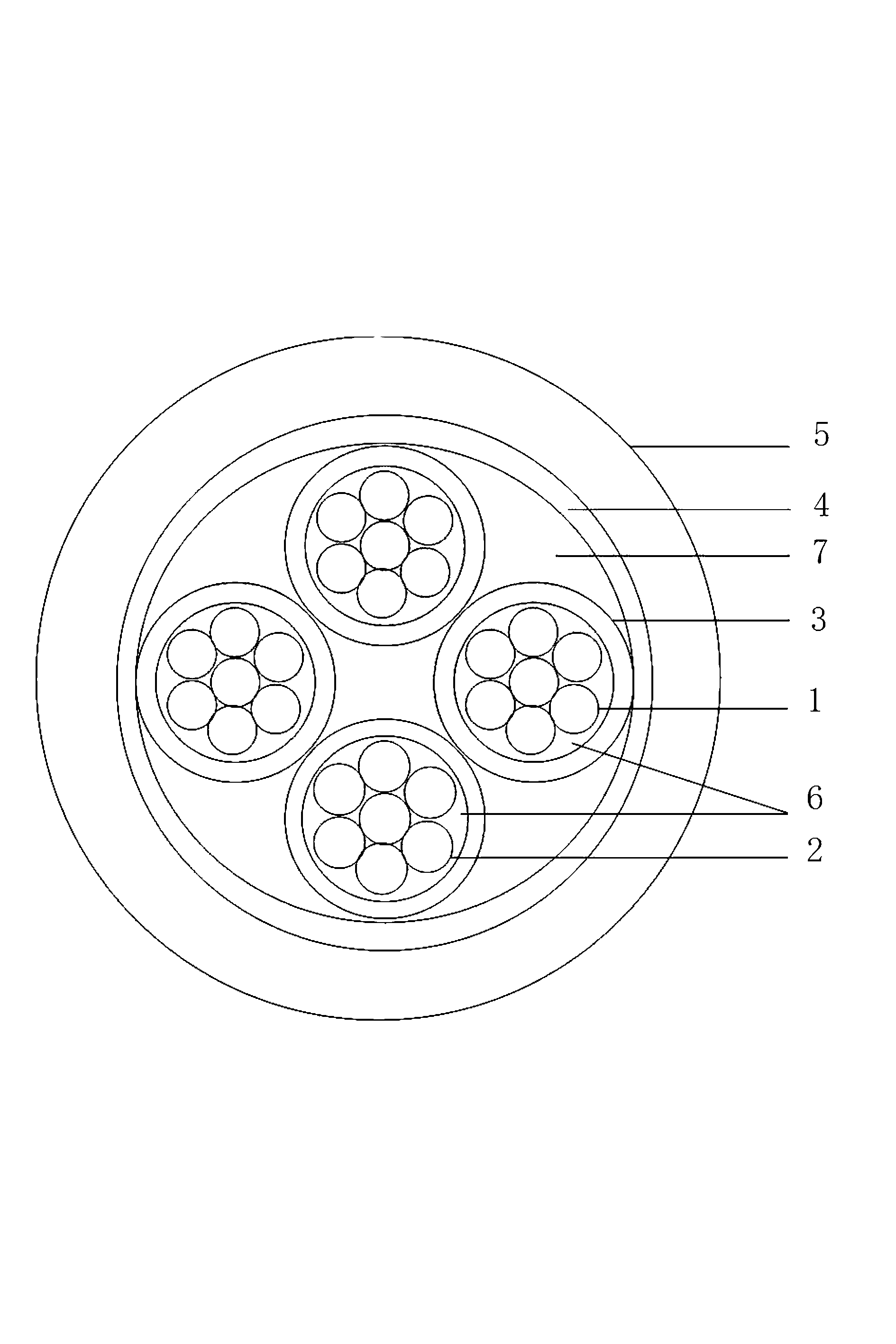

[0015] The conductor adopts four cores (that is, three cores are the main wire and one core is the ground wire, see figure 1 ), the main wire is made of copper, and the ground wire of the conductor is made of aluminum conductor. The conductor is provided with an insulating layer, a wrapping tape and a sheath layer in sequence, and a water-blocking layer is arranged between the conductor and the insulating layer. The water-blocking layer is made of water-blocking yarn, and the sheath layer is made of low-smoke halogen-free polyolefin material. It has the characteristics of low smoke, halogen-free, low corrosion and low toxicity.

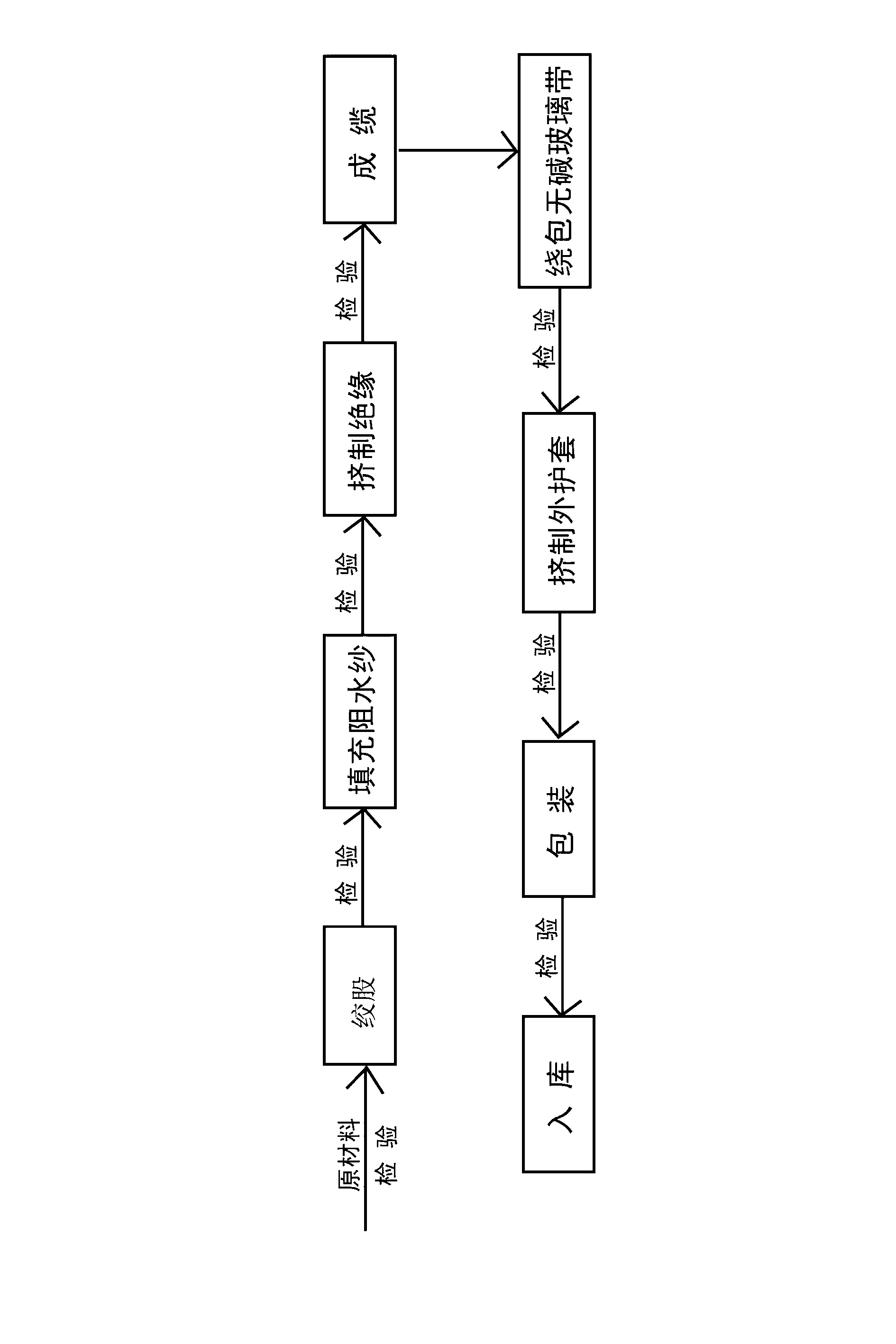

[0016] The specific steps of making the cable are as follows: a. Put 8 copper single wires or 8 aluminum single wires into the tube stranding machine for conductor stranding to make a conductor. The surface of the copper and aluminum single wires should be smooth and round without oil stains or scratches. Any defects such as scratches, burrs, etc. th...

Embodiment 2

[0018] The conductor adopts five cores (that is, three cores are the main wire, one core is the ground wire, and one core is the neutral wire), the main wire is made of copper, and the ground wire of the conductor is made of aluminum conductor. The conductor is provided with an insulating layer, a wrapping tape and a sheath layer in sequence, and a water-blocking layer is arranged between the conductor and the insulating layer. The water-blocking layer is made of water-blocking powder, and the sheath layer is made of low-smoke halogen-free polyolefin material. Low smoke, halogen-free, low corrosion and low toxicity and other characteristics.

[0019] The specific steps of making the cable are as follows: a. Put 4 copper single wires or 4 aluminum single wires into the tube stranding machine for conductor stranding to make a conductor. The surface of the copper and aluminum single wires should be smooth and round without oil stains or scratches. Any defects such as scratches, b...

Embodiment 3

[0021] The conductor adopts five cores (that is, three cores are the main wire, one core is the ground wire, and one core is the neutral wire), the main wire is made of copper, and the ground wire of the conductor is made of aluminum conductor. The conductor is provided with an insulating layer, a wrapping tape and a sheath layer in sequence, and a water-blocking layer is arranged between the conductor and the insulating layer. The water-blocking layer is made of water-blocking yarn, and the sheath layer is made of low-smoke halogen-free polyolefin material. It has the characteristics of low smoke, halogen-free, low corrosion and low toxicity.

[0022]The specific steps of making the cable are as follows: a. Put 6 copper single wires or 6 aluminum single wires into the tube stranding machine for conductor stranding to make a conductor. The surface of the copper and aluminum single wires should be smooth and round without oil stains or scratches. Any defects such as scratches, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com