Biodegradable polymer vesicles and preparation and application thereof

A technology for degrading polymers, polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

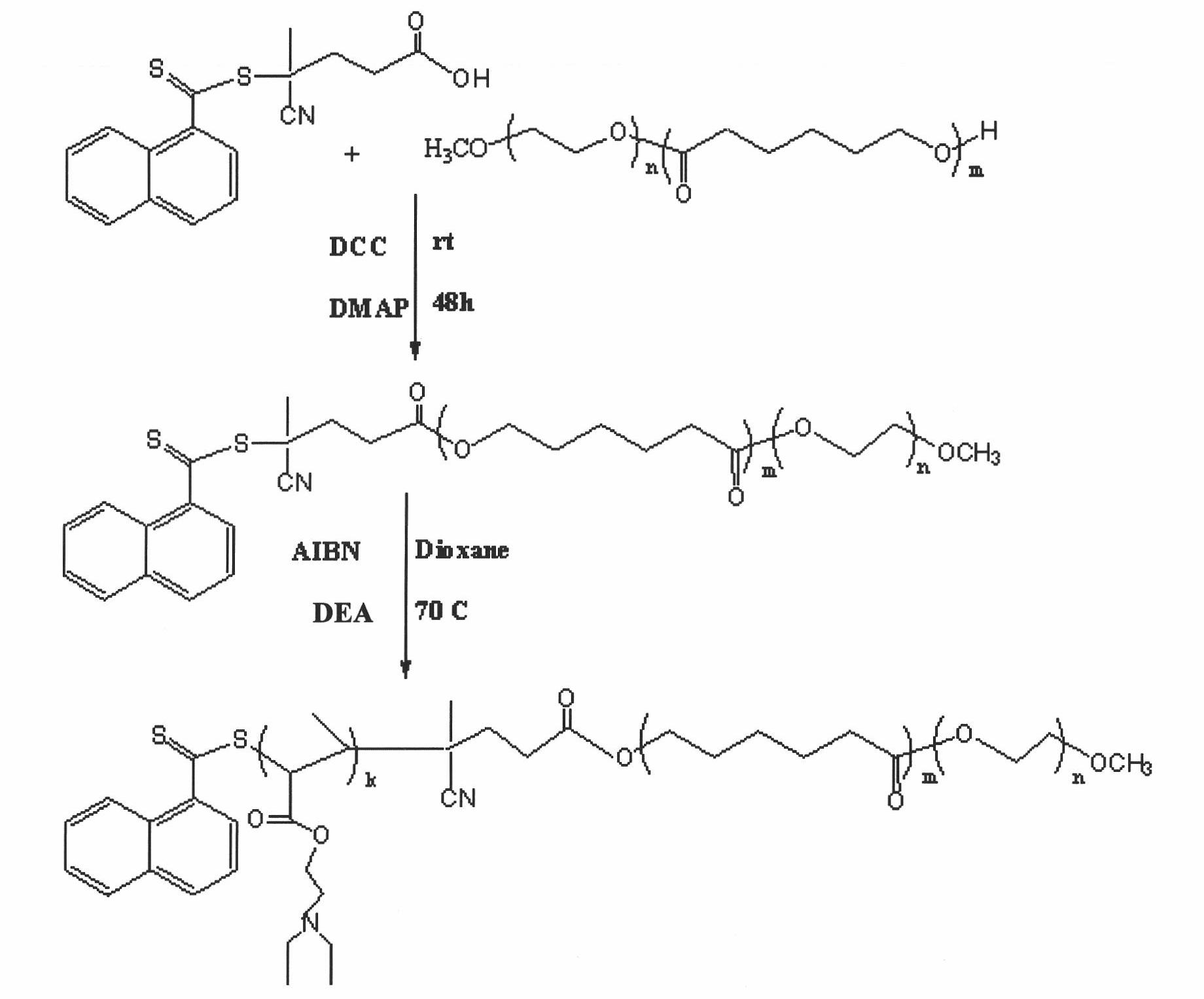

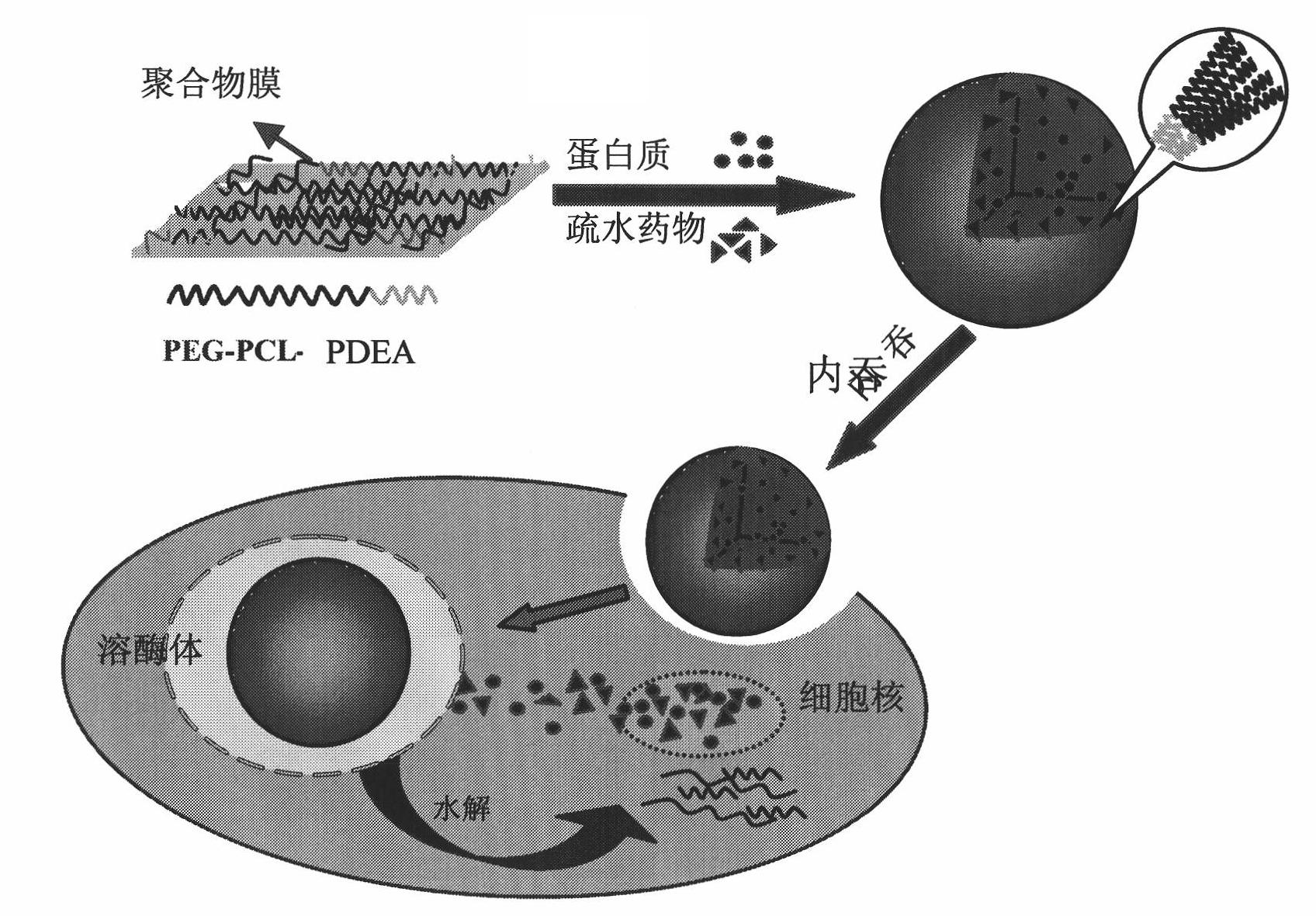

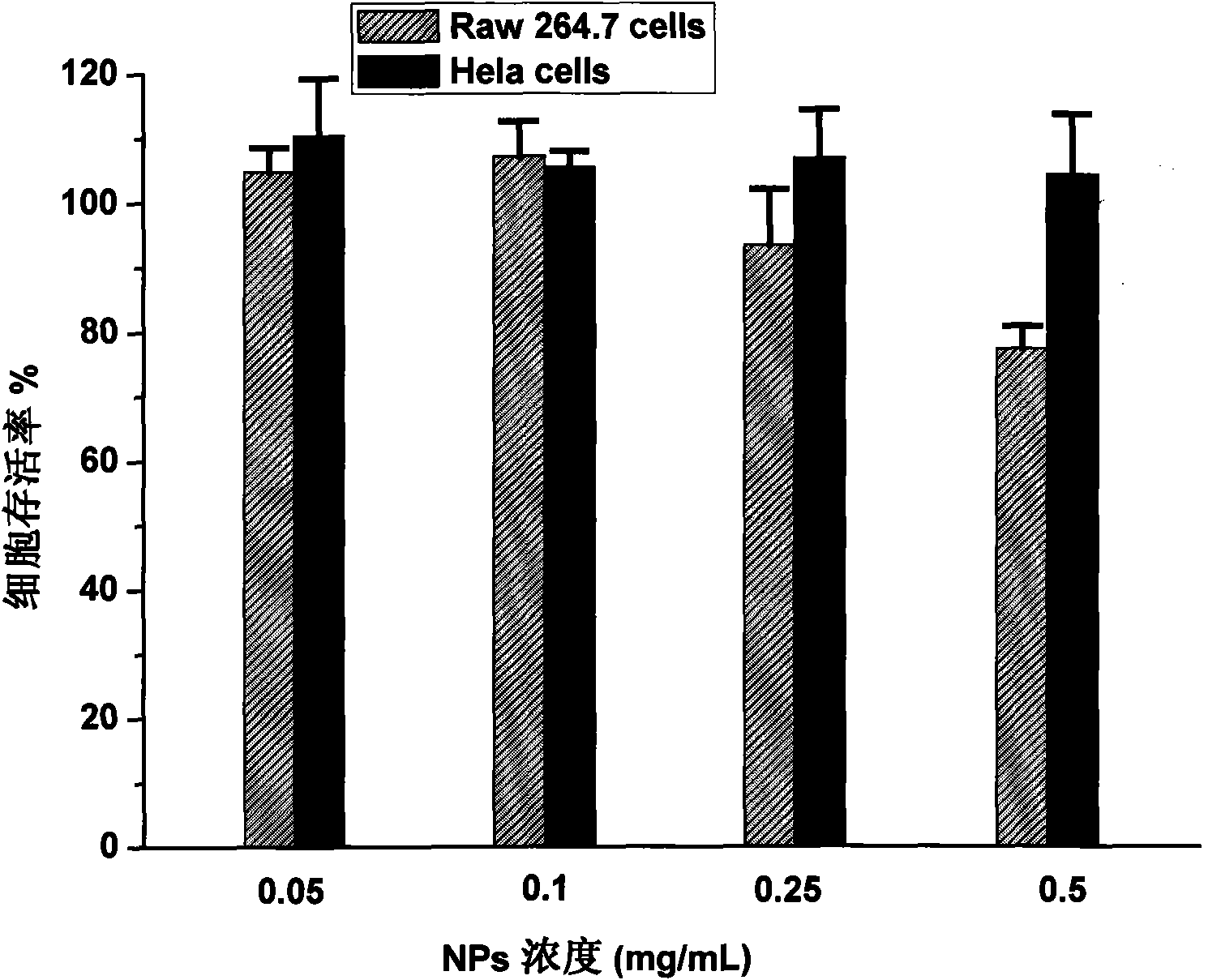

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one, RAFT method synthesizes triblock polymer PEG 5 -PCL 18 -PDEA 1

[0041] Under the protection of nitrogen, add macromolecular RAFT reagent PEG to a 10 ml Schlenk vacuum-sealed bottle 5 -PCL 18 - CPADN (0.5mg, 0.022mmol), add DEA monomer (0.028g, 0.15mmol) and AIBN (0.7mg, 4.3μmol) at a conversion rate of 70%, and then add 3.5ml of 1,4-dioxane. After the reaction bottle was ventilated with nitrogen for 30 minutes, the reaction bottle was placed in a preset 70° C. oil bath, and the reaction was sealed for 24 hours. After the reaction was finished, after the reaction flask was cooled, excess ether precipitated, and then the sample was filtered, vacuum-dried, and vacuum-dried for 48 hours to obtain a tri-block copolymer with a yield of 57%. The NMR results showed that the molecular weight of its PDEA was 1100, whose structure is marked as PEG 5 -PCL 18 -PDEA 1 .

Embodiment 2

[0042] Embodiment two, RAFT method synthesizes triblock polymer PEG 5 -PCL 18 -PDEA 4

[0043] Under the protection of nitrogen, add macromolecular RAFT reagent PEG to a 10 ml Schlenk vacuum-sealed bottle 5 -PCL 18 - CPADN (0.4mg, 0.017mmol), add DEA monomer (0.162g, 0.87mmol) and AIBN (0.6mg, 3.4μmol) at a conversion rate of 70%, and then add 3.5ml of 1,4-dioxane. After the reaction bottle was ventilated with nitrogen for 30 minutes, the reaction bottle was placed in a preset 70° C. oil bath, and the reaction was sealed for 24 hours. After the reaction was finished, after the reaction flask was cooled, excess n-hexane precipitated, then the sample was filtered, vacuum-dried, and vacuum-dried for 48 hours to obtain a tri-block copolymer with a yield of 65%. The NMR results showed that the molecular weight of PDEA was 4100, whose structure is marked as PEG 5 -PCL 18 -PDEA 4 .

Embodiment 3

[0044] Embodiment three, RAFT synthesis triblock polymer PEG 5 -PCL 18 -PAA 3

[0045] Under the protection of nitrogen, add macromolecular RAFT reagent PEG to a 10 ml Schlenk vacuum-sealed bottle 5 -PCL 18 - CPADN (0.5 mg, 0.022 mmol), add acrylic acid monomer (0.022 g, 0.3 mmol) and AIBN (0.7 mg, 4.3 μmol), then add 3 ml of 1,4-dioxane. After the reaction bottle was ventilated with nitrogen for 30 minutes, the reaction bottle was placed in a preset 70° C. oil bath, and the reaction was sealed for 24 hours. After the reaction was finished, after the reaction bottle was cooled, excess n-hexane precipitated, and then the sample was filtered, vacuum-dried, and vacuum-dried for 48 hours to obtain a tri-block copolymer with a yield of 86%. The NMR results showed that the molecular weight of PAA was 2700, whose structure is marked as PEG 5 -PCL 18 -PAA 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com