Preparation method and application of electrospinning nanofiber

A nanofiber, electrospinning technology, applied in electrospinning, application, fiber processing, etc., can solve the problems of short fiber filtration effect not as good as long fiber, easy to produce particle debris, poor filtration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Under normal temperature and pressure (15-35° C., 1 standard atmospheric pressure), weigh 0.5 g of chitosan, dissolve it in 10 ml of water, configure a 50 mg / ml solution, and ultrasonicate for 10 minutes until the solution is uniform and transparent. Add 1mg / ml peppermint essential oil and 1mg / ml organic fluorescent compound, stir and oscillate ultrasonically, inject the prepared solution into the syringe of the electrospinning equipment, set the spinning voltage to 18kV, and the propulsion speed of the spinning solution to 2ml / hr / needle, the distance from the spinning needle to the receiving plate is 25cm. Films were prepared by electrospinning equipment. figure 1 It is the electron microscope SEM image of the nanofiber prepared by the solution of 50mg / ml chitosan, peppermint essential oil and organic fluorescent compound when the spinning voltage is 18kV.

Embodiment 2

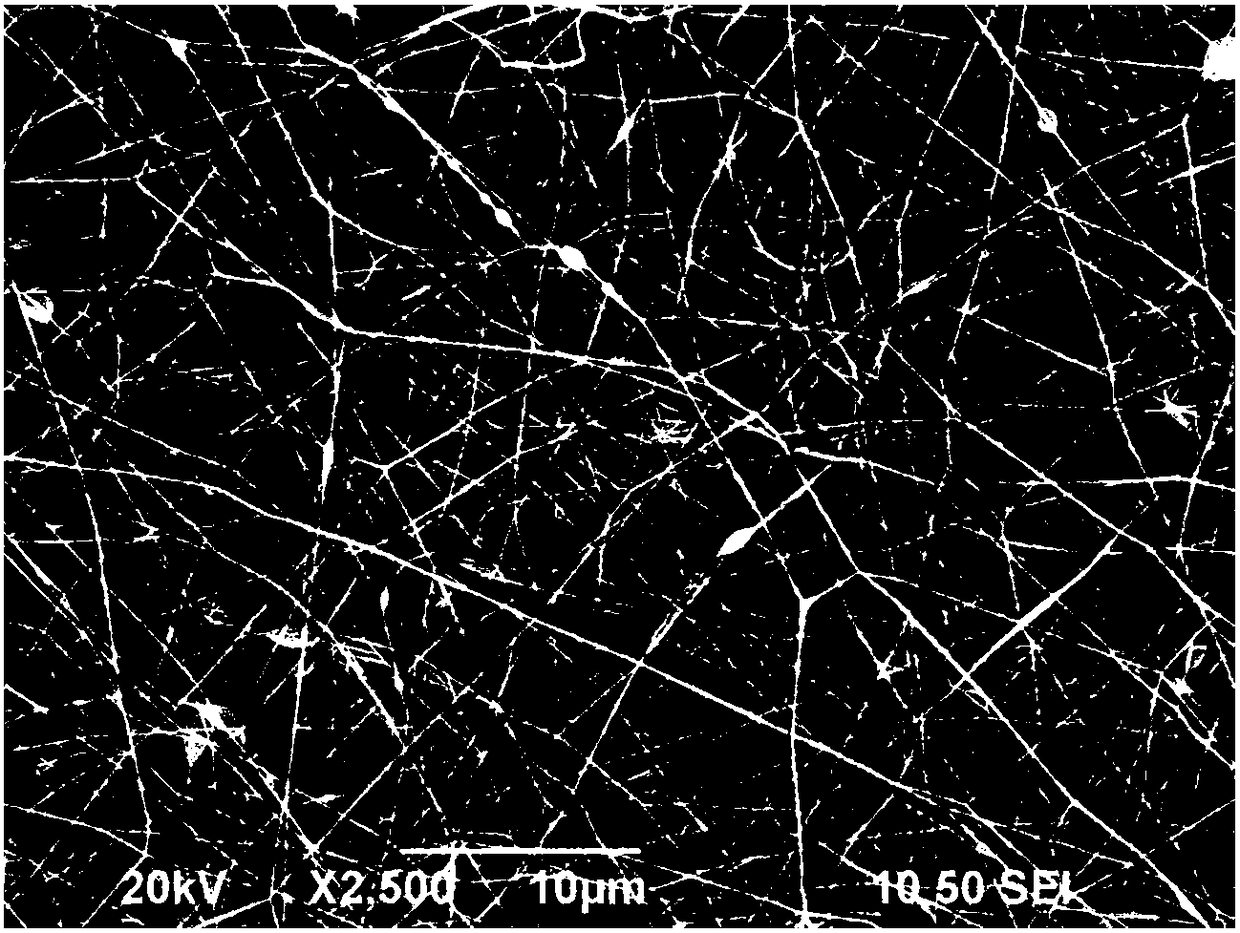

[0054] Under normal temperature and pressure (15-35°C, 1 standard atmospheric pressure), weigh 1.0 g of gelatin, dissolve it in 10 ml of water, and prepare a 100 mg / ml solution, and ultrasonicate for 10 minutes until the solution is uniform and transparent. Add 0.5mg / ml thymol and 0.5mg / ml organic fluorescent compound, inject the prepared solution into the syringe of the electrospinning equipment, set the spinning voltage to 20kV, and the propulsion speed of the spinning solution to 0.5ml / hr / needle, the distance from the spinning needle to the receiving plate is 25cm. Films were prepared by electrospinning equipment. figure 2 It is an electron microscope SEM image of nanofibers prepared by 100mg / ml gelatin, thymol and organic fluorescent compound solution when the spinning voltage is 20kV.

Embodiment 3

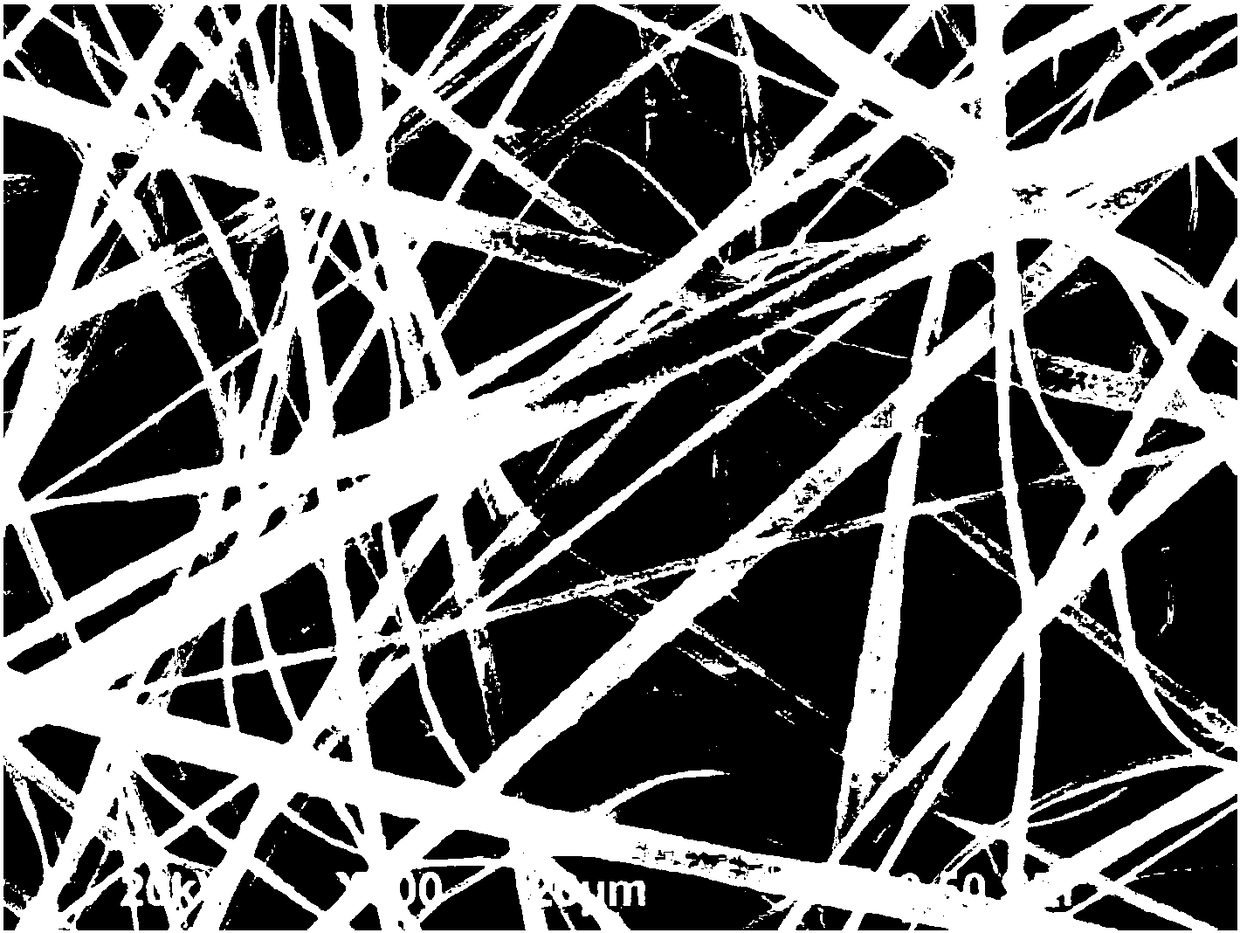

[0056] Under normal temperature and pressure (15-35°C, 1 standard atmospheric pressure), weigh 1.5g of polylactic acid, dissolve it in 10ml of chloroform, make a 150mg / ml solution, and ultrasonicate for 10 minutes until the solution is uniform and transparent. Add 5mg / ml of carvacrol and 5mg / ml of organic fluorescent compound, inject the prepared solution into the syringe of the electrospinning equipment, set the spinning voltage to 22kV, and the propulsion speed of the spinning solution to 0.5ml / hr / needle, the distance from the spinning needle to the receiving plate is 25cm. Films were prepared by electrospinning equipment. image 3 It is the electron microscope SEM image of the nano-spinning layer prepared by the solution of 150mg / ml polylactic acid, carvacrol and organic fluorescent compound when the spinning voltage is 22kV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com