Closed isocyanate coupling agent and application thereof

A technology of blocking isocyanate and isocyanate, which is applied in the direction of fibrous fillers, compounds of group 4/14 elements of the periodic table, and dyed organosilicon compounds. Use requirements, lower physical and mechanical properties of nylon composite materials, etc., to achieve the effect of improving dispersion state, increasing molecular weight, and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

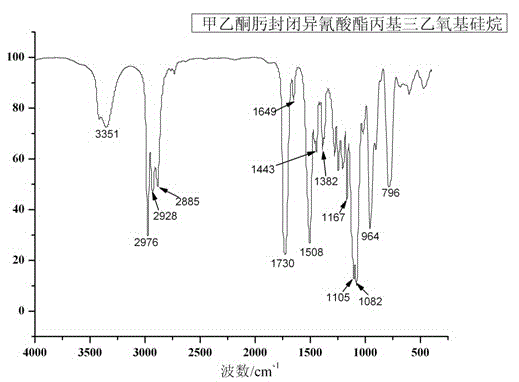

[0033] Weigh 15g of isocyanate propyltriethoxysilane, dilute it with 25ml of anhydrous toluene and add it into a 250ml three-necked flask, then weigh 6.3396g of methyl ethyl ketone oxime and dissolve it in 25ml of anhydrous toluene, transfer it to a constant pressure funnel, add methyl ethyl ketone dropwise Oxime, the dropwise addition process controls the reaction temperature not to exceed 40°C, and the dropwise addition time is 0.5h; after the dropwise addition is completed, keep the temperature for 0.5h, then rise to 80°C for 4h reaction, cool to room temperature, evaporate the solvent, and obtain methyl ethyl ketoxime blocked isocyanate propane base triethoxysilane coupling agent. Such as figure 1 , methyl ethyl ketoxime blocked isocyanate propyl triethoxysilane infrared data: wave number 2274cm -1 At -NCO characteristic absorption peak disappears, 1730cm -1 The carbonyl absorption peak in -NHCOO appears at 3351cm -1 Appeared -NH special absorption peak, 1382, 1443cm ...

Embodiment 2

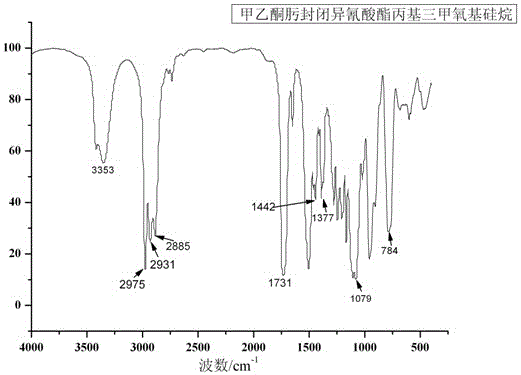

[0038] Weigh 8g of isocyanate propyltrimethoxysilane, dilute it with 25ml of anhydrous toluene and add it into a 250ml three-necked flask, then weigh 3.7346g of methyl ethyl ketone oxime and dissolve it in 25ml of anhydrous toluene, transfer it to a constant pressure funnel, add methyl ethyl ketone oxime dropwise , the dropping process controls the reaction temperature not to exceed 40°C, and the dropping time is 0.6h; after the dropping is completed, the temperature is kept constant for 0.6h, then raised to 80°C for 5h, cooled to room temperature, and the solvent is evaporated to obtain methyl ethyl ketoxime blocked isocyanate coupling agent. Such as figure 2 , methyl ethyl ketoxime blocked isocyanate propyl trimethoxysilane infrared data: wave number 2274cm -1 At -NCO characteristic absorption peak disappears, 1731cm -1 The carbonyl absorption peak in -NHCOO appears at 3353cm -1 Appeared -NH special absorption peaks, 1377, 1442cm -1 Respectively -CH 3 and -CH 2 Curve...

Embodiment 3

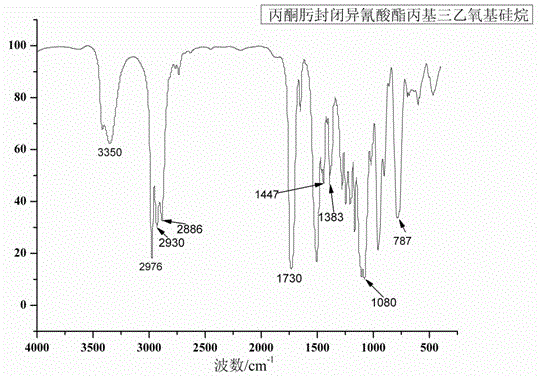

[0043] Weigh 10g of isocyanate propyltriethoxysilane, dilute it with 25ml of anhydrous toluene and add it to a 250ml three-necked flask, then weigh 2.9550g of acetone oxime and dissolve it in 25ml of anhydrous toluene, transfer it to a constant pressure funnel, and add acetone dropwise Oxime, the dropwise addition process controls the reaction temperature not to exceed 40°C, and the dropwise addition time is 0.5h; after the dropwise addition, the temperature is kept at a constant temperature for 0.5h, and then raised to 80°C for 5h reaction, cooled to room temperature, and the solvent is evaporated to obtain acetone oxime blocked isocyanate. joint agent. Such as image 3 , acetone oxime blocked isocyanate propyltriethoxysilane infrared data: wave number 2274cm -1 At -NCO characteristic absorption peak disappears, 1730cm -1 The carbonyl absorption peak in -NHCOO appears at 3350cm -1 Appeared -NH special absorption peaks, 1383, 1447cm -1 Respectively -CH 3 and -CH 2 Curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com