Heat-resistant PC/ABS alloy material and preparation method thereof

An alloy material and heat-resistant technology, applied in the field of heat-resistant PC/ABS alloy material and its preparation, can solve the problems of poor heat resistance of ABS, low heat distortion temperature, deterioration of material properties, etc., and achieve superior heat resistance. , Vicat softening point temperature increase, the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

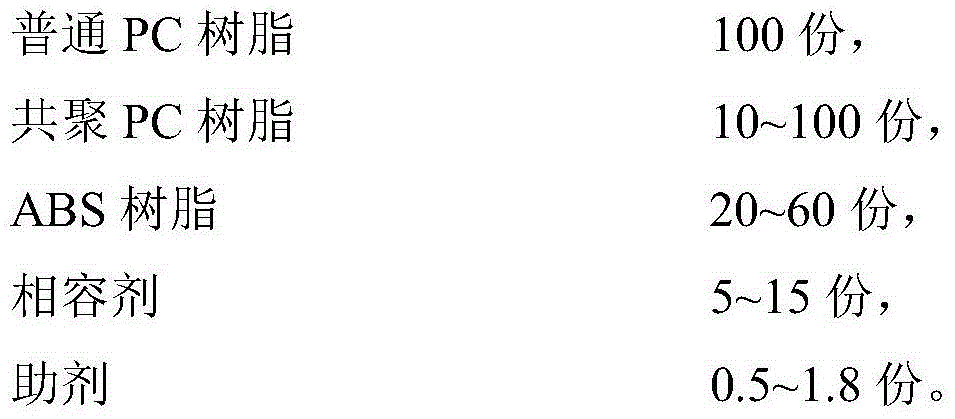

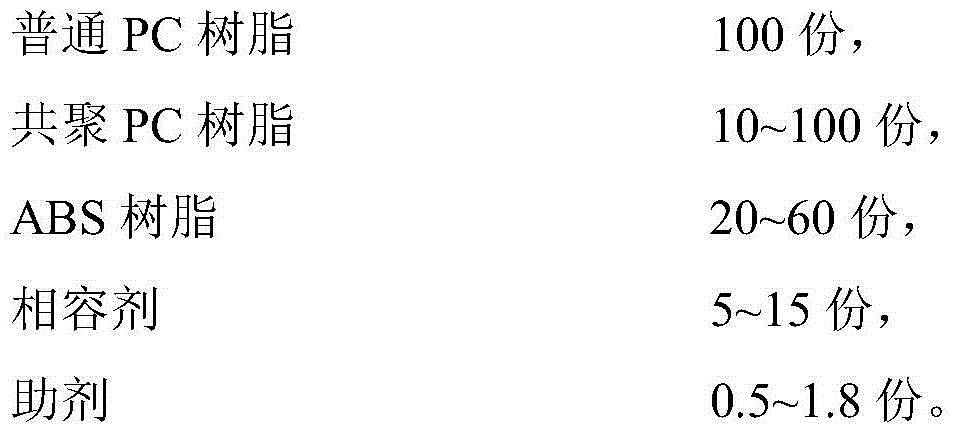

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 100 parts of ordinary PC resin, 10 parts of copolymerized PC resin, 20 parts of ABS resin, 5 parts of compatibilizer ABS-g-MAH and 1.6 parts of additives (0.6 parts of antioxidant and 1 part of lubricant PE wax, Among them, antioxidants include antioxidant 1076 and antioxidant 626, antioxidant 1076 / antioxidant 626=1 / 2), add to the high-speed mixer and mix at a high speed, control the speed of the high-mixer to 500rmp, and the mixing temperature at 80°C, mix for 3 minutes and mix well;

[0027] (2) Put the mixed material into the twin-screw extruder to extrude and granulate. The PC / ABS alloy material is obtained by cutting the strands out of the machine.

[0028] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 245° C. The extruded strips were placed at 50% relative humidity at 23°C for 24 hours before performing a performance test. The test r...

Embodiment 2

[0030] (1) Mix 100 parts of ordinary PC resin, 25 parts of copolymerized PC resin (Vicat softening temperature is 185°C), 30 parts of ABS resin, 7 parts of compatibilizer SMA and 1.7 parts of additives (1.2 parts of antioxidant and 0.5 parts of Lubricant PETS, wherein the antioxidant includes antioxidant 1010 and antioxidant 168, antioxidant 1010 / antioxidant 168=1 / 2), added to the high-speed mixer for high-speed mixing, and the speed of the high-mixer is controlled to 700rmp, mixing temperature is 40°C, mix for 6min and mix well;

[0031] (2) Put the mixed material into the twin-screw extruder to extrude and granulate. The PC / ABS alloy material is obtained by cutting the strands out of the machine.

[0032] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 245° C. The extruded strips were placed at 50% relative humidity at 23°C for 24 hours before performing...

Embodiment 3

[0034] (1) Mix 100 parts of ordinary PC resin, 45 parts of copolymerized PC resin (Vicat softening temperature is 205°C), 60 parts of ABS resin, 15 parts of compatibilizer MBS and 1.6 parts of additives (0.8 parts of antioxidant and 0.8 parts of Lubricant PE wax, where the antioxidants include antioxidant 1076 and antioxidant 168, antioxidant 1076 / antioxidant 168=1 / 2), add to the high-speed mixer and mix at high speed, control the speed of the high-mixer The temperature is 600rmp, the mixing temperature is 60°C, and the mixing is uniform for 10 minutes;

[0035] (2) Put the mixed material into the twin-screw extruder to extrude and granulate. The PC / ABS alloy material is obtained by cutting the strands out of the machine.

[0036] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 245° C. The extruded strips were placed at 50% relative humidity at 23°C for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com