Moisture-absorbing antistatic dyeable polypropylene fibre and preparation method thereof

A polypropylene fiber, polypropylene technology, used in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the problems of moisture absorption, dyeability and poor antistatic properties, and achieve antistatic properties. High performance and good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material polypropylene is a commercial product with a melt index of 35g / 10min and a melting point of 166°C; the mass ratio of the hard segment to the soft segment of the self-made PBT-PEG copolyether ester is 60:40, the intrinsic viscosity is 1.02g / dl, and the melting point 198°C, roughly the same as commercially available.

[0040] The mass ratio of sheath / core in the composite fiber is 85:15, and the blending mass ratio of PP and PBT-PEG copolyetherester in the sheath is 94:6. The copolyether ester and polypropylene blend chip (A) constituting the skin layer and the copolyether ester (B) constituting the core layer are pre-dried with dehumidified hot air with a dew point temperature of -70°C at 110°C for 6h, and dried The water content of slices should be less than 50ppm. Melt the above two slices of A and B respectively with two screw extruders (A screw diameter 55mm, B screw diameter 30mm) and adjust the melt temperature. The two-component melts of A and B...

Embodiment 2

[0044] Raw material and spinning equipment are with embodiment 1.

[0045] The mass ratio of sheath / core in the composite fiber is 80:20, and the blending mass ratio of PP and PBT-PEG copolyetherester in the sheath is 92:8. The technological parameters of the spinning-post-processing process are: melt temperature 245°C, stretching roll GR1 temperature 52°C, setting roll GR2 temperature 108°C, draw ratio 2.6 times, winding speed 2565m / min.

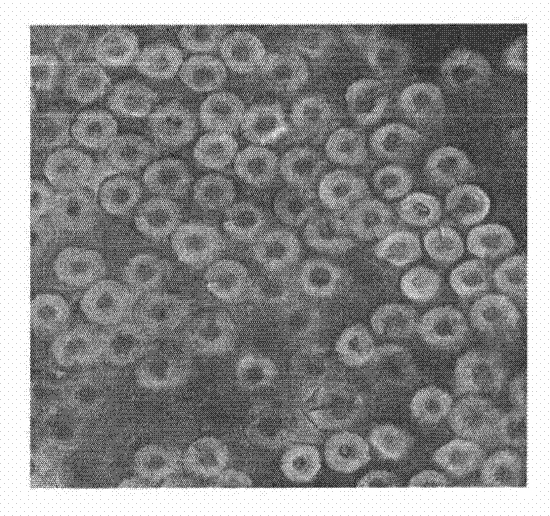

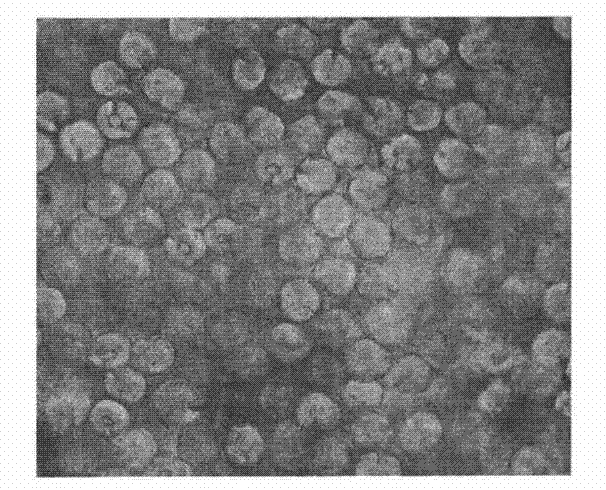

[0046] The specification of the obtained fiber is 123dtex / 72f, the breaking strength is 3.51cN / dtex, the breaking elongation is 51.4%, the equilibrium moisture regain is 1.55%, and the volume specific resistance of the fiber is 3.3×10 9 Ω·cm, the induced static voltage of the fabric is 3.0kV, and the half-life is 3.9s. The optical micrographs of the fiber sections after dyeing showed that the core layer and the skin layer were dyed at the same time. The electrostatic voltage of the dyed fabric is 3.0kV, and the half-life is 4.9s. The dye...

Embodiment 3

[0048] The raw material polypropylene is a commercial product with a melt index of 28 g / 10 min and a melting point of 166° C.; the self-developed PBT-PEG copolyether ester is the same as in Example 1.

[0049] The mass ratio of sheath / core in the composite fiber is 80:20, and the blending mass ratio of PP and copolyetherester in the sheath is 90:10. Spinning equipment is with embodiment 1. The technological parameters of the spinning-post-processing process are: melt temperature 250°C, stretching roll GR1 temperature 55°C, setting roll GR2 temperature 112°C, draw ratio 2.6 times, winding speed 2560m / min.

[0050] The specification of the obtained fiber is 123dtex / 72f, the breaking strength is 3.32cN / dtex, the breaking elongation is 46.4%, the equilibrium moisture regain is 1.58%, and the volume specific resistance of the fiber is 2.6×10 9 Ω·cm, the induced static voltage of the fabric is 2.76kV, and the half-life is 3.1s. The optical micrographs of the fiber sections after d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com