Lead-acid storage battery intelligent full-automatic cast-weld production line and process thereof

A lead-acid battery, lead-acid battery technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve problems such as low processing efficiency, achieve high processing efficiency, improve processing efficiency, and achieve the effect of automatic recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

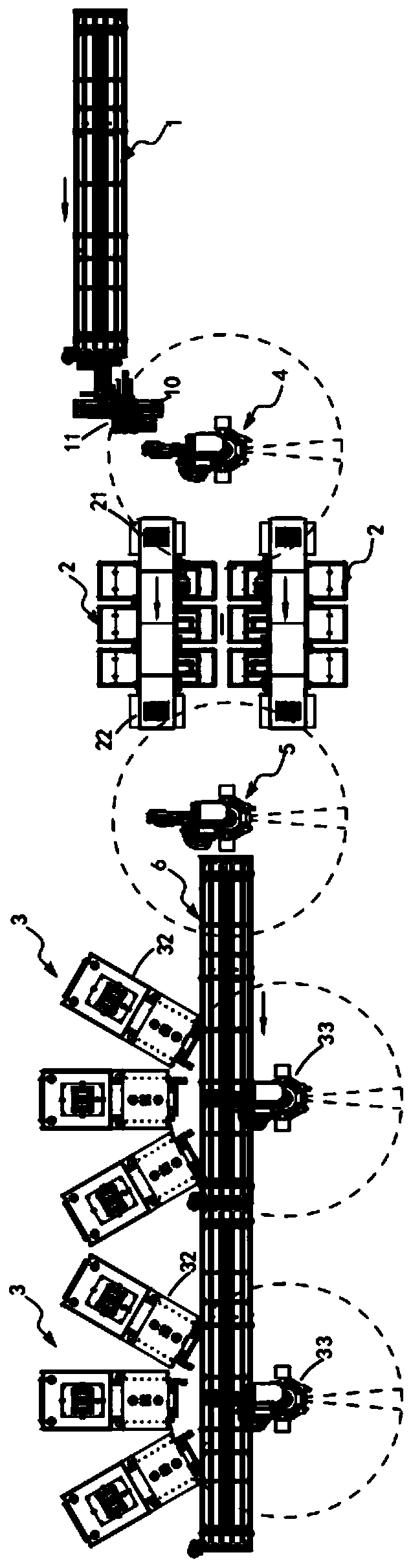

[0077] Such as figure 2 , 3 , 4, 8 and 9, an intelligent full-automatic casting and welding production line for lead-acid batteries includes an input line 1, at least one set of brush cutting equipment 2 and at least one set of casting and welding equipment 3, and the input line 1 is used for inputting For the lead-acid battery 10 to be cast and welded, the output station 11 on it is set opposite to the feed station 21 on the adjacent brush cutting equipment 2, and the discharge station 22 of the brush cutting equipment 2 Adjacent to the corresponding casting and welding equipment 3,

[0078] The output station 11 on the input line 1 is adjacently provided with a first grasping manipulator 4, and the discharge station 22 of the brush cutting device 2 is adjacently provided with a second grasping manipulator 5. One side of the gripping manipulator 5 is adjacent to a conveying line 6;

[0079] The brush cutting equipment 2 is provided with an automatic feeding mechanism 23, ...

Embodiment 2

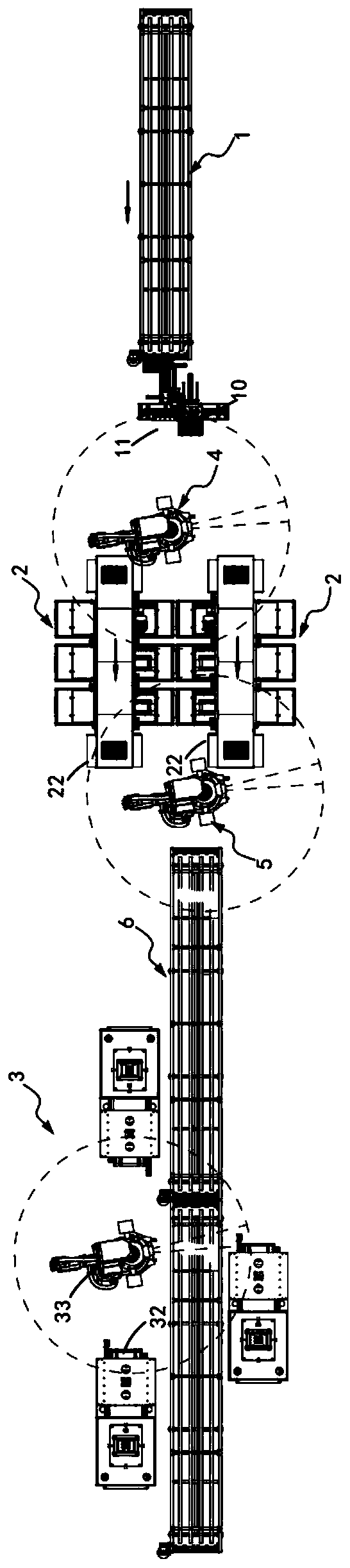

[0097] Figure 6 It is a schematic structural diagram of Embodiment 2 of an intelligent full-automatic casting and welding production line for lead-acid batteries of the present invention; , for the sake of brevity, only the differences from Example 1 are described below, and this Example 2 and figure 1 Example 1 shown differs in that:

[0098] Such as Figure 6 and Figure 7 The automatic feeding mechanism 23 also includes a reusing assembly 233, which is arranged directly above the stepping assembly 232, which grabs the loading tray 231 at the discharge station 22 and rotates to the The 21 places of the feeding station are recycled.

[0099] It should be noted that the recycling component 233 includes a truss set 2331 and a pneumatic claw set 2332. The pneumatic claw set 2332 is driven by the truss set 2331 to reciprocate between the discharge station 22 and the feed station 21, wherein the truss set 2331 is the The conventional structure that the motor drives the gear ...

Embodiment 3

[0101] Figure 19 It is a schematic structural view of Embodiment 3 of an intelligent full-automatic casting and welding production line for lead-acid batteries of the present invention; , for the sake of brevity, only the differences from Example 1 are described below, and this Example 3 and figure 1 Example 1 shown differs in that:

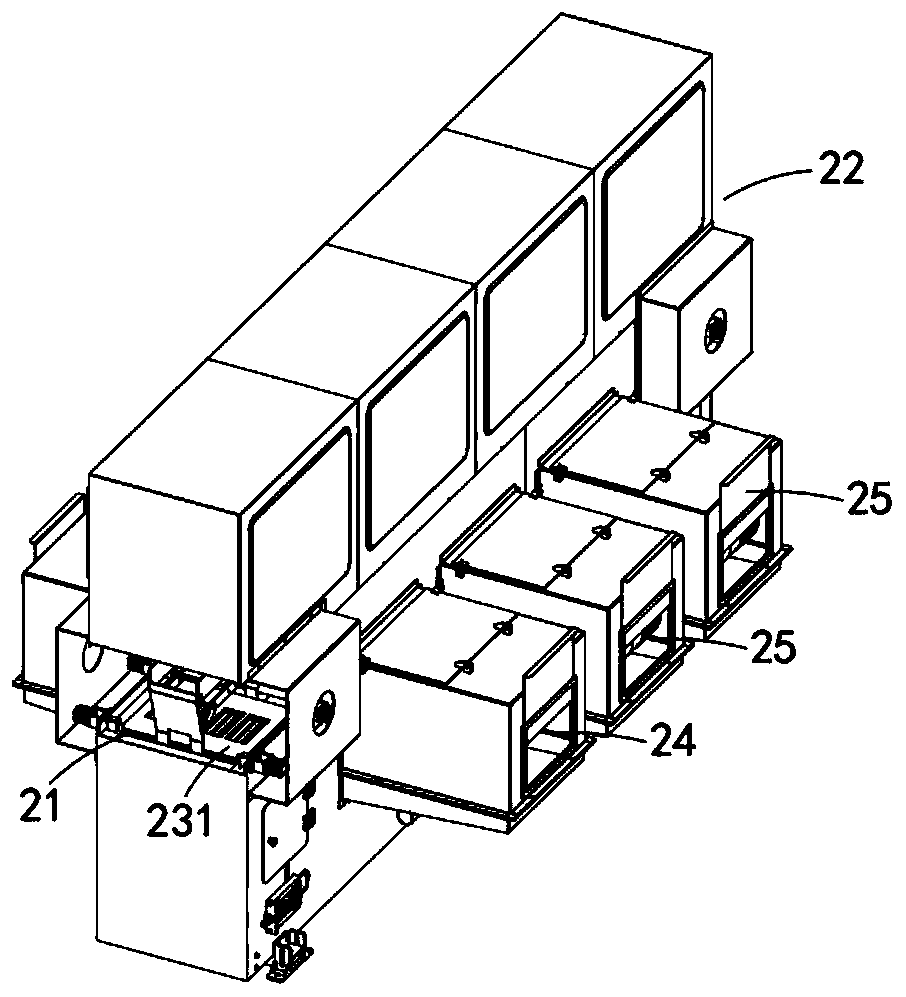

[0102] Such as Figure 19 to Figure 21 As shown, the difference between the structure of the brush ear mechanism 25 and the roller brush assembly disclosed in the patent of CN201920525436.0 is that the two ends of the brush roller 251 of the brush ear mechanism 25 are provided with rotating shafts 252 for quick disassembly and assembly. The assembled structure includes a plug joint 2511 disposed at the end of the brush roller 251 , a slot 2521 disposed at the end connecting the rotating shaft 252 and the brush roller 251 , and a limiting block 2513 .

[0103] During installation, the plug joint 2511 is inserted into the slot 2521, and the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com