Multi-station casting machine

A casting machine, multi-station technology, applied in casting equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of large differences in crystallinity and strength, poor strength of casting products, low work efficiency, etc., to ensure strength, Good crystallization effect, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

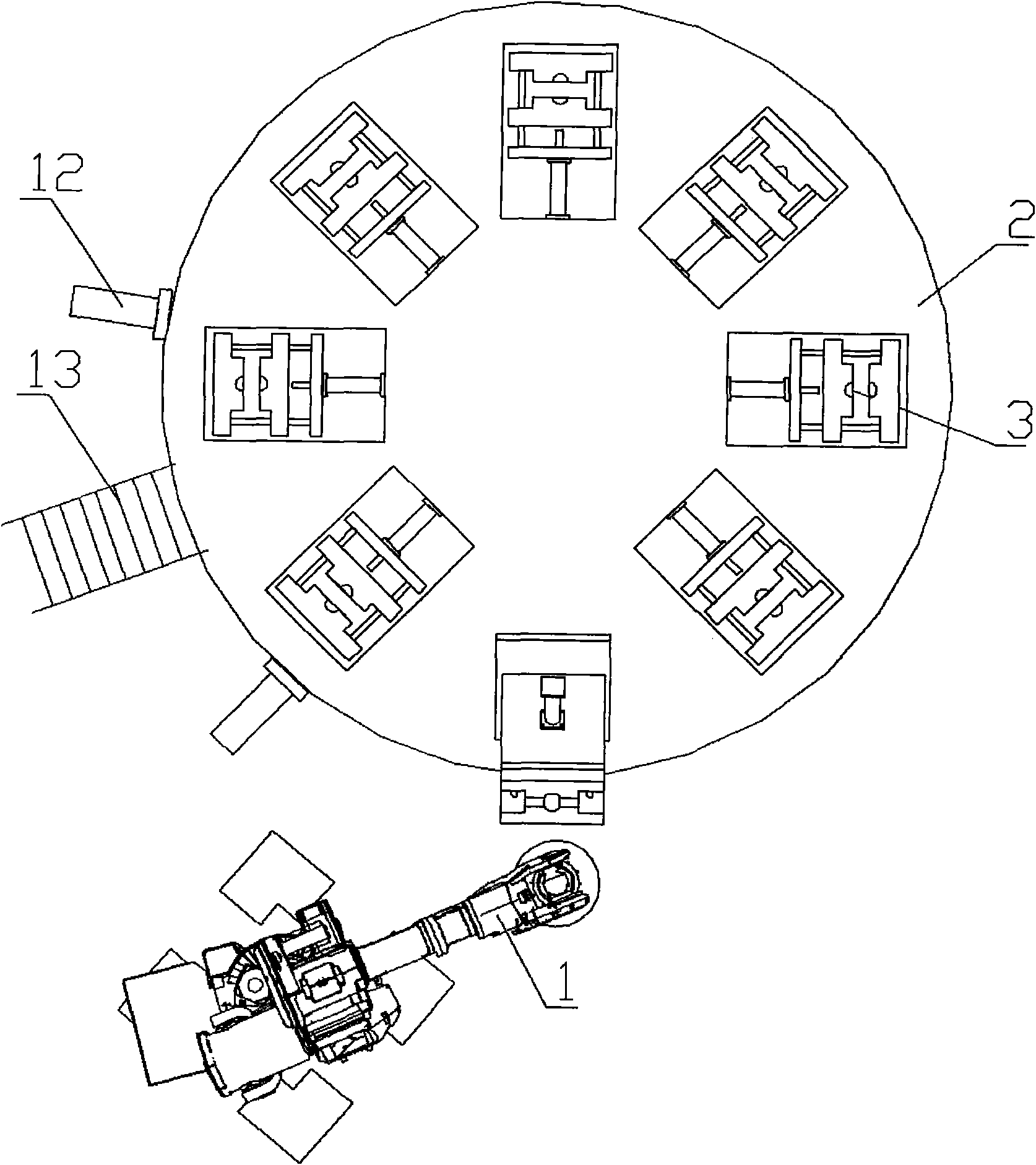

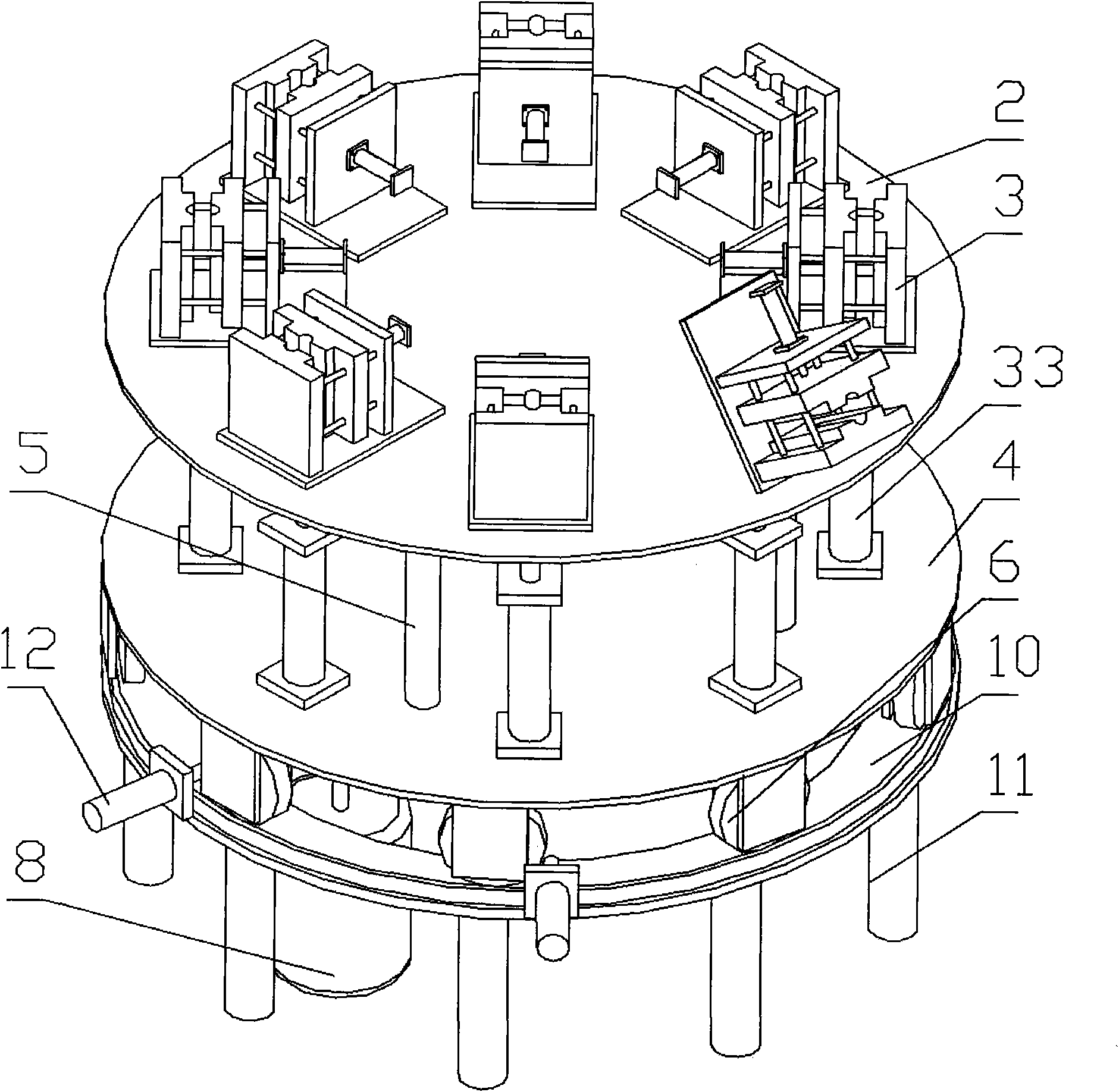

[0022] Example: see Figures 1 to 6 As shown, a multi-station casting machine includes a pouring robot 1, which is fixed on one side of a workbench 2, and there are no less than three casting units 3 distributed in a circular array on the workbench 2;

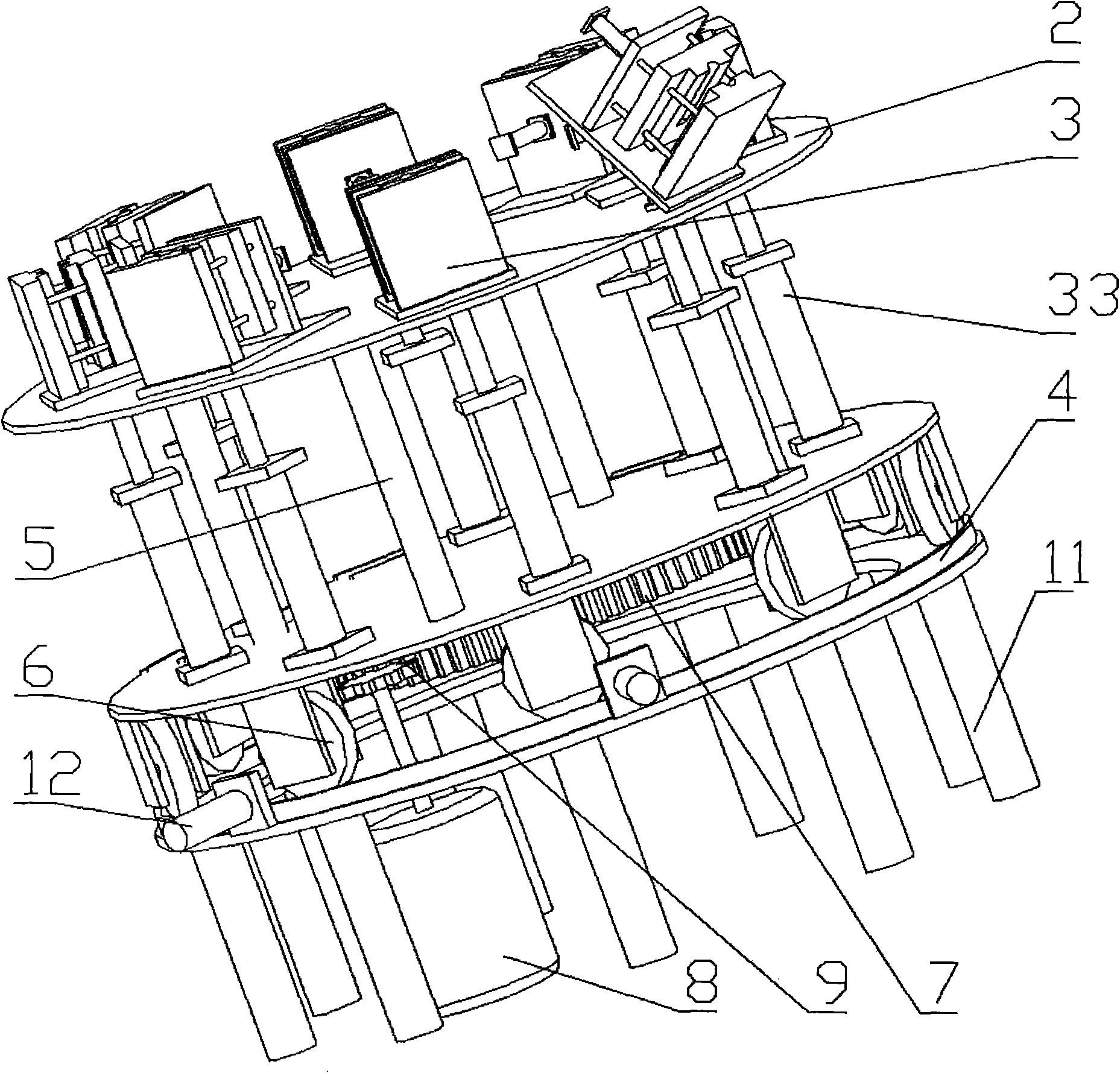

[0023] The structure of each casting unit 3 is made up of guide rod 31, pressing oil cylinder 32, rotating oil cylinder 33, rotating plate 34, back seat plate 35, pouring lower mold 37 and pouring upper mold 36, back seat plate 35 and pouring lower mold 37 is fixed on the rotating plate 34, the rotating plate 34 is hinged on the workbench 2, the two ends of the guide rod 31 are respectively fixed on the rear seat plate 35 and the casting lower mold 37, and the pressing oil cylinder 32 drives the casting upper mold 36 along the guide rod 31 Sliding, the rotary cylinder 33 is fixed on the support platform 4, and the piston of the rotary cylinder 33 is hinged on the rotary plate 34;

[0024] Both the lower casting mold 37 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com