Hydraulic jacking device and method of using the same

A jacking device and hydraulic technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of difficult transfer of heavy-tonnage tower workpieces, and achieve the effects of reducing manufacturing and transportation costs and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

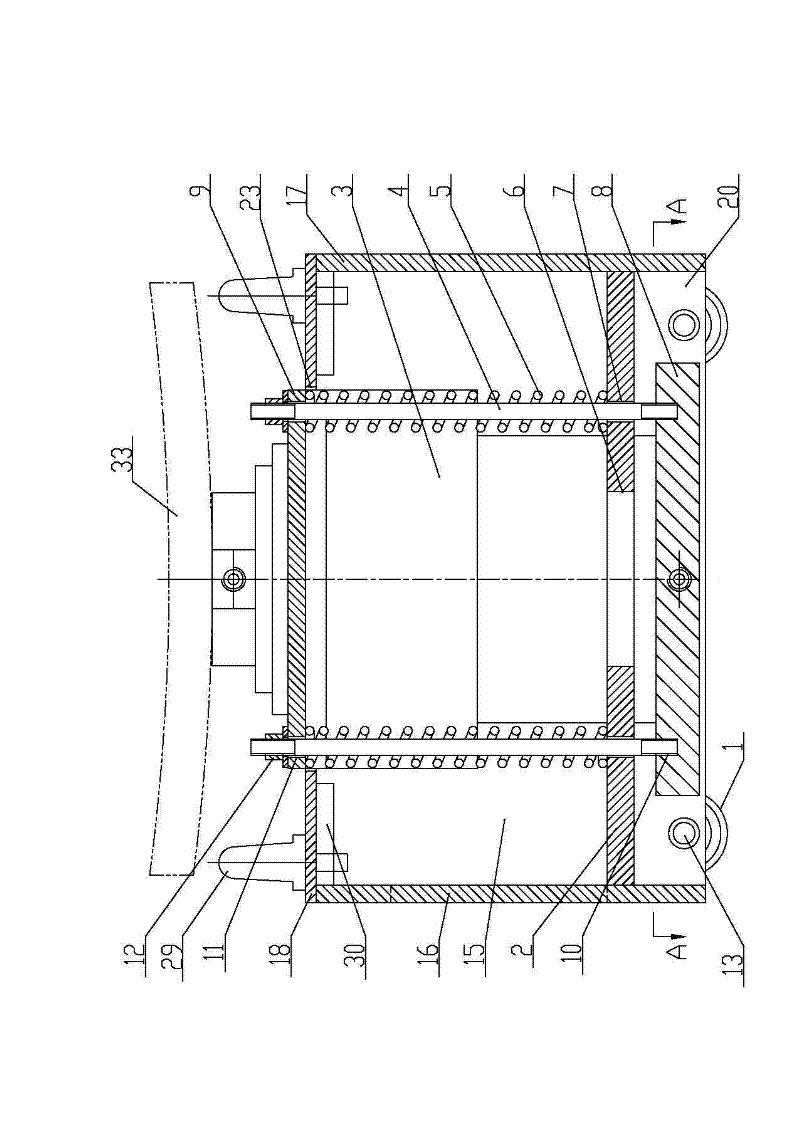

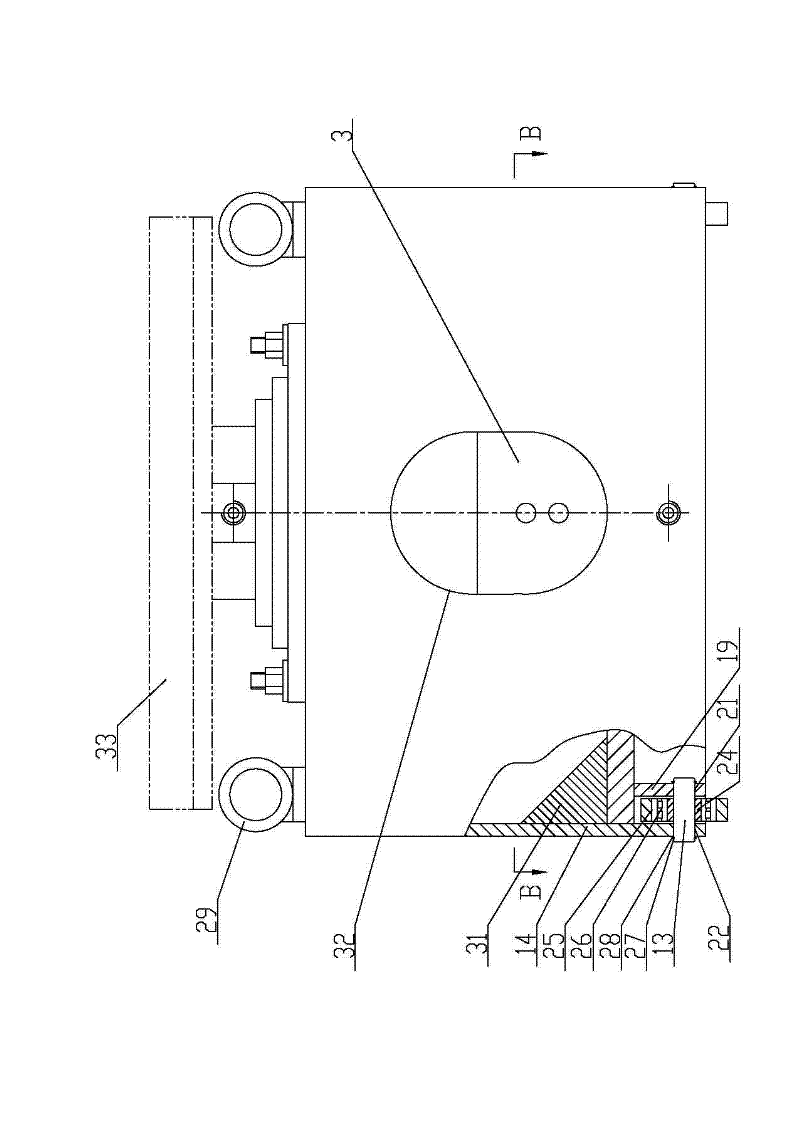

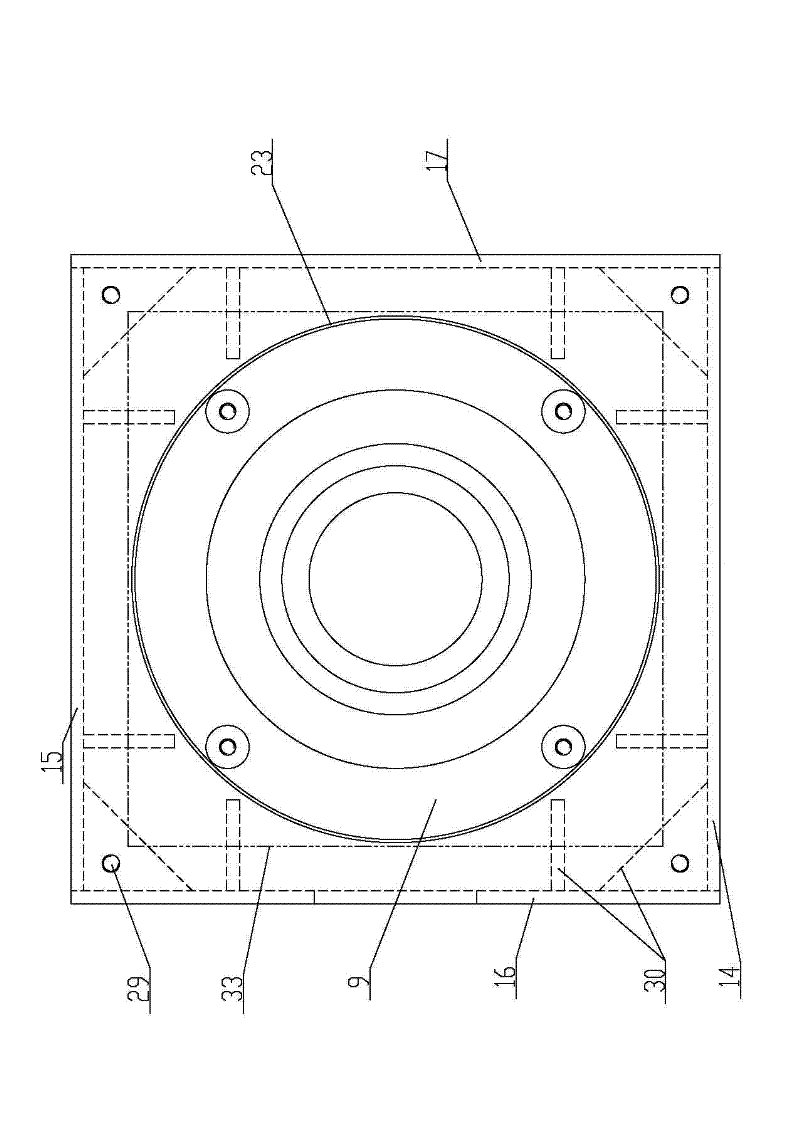

[0024] Embodiment 1: as attached figure 1 , 2 , 3, the hydraulic jacking device includes a box, a roller 1, a supporting plate 2, a hydraulic cylinder 3, a support rod 4 and a compression spring 5; the bottom of the box is equipped with a roller 1, and the inner cavity of the box is fixed with The supporting plate 2 has a supporting plate cylinder hole 6 in the middle of the supporting plate 2, and there are connecting rod through holes 7 on the supporting plate 2 around the supporting plate cylinder hole 6; The piston rod of the heavy object, the cylinder body top of the hydraulic cylinder 3 has a hydraulic cylinder flange 9, the cylinder body lower end of the hydraulic cylinder 3 is fixed with a hydraulic cylinder seat plate 8, and the hydraulic cylinder 3 bottom is sleeved in the supporting plate cylinder hole 6 and can Moving down, the hydraulic cylinder base plate 8 is located in the inner cavity of the box below the supporting plate 2, and the support rod 4 is fixedly i...

Embodiment 2

[0034] Embodiment 2: A method of using a hydraulic jacking device: first, the hydraulic jacking device is pushed to the bottom of the tower tube workpiece through the roller 1, and the hydraulic cylinder 3 is filled with oil by controlling the hydraulic valve, and the piston rod at the upper end of the hydraulic cylinder 3 Move and make the upper part of the arc-shaped top plate 33 fully contact with the lower end of the tower workpiece; then, the piston rod continues to move up and bear the gravity of the tower workpiece, and the reaction force of the tower workpiece to the piston rod of the hydraulic cylinder 3 makes the hydraulic cylinder 3 and the hydraulic cylinder The flange 9 moves down and compresses the compression spring 5, and the hydraulic cylinder 3 drives the hydraulic cylinder seat plate 8 to move down together through the support rod 4 until the hydraulic cylinder seat plate 8 fully touches the ground. Then, control the hydraulic valve so that the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com