Double-beam crane and vinasse conveying system adopting double-beam crane

A double-girder crane and transmission system technology, applied to cranes, trolley cranes, track systems, etc., can solve the problems of high labor intensity, increased wine-making costs, and long working hours, so as to reduce wine-making costs and labor intensity , The effect of saving manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

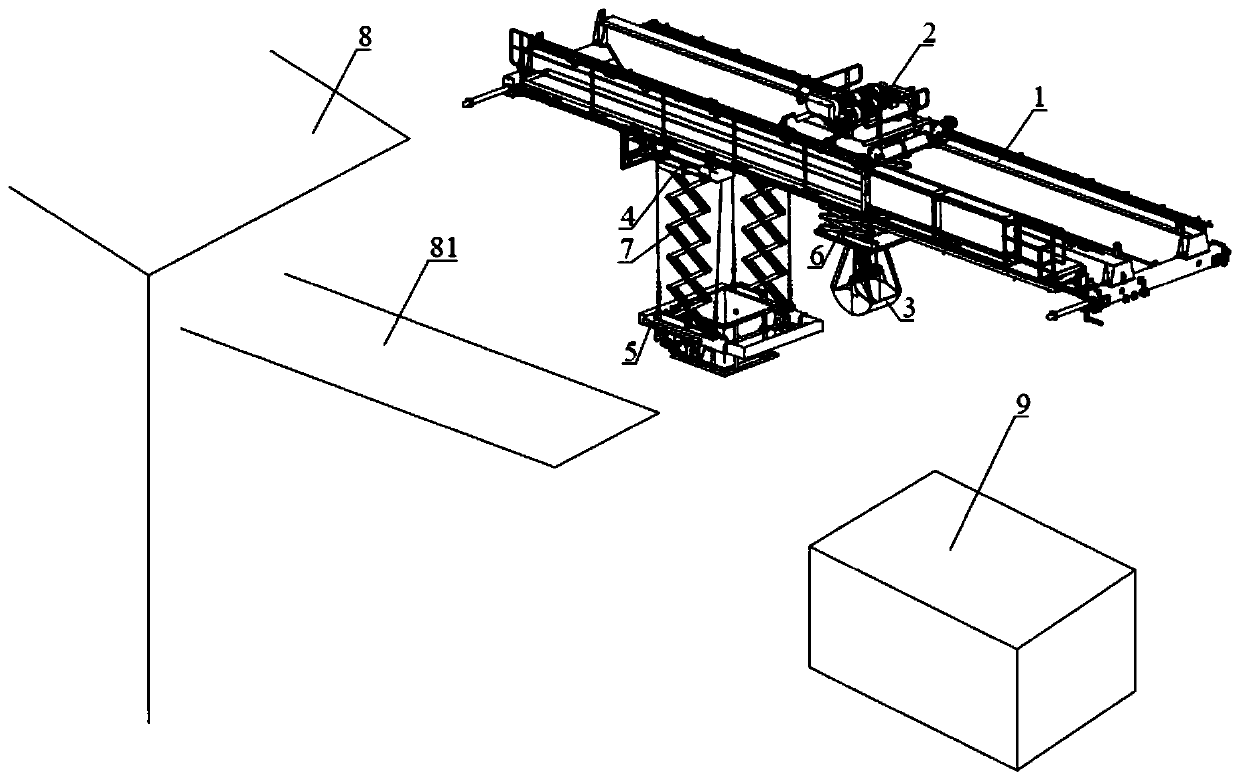

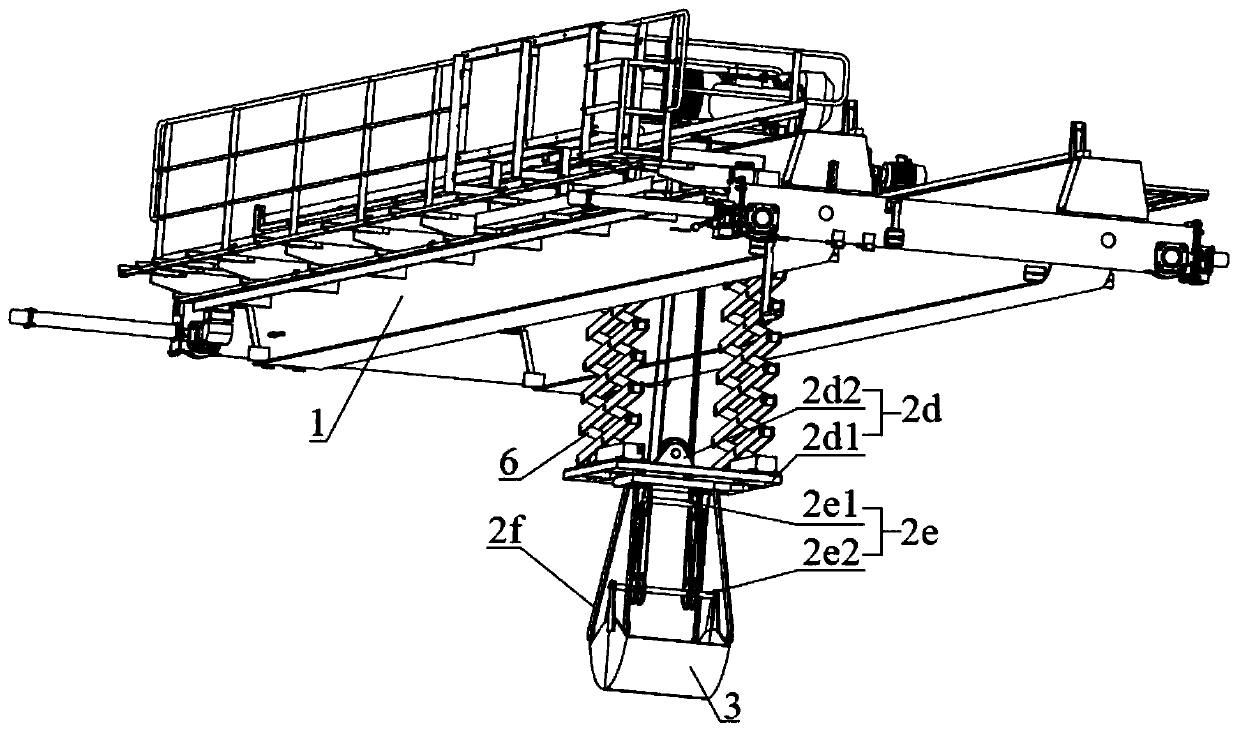

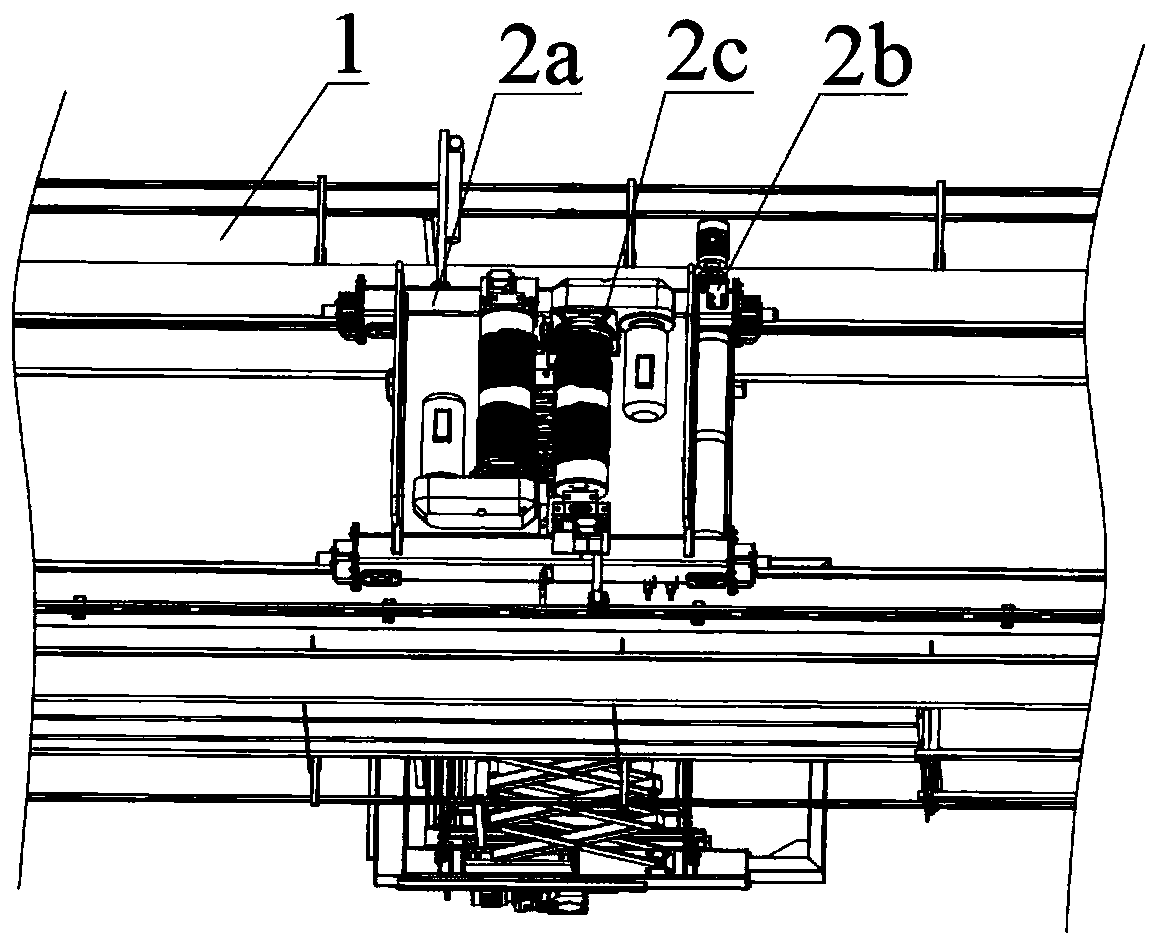

[0048] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7 , attached drawing 8 and attached Figure 9 In this embodiment shown, a distiller's grains conveying system using a double-girder crane includes a main beam 1, a lifting device 2, a vehicle frame 2a, a running mechanism 2b, a lifting device 2c, a lifting assembly 2d, a hanging plate 2d1, and a fixed pulley assembly 2d2, pulley rod assembly 2e, fixed pulley rod 1 2e1, fixed pulley rod 2 2e2, swing arm 2f, grab mechanism 3, lifting device 4, frame 2 4a, traveling mechanism 4b, lifting mechanism 4c, turning device 5, outer Frame body 5a, inner frame body 5b, rotating mechanism 5c, gear box 5c1, gear motor 5c2, hopper 5d, lifting shaft 5d1, latch mechanism 5e, electric push rod 5e1, latch hole 5e2, guide block 5f, scissors and fork mechanism 1 6, scissors and fork mechanism two 7, distillation production line 8, transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com