Nuclear fuel element core body removing device

A nuclear fuel element and core technology, applied in the field of nuclear testing, can solve the problems of cladding damage, low efficiency, etc., and achieve the effects of reducing the positioning process, reducing the manufacturing, and reducing the radiation dose value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

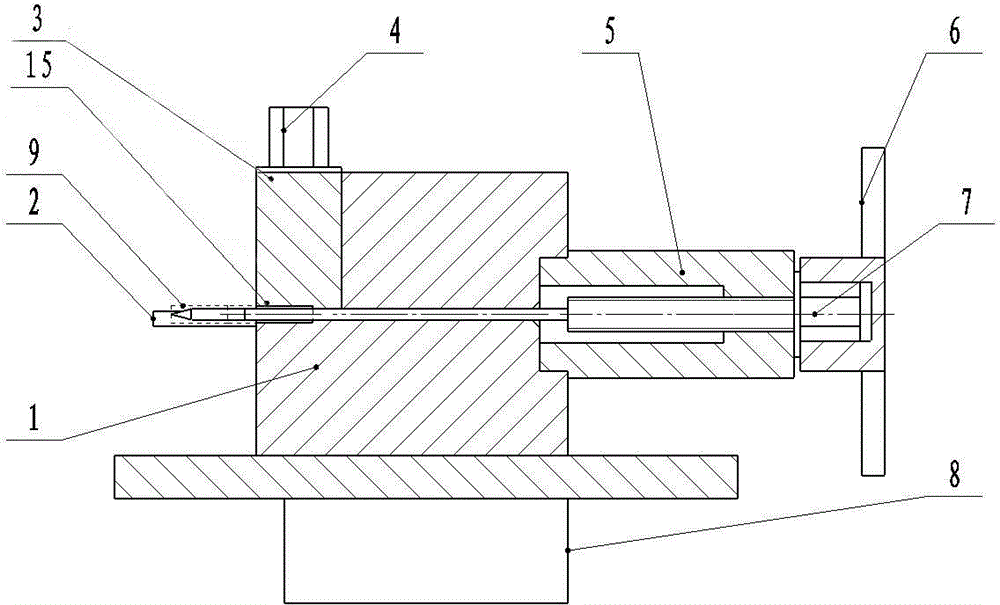

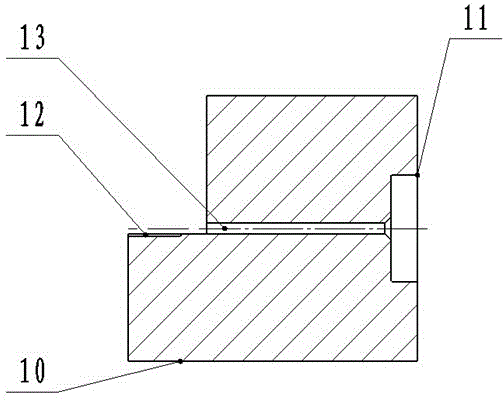

[0025] like figure 1 , figure 2 , image 3 and Figure 5 As shown, a nuclear fuel element core removal device includes a fixed clamp block 1 , a movable clamp block 3 , a thimble 7 and a guide sleeve 5 , and the bottom 10 of the fixed clamp block is arranged on a grooved base 8 . The upper end surface of the fixing clamp block 1 forms a two-step stepped shape, that is, the upper end surface of the fixing clamp block 1 forms a two-step platform with different heights. The movable clamping block 3 is arranged on the lower platform at the horizontal position of the upper end surface of the fixed clamping block 1 and is connected with the fixed clamping block 1, wherein the fixed clamping block 1 and the movable clamping block 3 are connected in a detachable manner, such as using locks, bolts , screws, etc. for connection. The side wall on the side where the horizontal position of the upper end surface of the fixed clamp block 1 is high is indented to form a circular position...

Embodiment 2

[0029]This embodiment is further limited as follows on the basis of Embodiment 1: the movable clamp block 3 of this embodiment is formed with a first positioning screw hole passing through its upper and lower end surfaces, and the upper end surface of the fixed clamp block 1 has a low horizontal position. The concave structure has a second positioning screw hole corresponding to the position of the first positioning screw hole, and the movable clamping block 3 is connected with the fixed clamping block 1 through the clamping bolt 4 passing through the first positioning screw hole and embedded in the second positioning screw hole. In this embodiment, the fixed clamping block 1 and the movable clamping block 3 are connected by clamping bolts 4, which is more convenient for master-slave manipulators to operate, and can further improve work efficiency.

Embodiment 3

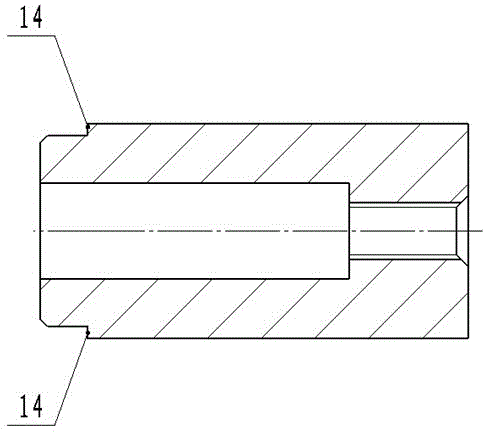

[0031] like figure 1 and Figure 4 As shown, the present embodiment has the following improvements on the basis of embodiment 1 or embodiment 2: the thimble 7 of the present embodiment includes a thimble end 19 connected in sequence, a guide rod 18, a welding rod 17 and a thimble head 16, Wherein, the thimble head 16 is a slender flat-headed rod, and the end 19 of the thimble is provided with an inner hexagonal wrench 6 . An internal thread is formed on the side wall of the inner channel of the guide sleeve 5 , and the guide rod 18 is formed with an external thread matched with the internal thread of the guide sleeve 5 . In the application of this embodiment, one end of the guide rod 18 is embedded in the inner channel of the guide sleeve 15 and connected with the guide sleeve 5 by thread matching, the welding rod 17 passes through the circular channel 13, and the thimble head 16 is embedded in the upper semicircular groove 15 and the lower semicircular groove 12, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com