Apparatus and process for producing absorbent

An absorber and gas technology, which is applied in the field of absorber devices, can solve problems such as hindering the uniform dispersion of superabsorbent polymer 5, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

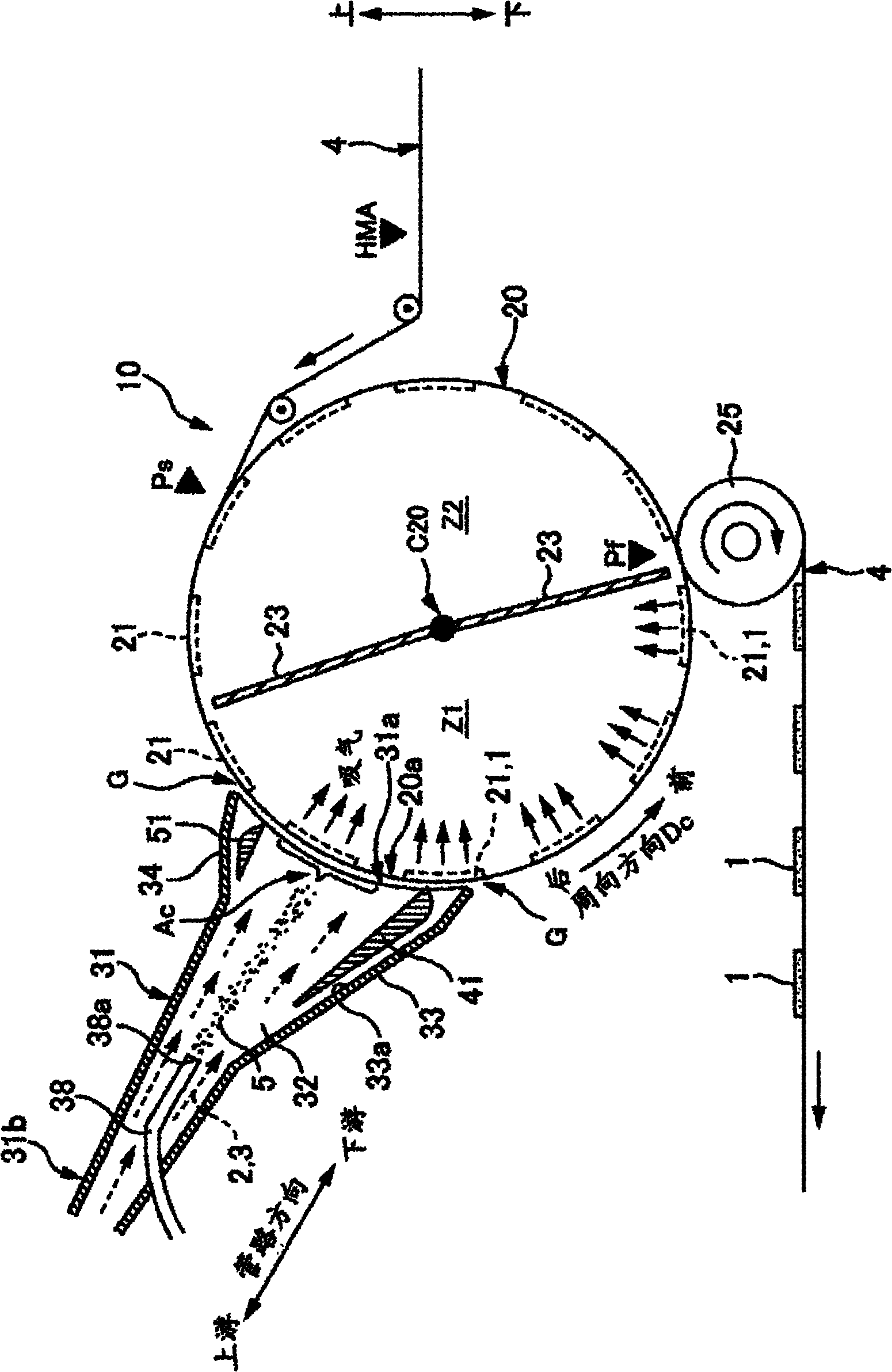

[0089] figure 2 is a side view of the apparatus 10 for manufacturing the absorbent body 1 according to the present embodiment. exist figure 2 In , only the portion of the conduit 31 of the manufacturing device 10 is shown in vertical section.

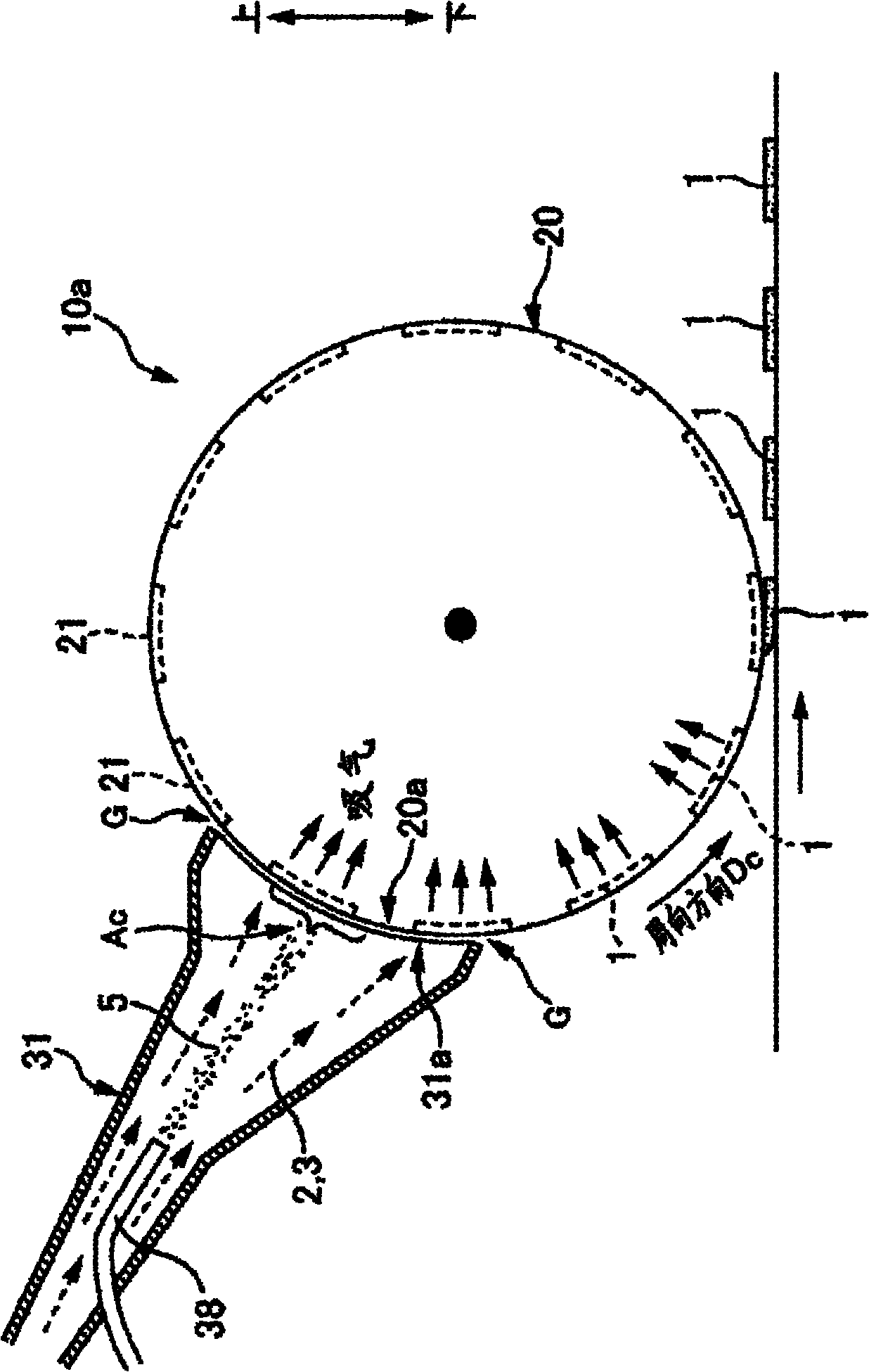

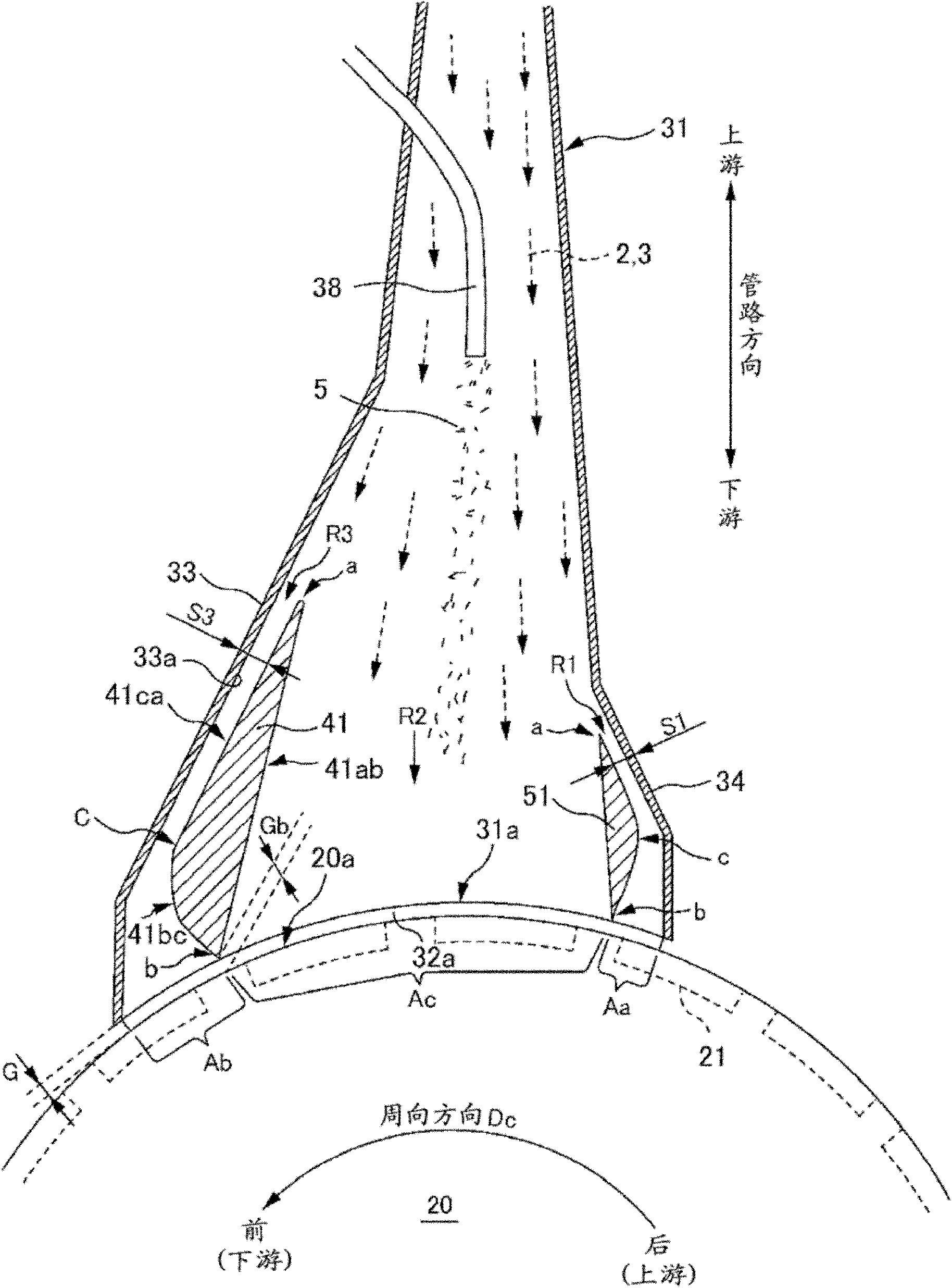

[0090] The apparatus 10 for manufacturing the absorbent body 1 according to the present embodiment is a so-called fiber lamination apparatus that layers pulp fibers 2 as liquid-absorbent fibers to form the absorbent body 1 . In terms of main structure, this manufacturing apparatus 10 includes: (1) a rotating drum 20 (corresponding to a prescribed member) which continues around a horizontal axis C20 in one direction (for example, counterclockwise) of the circumferential direction Dc; (2) the conduit 31 that discharges the pulp containing pulp from the spreading port 31a (corresponding to the opening) provided at a predetermined position of the rotary drum 20 in the circumferential direction Dc to the outer peripheral surface 20a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com