Chemical fiber yarn tube dyeing device and method for using device to achieve bobbing dyeing of aramid yarn

A technology of aramid yarn and yarn tube, which is applied in the field of textile products, can solve problems such as dye liquor system disorder, energy consumption, and difficulty in control, and achieve the goals of reducing uneven dyeing rate, improving sufficiency, and improving dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

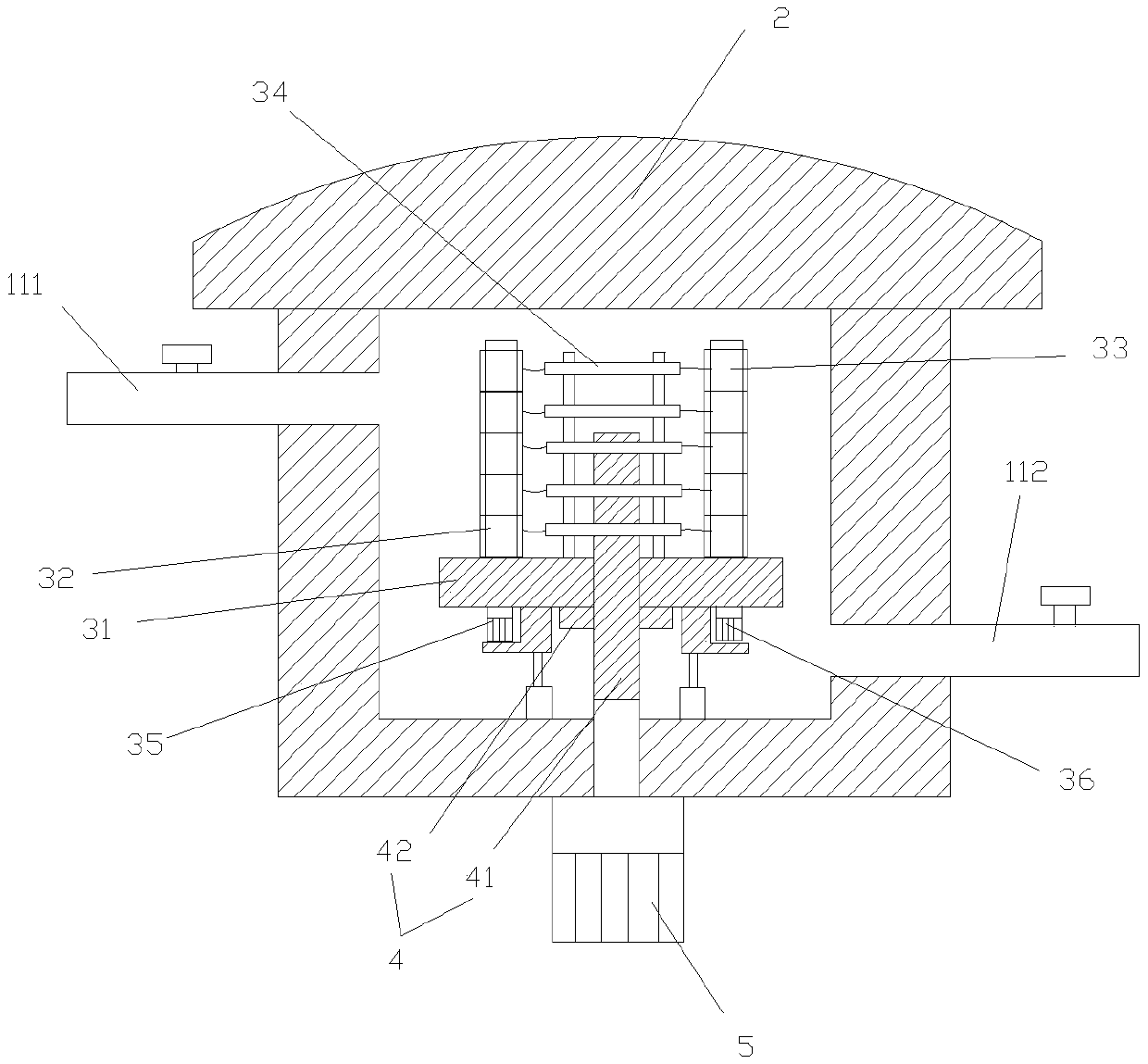

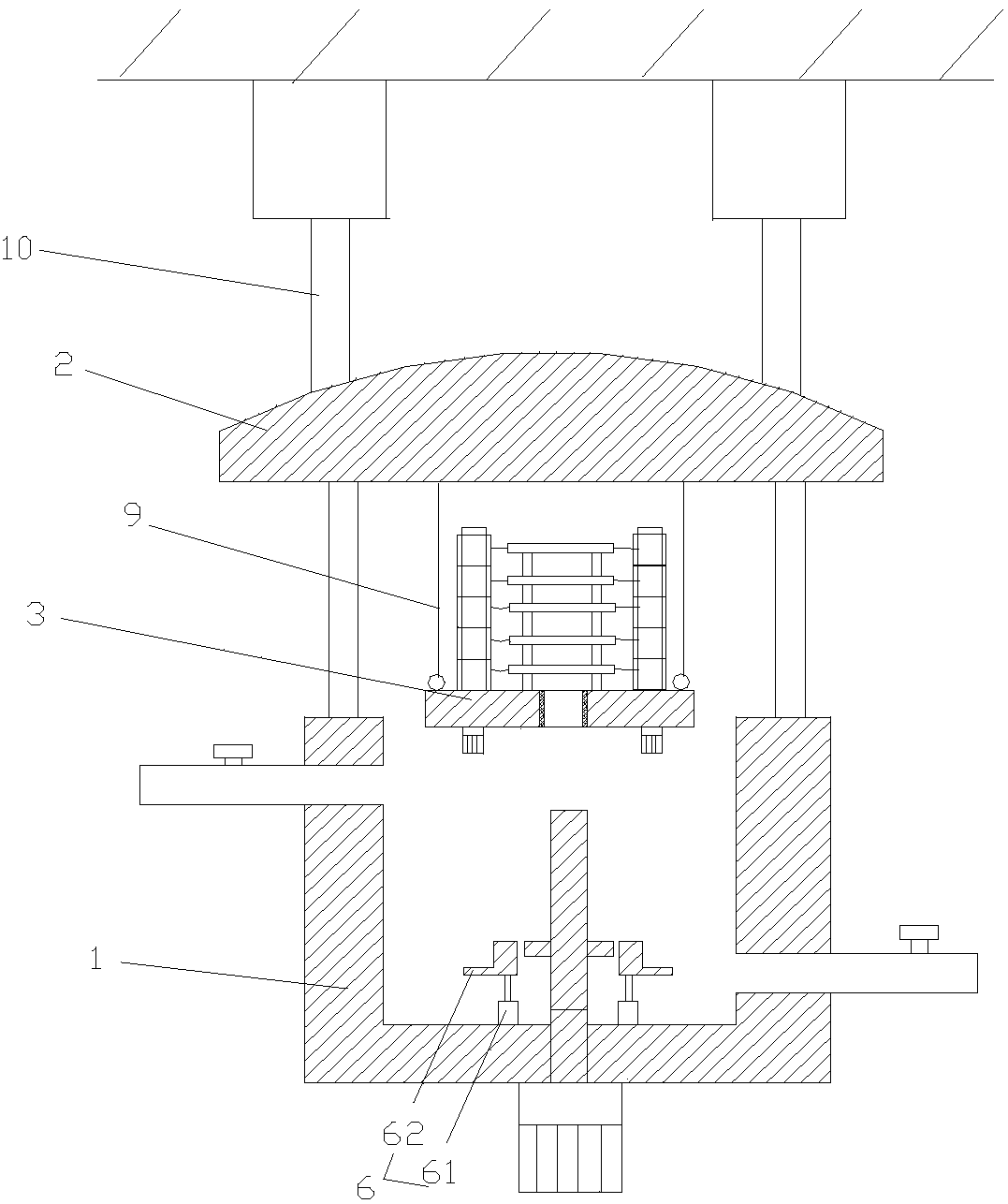

[0046] Such as Figure 1-2 As shown, this embodiment discloses a tube dyeing device for chemical fiber yarn, which includes a dyeing vat 1, a vat cover 2, a winding frame 3, and a heating device. The winding frame 3 can be placed in the dye vat 1, the vat 2 is closed on the dye vat 1, and the heating device is used to heat the dye vat 1.

[0047] The dye vat 1 includes a feed end 111 and a discharge end 112; both of the feed end 111 and the discharge end 112 are provided with valves. The heating device of the present invention is a heating device of the prior art, preferably a heating tube arranged on the dye vat 1 .

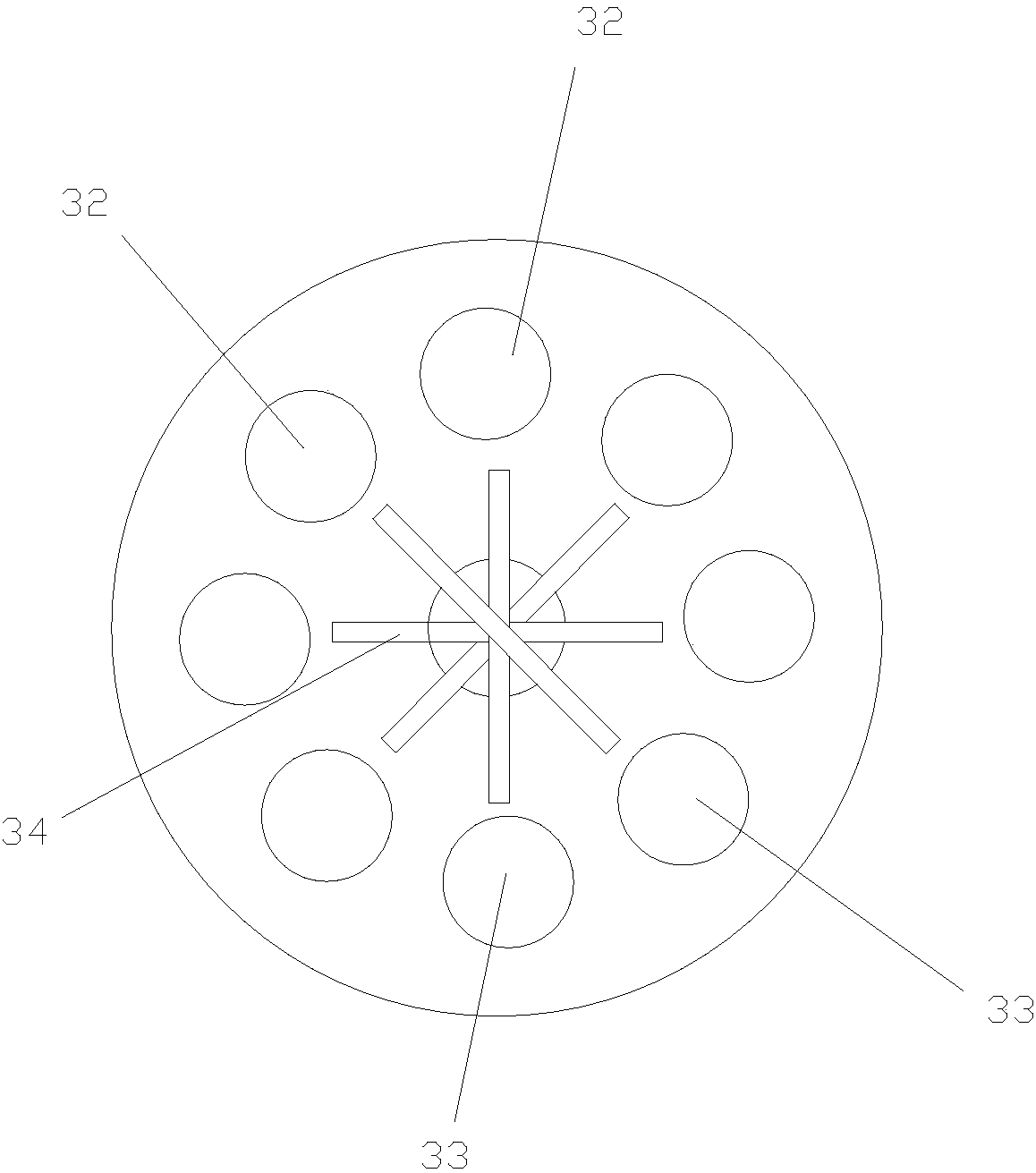

[0048] The winding frame 3 includes a chassis 31 , a first support round bar 32 , a second support round bar 33 , a yarn passage tube 34 , a first motor 35 , and a second motor 36 . The bottom of the first support round bar 32 and the bottom of the second support round bar 33 are all rotatably connected with the chassis 31, and the tops of the first support ro...

Embodiment 2

[0066] The present invention also provides a method for tube dyeing aramid fibers using the above chemical fiber yarn tube dyeing device, comprising the following steps:

[0067] (1) Pretreat the aramid yarn after winding: at 80°C, place the aramid yarn in the treatment solution with a bath ratio of 1:20, boil for 40 minutes, and then dry. The treatment solution includes the following raw materials in parts by mass: 2 parts of urea, 3 parts of triphosphite, 4 parts of non-phosphorus neutral degreasing spirit TF-104M, and 900 parts of water.

[0068] (2) Set the aramid yarn wound after pretreatment in the first support rod 32 , and place the yarn tube 37 in the second support rod 33 . The joint of the aramid yarn wound in the first support rod 32 is introduced into the corresponding yarn tube 37 in the second support rod 33 through the yarn channel tube 34 and fixed on the yarn tube 37 .

[0069] (3) Add cationic dye solution into dye vat 1, and the bath ratio of yarn to dye s...

Embodiment 3

[0074] The aramid yarn dyed by the method of Example 2 was tested for color fastness, and the results are shown in Table 1, wherein the cationic dyes are cationic blue X-GRRL, cationic blue X-BL, and cationic red X-GTL.

[0075] Table 1

[0076]

[0077] It can be seen from Table 1 that the color fastness of the aramid yarn prepared by the method of the present invention can basically be maintained at level 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com