Gum dipping device for cord fabric

A dipping device and cord fabric technology, which is applied in the direction of textile material cleaning device, textile and paper making, liquid/gas/steam textile material processing, etc., can solve the deviation of cord fabric, affect product quality, and it is difficult to ensure cord fabric Solve problems such as uniform coating of glue, achieve uniform glue and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

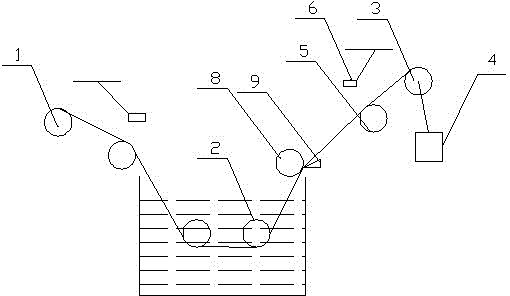

[0018] see figure 1 , the present invention relates to a cord fabric dipping device, mainly composed of an unwinding roller 1, a dipping roller 2 and a winding roller 3, the winding roller 3 is connected with a motor 4, and the unwinding roller 1 and the Correcting rollers 5 are arranged between the dipping rollers 2 and between the dipping rollers 2 and the winding roller 3, and adjustment motors 6 are arranged at both ends of the correcting rollers 5 to control the left and right displacement of the correcting rollers 5. A photoelectric sensor 7 is installed above the correction roller 5, and the photoelectric sensor 7 monitors the positions of the two ends of the cord fabric in real time. Once a deviation occurs, the adjustment motor 6 will be started for adjustment. A squeegee device is arranged near the squeegee. The squeegee device includes a squeegee roller 8 and a scraper 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com