Sizing device for textile fabric

A technology for textile fabrics and sizing rollers, which is applied to the field of sizing devices for textile fabrics, can solve the problems of easy residues on the surface of the sizing rollers, affecting the quality of fabric sizing, processing operations, limitations of applicability and practicability, etc., so as to ensure uniformity and Reliability, practicability, good use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

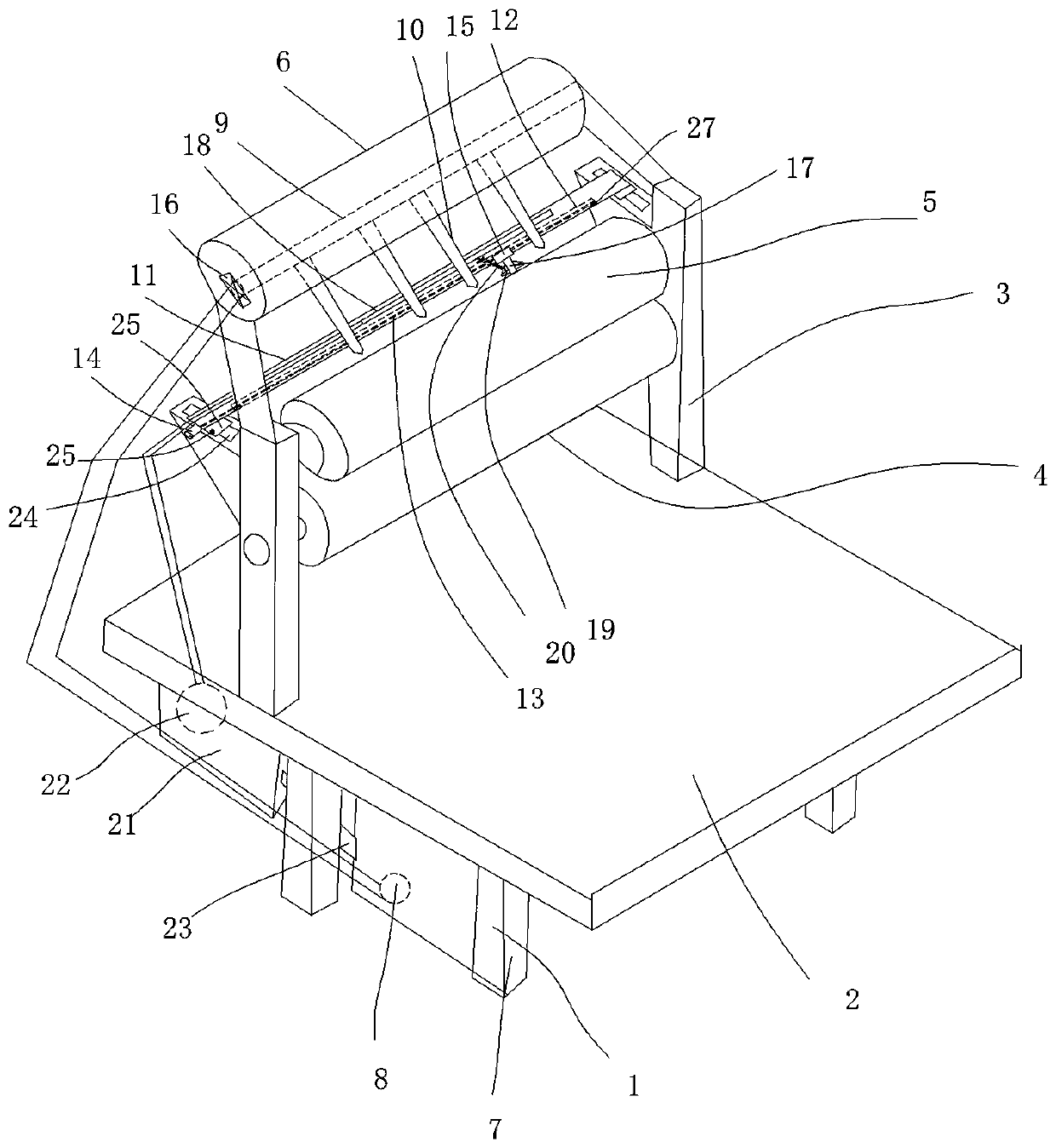

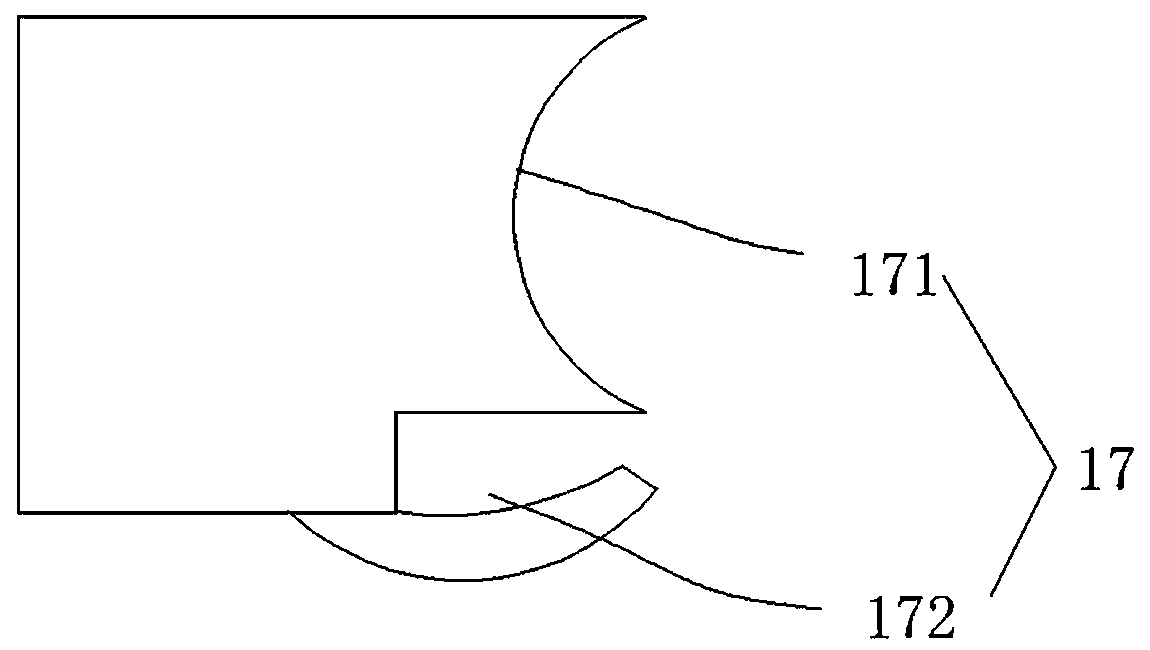

[0016] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is the specific structure diagram of the rubber scraper.

[0017] See figure 1 and figure 2 , a sizing device for textile fabrics, comprising a support 1, a sizing platform 2 arranged on the support 1, a sizing support 3 is arranged on the support 1, and a parallel The guide roller 4 and the sizing roller 5 are fixed on the sizing support 3 with a spraying pole 6 parallel to the sizing roller 5, and the spraying pole 6 is arranged above the sizing roller 5 , a slurry storage box 7 is fixed on the support 1, a booster pump 8 is arranged in the slurry storage box 7, a slurry guiding channel 9 is arranged in the spraying rod 6, the booster The pressure pump communicates with the slurry-guiding channel, and the spraying nozzle 10 connected with the slurry-guiding channel 9 is uniformly arranged on the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com