Method for reducing OLED color mixture defect and OLED display panel

A display panel and panel technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as light-emitting devices not working properly, and achieve the goal of ensuring production costs, improving production yield, and reducing color mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

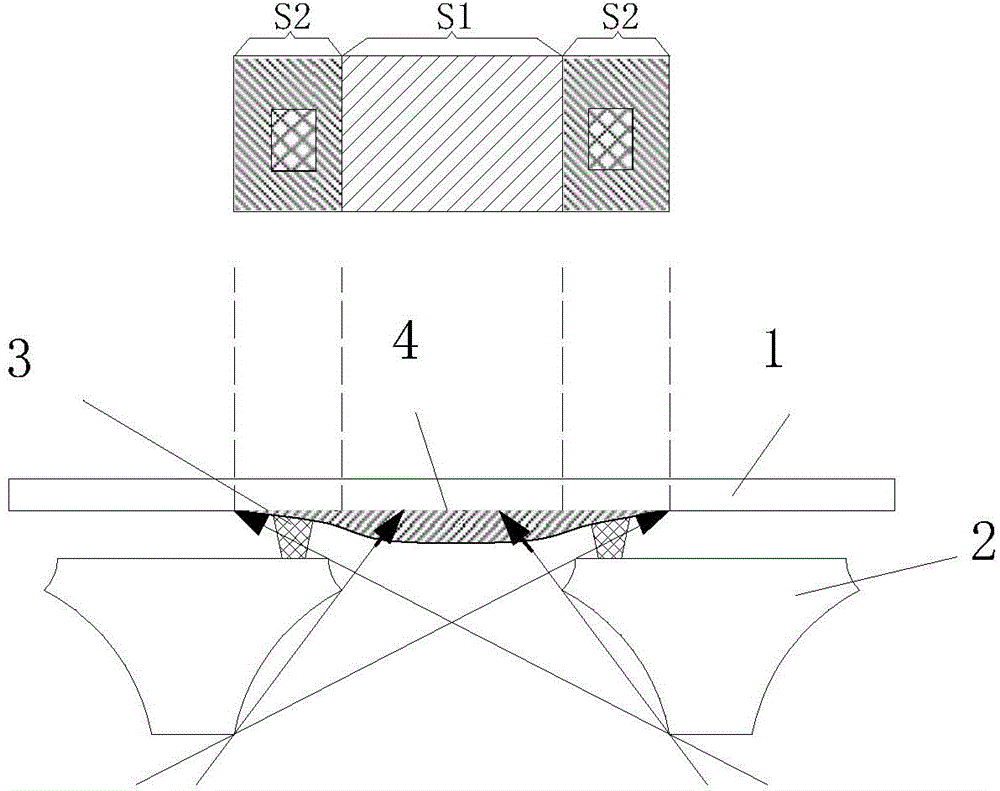

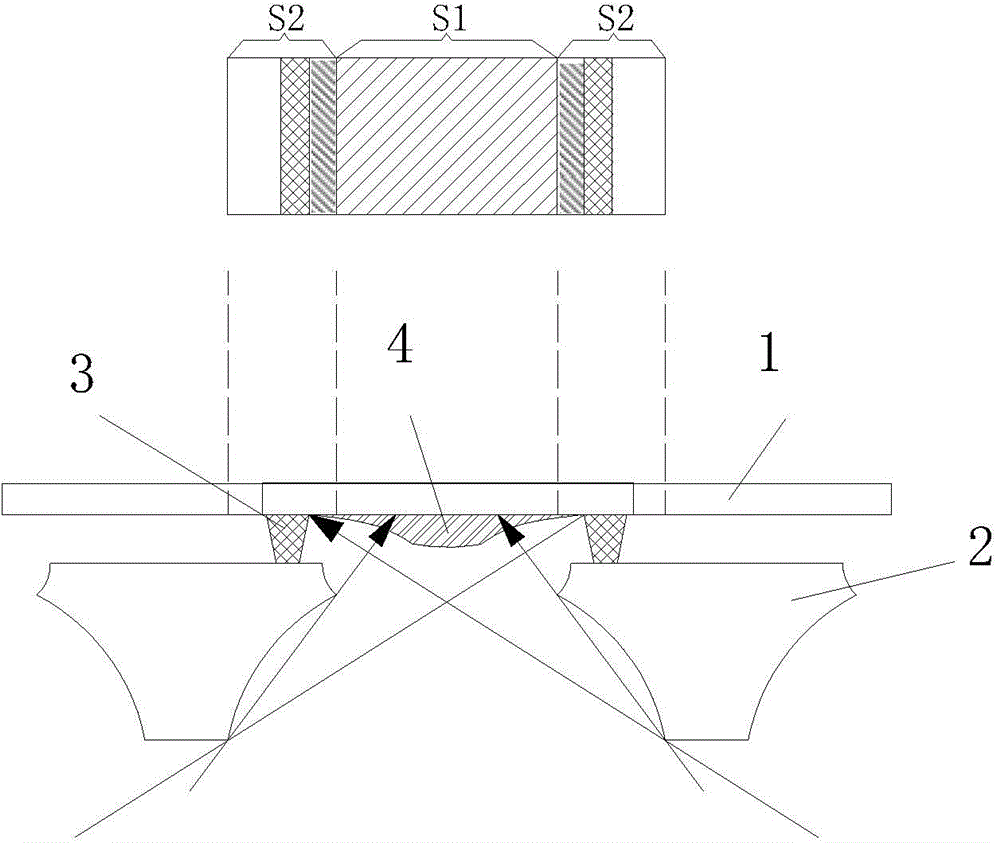

[0042] The invention provides a method for reducing OLED color mixing defects, which is applied in the OLED evaporation process, combined with figure 2 and image 3 As shown, a substrate 1 is provided, preferably, the substrate is a glass substrate.

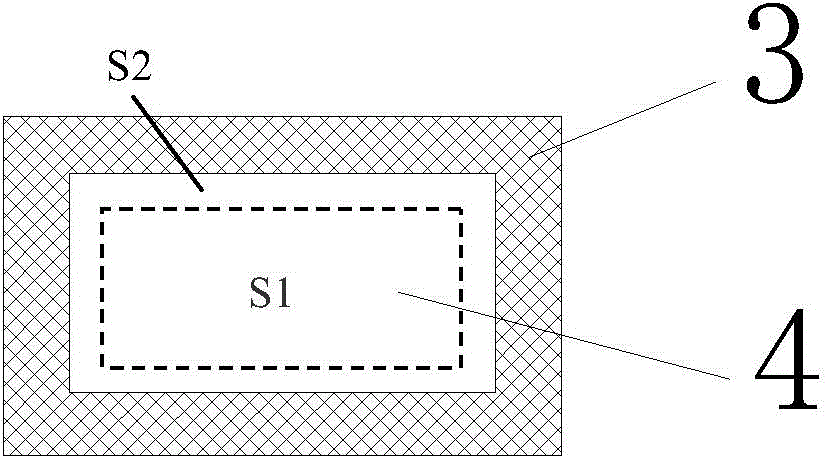

[0043] A spacer layer 3 is formed on the surface of the substrate 1, and the spacer layer 3 is adjacent to the preset evaporation area S1. Preferably, the spacer layer is a photoresist, and the spacer layer 3 is ring-shaped and the preset evaporation area S1 Surrounding, wherein, the area of the preset evaporation zone S1 is smaller than or equal to the area surrounded by the spacer layer 3 .

[0044] Provide a mask plate 2 with an evaporation hole, the mask plate 2 is in contact with the spacer layer, and the evaporation hole of the mask plate 2 is aligned with the preset evaporation area S1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com