Color filter and manufacturing method thereof

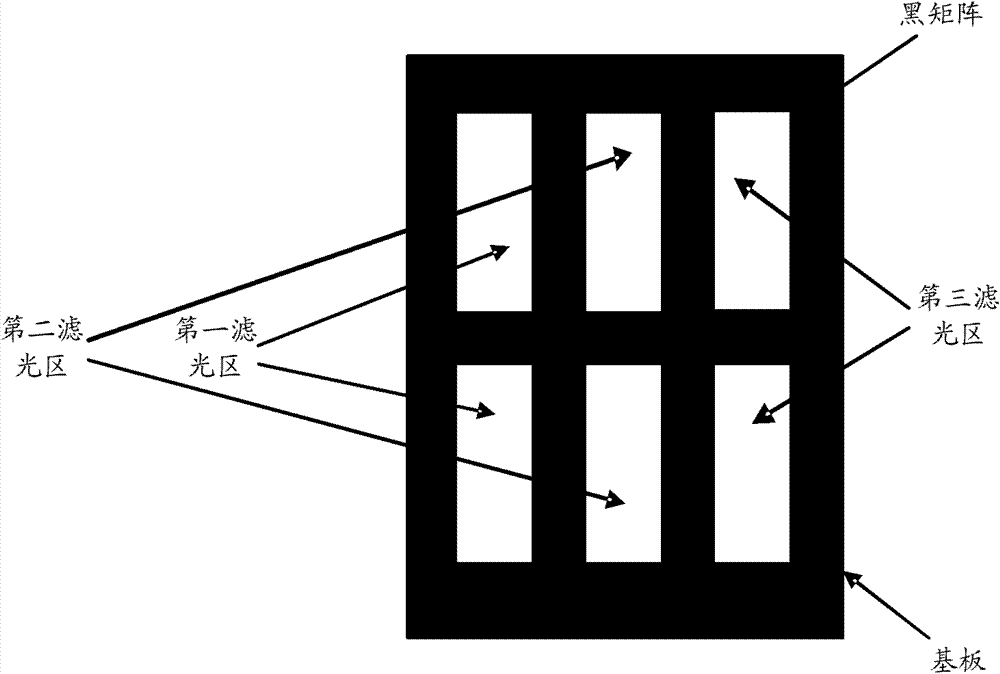

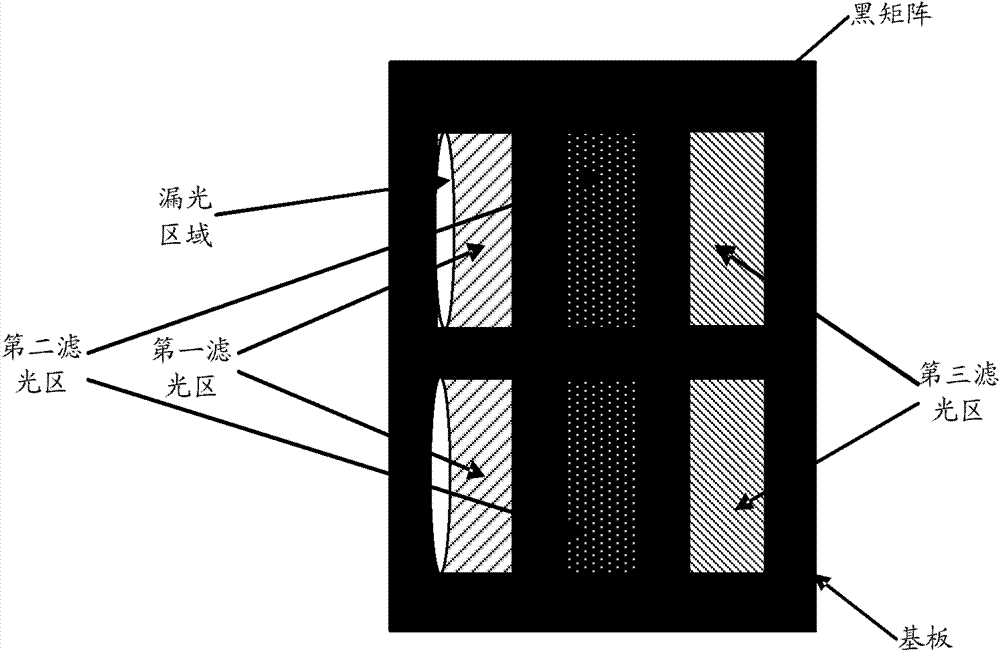

A color filter and color filter technology, applied in the field of optical filters, can solve problems such as color distortion, color confusion, and interactive overlapping, and achieve the effects of avoiding inaccurate alignment, saving manufacturing costs, and increasing aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

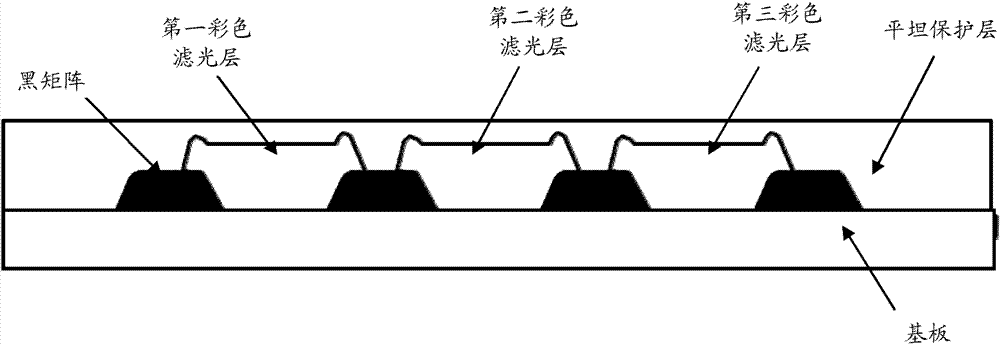

[0033] In the present invention, firstly, the ink-repellent treatment can be carried out on the substrate, and the larger contact angle formed between the ink-repellent surface and the photoresist can be used to make the color filter region form a shape with a wide top surface and a narrow bottom surface, so as to be compatible with the black The matrices are closely connected; then, the black matrix is made by the method of back exposure. The above operation method increases the aperture ratio of the color filter while reducing a mask plate, which can ensure the flatness of the color filter; moreover, it can avoid light leakage and color mixing, and then obtain low cost and high flatness. , Optical quality color filter structure.

[0034] Specifically, firstly, an ink-repellent layer can be coated on the substrate, and then three color filter regions of R, G, and B can be sequentially formed on the substrate by using a front-side coating, exposure and development method. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com