Electromagnetic vapor-plating device

An electromagnetic and evaporation technology, applied in the direction of vacuum evaporation plating, circuits, electrical components, etc., can solve the problems of inability to control the magnetic strength of the magnet, sagging of the shadow mask, and color mixing, so as to improve product yield and avoid color mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

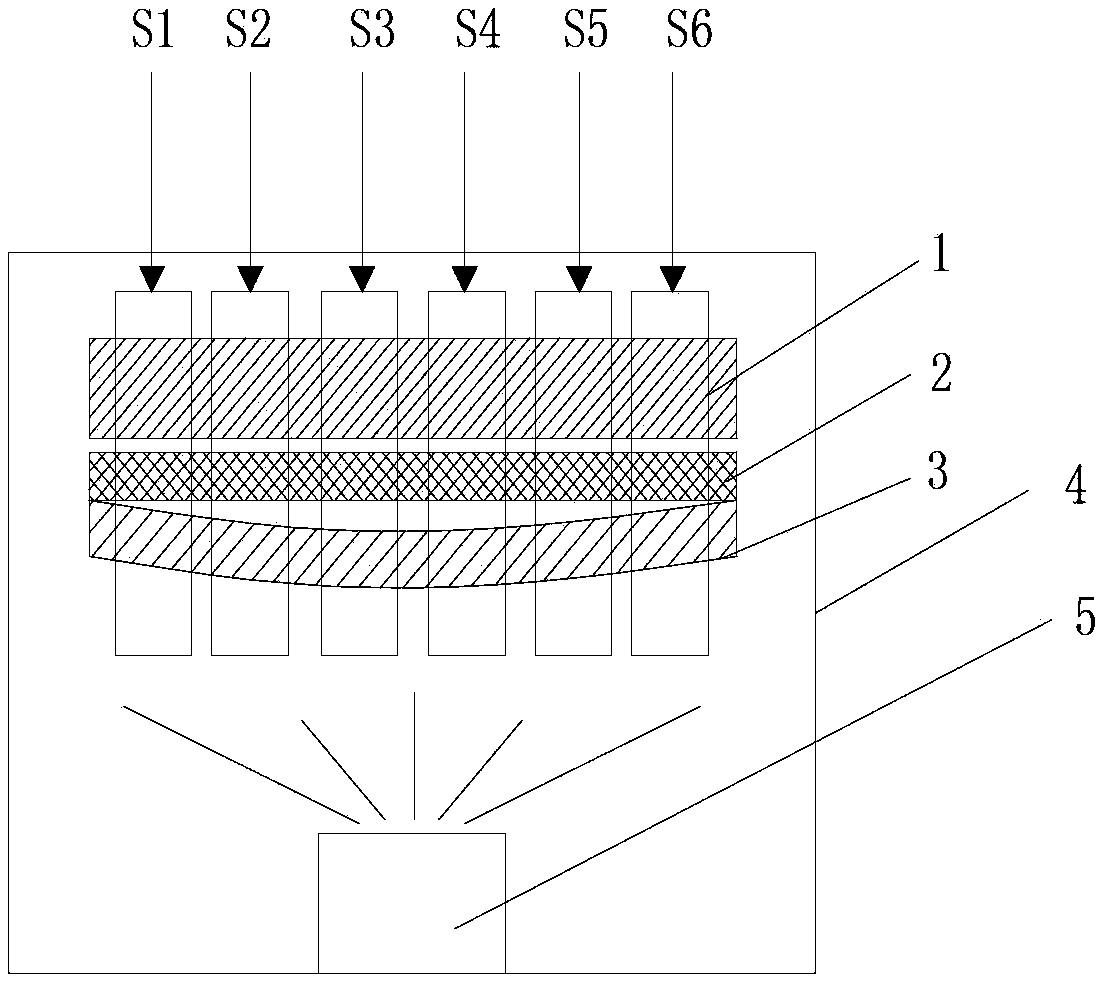

[0028] image 3 The side view of a kind of thermal evaporation device provided for the present invention, as image 3 As shown, the coating control device includes a main reaction chamber 4, the bottom of the main reaction chamber 4 is provided with a film-forming material evaporation source 5, and the top of the evaporation source 5 is sequentially provided with metal shields from bottom to top. Cover 3, hard substrate 2 and clamping frame 1; preferably, the hard substrate 2 is a glass substrate.

[0029] In addition, a plurality of electromagnet units are placed on the clamping frame 1 to attract the metal mask to the lower surface of the hard substrate 2 , and the evaporation source 5 sprays an organic gas source upward to coat the surface of the hard substrate 2 .

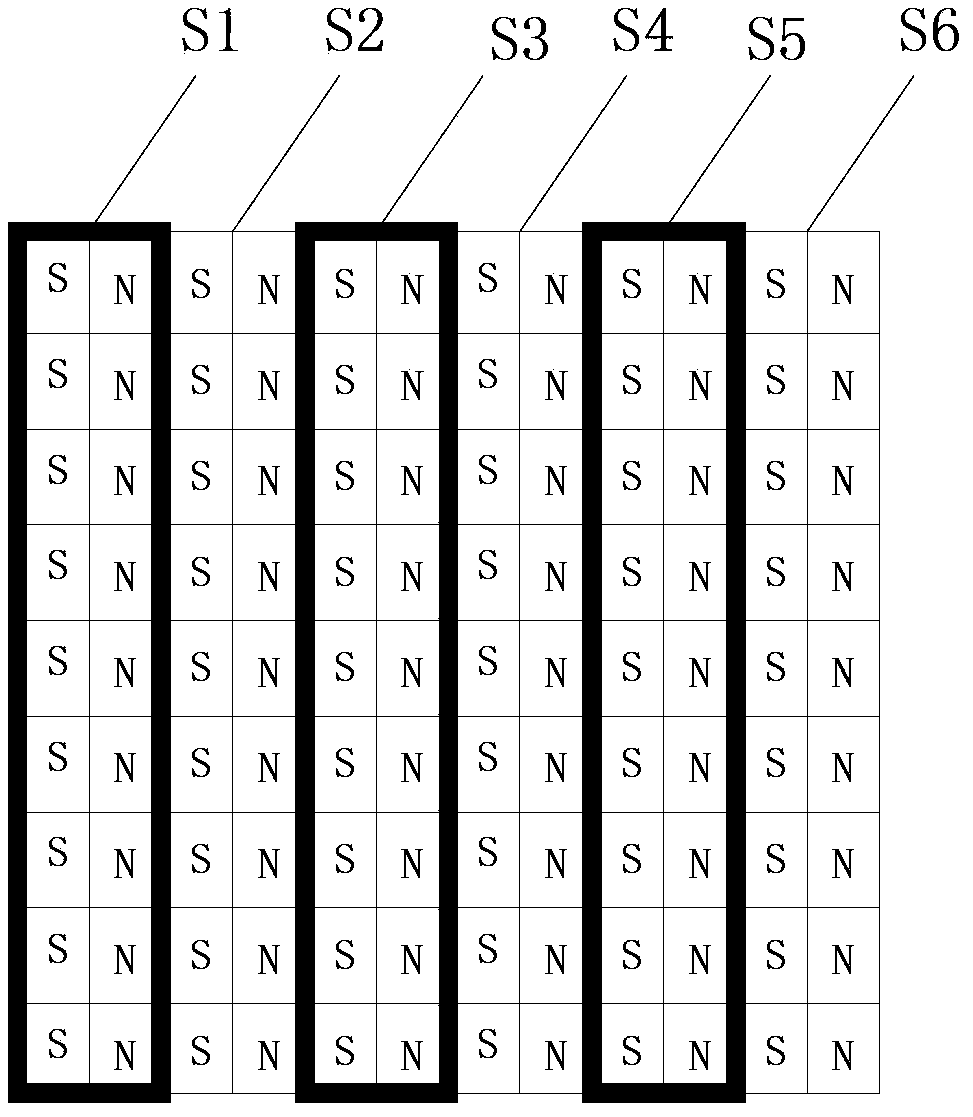

[0030] Among them, the plurality of electromagnet units arranged on the clamping frame 1 form the first electromagnetic area A1, the second electromagnetic area A2, the third electromagnetic area A3..., and so...

Embodiment 2

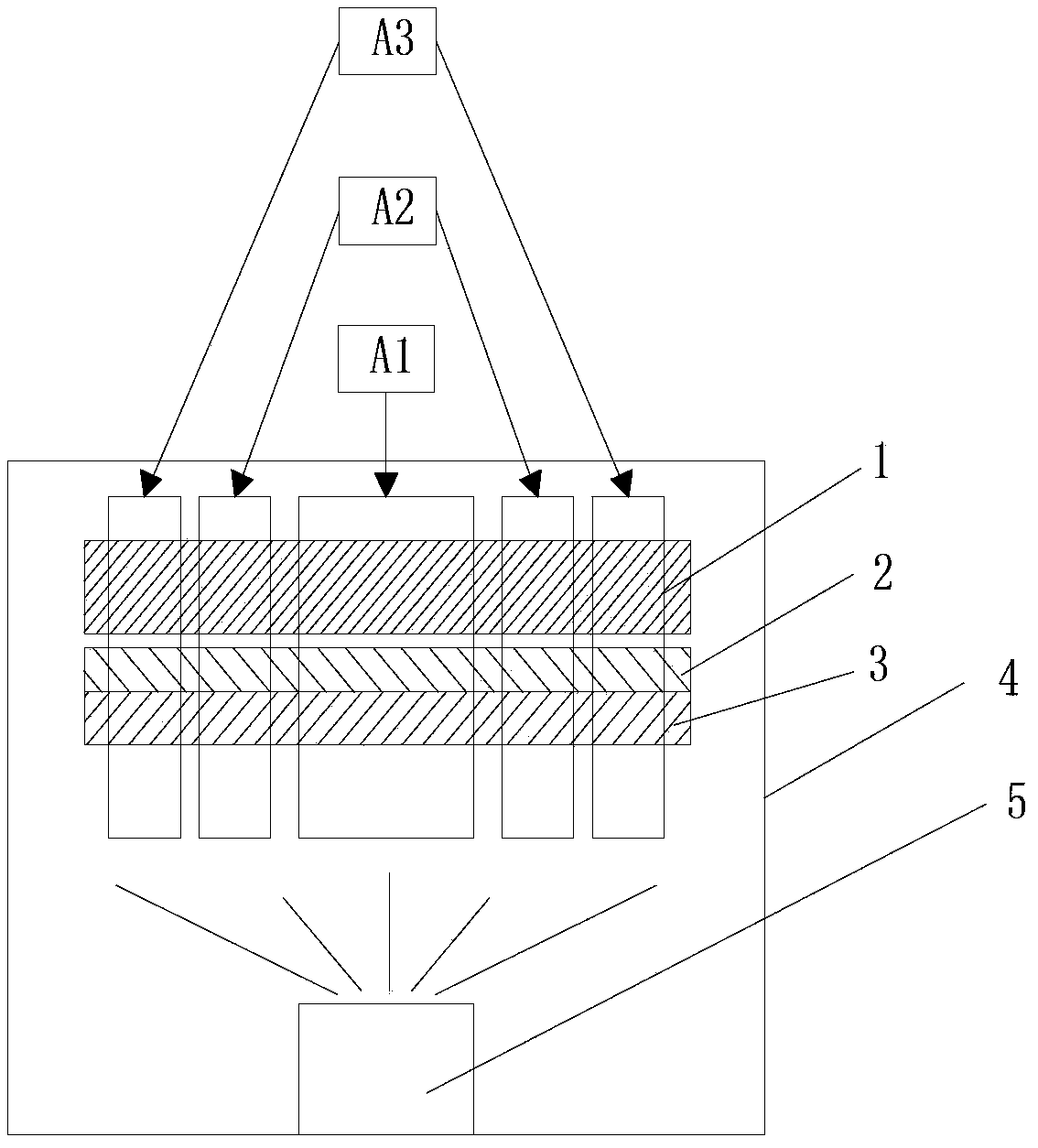

[0034] Preferably, the electromagnetic evaporation device in the present invention also includes a programmable control device and a sensor, the programmable control device is electrically connected with each electromagnet unit, to control the magnetic polarity and magnetic intensity of each electromagnet unit, and the sensor It is also electrically connected with the programmable control device (such as PLC, Programmable Logic Controller programmable control device).

[0035] Figure 5It is a side view of a partial structure of an electromagnetic evaporation device of the present invention; as Figure 5 As shown, a hard substrate 2 is provided between the metal mask 3 and the clamping frame 1, and a sensor 6 is provided above each electromagnetic region formed after the electromagnetic unit fixed on the clamping frame 1 is energized, and the The sensor 6 is a magnetic sensor, which is used to monitor the magnetic force intensity of each electromagnet unit in the electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com