Patents

Literature

39results about How to "Increase padding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

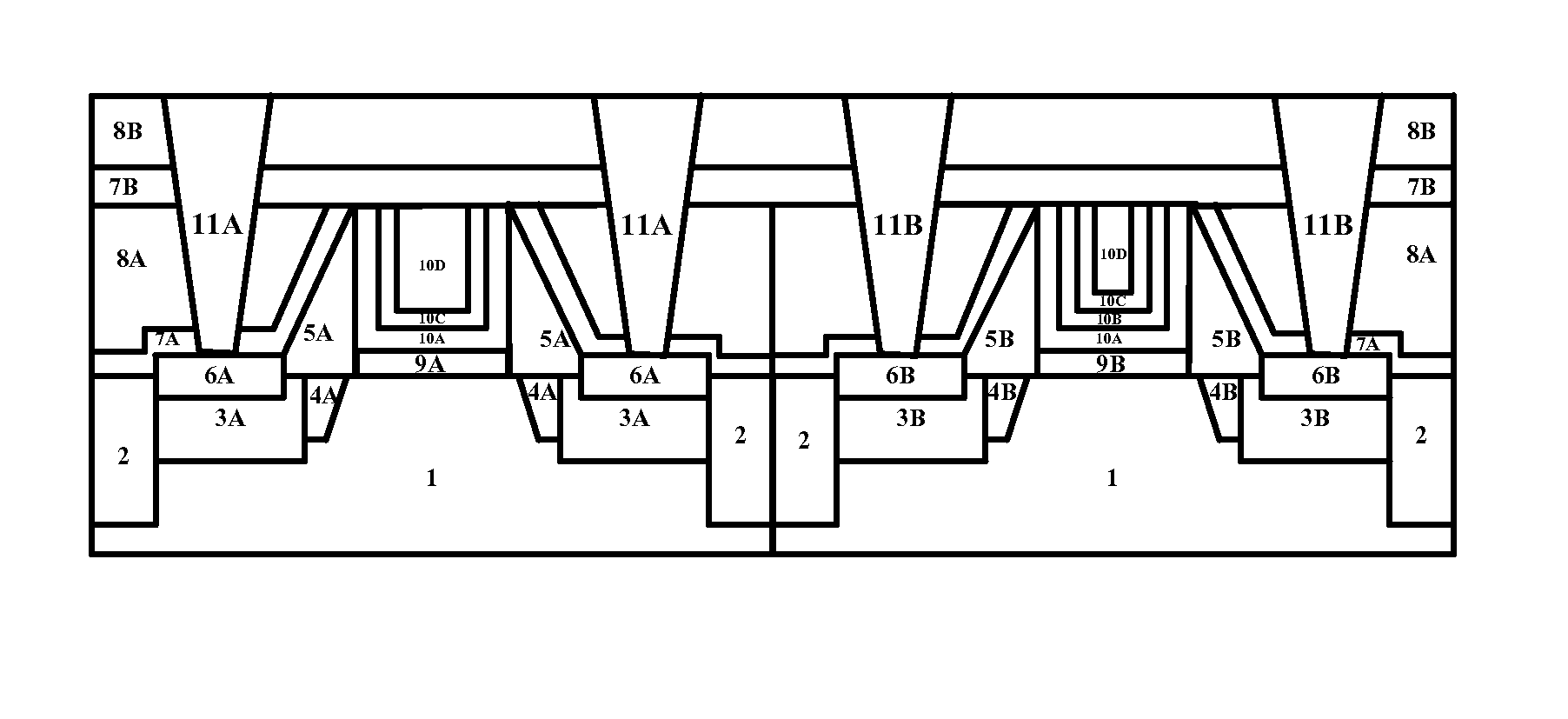

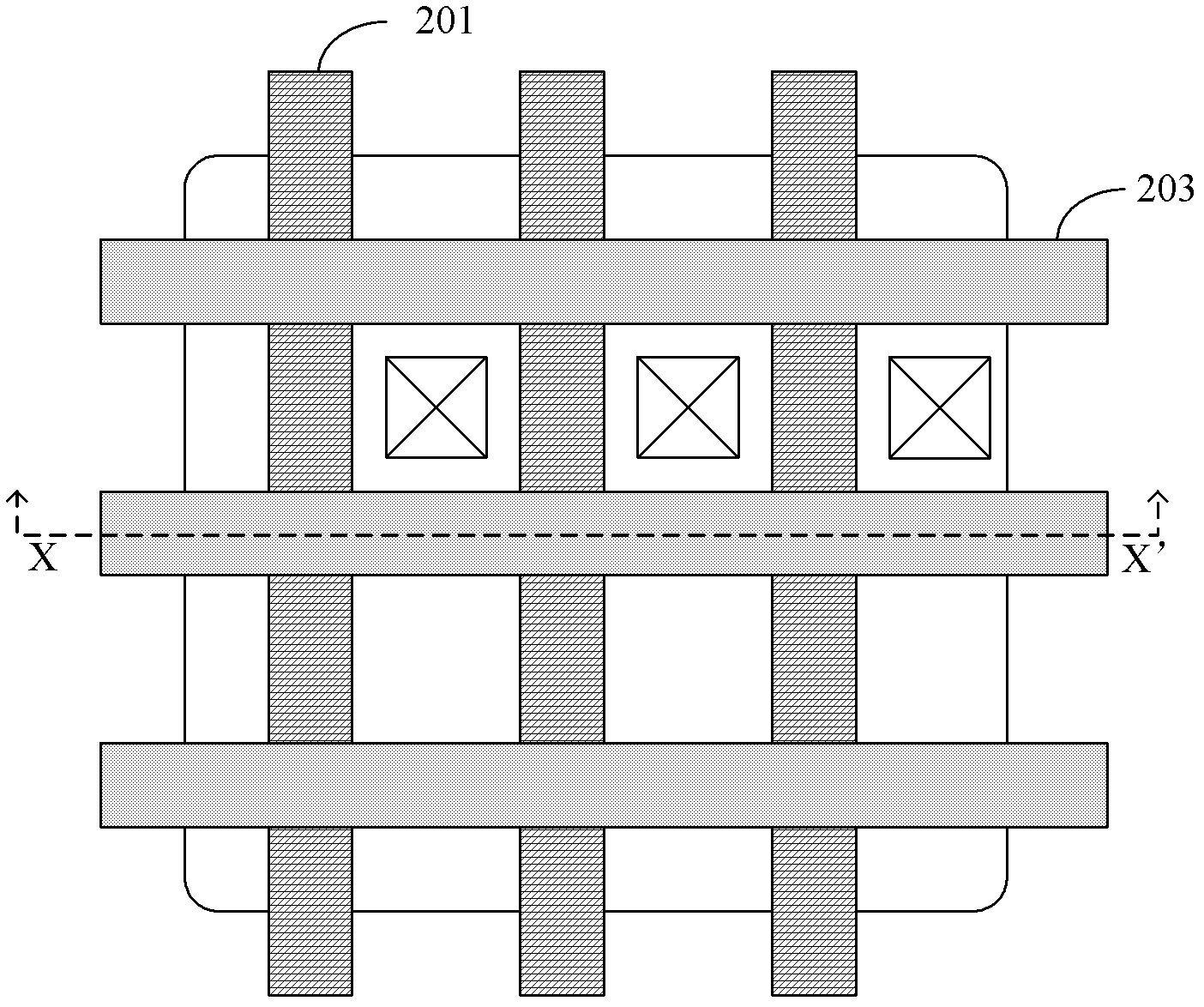

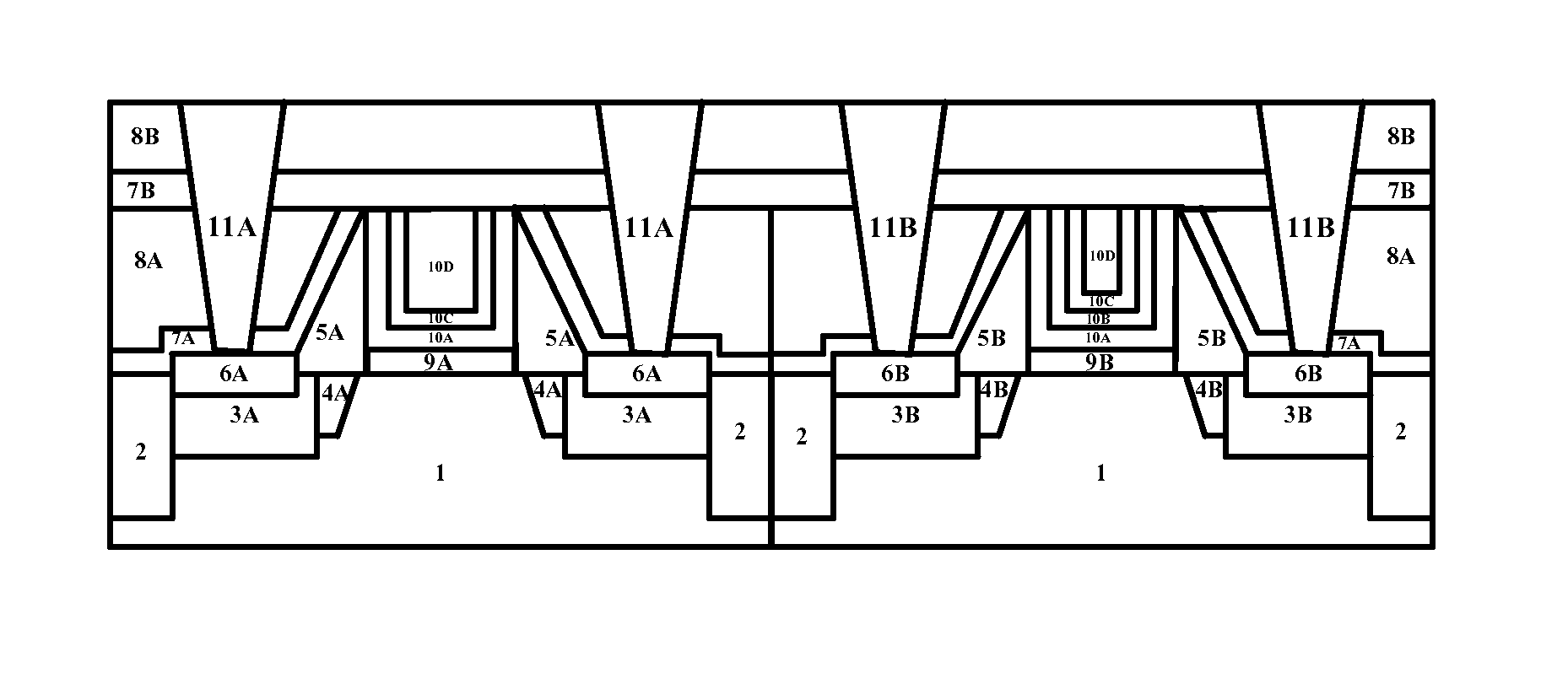

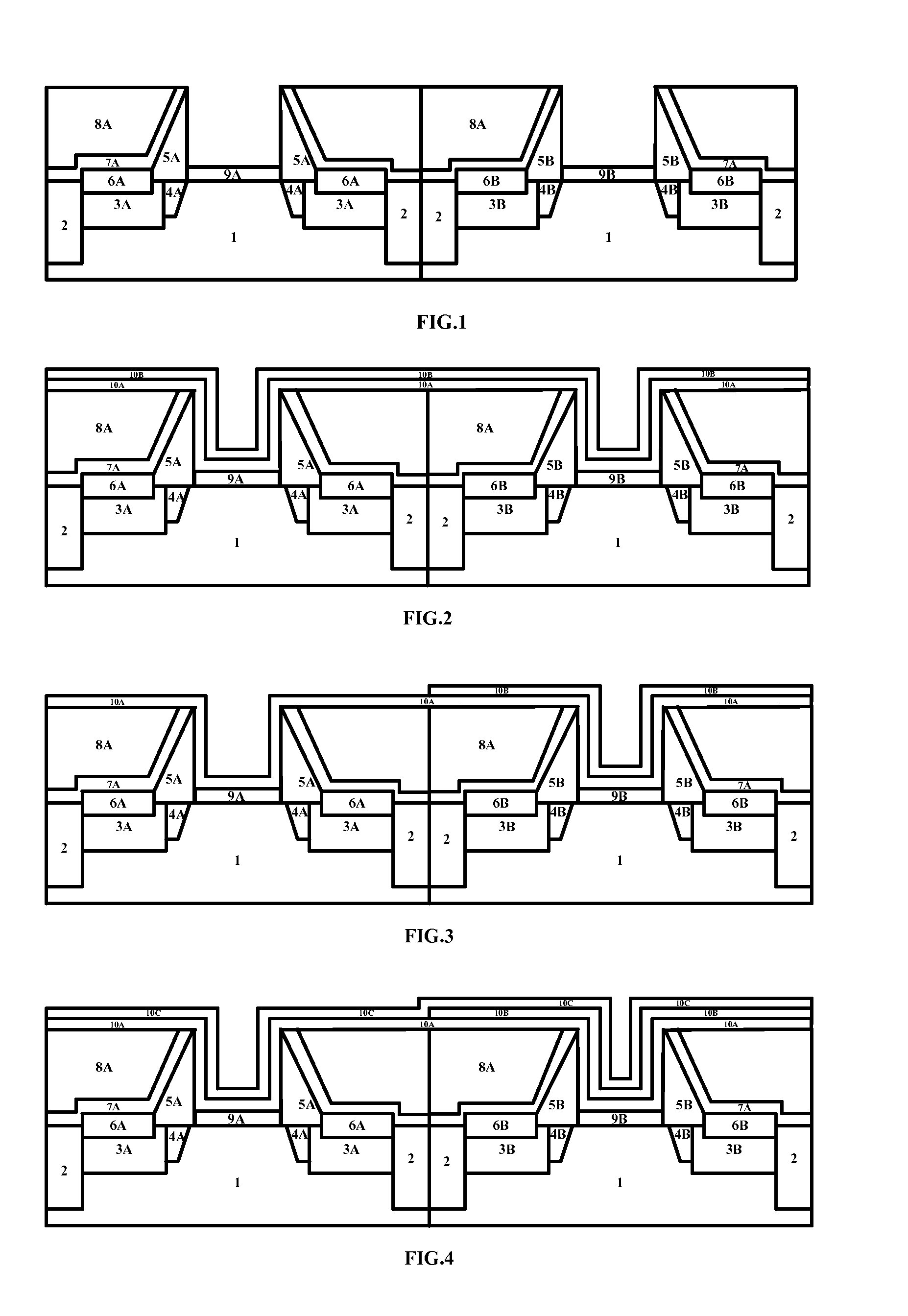

Semiconductor device and method of manufacturing the same

ActiveUS20140027857A1Lower gate resistanceIncrease paddingTransistorSemiconductor/solid-state device manufacturingWork functionBlocking layer

The present invention discloses a semiconductor device, comprising a substrate, a plurality of gate stack structures on the substrate, a plurality of gate spacer structures on both sides of each gate stack structure, a plurality of source and drain regions in the substrate on both sides of each gate spacer structure, the plurality of gate stack structures comprising a plurality of first gate stack structures and a plurality of second gate stack structures, characterized in that each of the first gate stack structures comprises a first gate insulating layer, a first blocking layer, a first work function regulating layer and a resistance regulating layer, and each of the second gate stack structures comprises a second gate insulating layer, a first blocking layer, a second work function regulating layer, a first work function regulating layer and a resistance regulating layer.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

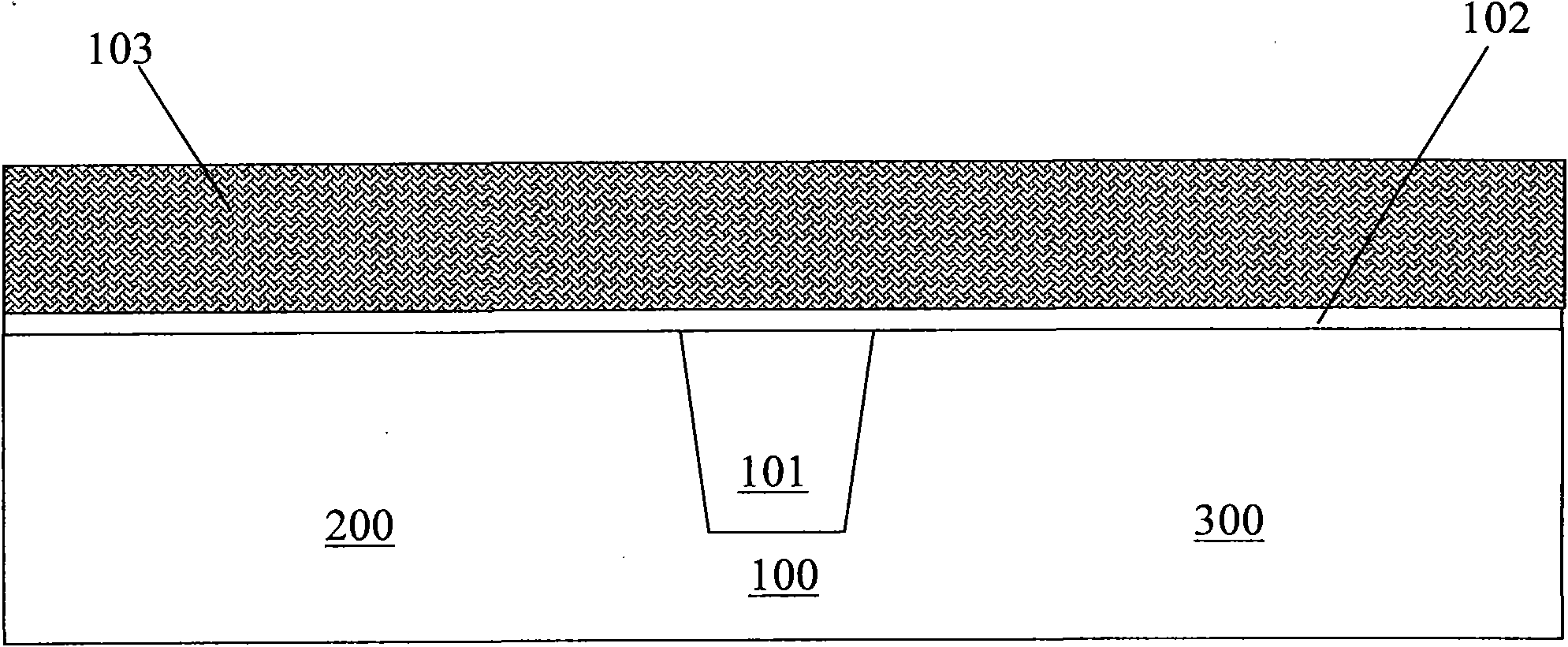

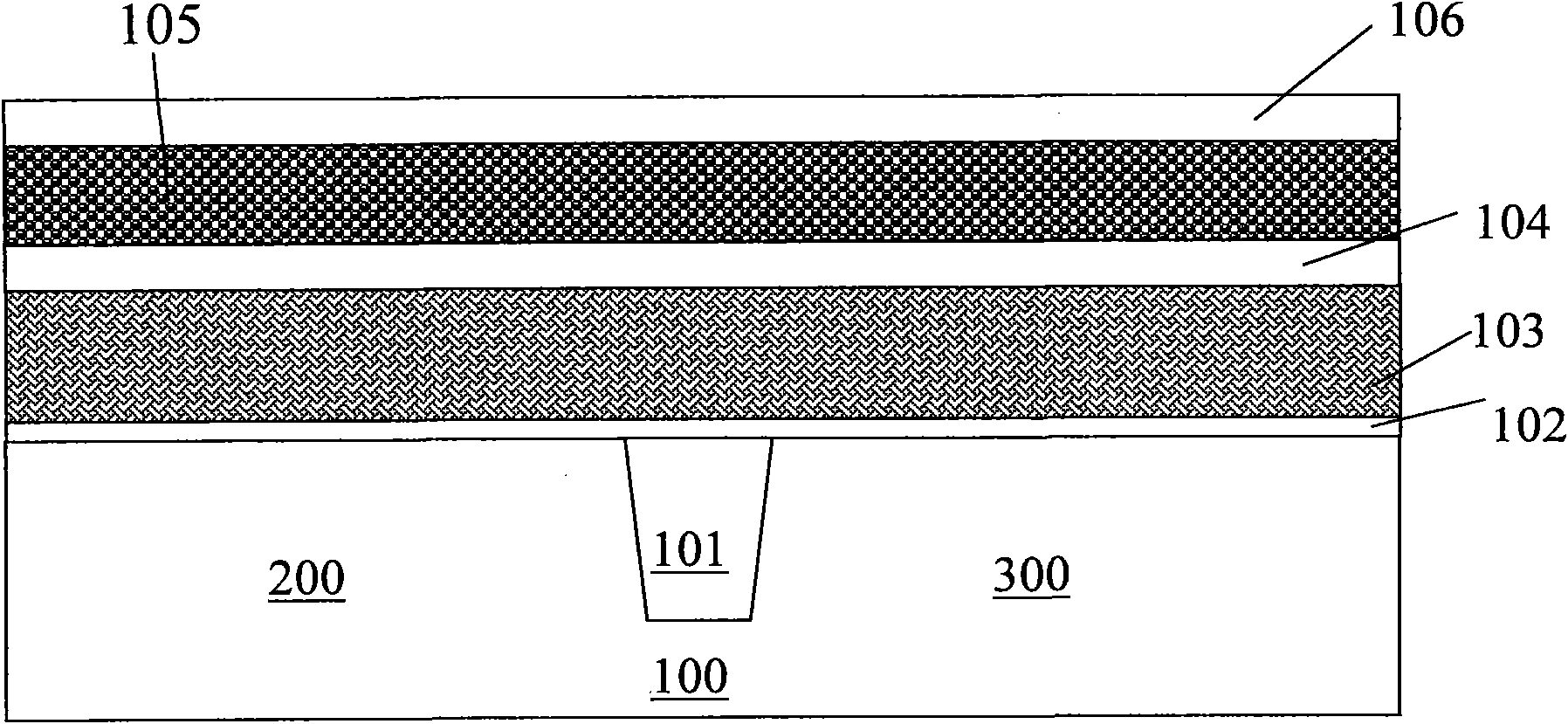

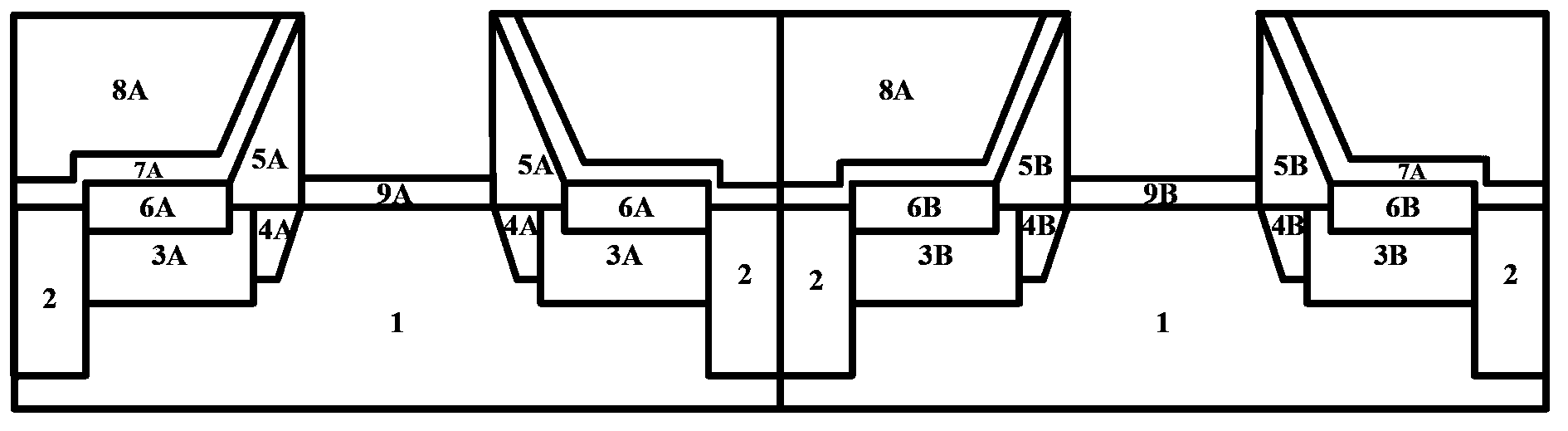

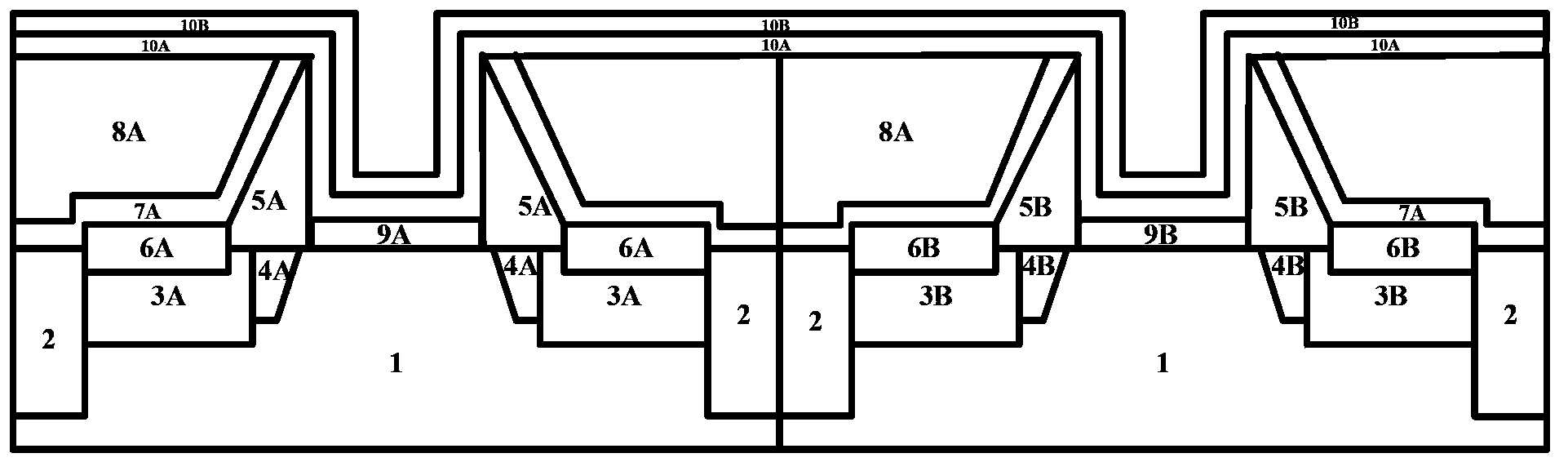

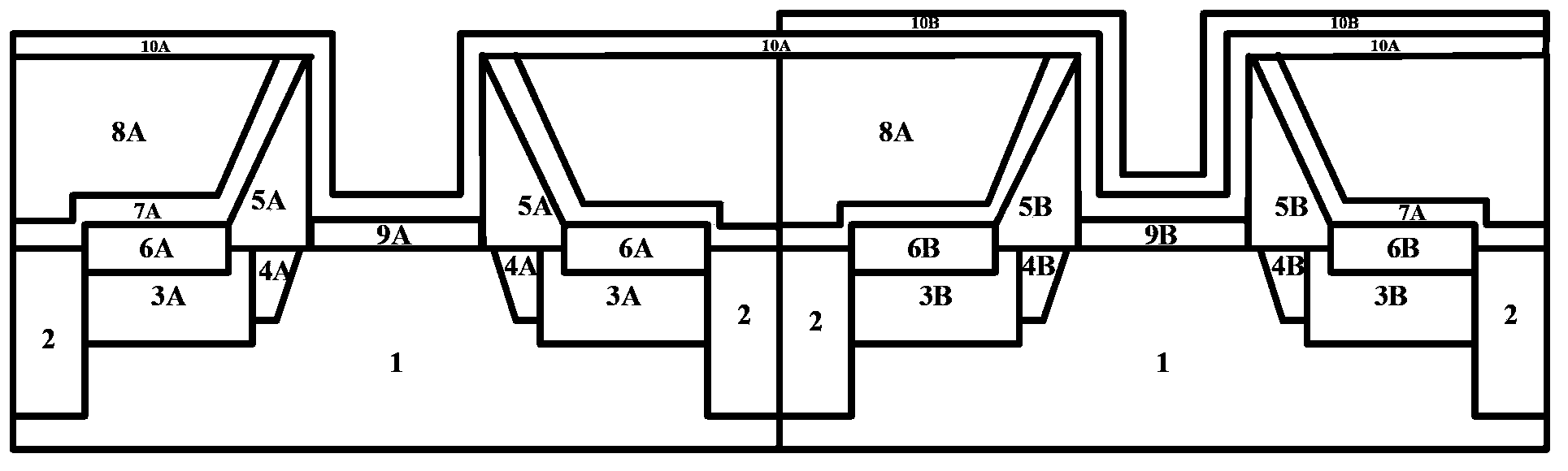

Planarization method for back gate process and device structure thereof

InactiveCN102386085AHighly precise controlLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice formEngineering

The invention provides a planarization method for a back gate process of an MOS (metal oxide semiconductor) device and a structure thereof. In the back gate process of the MOS device, a CMP (chemical mechanical planarization) process is utilized for planarization of an interlay dielectric layer, and an etching technology is utilized to remove a hard masking layer on a false gate stacking layer, so that the purpose of accurately controlling the heights of a false gate and a metal gate is achieved. In addition, the MOS device forms T-shaped stacking of the gates, and the length of the gate at the upper part is more than that of the gate at the lower part, so that the filling space of the metal gate material in a gate groove is enlarged so as to be beneficial to reducing the resistance of the metal gate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

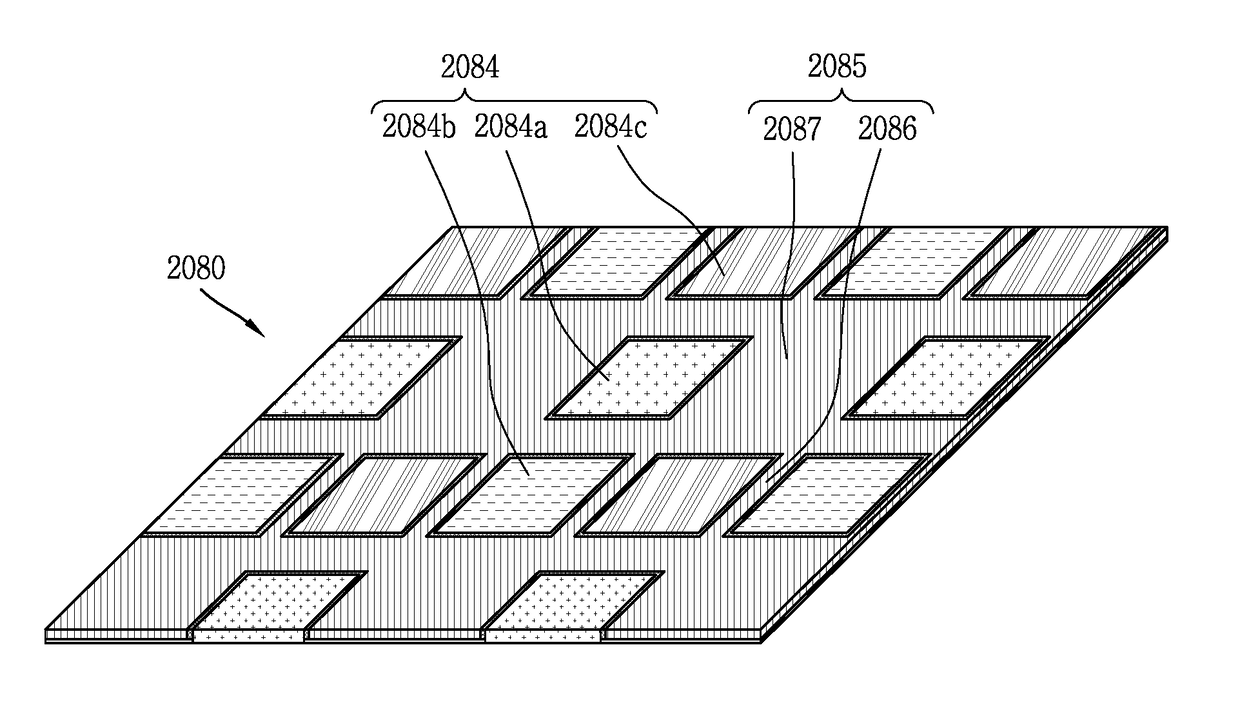

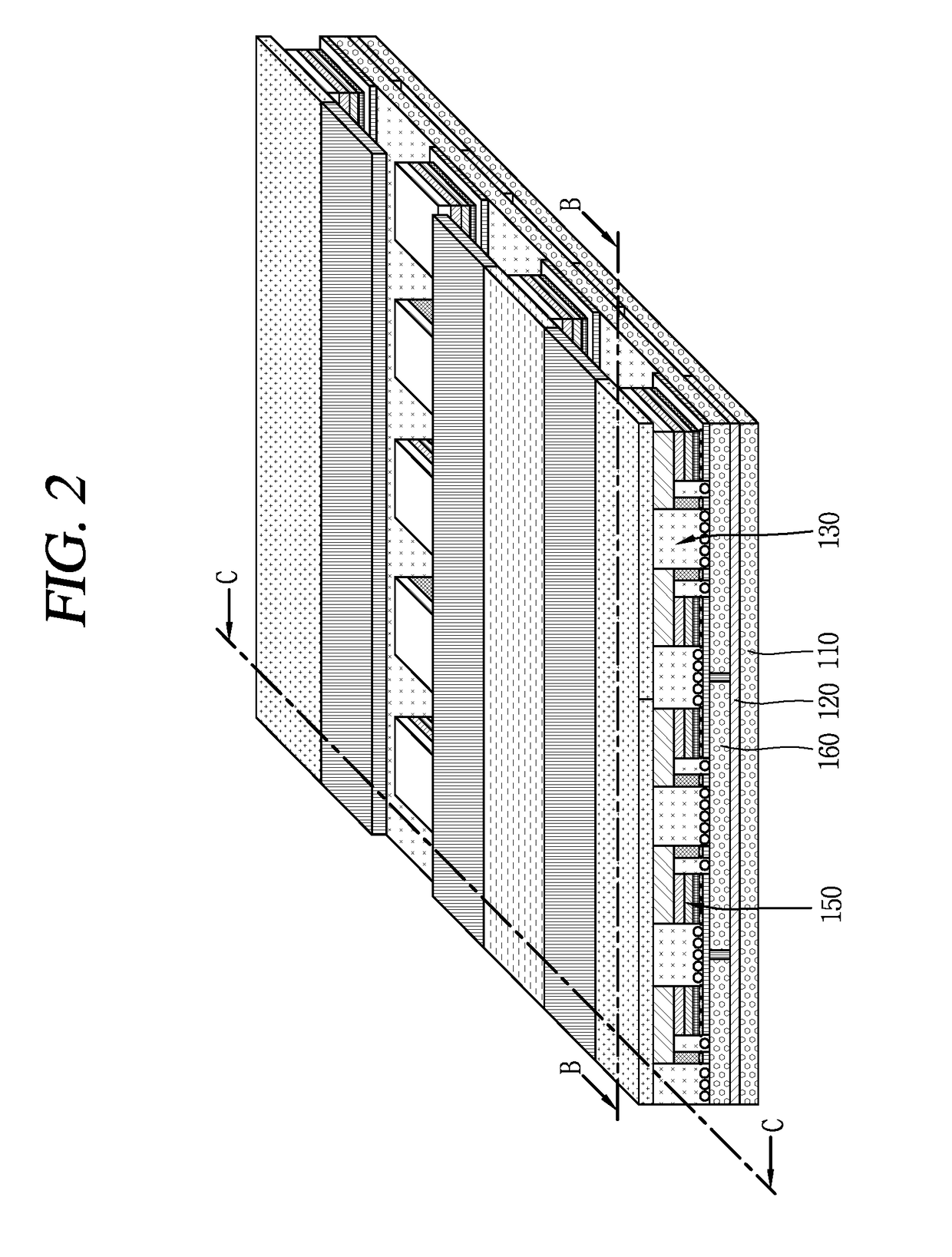

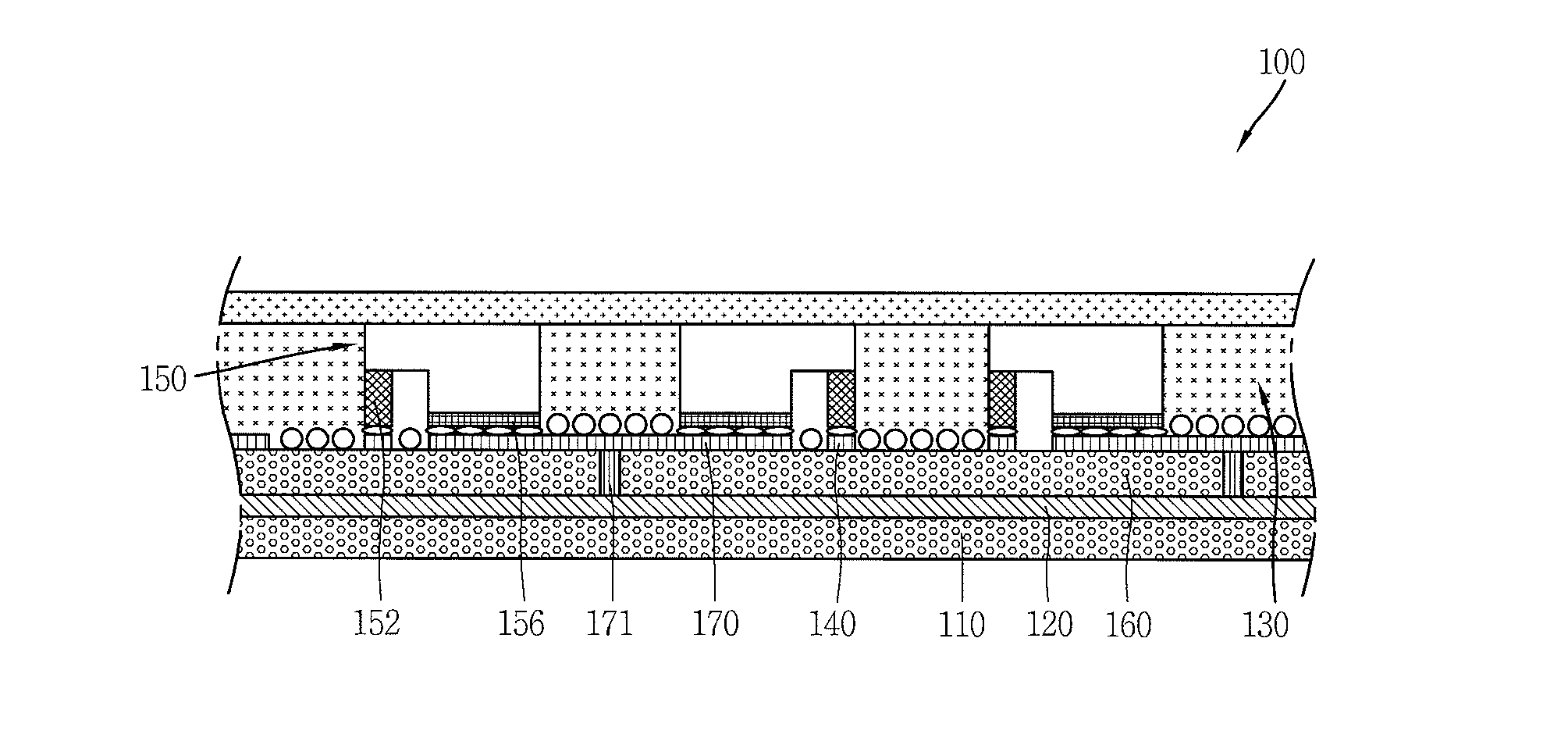

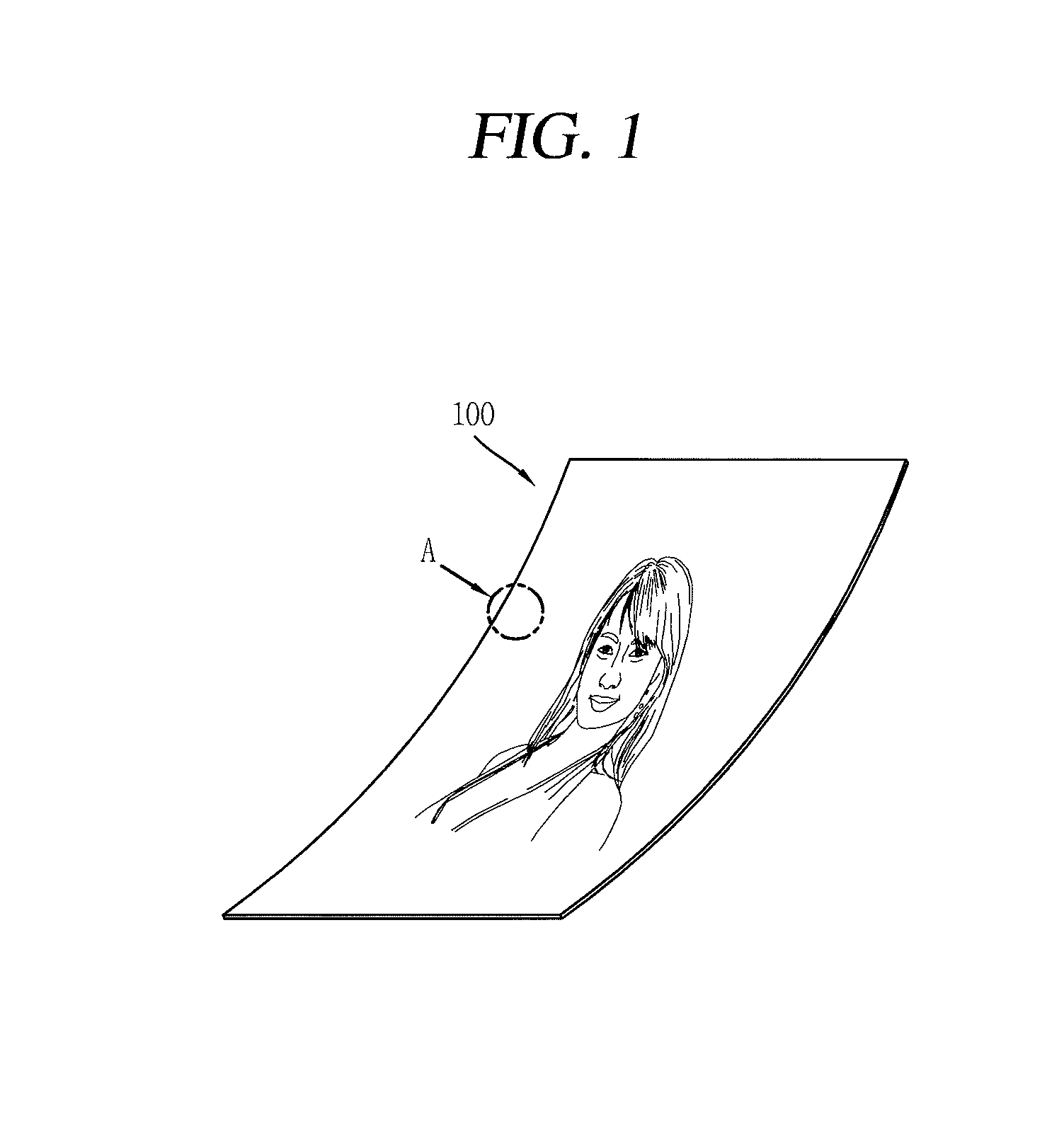

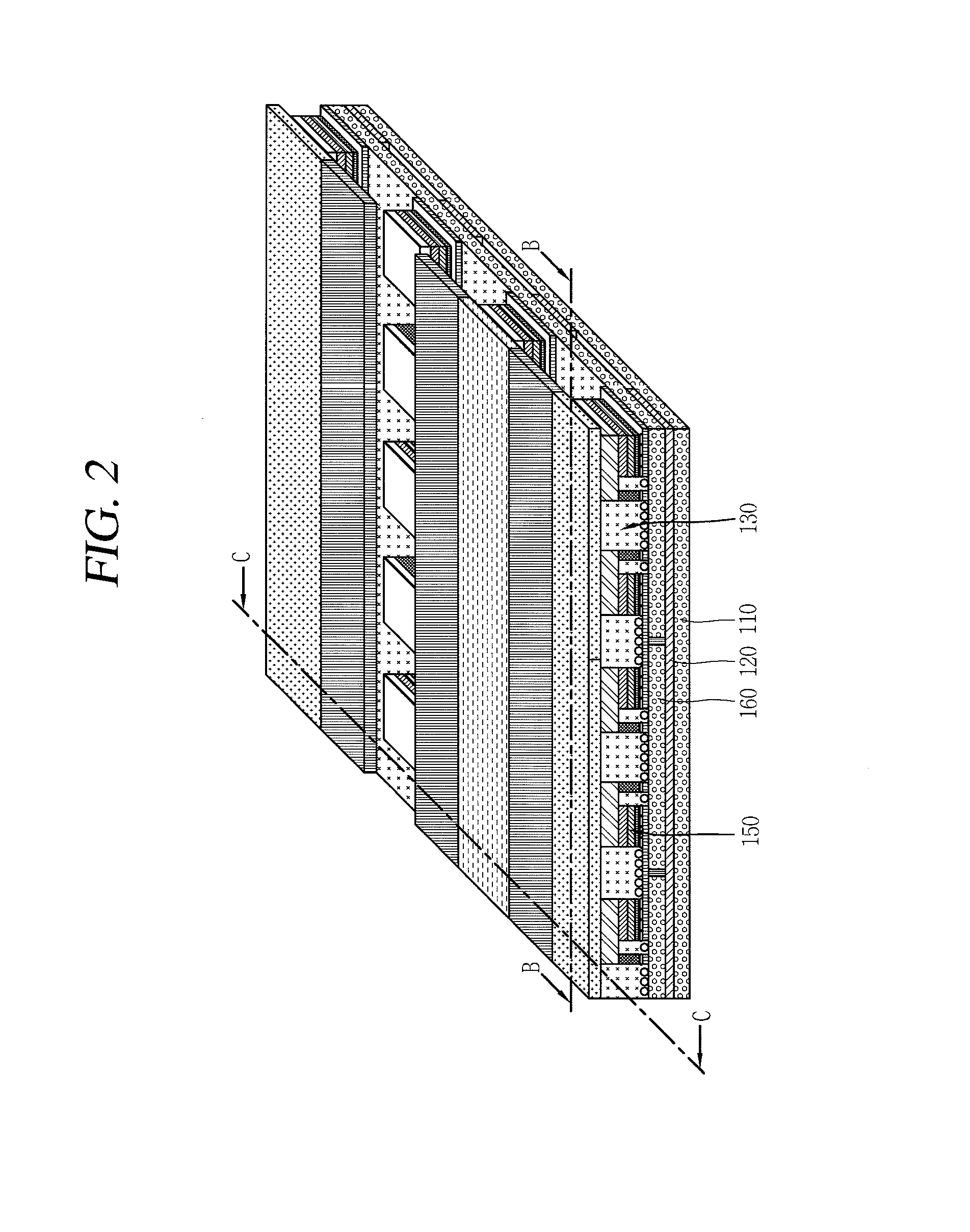

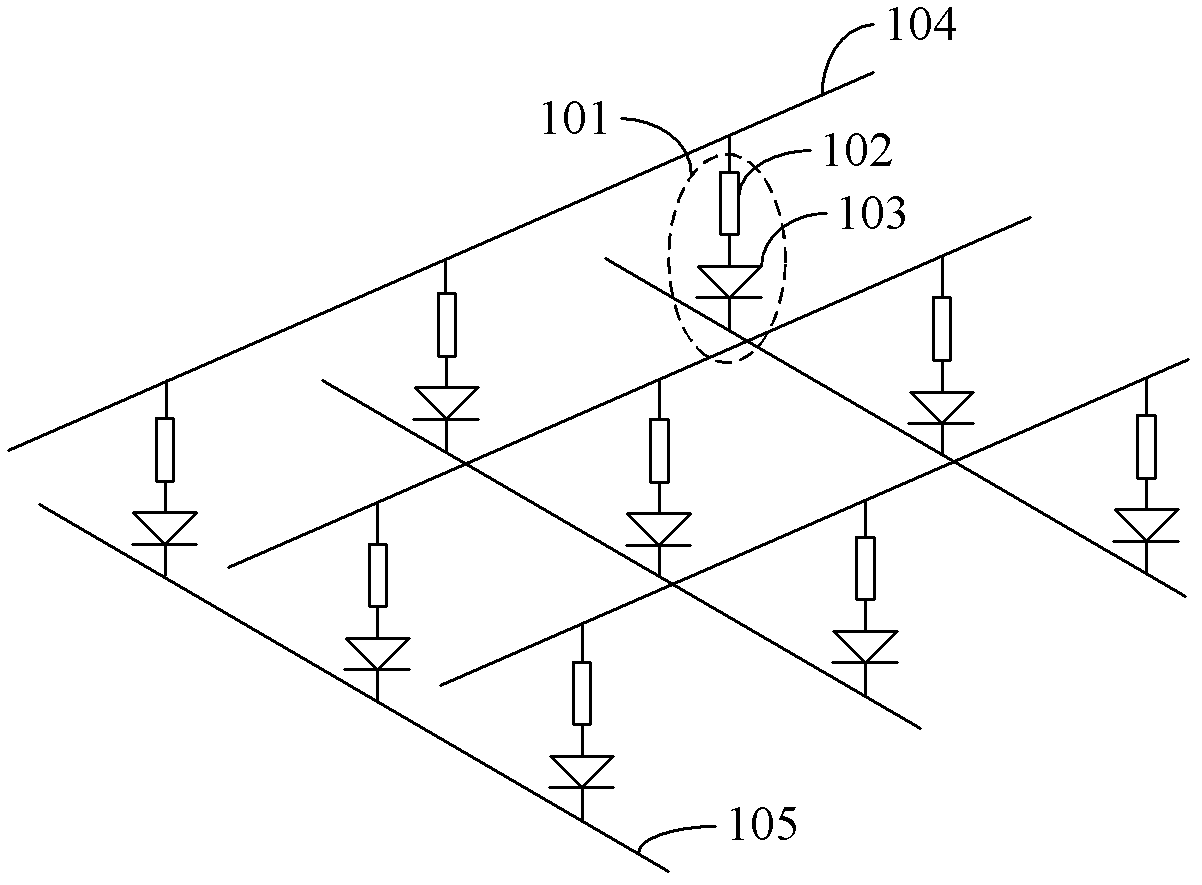

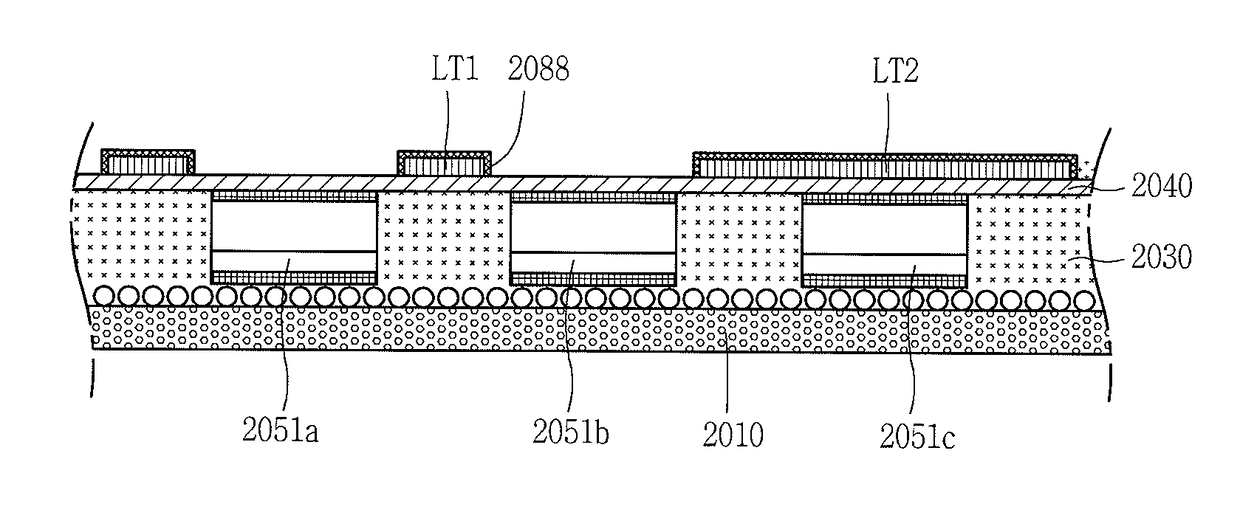

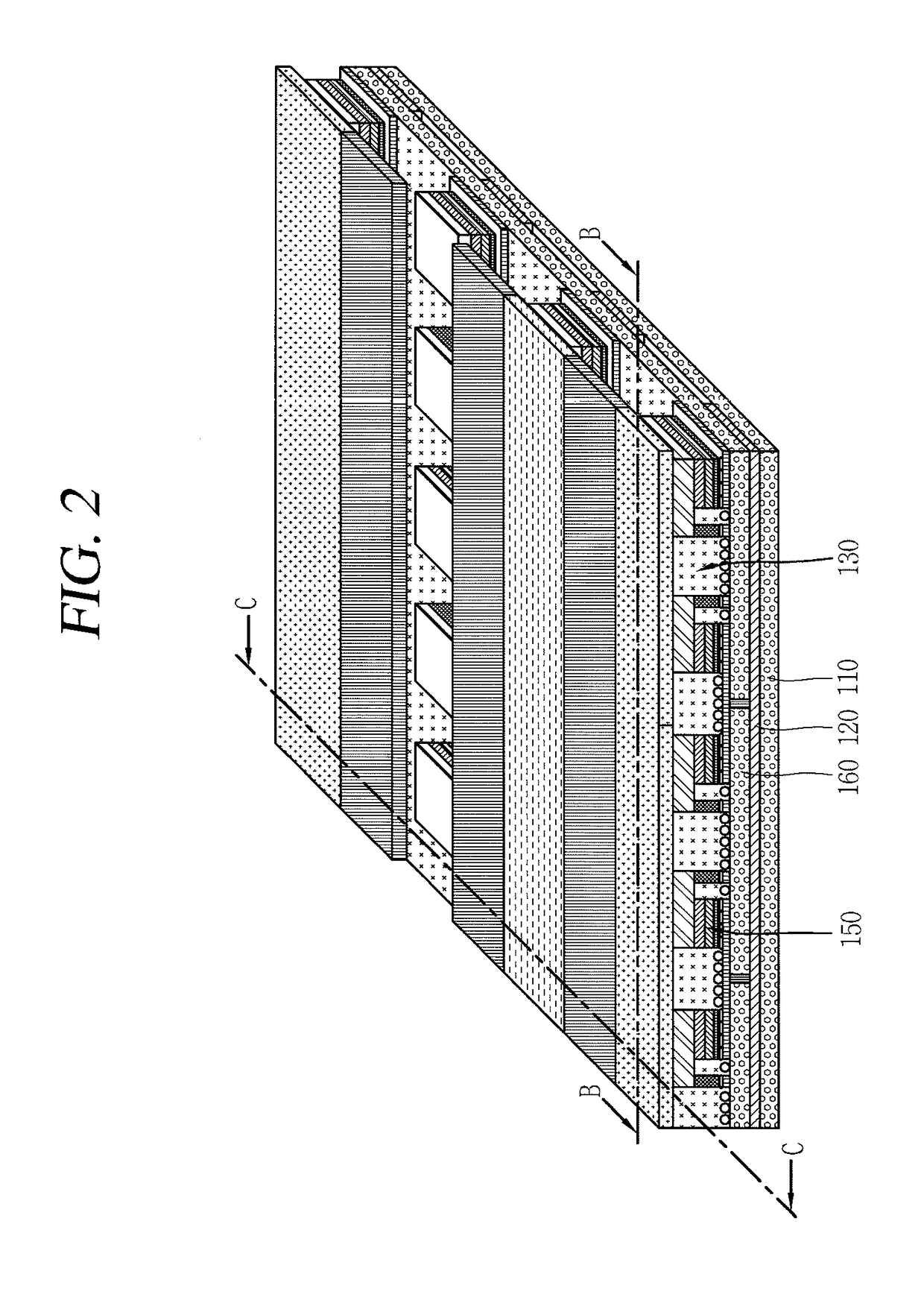

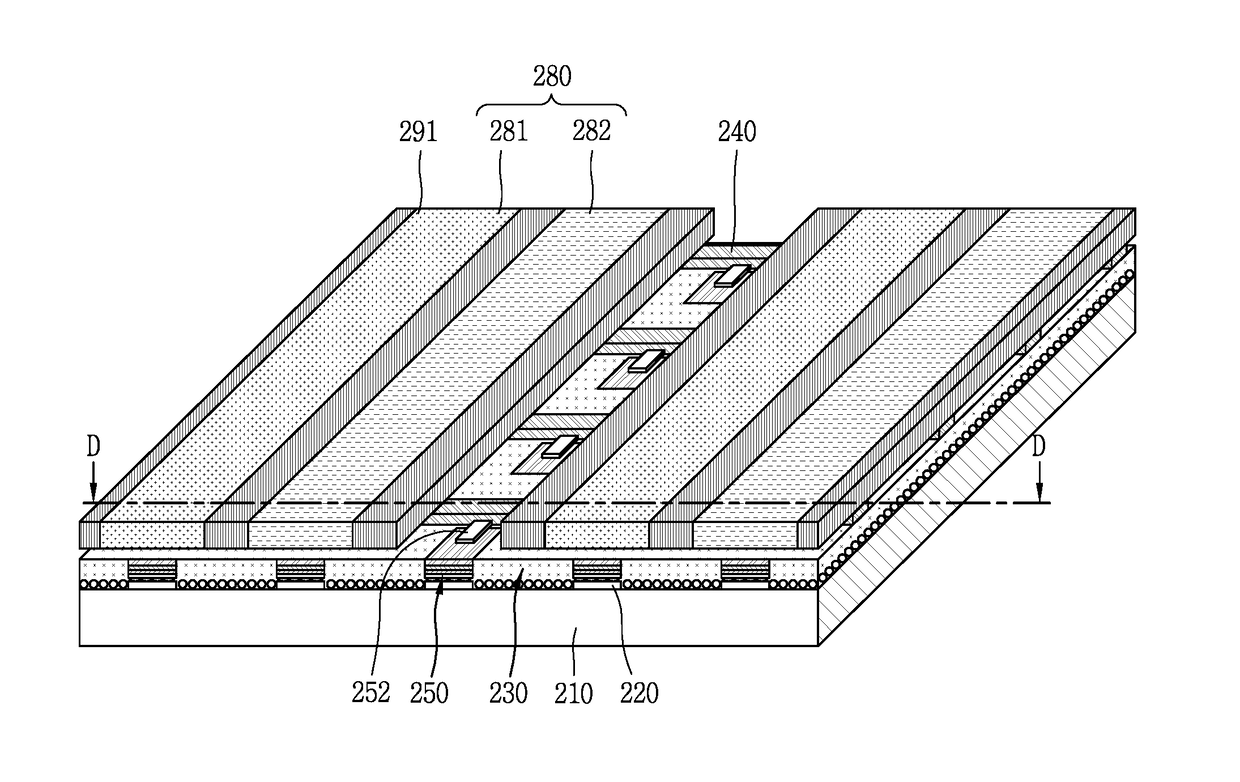

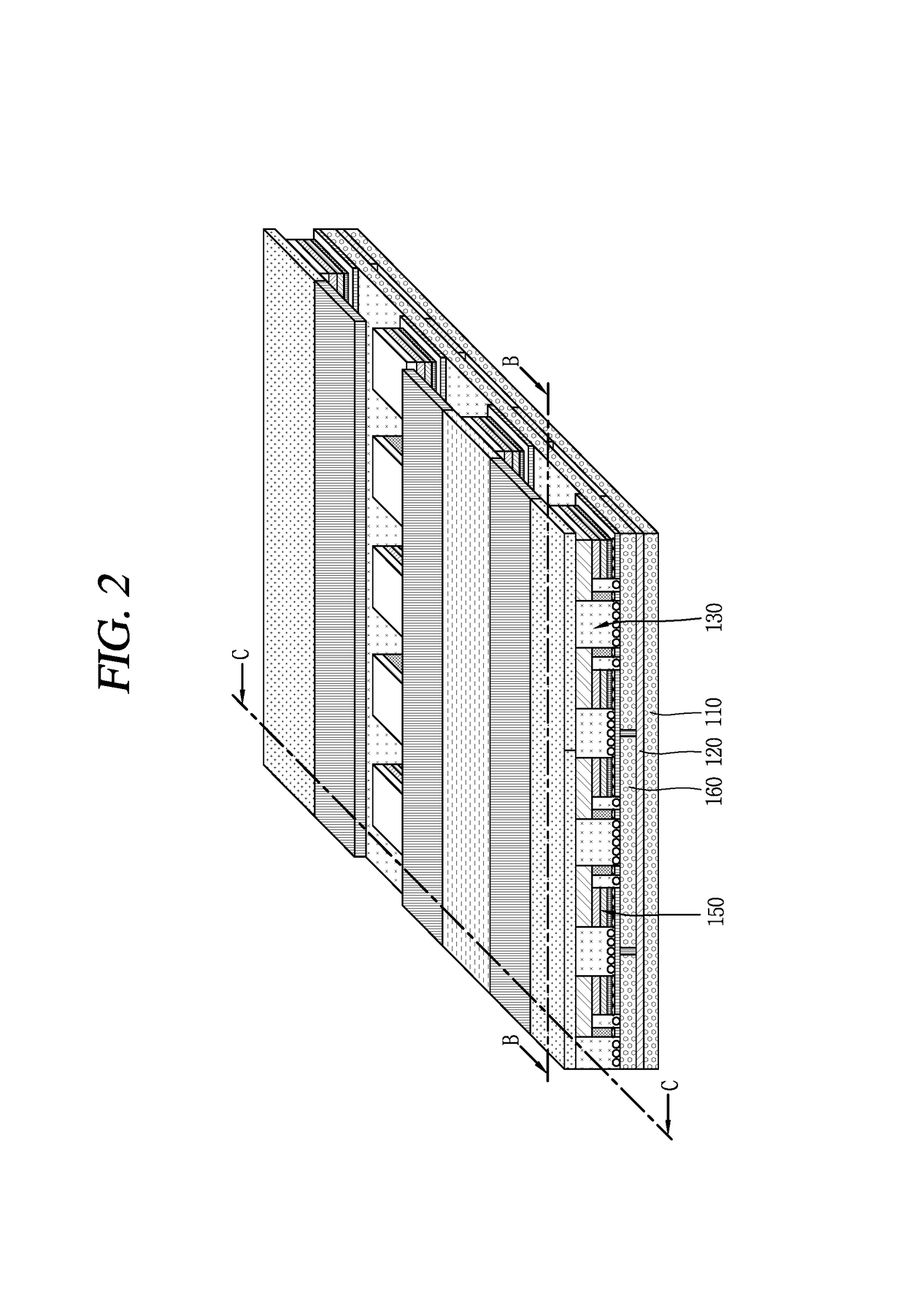

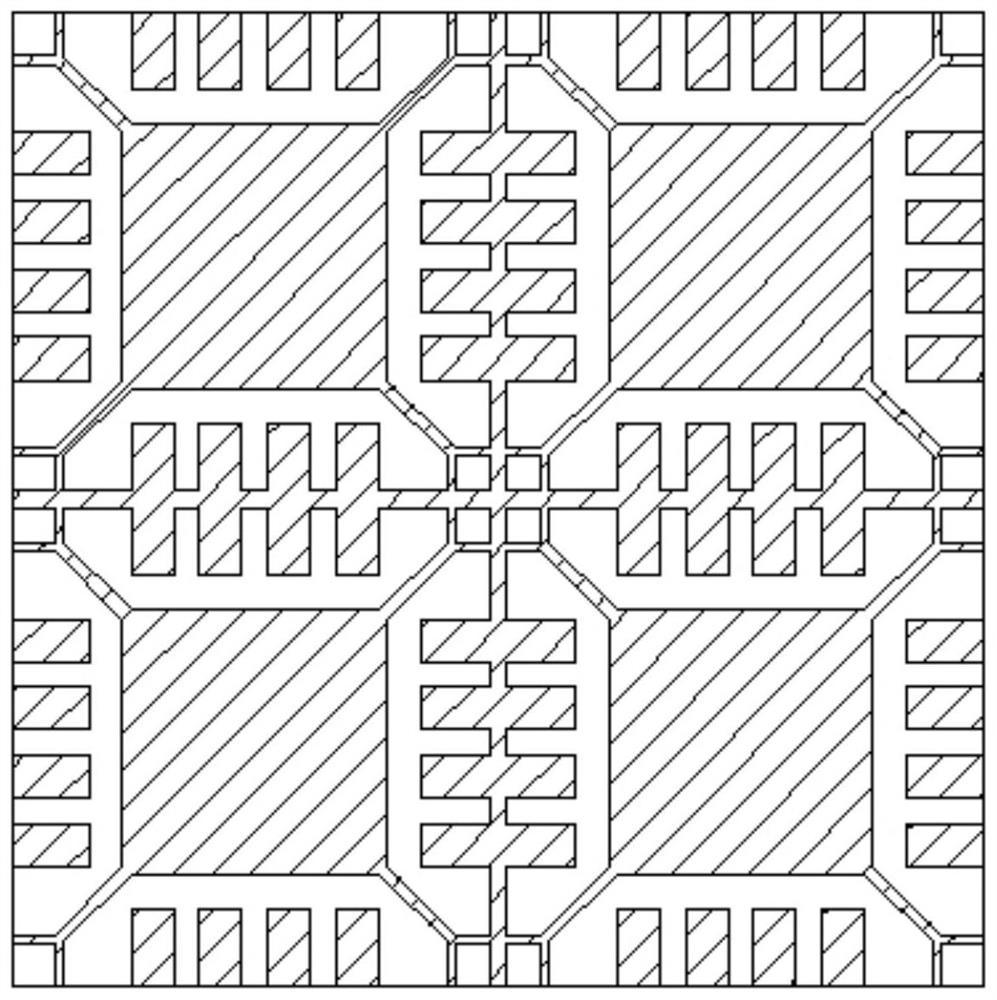

Display device using semiconductor light emitting device and method for manufacturing

ActiveUS20170200765A1Increase paddingAvoid mixing colorsSolid-state devicesSemiconductor devicesPhosphorFluorescence

A display device include a substrate including a wiring electrode; an adhesive layer disposed on the substrate; a plurality of semiconductor light emitting devices adhered to the adhesive layer, and electrically connected to the wiring electrode; and a phosphor layer disposed to cover the plurality of semiconductor light emitting devices. Further, the phosphor layer includes a plurality of phosphor portions for converting a wavelength of light, and a plurality of partition wall portions formed between the plurality of phosphor portions, and the plurality of partition wall portions are sequentially disposed between the phosphor portions along a first direction and a second direction crossing each other, respectively, and at least one of the sequentially disposed partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices.

Owner:LG ELECTRONICS INC

Display device using semiconductor light emitting device and method of manufacturing the same

ActiveUS20160293805A1Increase paddingSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorFluorescence

A display device including a plurality of semiconductor light emitting devices mounted on a substrate, and a phosphor layer including a plurality of phosphor portions configured to convert a wavelength of light and a plurality of partition wall portions formed between the plurality of phosphor portions. Further, a least one of the plurality of partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices along a thickness direction of the phosphor layer.

Owner:LG ELECTRONICS INC

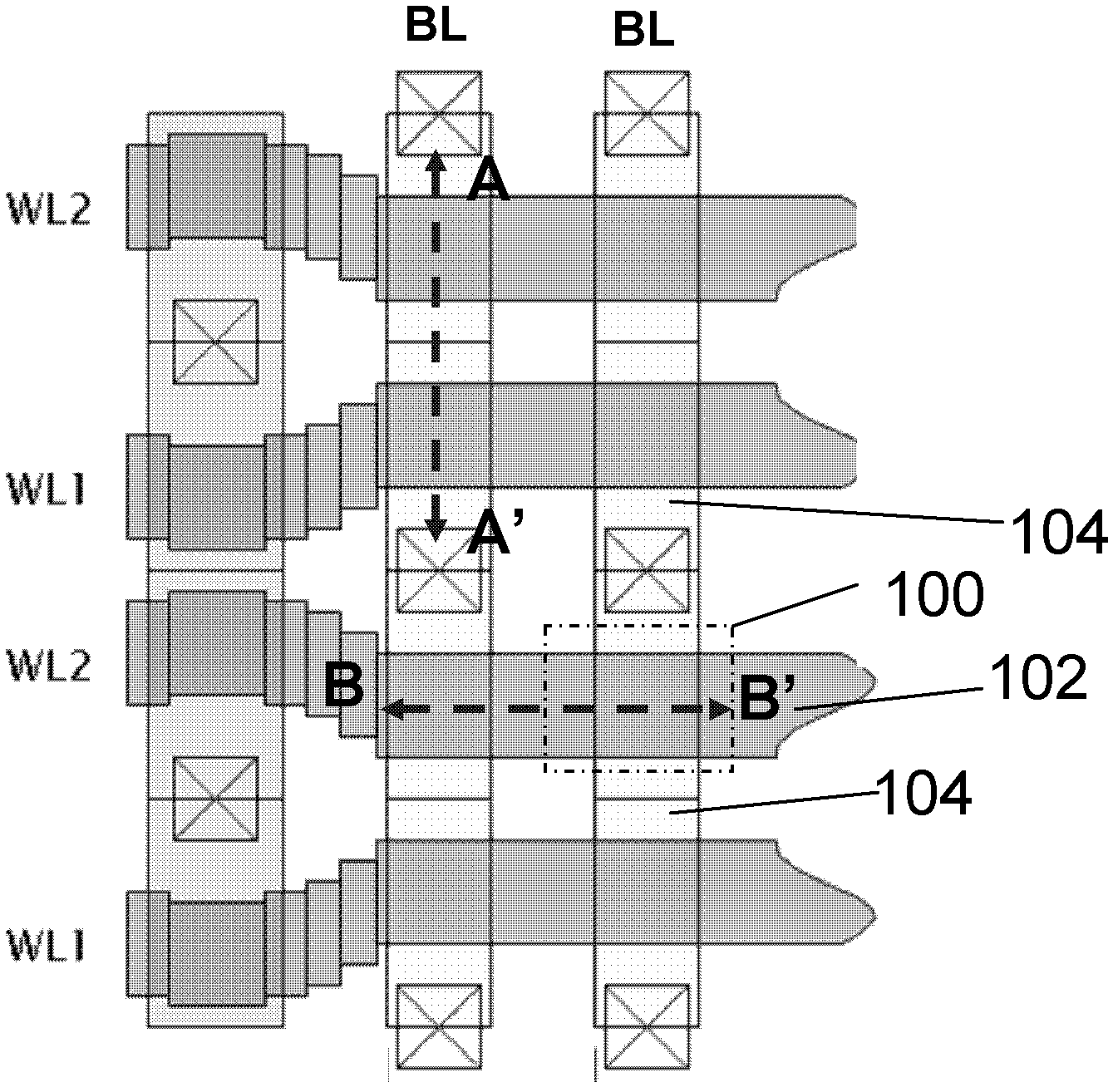

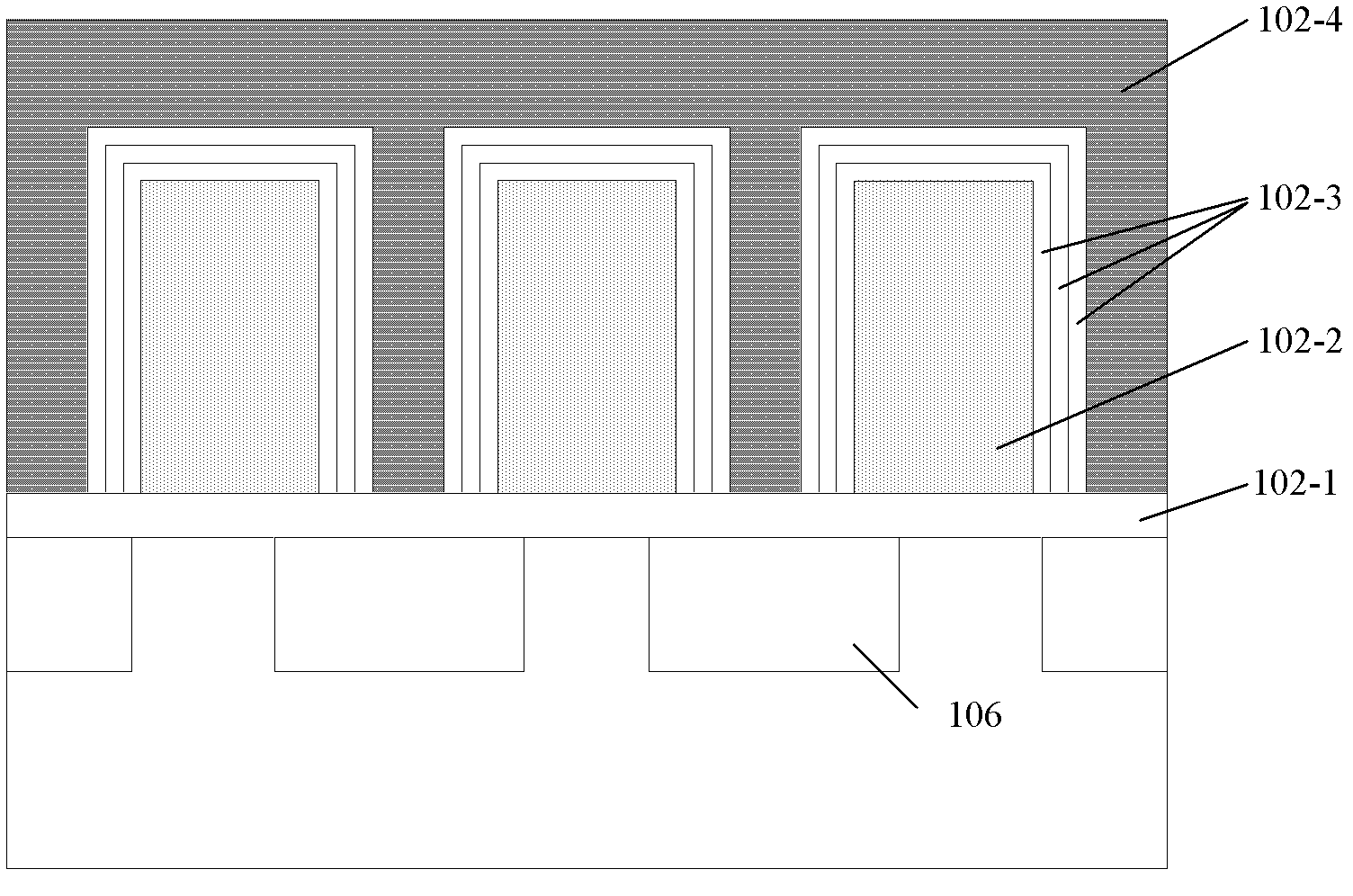

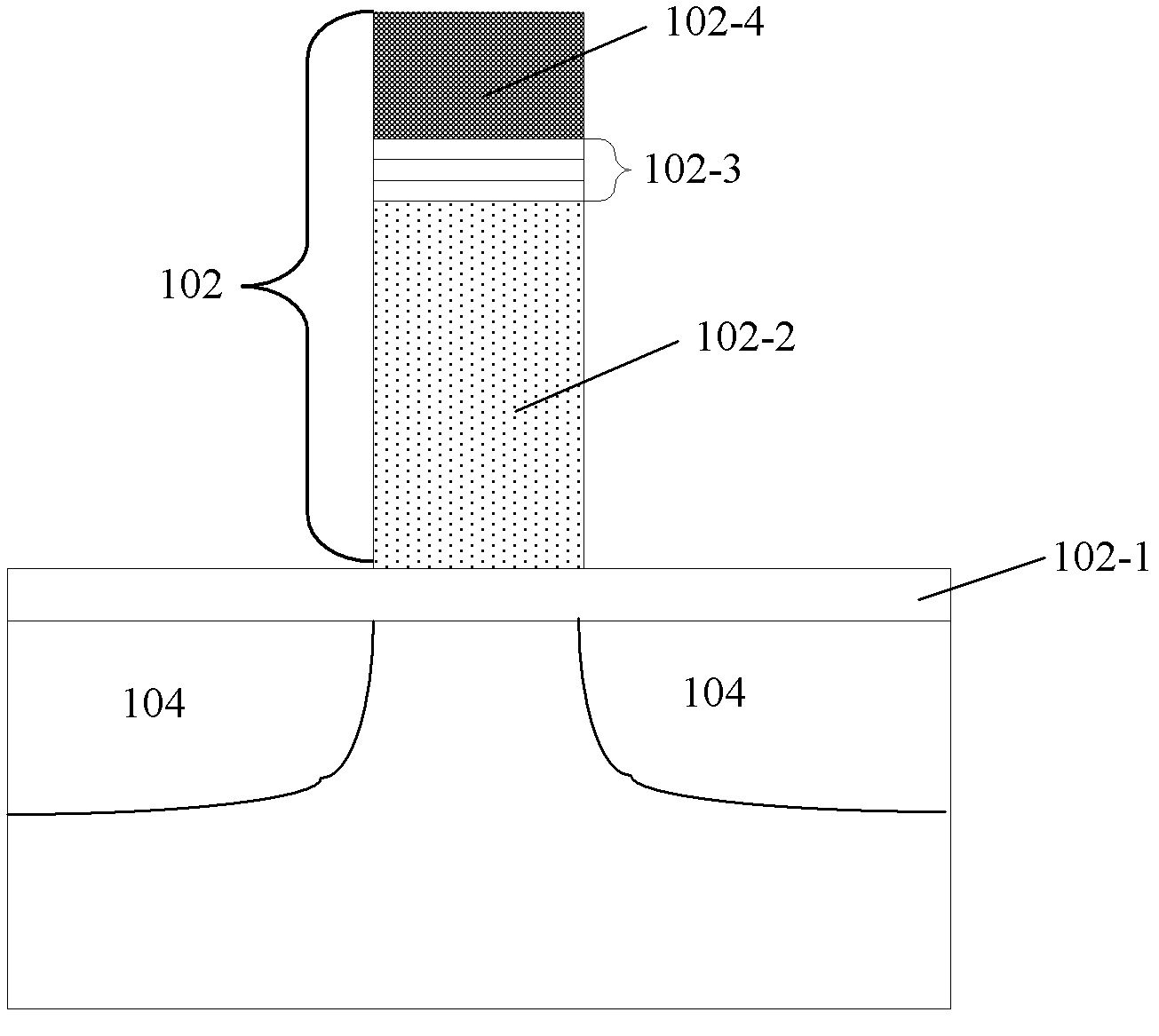

Semiconductor memory and manufacturing method thereof

InactiveCN103258860AImprove reliabilityImprove performanceTransistorSolid-state devicesSemiconductor materialsSingle crystal

The invention discloses a semiconductor memory which is a memory unit in a not or (NOR) type flash-memory memory array. The semiconductor memory comprises a substrate, a tunneling layer, a floating gate, a control gate and a barrier layer, wherein the tunneling layer is arranged on the substrate, the floating gate and the control gate are arranged on the tunneling layer, and the barrier layer is arranged between the floating gate and the control gate. The floating gate is made of monocrystal semiconductor materials or microcrystal semiconductor materials. The monocrystal or the microcrystal is of a compact structure, spreading of doping objects in the polycrystalline silicon floating gate through crystal particle gaps is effectively avoided, performance and reliability of the memory are improved, the even and high-quality barrier layer can be easily formed on the monocrystal or microcrystal floating gate, and the reliability of the memory is further improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

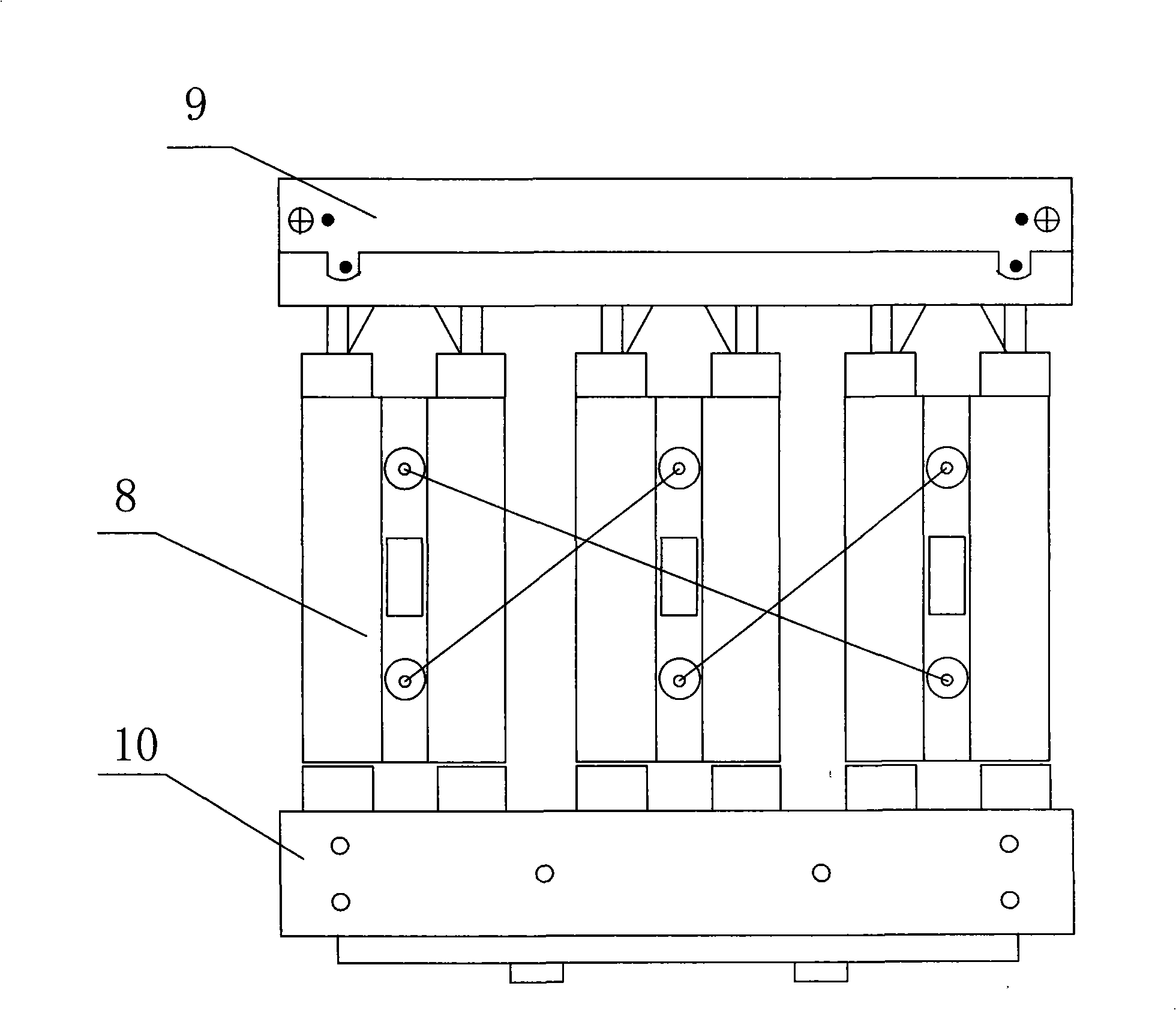

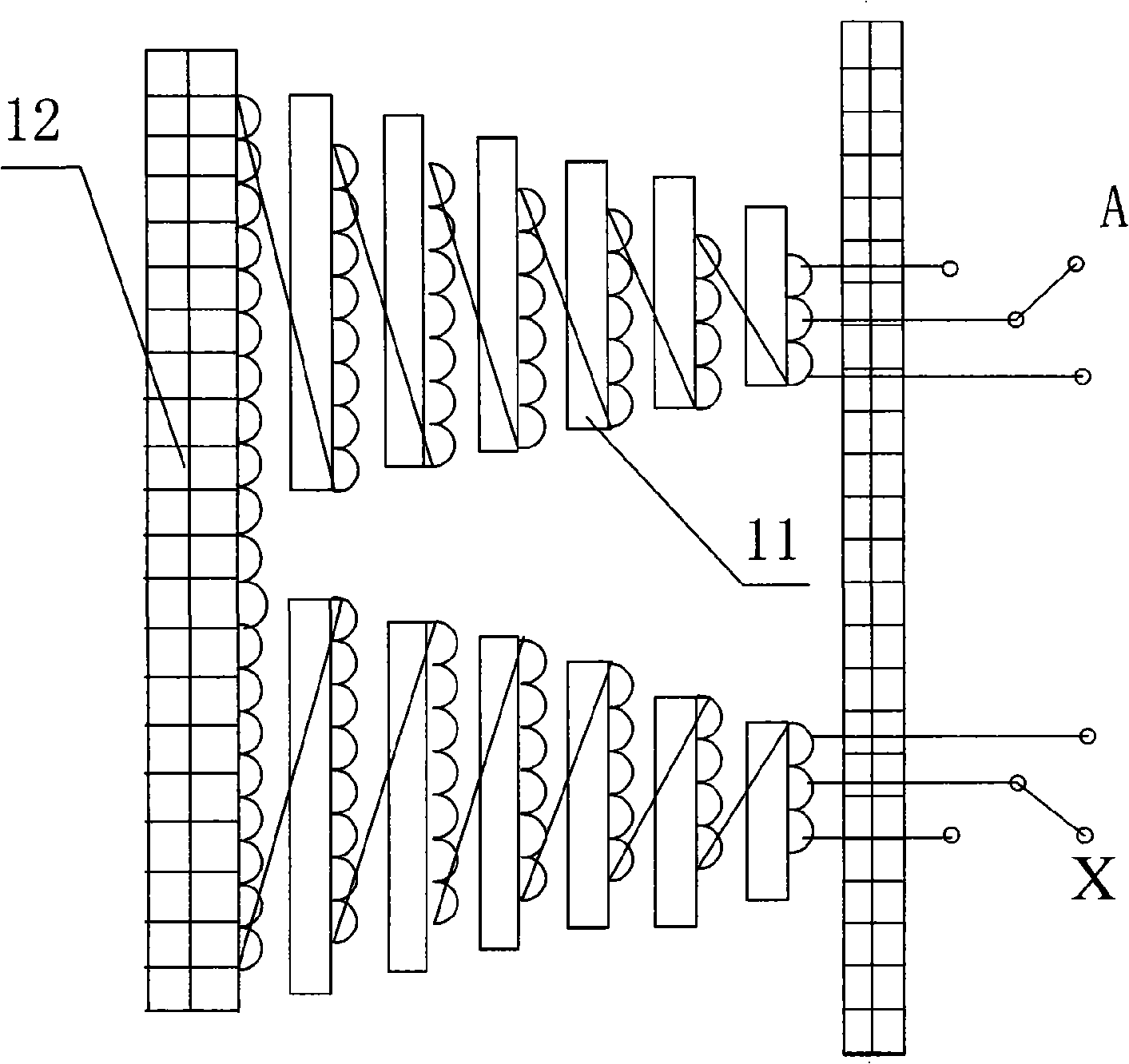

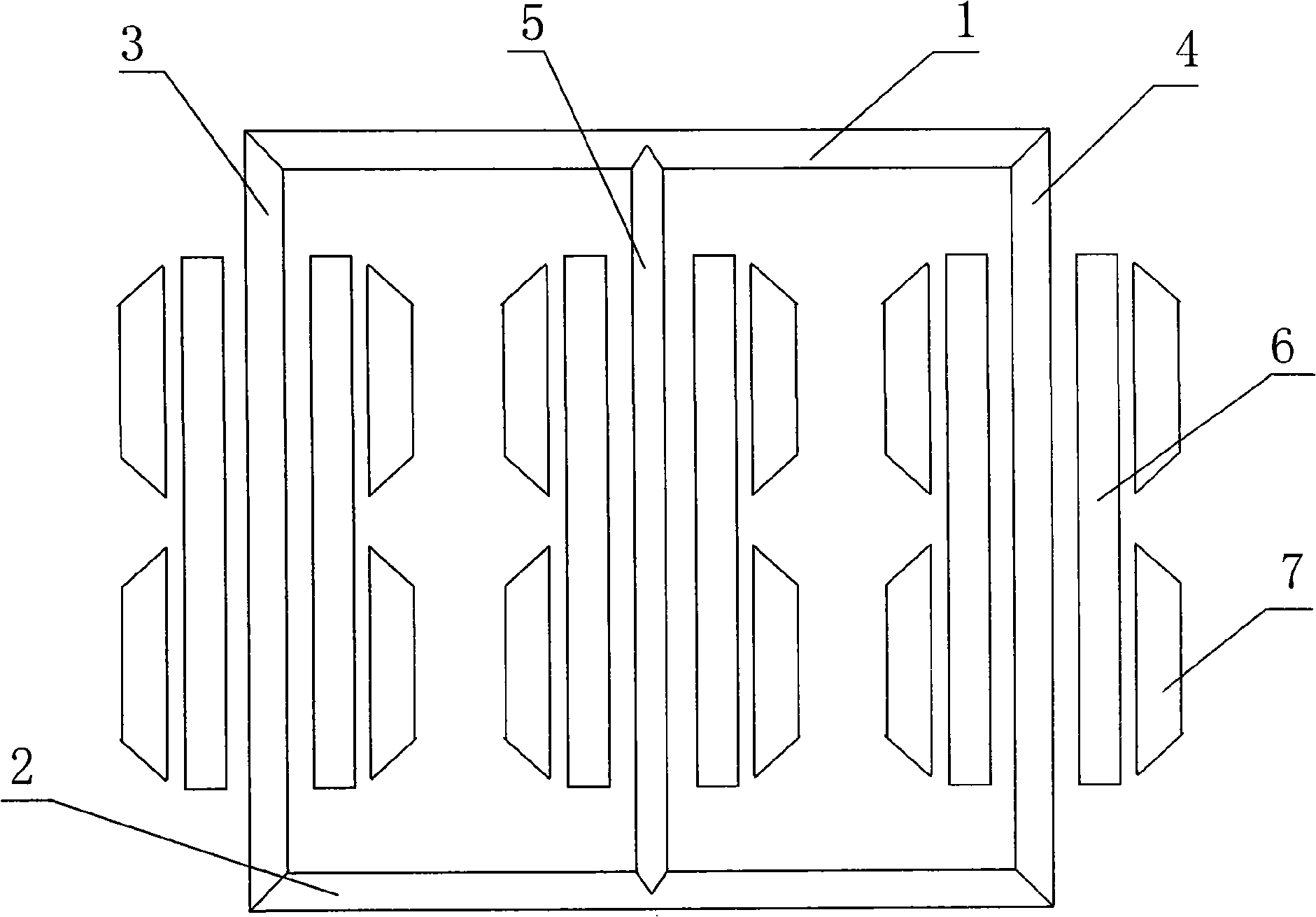

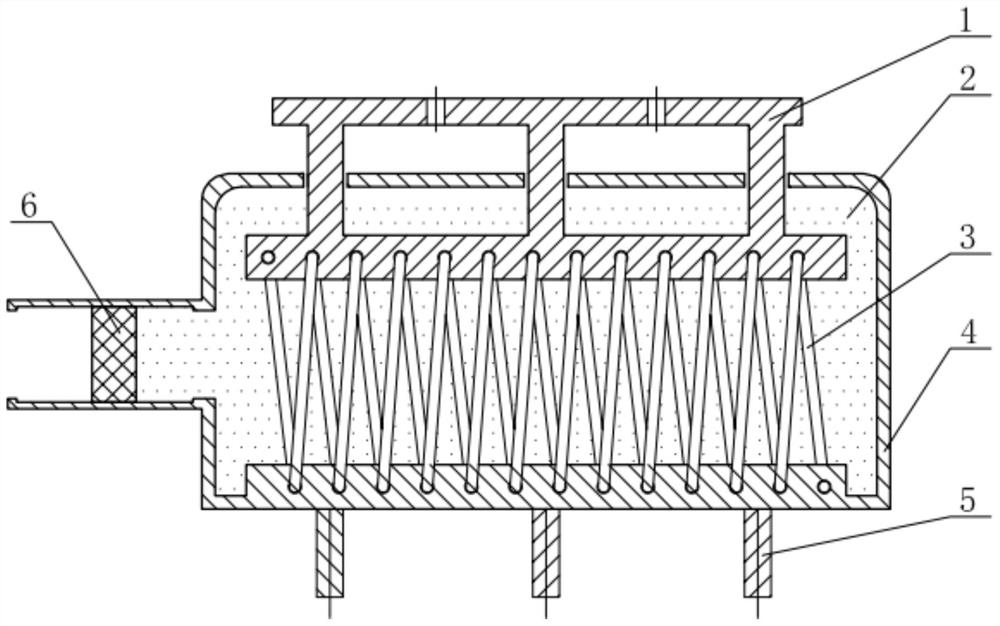

Epoxy cast dry transformer

InactiveCN101308721AReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyLow voltage

Disclosed is an epoxy resin cast dry type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp, and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to the outer layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost and requires no daily maintenance. The epoxy resin cast dry type transformer is of strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

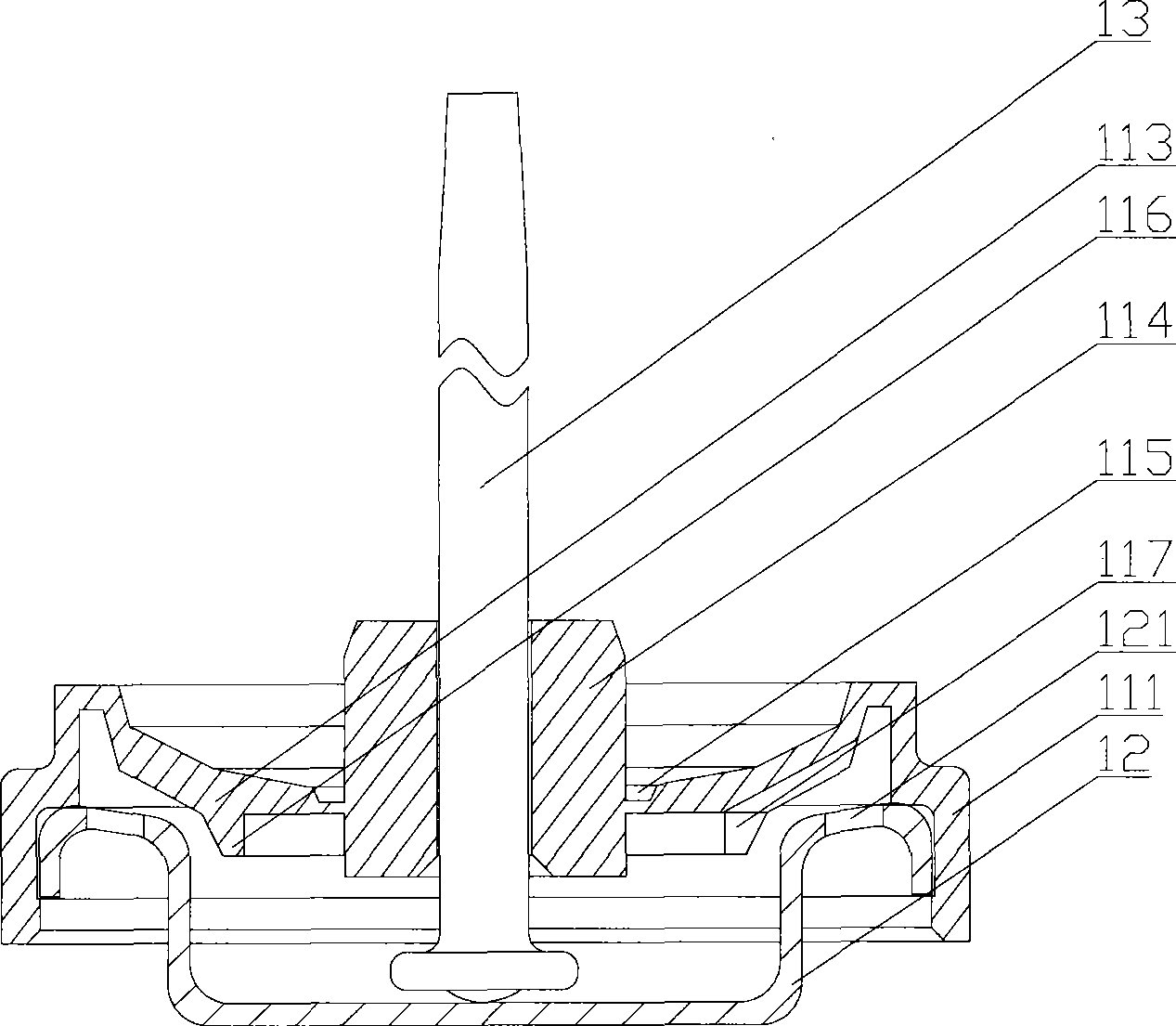

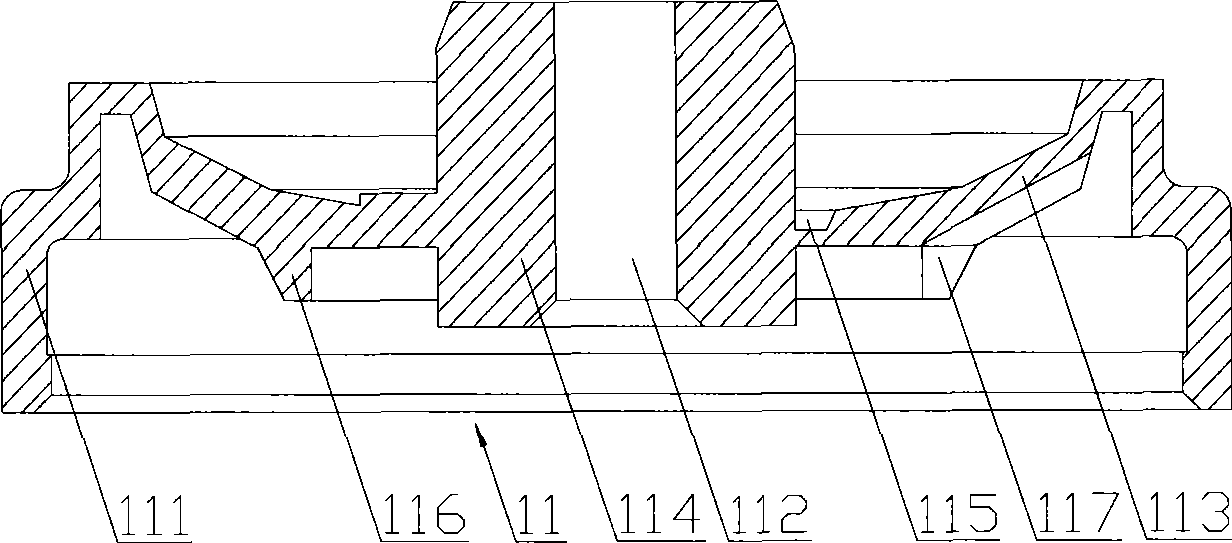

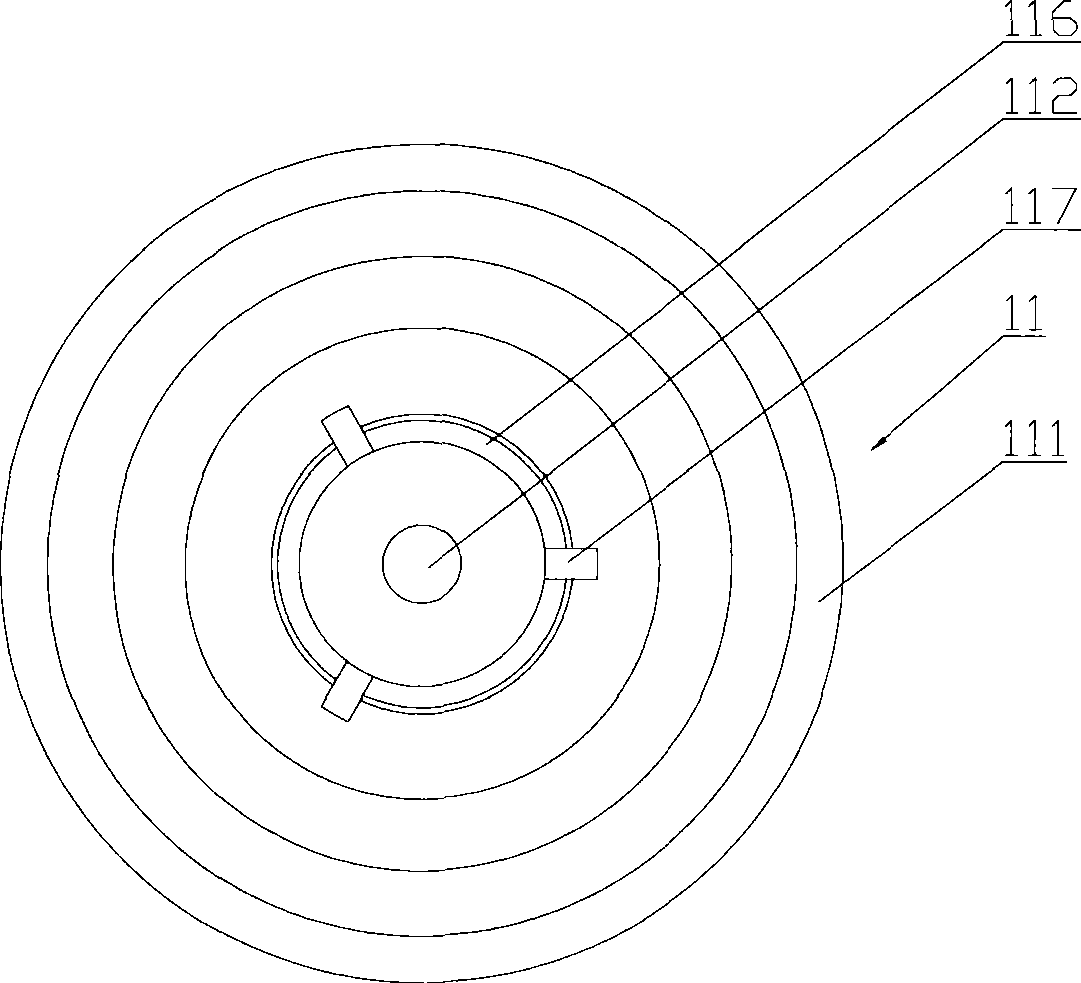

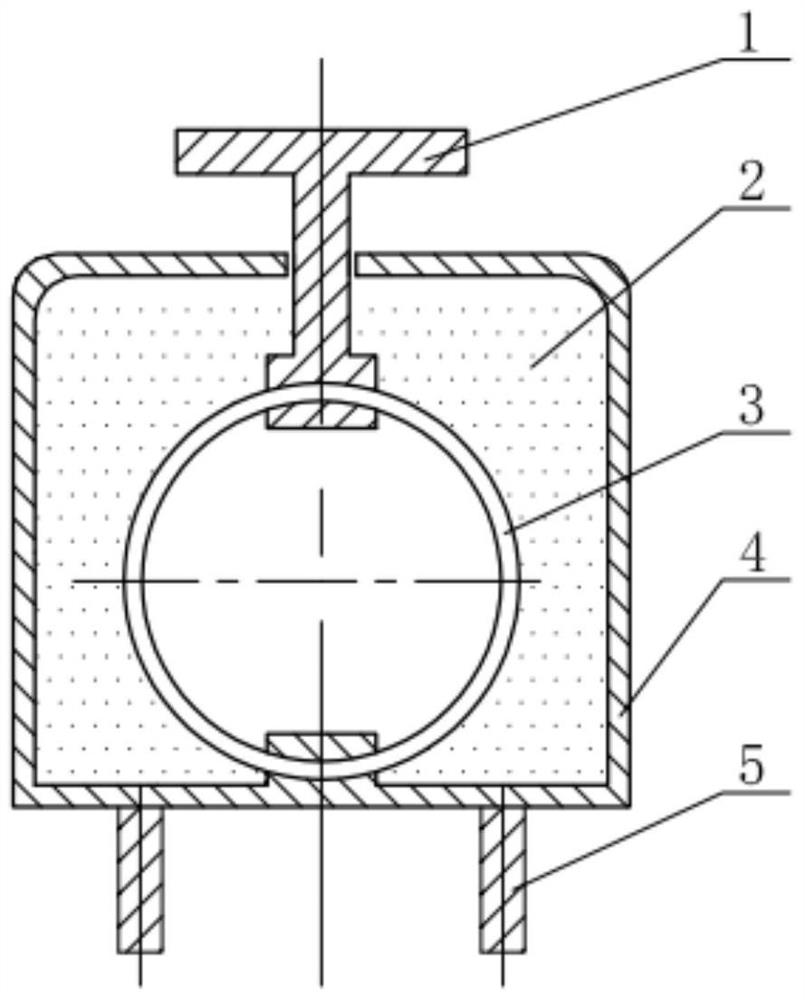

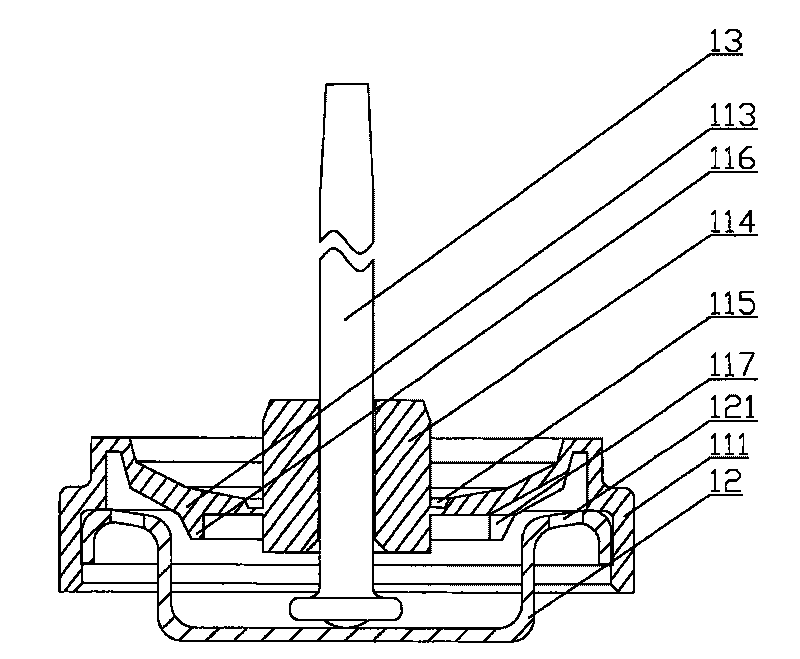

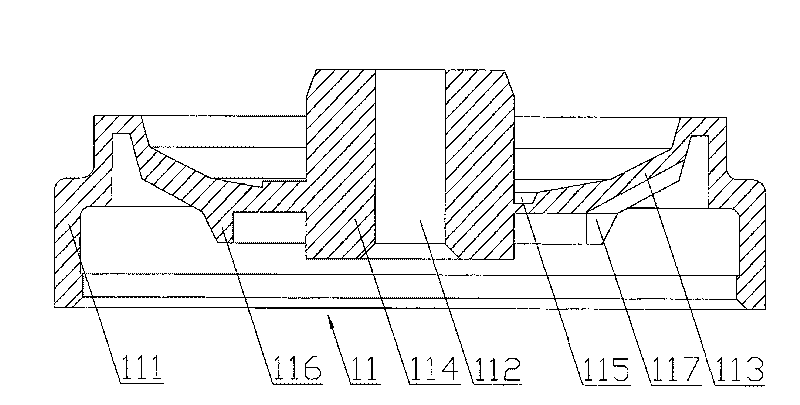

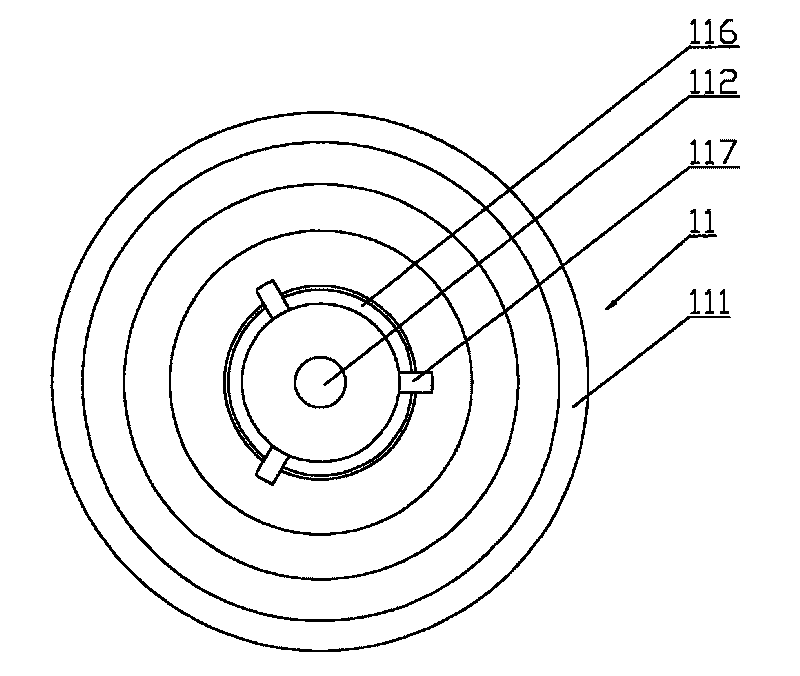

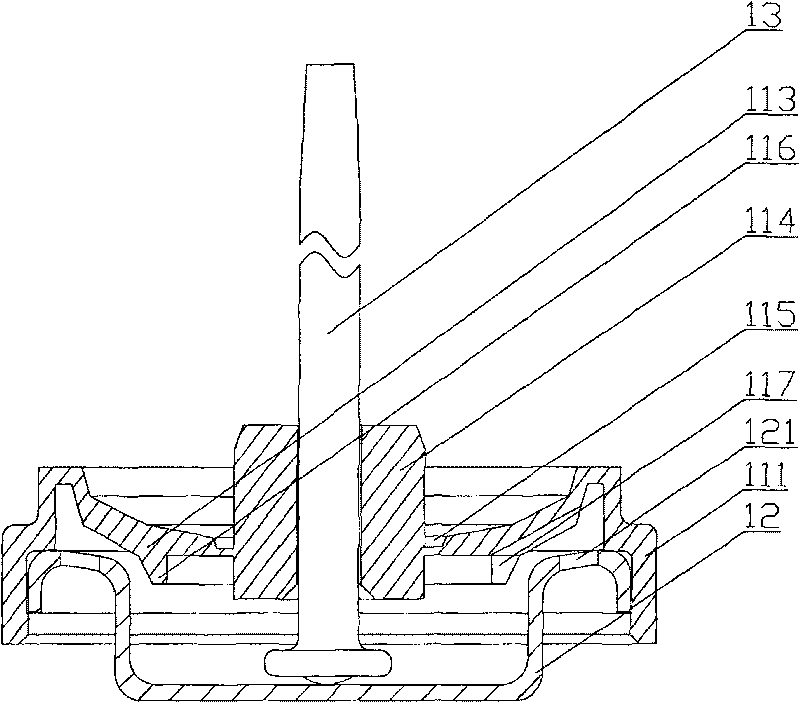

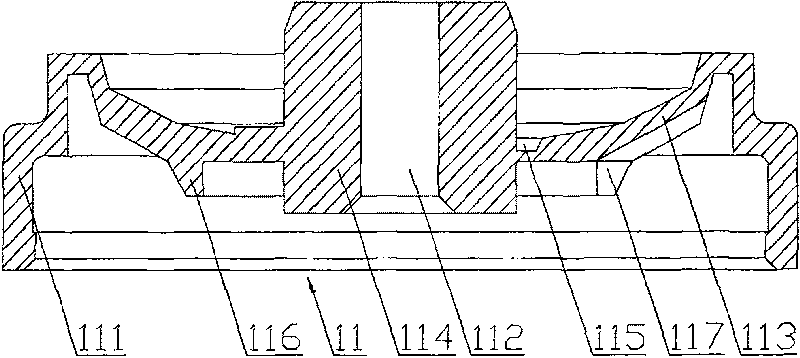

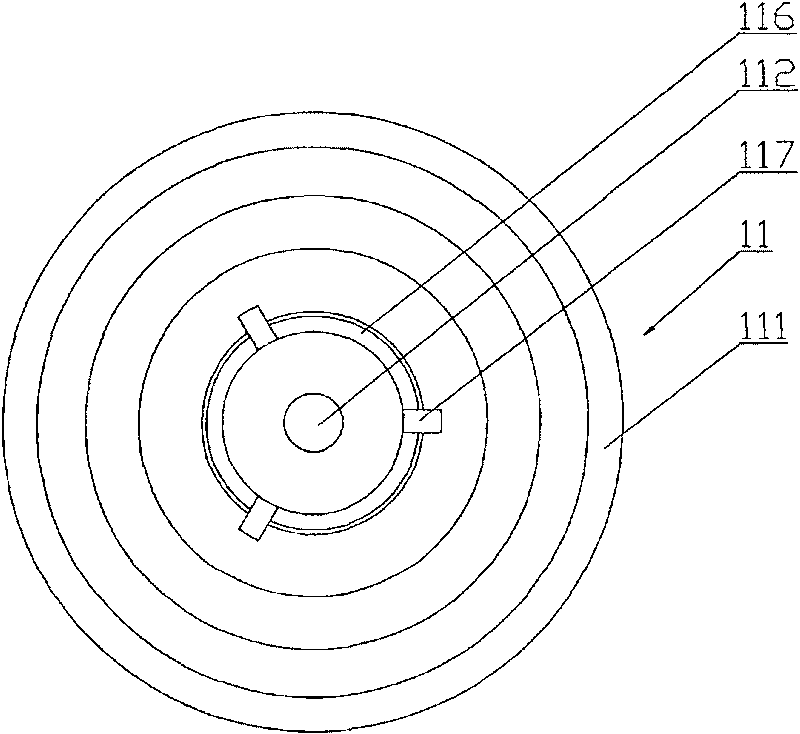

Current collection body for battery

ActiveCN101425567AUniform mass distributionExtended service lifeSmall-sized cells cases/jacketsElectrode carriers/collectorsCapacitanceMechanical engineering

The invention discloses a battery collector body. A sealing ring thereof is a rotating body; the bottom cover of the rotating body is provided with a raised structure protruding towards the sealing ring; and a deflation hole on the bottom cover is arranged in the raised structure. The raised structure is used for supporting the sealing ring when the sealing ring falls down due to a broken explosion-proof channel, thereby a broken opening communicated with the sealing ring and a deflation channel of the deflation hole are formed. Because the sealing ring is the rotating body, the mass distribution of the sealing ring is more uniform during the injection mold and processing, thereby the problem that the sealing ring is friable and easily broken in the prior art is effectively avoided, the service life is prolonged, and the reliability is improved. Because the deflation hole is arranged in the raised structure and is not on an identical plane with the bottom surface of the bottom cover, the tail end of a holddown spring is not easy to extend. In addition, because the thickness of the sealing ring is relatively lowered, the inside of the battery is ensured to have a larger space filled with active substances, thereby the capacitance of the battery is obviously improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

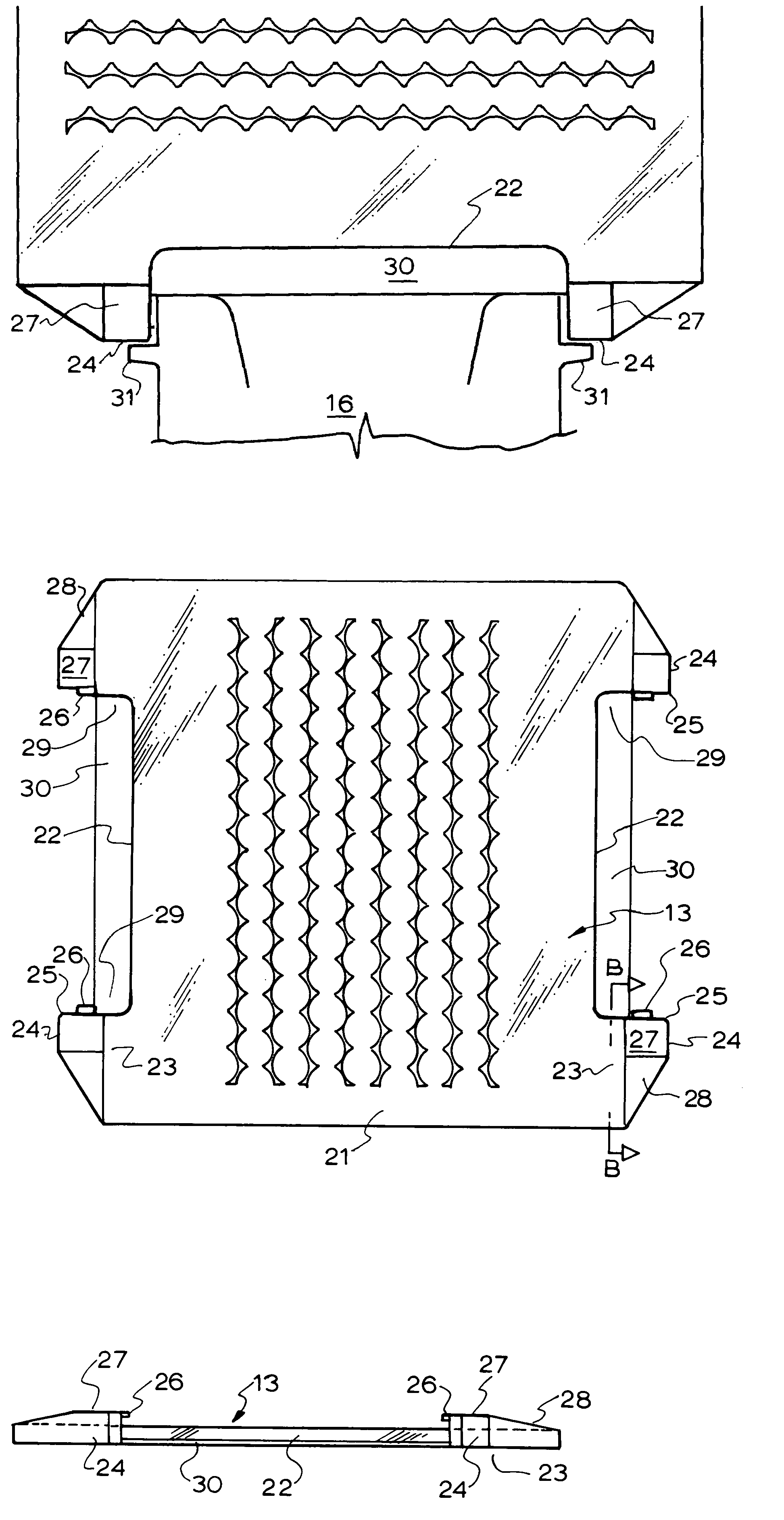

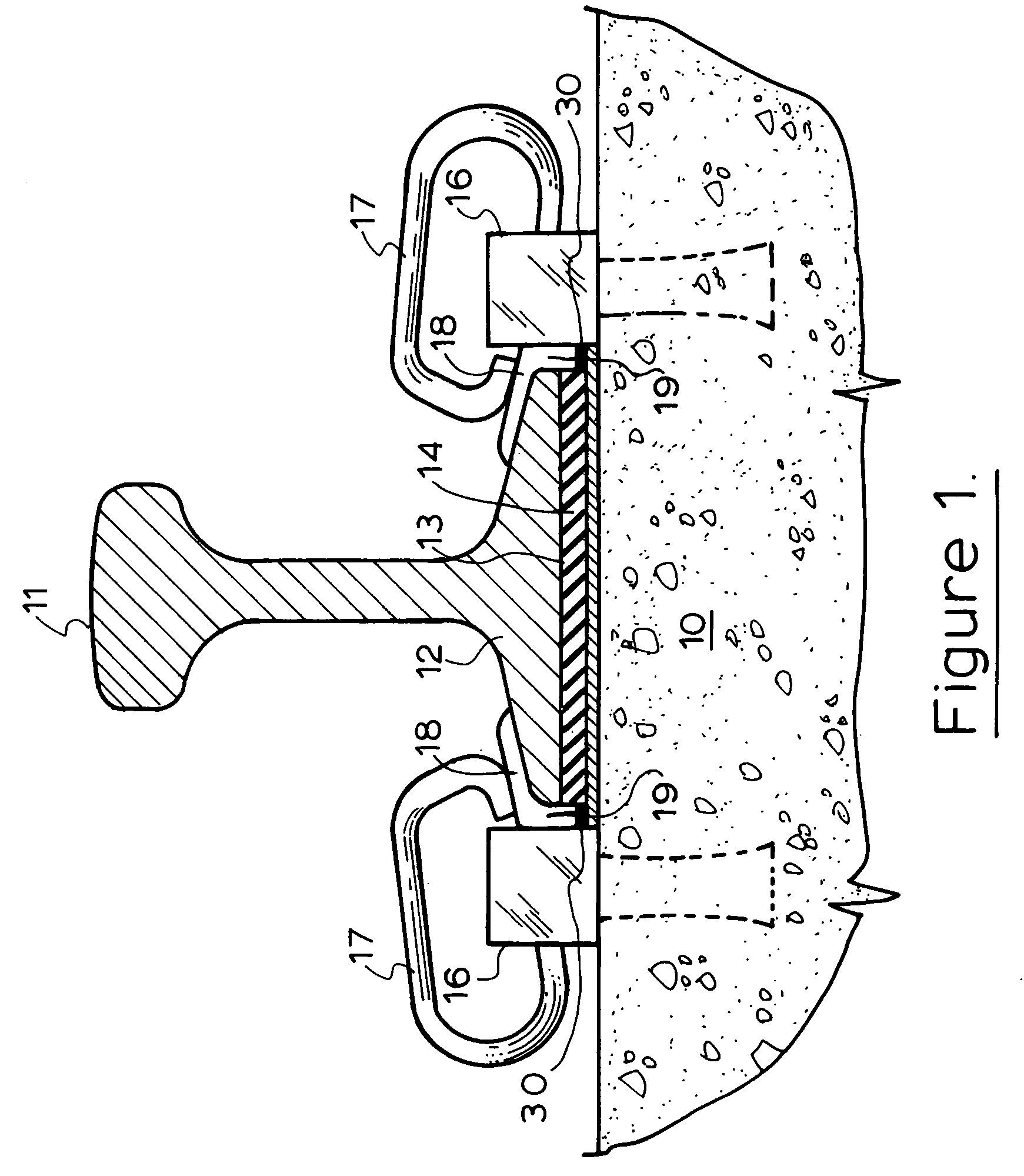

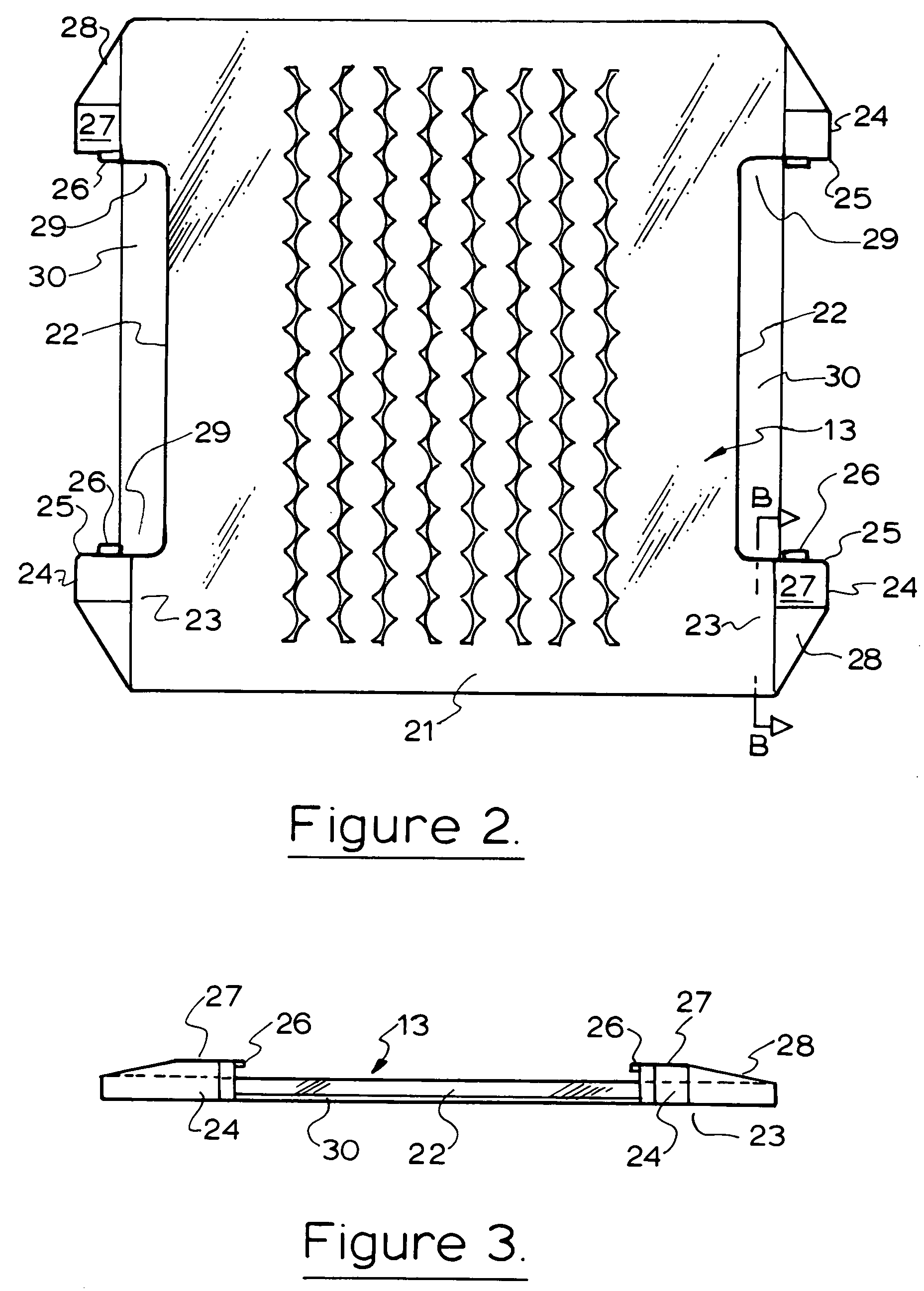

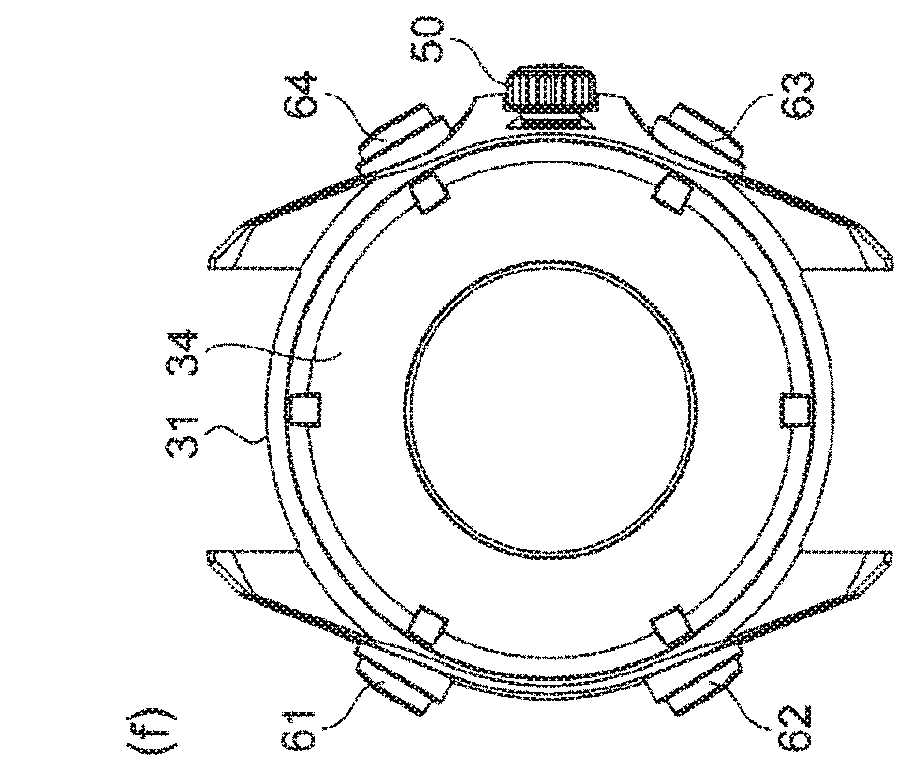

Rail seat assembly

A rail seat which includesa) a rail tieb) a pair of rail fastening support shoulders mounted on said rail tie so that a rail can be held to the tie between said shoulders each shoulder having a a rail face and side portions on each side of said rail face extending away from the railc) a rail pad adapted to lie on said tie between said shoulders which has a pair of projections extending parallel to the tie along side each side portion of each shoulder.The rail seat is adapted to be used with a deep post insulator and incorporates a rib on the support shoulder extending from each side portion against which a face of the rail pad projections abut to locate the pad in position to accommodate the post of the insulator. The rail pad projections are proportioned to prevent the pad from moving out of position under the creep load conditions present when rail cars pass over the rail seat. A resilient tab is provided on each projection to abut the side portions of the support shoulder to retain the pad in position between the support shoulders during transport of the rail tie to the installation site.

Owner:PROGRESS RAIL SERVICES

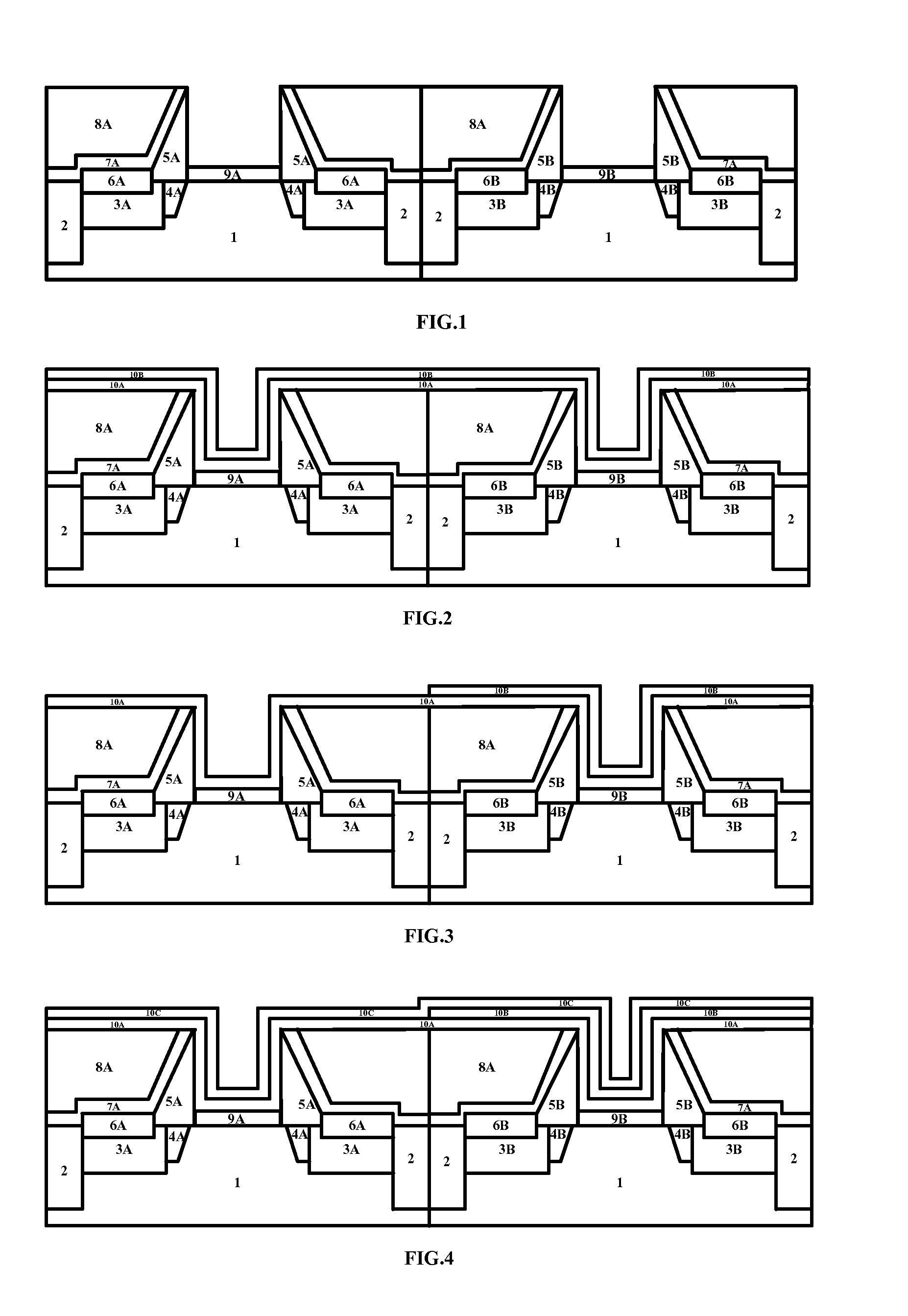

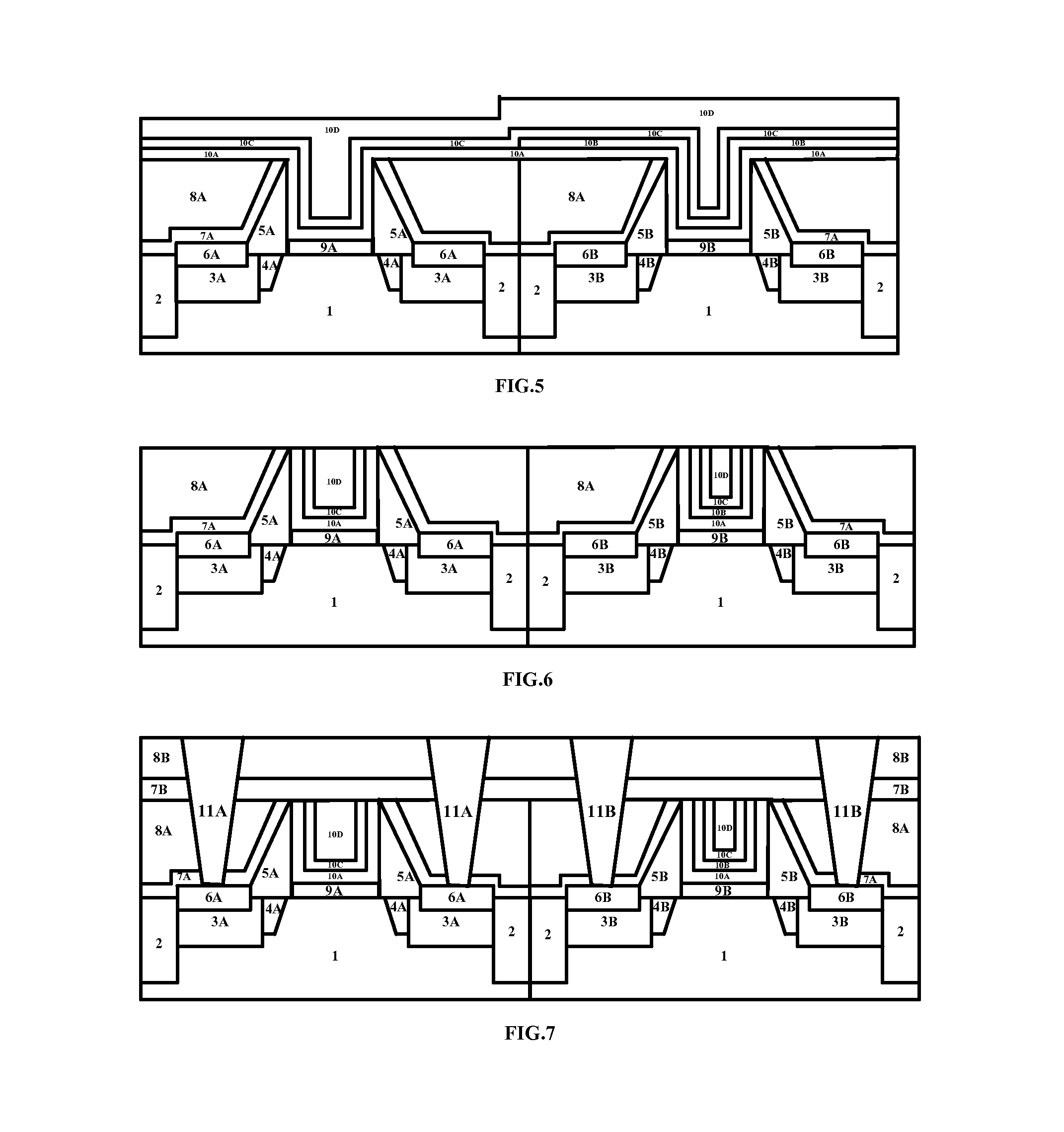

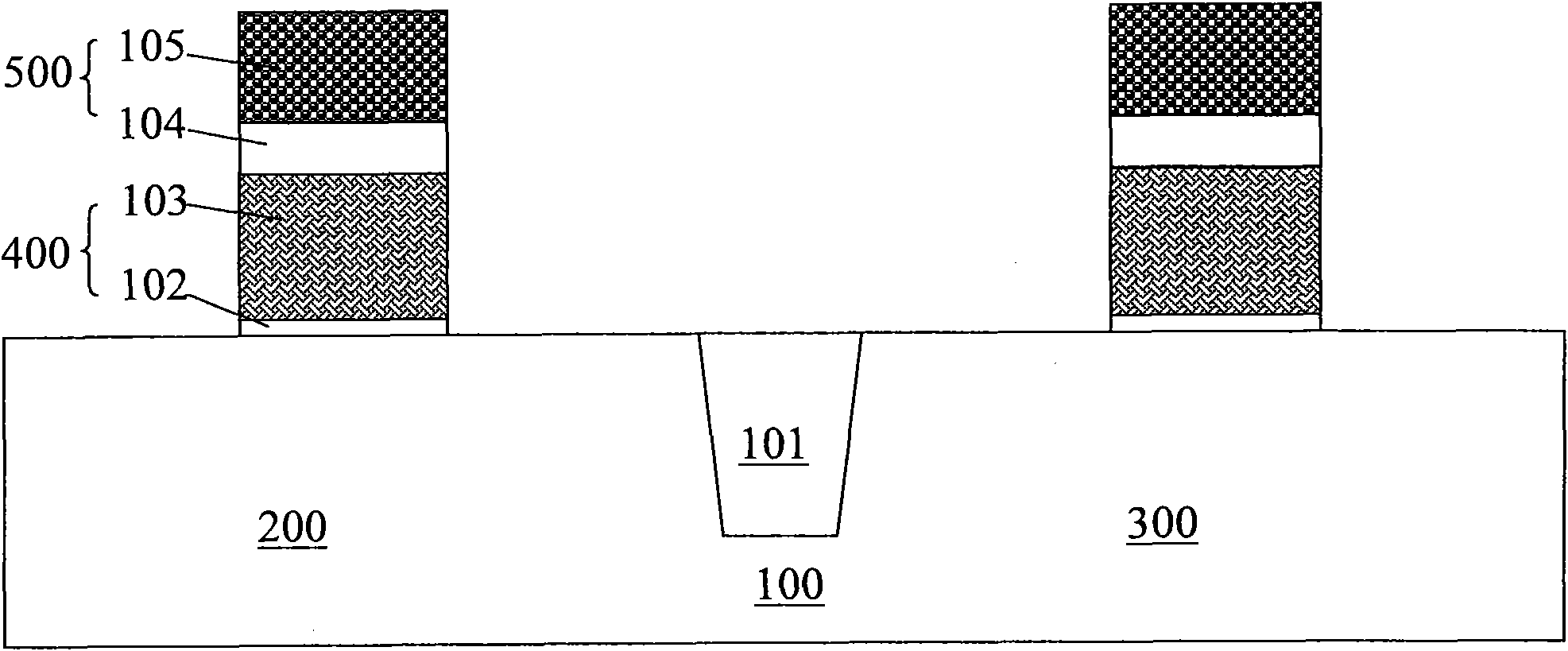

Semiconductor device and manufacturing method thereof

ActiveCN103579314ASimplified Gate StructureIncrease paddingTransistorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceInsulation layer

The invention discloses a semiconductor device which comprises a substrate, a plurality of grid stacking structures, a plurality of grid sidewall structures and a plurality of source-drain regions. The grid stacking structures are arranged on the substrate. The two sides of each grid stacking structure are provided with the grid sidewall structures. The positions, on the two sides of each grid sidewall structure, of the substrate are provided with the source-drain regions. The grid stacking structures comprise a plurality of first grid stacking structures and a plurality of second grid stacking structures. The semiconductor device is characterized in that each first grid stacking structure comprises a first grid insulation layer, a first blocking layer, a first work function regulating layer and a resistance regulating layer, and each second grid stacking structure comprises a second grid insulation layer, the first blocking layer, a second work function regulating layer, the first work function regulating layer and the resistance regulating layer. According to the semiconductor device and a manufacturing method thereof, firstly, an NMOS work function regulating layer is selectively deposited, and then a PMOS work function regulating layer is deposited. Consequently, a PMOS metal grid structure is simplified, metal grid work functions are effectively controlled, meanwhile, the filled spaces of the resistance regulating layers are enlarged, and the grid resistance is effectively reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

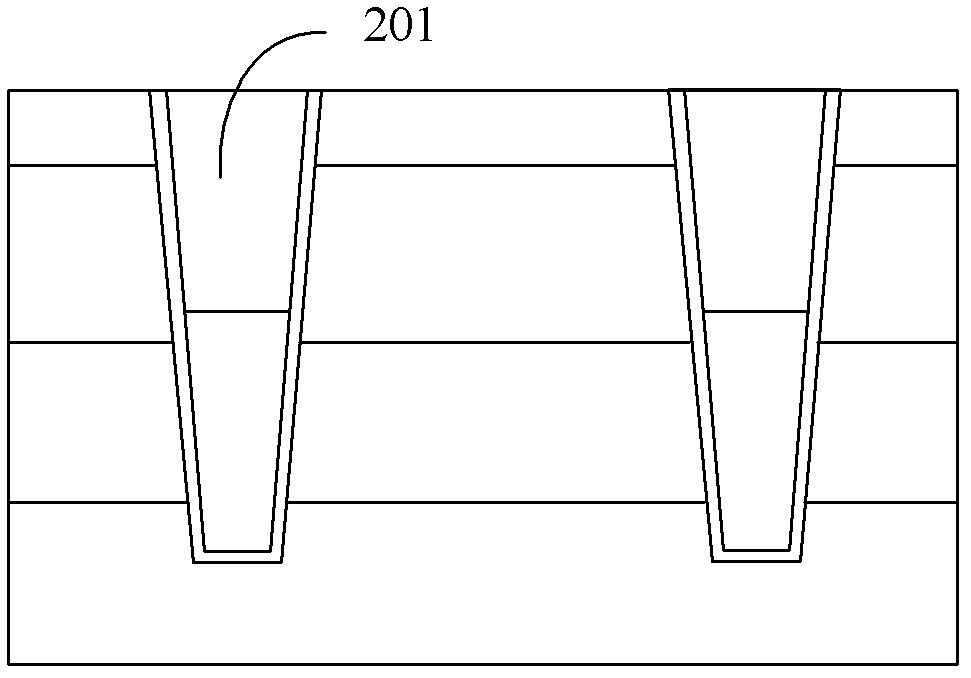

Method for manufacturing phase change memory

ActiveCN102810631AIncrease choiceSimple processSemiconductor/solid-state device manufacturingPhase-change memorySemiconductor materials

A method for manufacturing a phase change memory comprises the steps of providing a semiconductor substrate; imaging a first hard mask layer to form a first hard mask image; etching the first hard mask image used as a mask so as to form deep grooves; forming a liner layer for covering the deep grooves without damaging the shapes of the deep grooves; filling a semiconductor material in the deep grooves coated with the liner layer to form a semiconductor layer; removing a part of the liner layer positioned on the semiconductor layer; depositing a dielectric material on the semiconductor layer until the deep grooves are filled with the dielectric material; removing the redundant dielectric material through a planarization process until a second hard mask layer is exposed; imaging the second hard mask layer to form a second hard mask image; removing a part of the exposed dielectric layer of the second hard mask image by ashing, and forming a recess encircled by the rest dielectric layer and an epitaxial layer; and moving a part of the epitaxial layer by using the second hard mask image as a mask so as to form shallow grooves. The method for manufacturing the phase change memory is simple.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Display device using semiconductor light emitting device and method of manufacturing the same

ActiveUS9666765B2Increase paddingSolid-state devicesSemiconductor/solid-state device manufacturingFluorescencePhosphor

A display device including a plurality of semiconductor light emitting devices mounted on a substrate, and a phosphor layer including a plurality of phosphor portions configured to convert a wavelength of light and a plurality of partition wall portions formed between the plurality of phosphor portions. Further, a least one of the plurality of partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices along a thickness direction of the phosphor layer.

Owner:LG ELECTRONICS INC

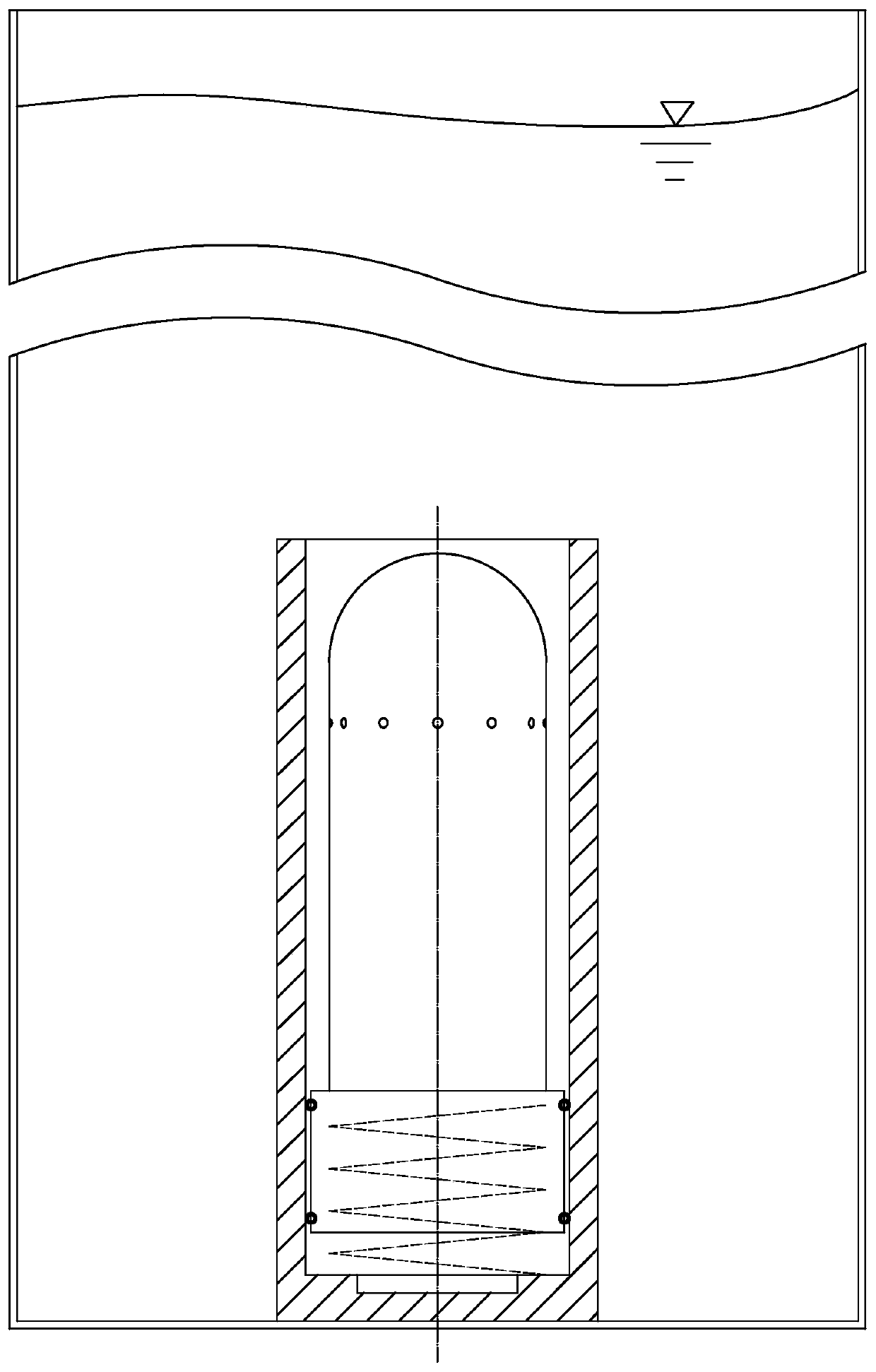

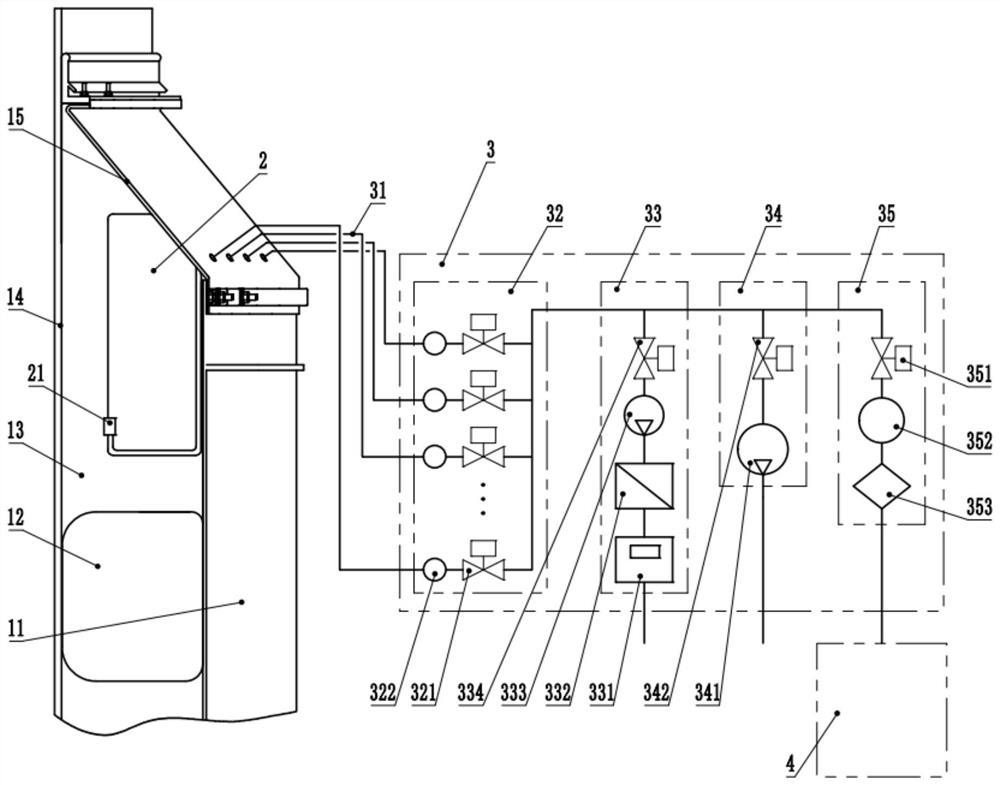

Underwater pressure-equalizing exhaust emission experiment device

ActiveCN110701952AControllable initial speedReduce angle of attackLaunching weaponsEngineeringMechanical engineering

The invention discloses an underwater pressure-equalizing exhaust emission experiment device. In the underwater pressure-equalizing exhaust emission experiment device, the situation that the free exhaust motion of a navigation body is difficult to study due to the given motion track of the navigation body is avoided. According to the underwater pressure-equalizing exhaust emission experiment device, the navigation body and a pusher are sequentially arranged in an emission cylinder from top to bottom, the navigation body is pushed by the pusher to make the action of emitting out of the emissioncylinder, the navigation body comprises a head cover and a cylinder body, the head cover is detachably connected to the top of the cylinder body, an exhaust hole is machined in the top of the cylinder body in the circumferential direction of the cylinder body, a first bottom hole is formed in the bottom of the cylinder body, a double-head piston is vertically arranged in the cylinder body, the upper end of the double-head piston is tightly attached to the exhaust hole, the lower end of the double-head piston is arranged at the bottom of the cylinder body, and a sealing ring is arranged outside the exhaust hole of the cylinder body in a sleeving mode. The underwater pressure-equalizing exhaust emission experiment device is used for underwater emission experiments of the navigation body.

Owner:HARBIN INST OF TECH AT WEIHAI

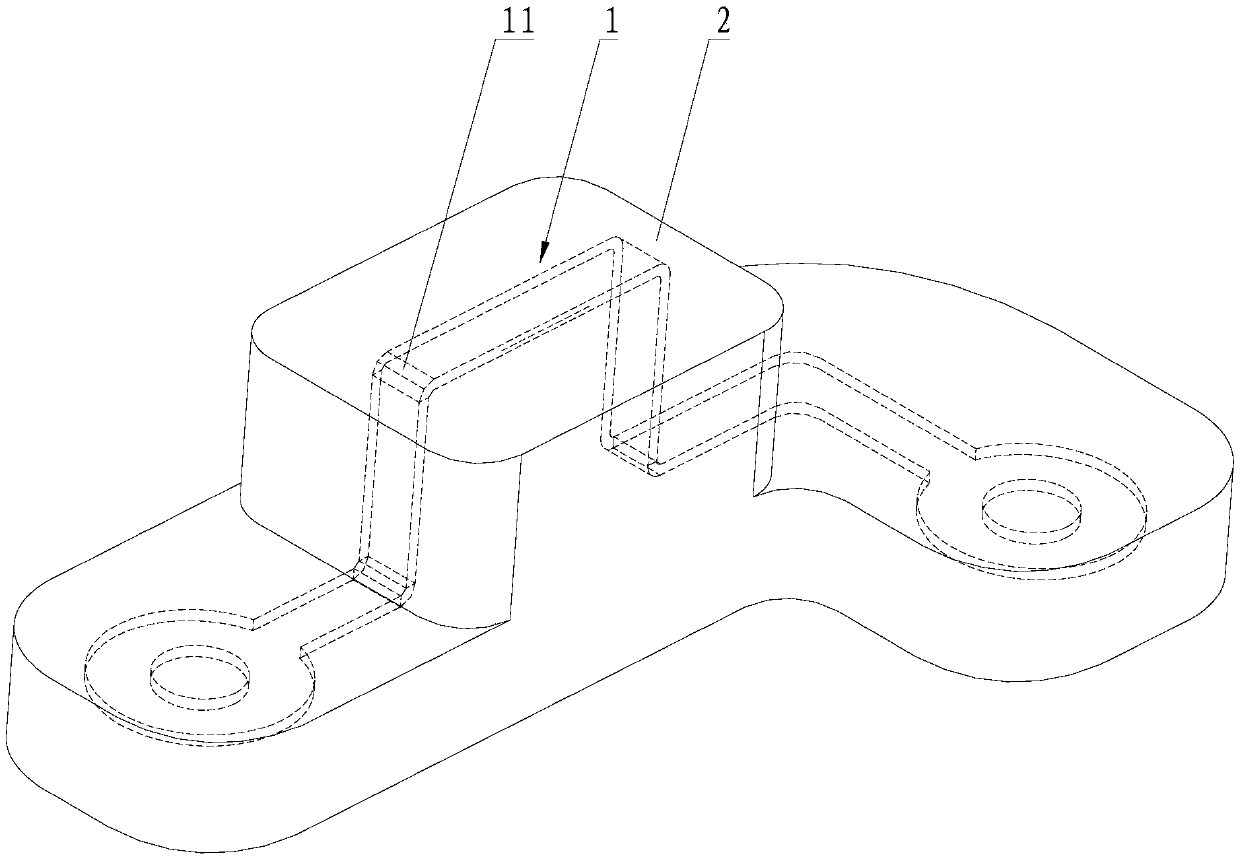

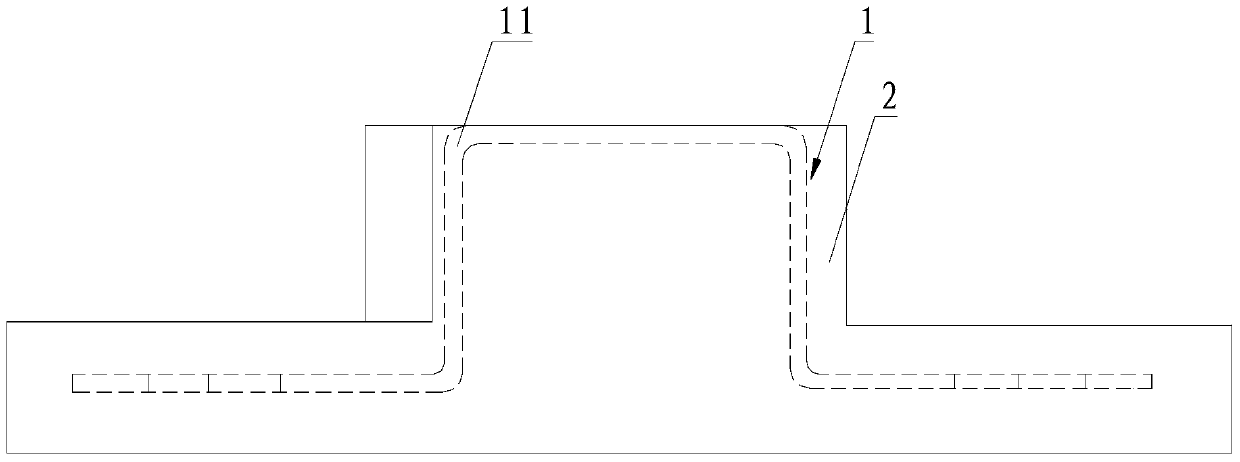

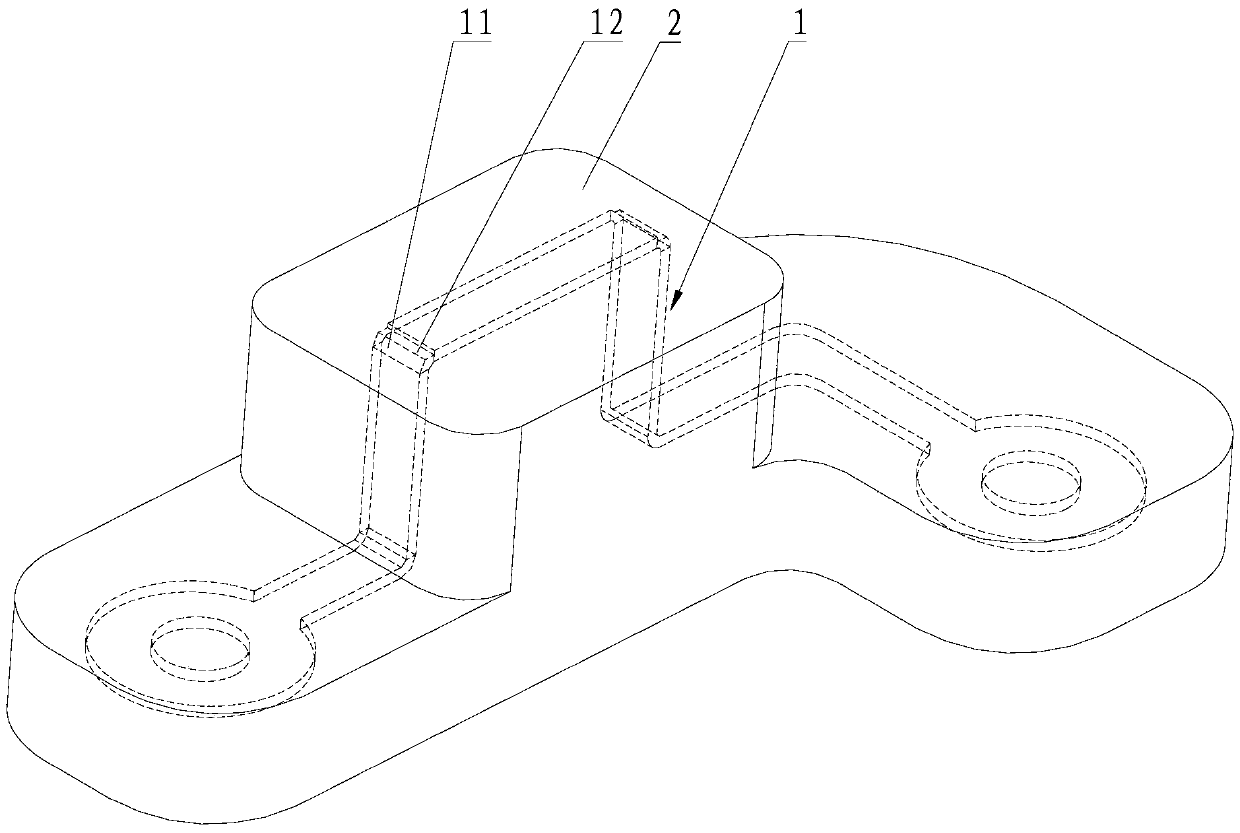

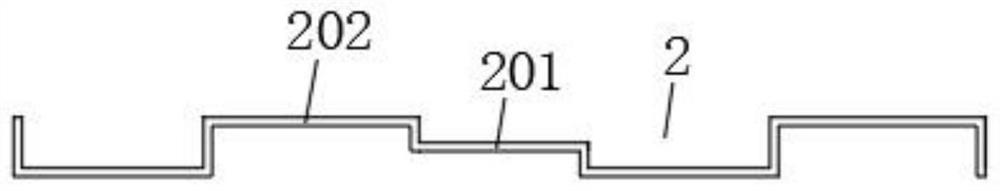

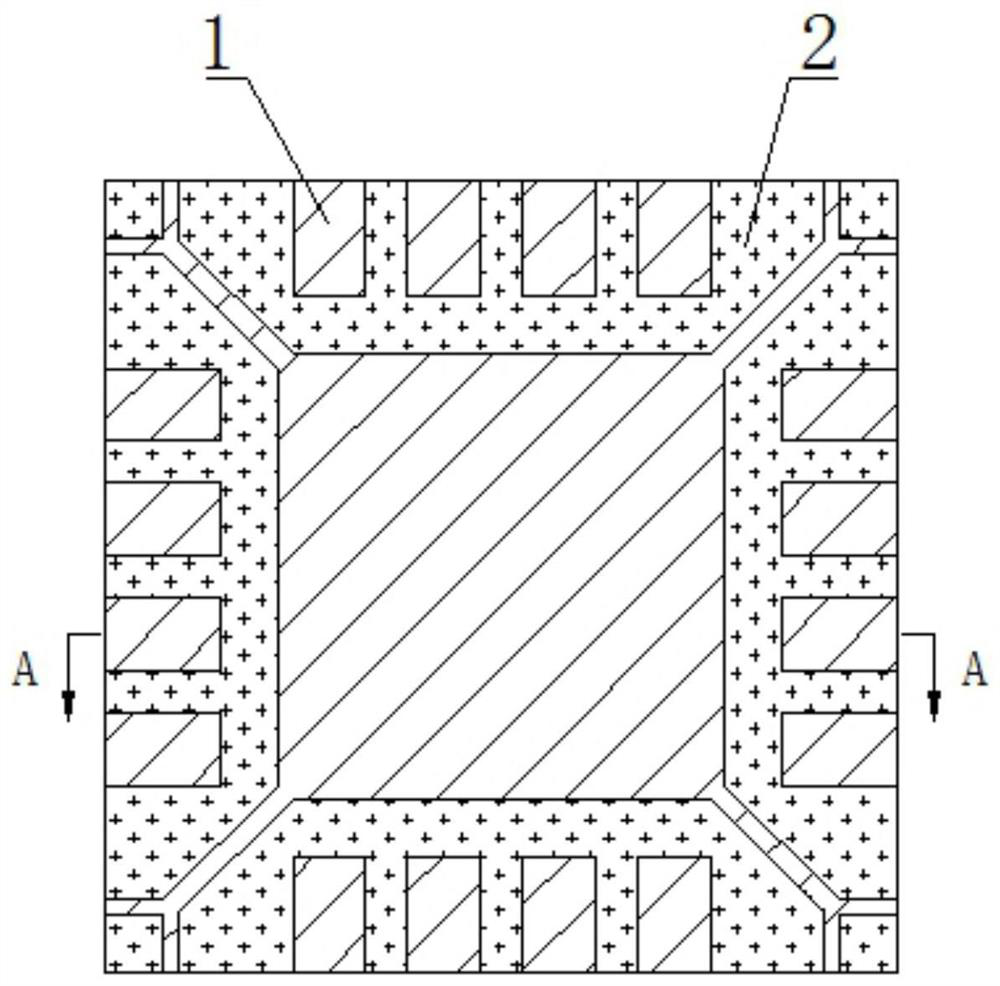

Insert structure for injection moulding

The invention discloses an insert structure for injection moulding. The insert structure comprises an insert body. A bent part is arranged on the insert body. A step part is arranged on the bent part. According to the insert structure for injection moulding, the defects of injection moulding can be avoided, it is unnecessary to modify an injection moulding mould, the defects of injection moulding can be overcome with the low cost, and production competitiveness of enterprises is improved.

Owner:SHENZHEN SUNWAY COMM

Display device using semiconductor light emitting device and method for manufacturing

ActiveUS10096750B2Increase paddingAvoid mixing colorsSolid-state devicesSemiconductor devicesPhosphorDisplay device

A display device include a substrate including a wiring electrode; an adhesive layer disposed on the substrate; a plurality of semiconductor light emitting devices adhered to the adhesive layer, and electrically connected to the wiring electrode; and a phosphor layer disposed to cover the plurality of semiconductor light emitting devices. Further, the phosphor layer includes a plurality of phosphor portions for converting a wavelength of light, and a plurality of partition wall portions formed between the plurality of phosphor portions, and the plurality of partition wall portions are sequentially disposed between the phosphor portions along a first direction and a second direction crossing each other, respectively, and at least one of the sequentially disposed partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices.

Owner:LG ELECTRONICS INC

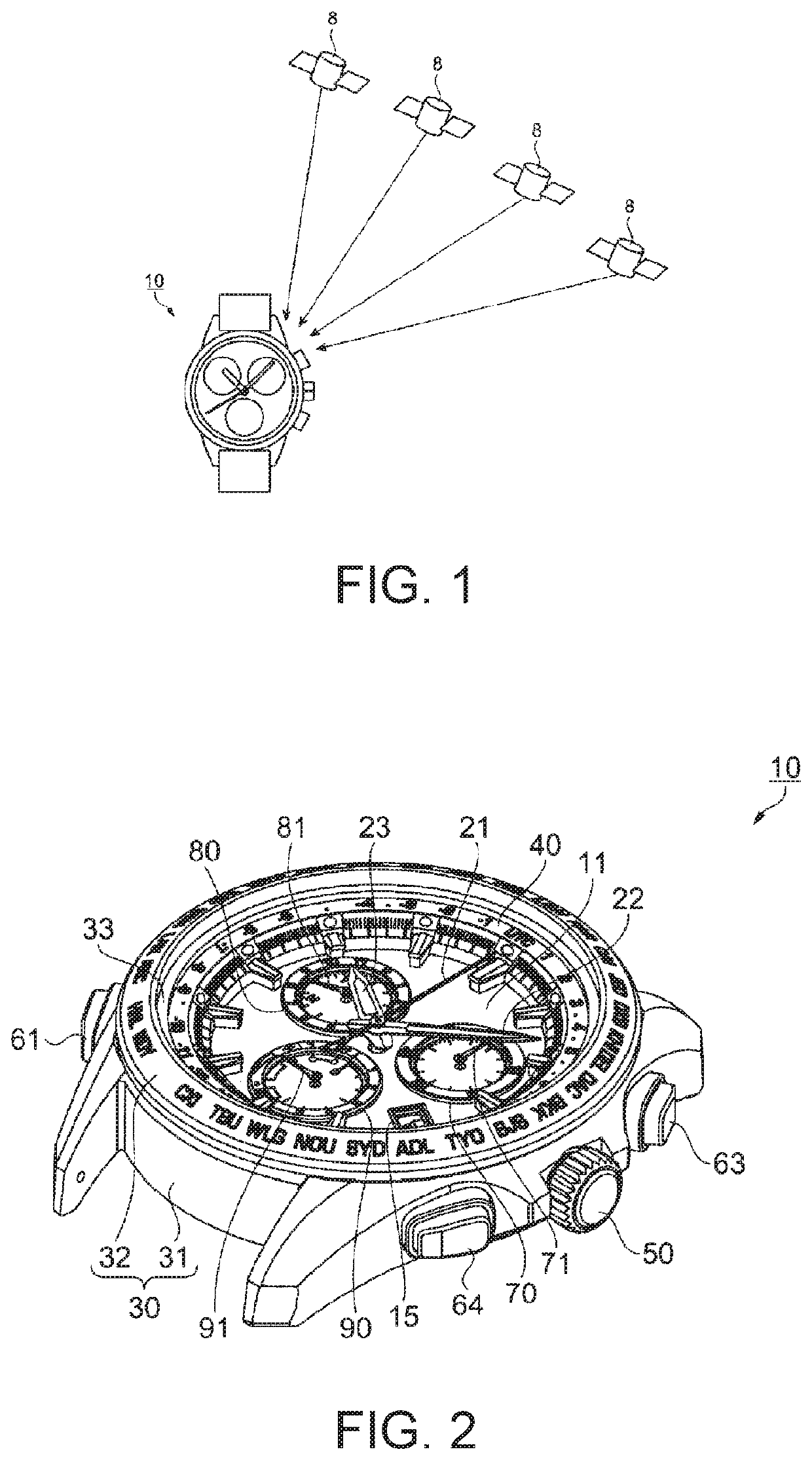

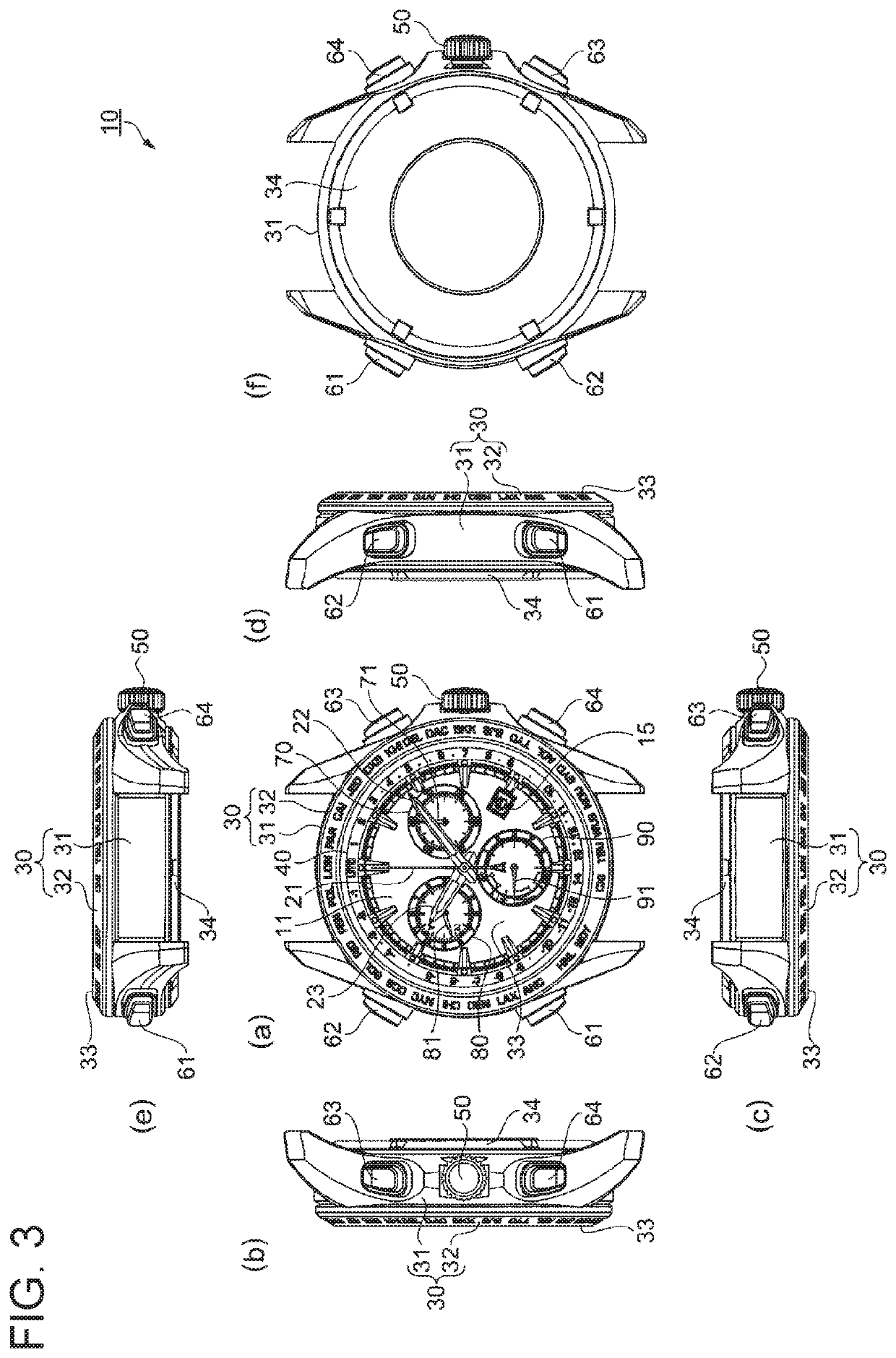

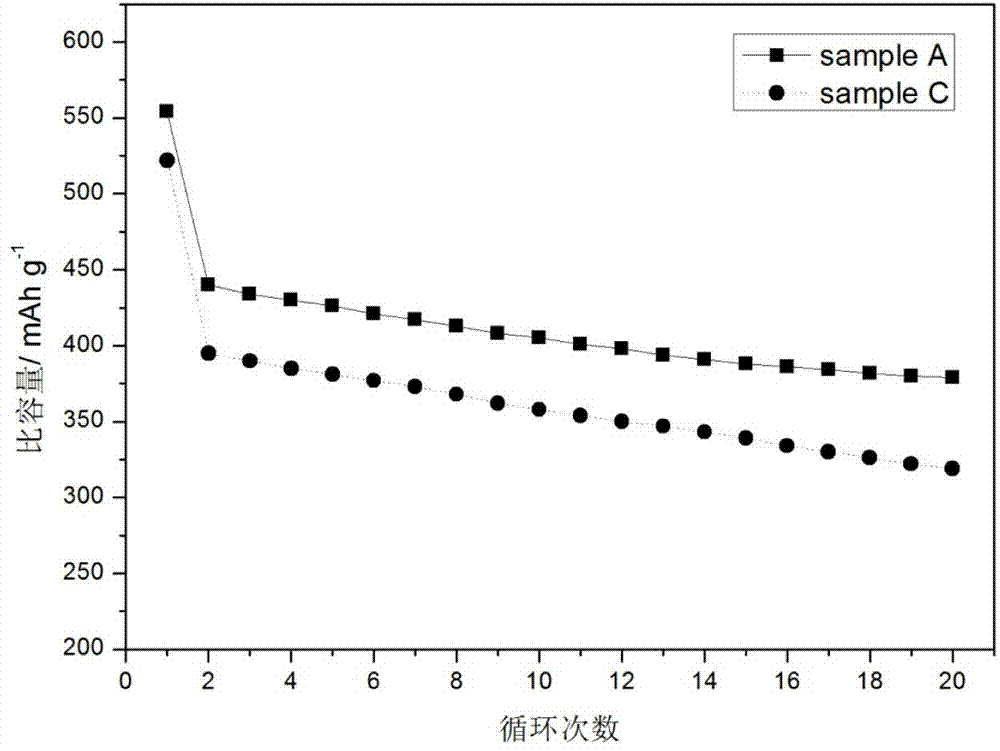

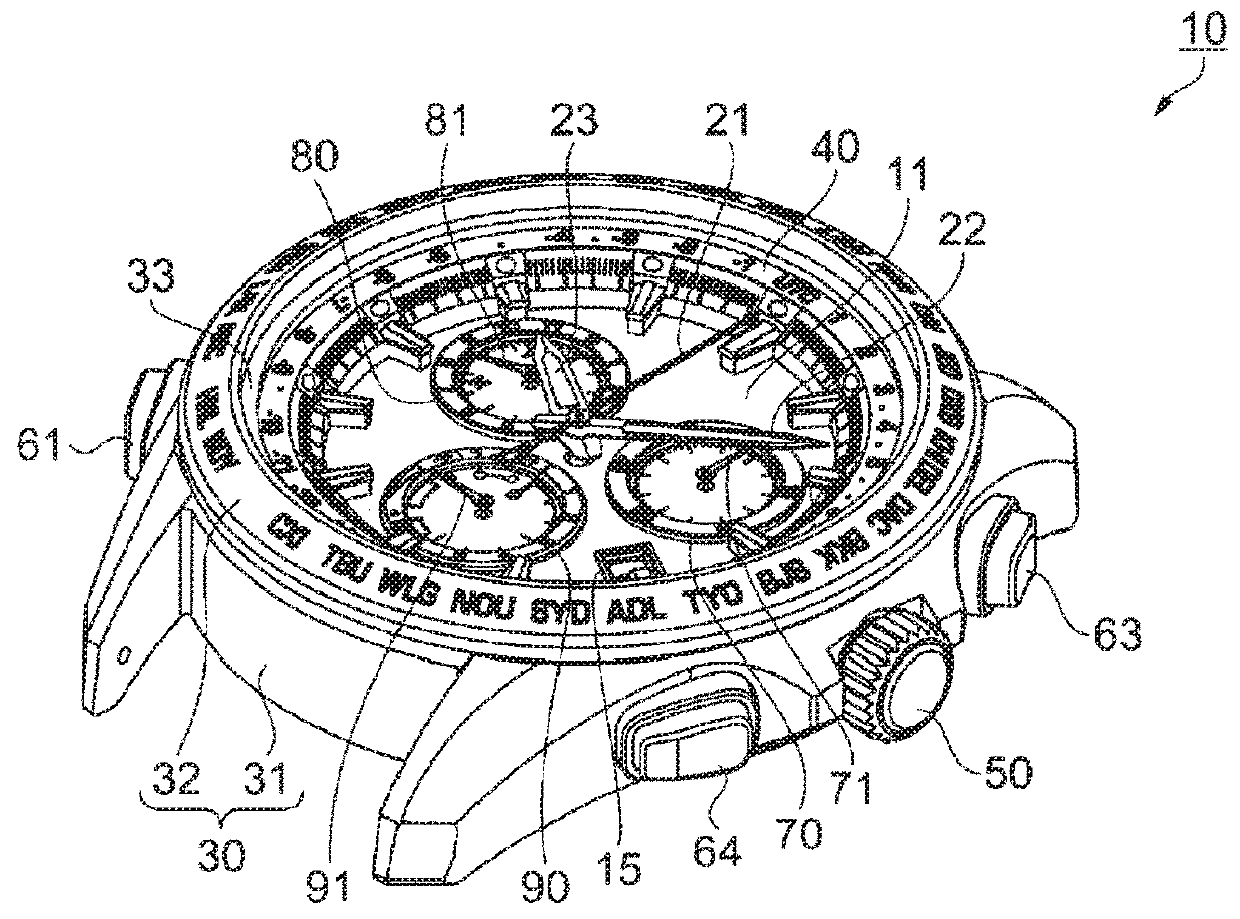

Electronic timepiece

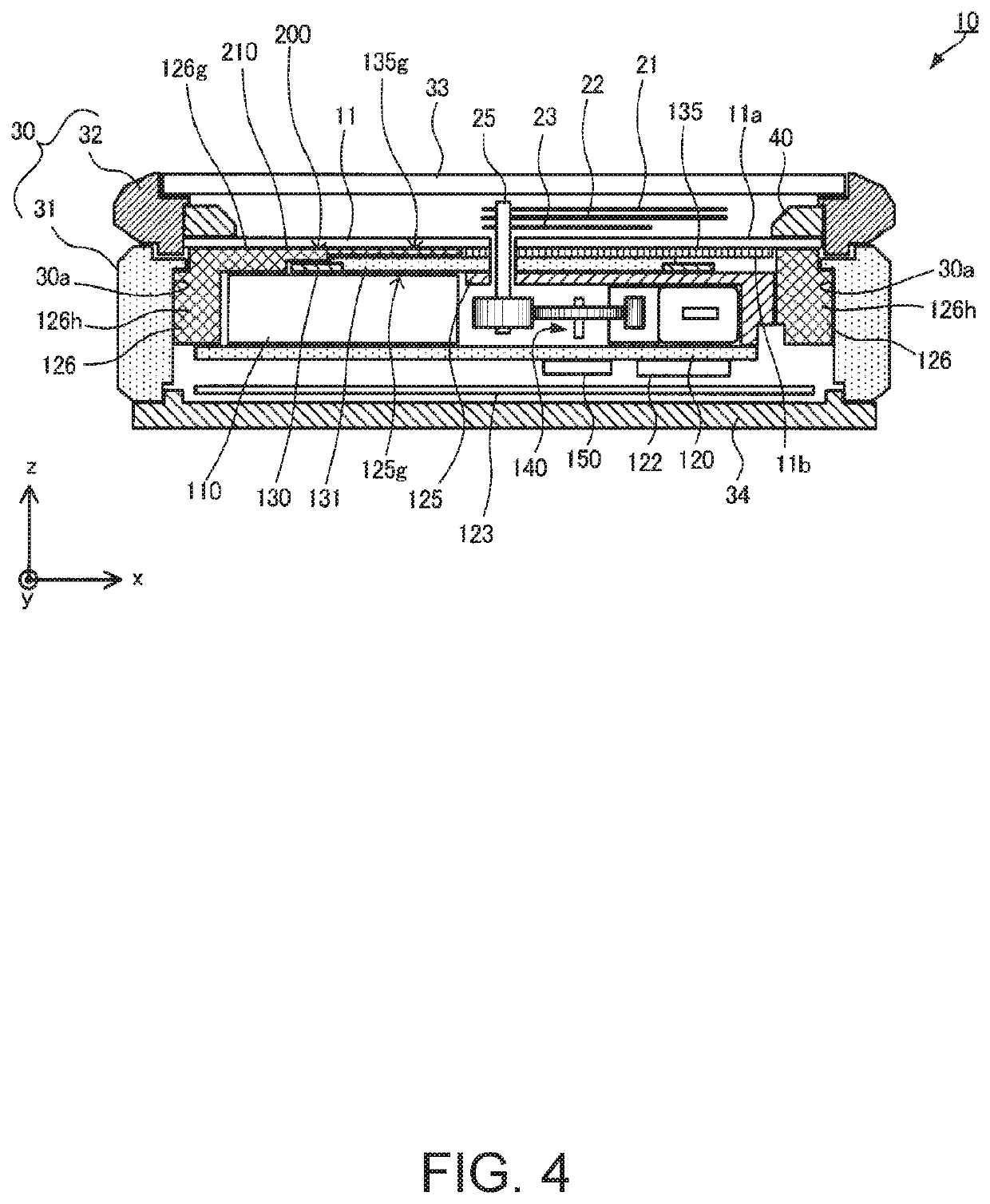

ActiveUS10802448B2Inhibition of thickness increaseIncrease paddingElectronic time-piece structural detailsElectric power supply circuitsElectrical batteryEngineering

Provided is technology that suppresses increasing the thickness of the electronic timepiece when a member is provided to obscure the area where the solar battery is not located above the antenna. An electronic timepiece has: an optically transmissive dial; a solar battery having a photovoltaic solar cell; an antenna disposed relative to the dial in the direction in which the external light is emitted, and configured to receive radio signals; and a cover member having a first part disposed between the dial and the antenna. In plan view, the antenna has a part that does not overlap the solar cell; the first part has a part that does overlaps the part of the antenna that does not overlap the solar cell; and in section view perpendicular, has an overlap between the first part and the solar battery.

Owner:SEIKO EPSON CORP

Method of manufacturing semiconductor device

ActiveUS8853024B2Lower gate resistanceEffective controlTransistorSemiconductor/solid-state device manufacturingEtchingDevice material

The present invention discloses a method for manufacturing a semiconductor device comprising the steps of: forming a plurality of source and drain regions in a substrate; forming a plurality of gate spacer structures and an interlayer dielectric layer around the gate spacer structures on the substrate, wherein the gate spacer structures enclose a plurality of first gate trenches and a plurality of second gate trenches; sequentially depositing a first gate insulating layer and a second gate insulating layer, a first blocking layer and a second work function regulating layer in the first and second gate trenches; performing selective etching to remove the second work function regulating layer from the first gate trenches to expose the first blocking layer; depositing a first work function regulating layer on the first blocking layer in the first gate trenches and on the second work function regulating layer in the second gate trenches; and depositing a resistance regulating layer on the first work function regulating layer in the first gate trenches and on the first work function regulating layer in the second gate trench.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

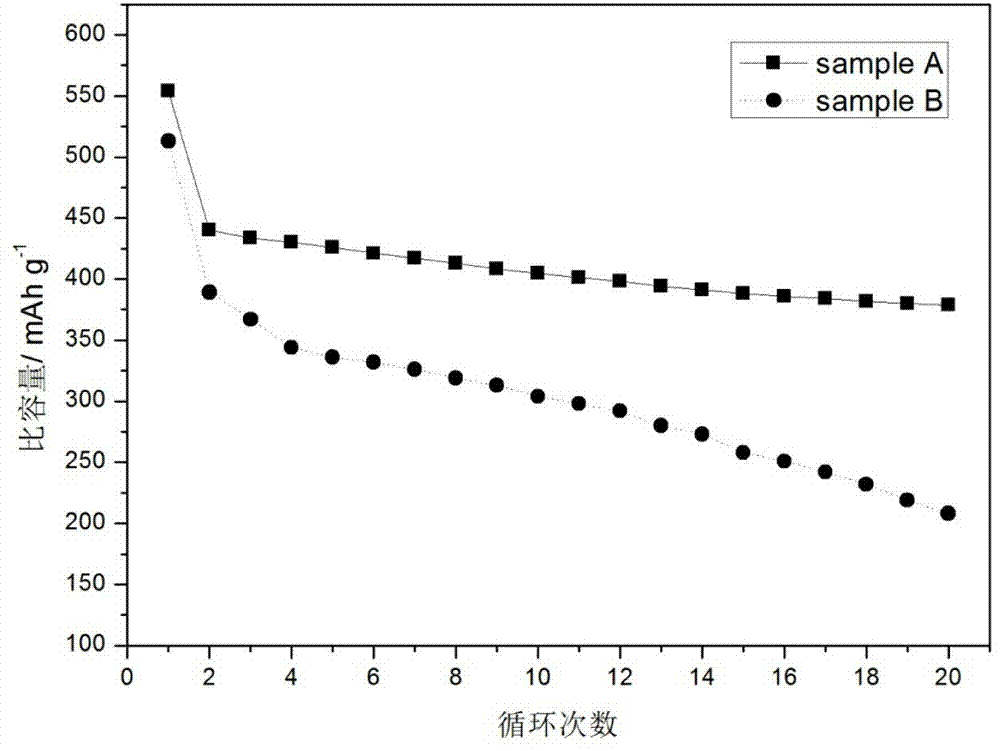

Method for manufacturing tin-stibium-nickel alloy cathode material of lithium ion battery

The invention discloses a method for manufacturing a tin-stibium-nickel alloy cathode material of a lithium ion battery, comprising the following steps of: taking a carbon fiber cloth as a substrate; and adopting an electrodeposition process to plate tin-stibium-nickel alloys on the substrate, wherein a tin-stibium-nickel electrodeposition solution comprises 0.1-0.5 mol / L of soluble tin salt, 0.1-0.5 mol / L of soluble stibium salt, 0.1-0.5 mol / L of soluble nickel salt, 0.08-0.12 mol / L of ammonium salt, 0.08-0.12 mol / L of surface active agent. The electrodeposition process is utilized to manufacture the tin-stibium-nickel alloys, and a ternary alloy structure buffers volume change of the cathode material in the process of lithium insertion / extraction. Double-active components can insert / extract lithium at different levels, thus improving the insertion / extraction efficiency; and non-active components are introduced to reduce the volume expansibility in the process of lithium insertion / extraction. In addition, the carbon fiber cloth has a lithium storage function, so that the flexibility of the carbon fiber cloth also buffers the volume change of the alloys on the substrate effectively. Therefore, the manufactured tin-stibium-nickel alloys can improve the capacity and cyclical stability of the lithium ion battery. The method is simple in operation, can be carried out in water, is environmentally-friendly, and is in no need of high temperature and high pressure as well as inert gas protection. Performances can be controlled, and the thickness of an alloy layer can be changed by changing electrodeposition current density and time, thus regulating and controlling the weight or capacity of the material.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Electronic timepiece

ActiveUS20180275619A1Increasing the thicknessInhibition of thickness increaseElectronic time-piece structural detailsElectric power supply circuitsElectrical batteryEngineering

Provided is technology that suppresses increasing the thickness of the electronic timepiece when a member is provided to obscure the area where the solar battery is not located above the antenna. An electronic timepiece has: an optically transmissive dial; a solar battery having a photovoltaic solar cell; an antenna disposed relative to the dial in the direction in which the external light is emitted, and configured to receive radio signals; and a cover member having a first part disposed between the dial and the antenna. In plan view, the antenna has a part that does not overlap the solar cell; the first part has a part that does overlaps the part of the antenna that does not overlap the solar cell; and in section view perpendicular, has an overlap between the first part and the solar battery.

Owner:SEIKO EPSON CORP

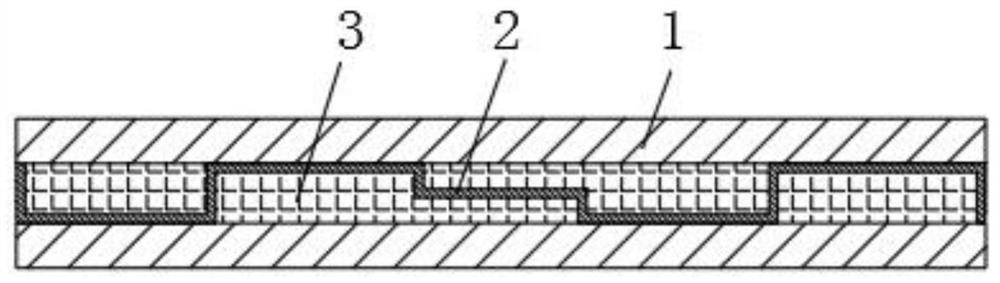

Composite fireproof heat preservation plate based on inorganic light aggregate and preparation method thereof

InactiveCN112267586AHigh strengthReduce weightMetal-working feeding devicesHeat proofingAggregate (composite)Heat conservation

The invention discloses a composite fireproof heat preservation plate based on inorganic light aggregate and a preparation method thereof, the heat preservation plate comprises two inorganic light aggregate plates, a connecting rib plate is fixedly mounted between the two inorganic light aggregate plates, a filling layer is arranged in a gap between each of the two inorganic light aggregate platesand the connecting rib plate, a sealing plate is fixedly installed at one ends of the two inorganic light aggregate plates, the other sealing plate is fixedly installed at the other ends of the two inorganic light aggregate plates, the two sealing plates are arranged at openings in the two ends of the connecting rib plate respectively, the connecting rib plate comprises a connecting plate and twoS-shaped plates, the two S-shaped plates are fixedly connected to the two ends of the connecting plate correspondingly, and the two S-shaped plates are distributed in a central symmetry mode relativeto the center of the connecting plate. According to the composite fireproof heat preservation plate based on inorganic light aggregate and the preparation method thereof, the composite fireproof heatpreservation plate is high in strength, the overall weight of the composite fireproof heat preservation plate is reduced under the condition that the heat preservation and fire prevention performanceof the composite fireproof heat preservation plate is guaranteed, and transportation and use are facilitated.

Owner:舒城诚鑫建材有限公司

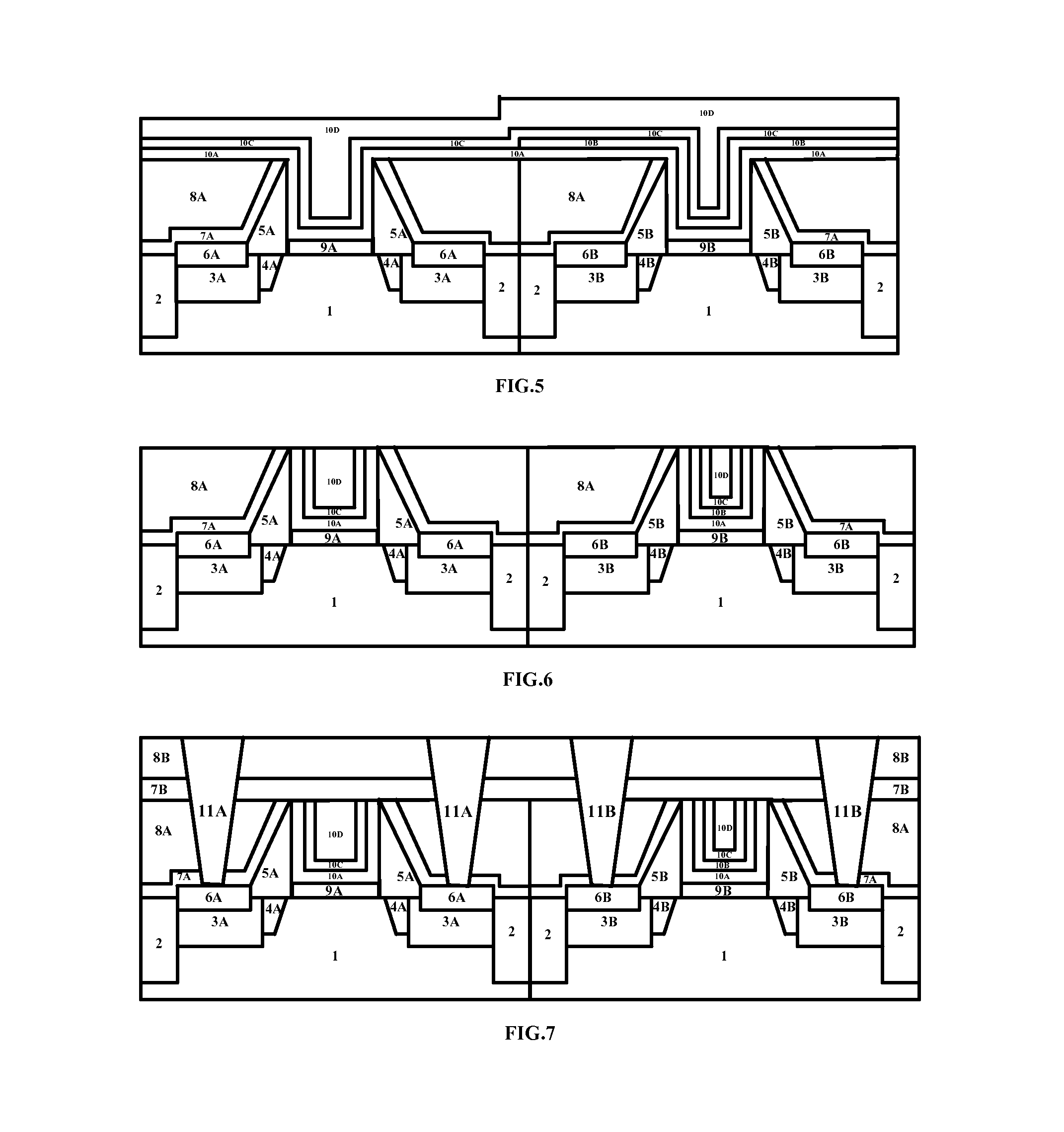

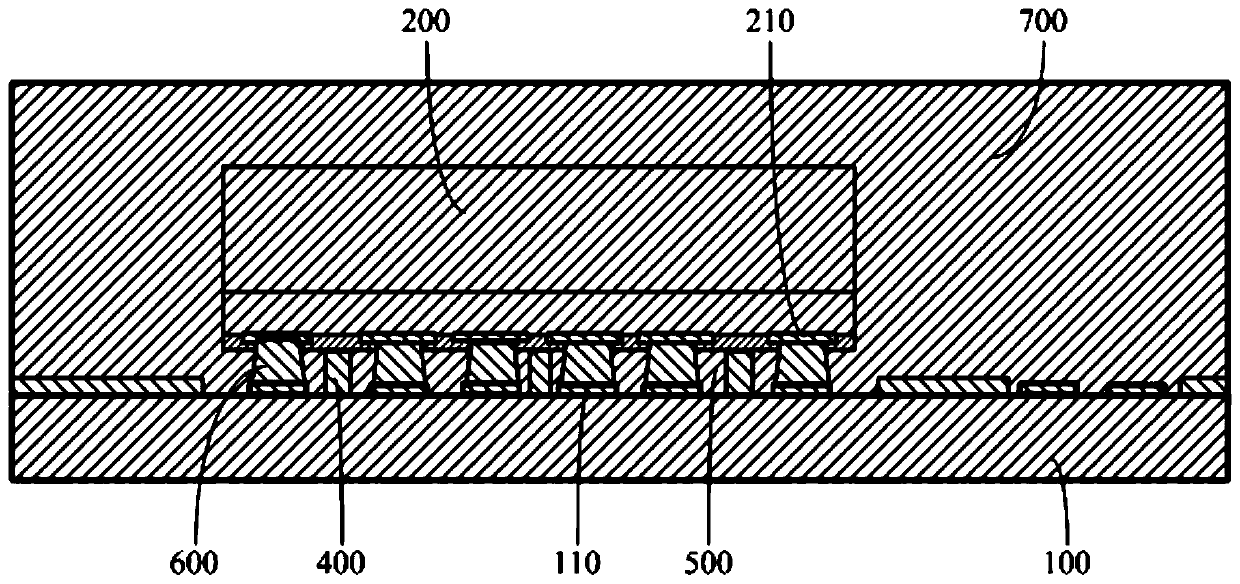

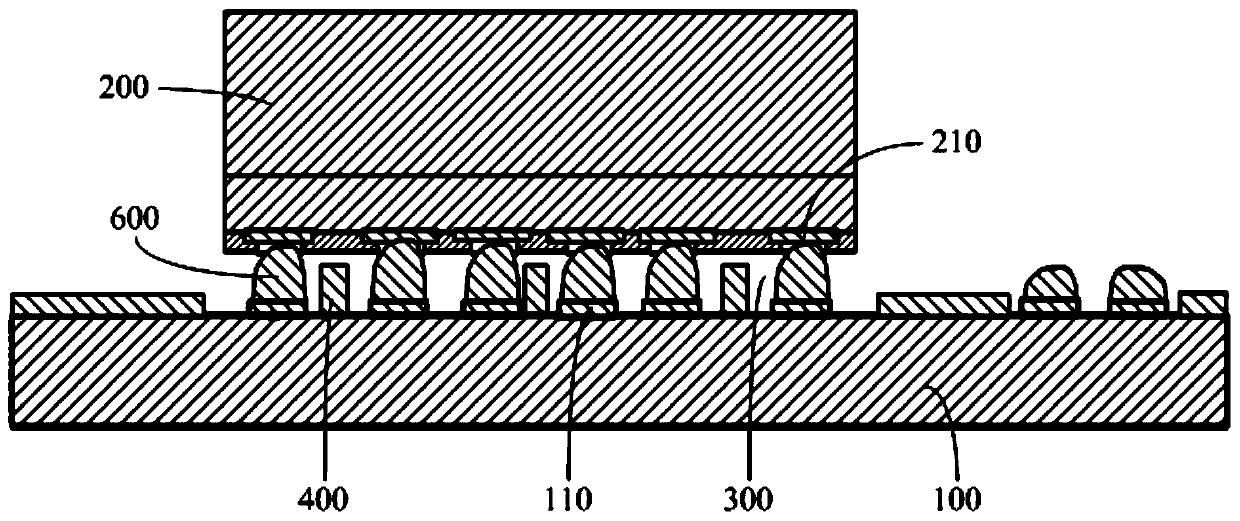

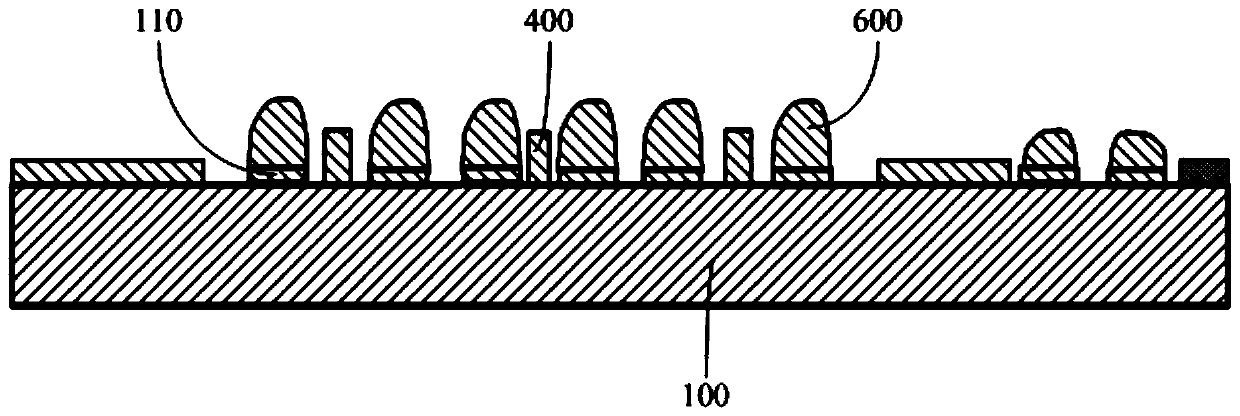

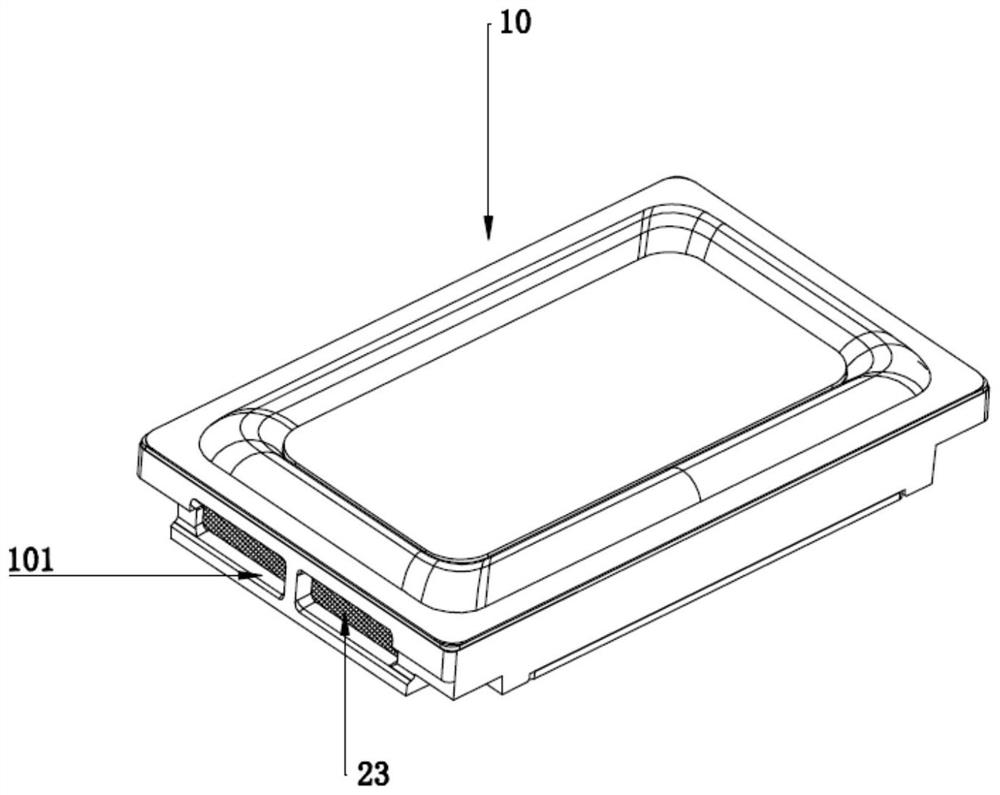

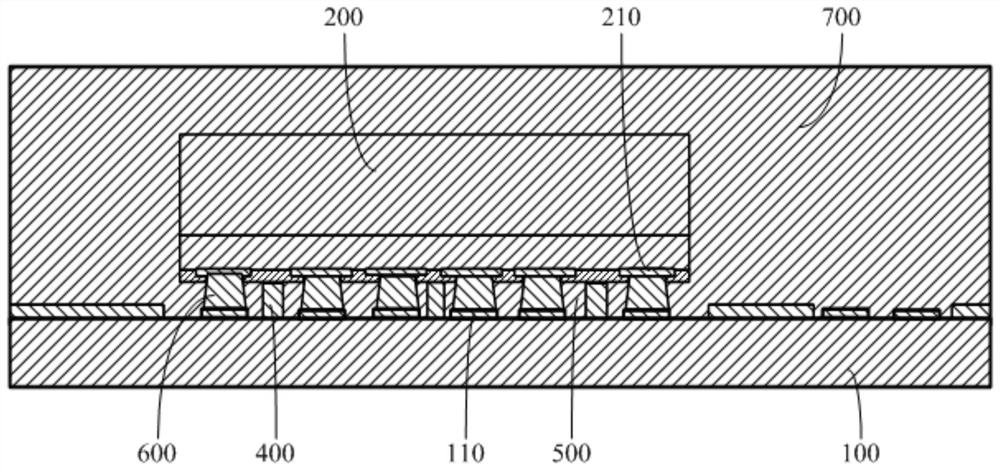

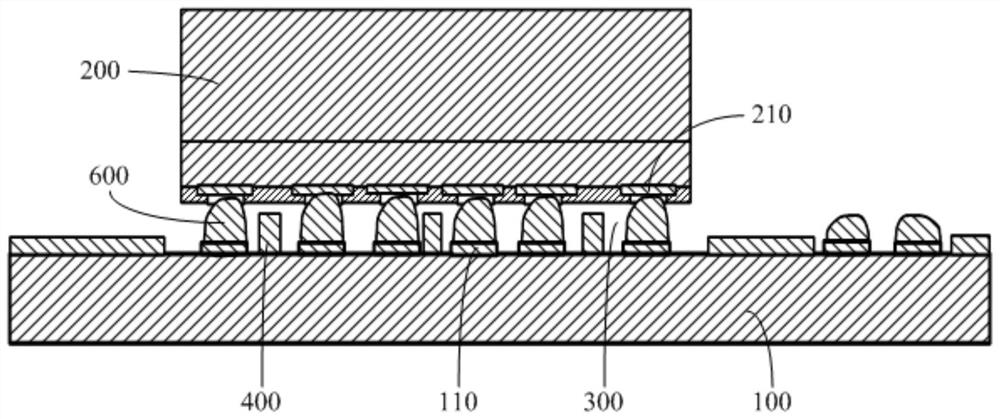

Circuit board device, preparation method thereof and electronic equipment

ActiveCN111354705AAvoid voidsFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

The invention discloses a circuit board device, and the circuit board device comprises: a substrate (100) which is provided with a first bonding pad (110); a chip module (200) wich is provided with asecond bonding pad (210), wherein the first bonding pad (110) is electrically connected with the second bonding pad (210), and a filling space (300) is formed between the chip module (200) and the substrate (100); a supporting piece (400) which is supported between the substrate (100) and the chip module (200); and a filling part (500) which is filled into the filling space (300) . According to the scheme, the problem that the packaged chip is prone to short circuit in the packaging process on the circuit board can be solved. The invention further discloses a preparation method of the circuitboard device and electronic equipment.

Owner:维沃移动通信(重庆)有限公司

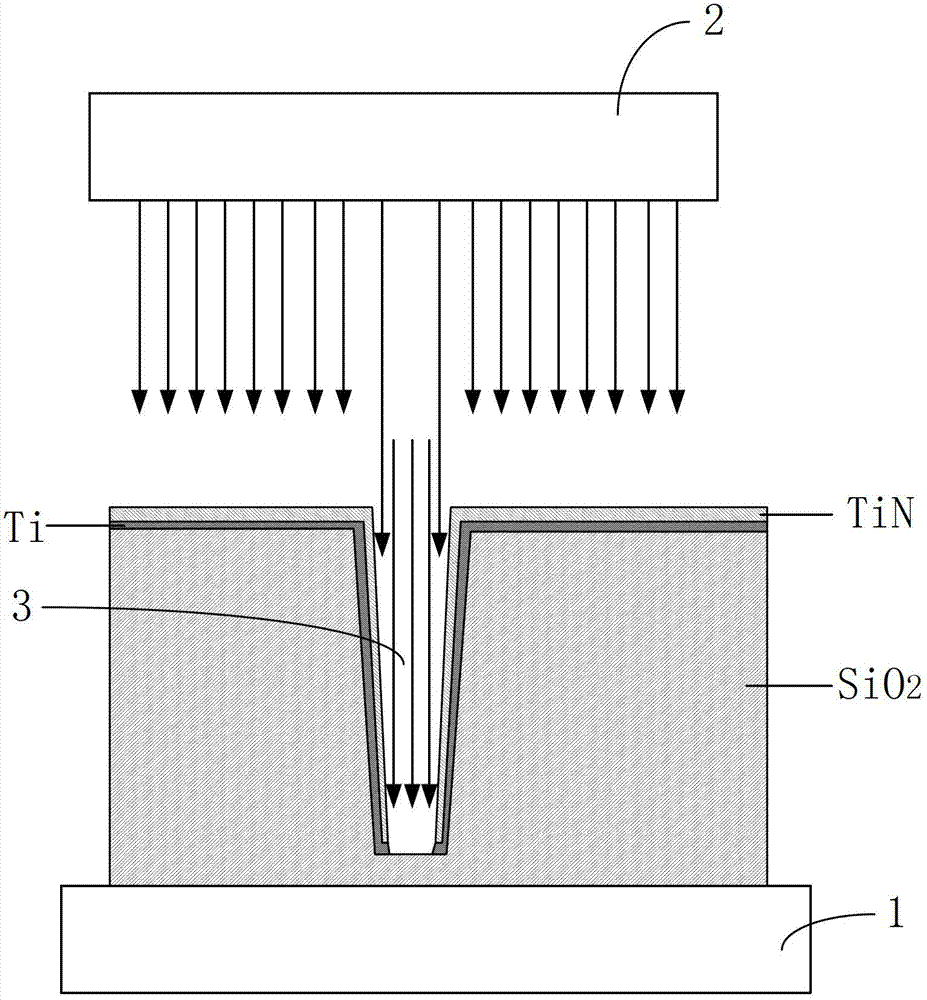

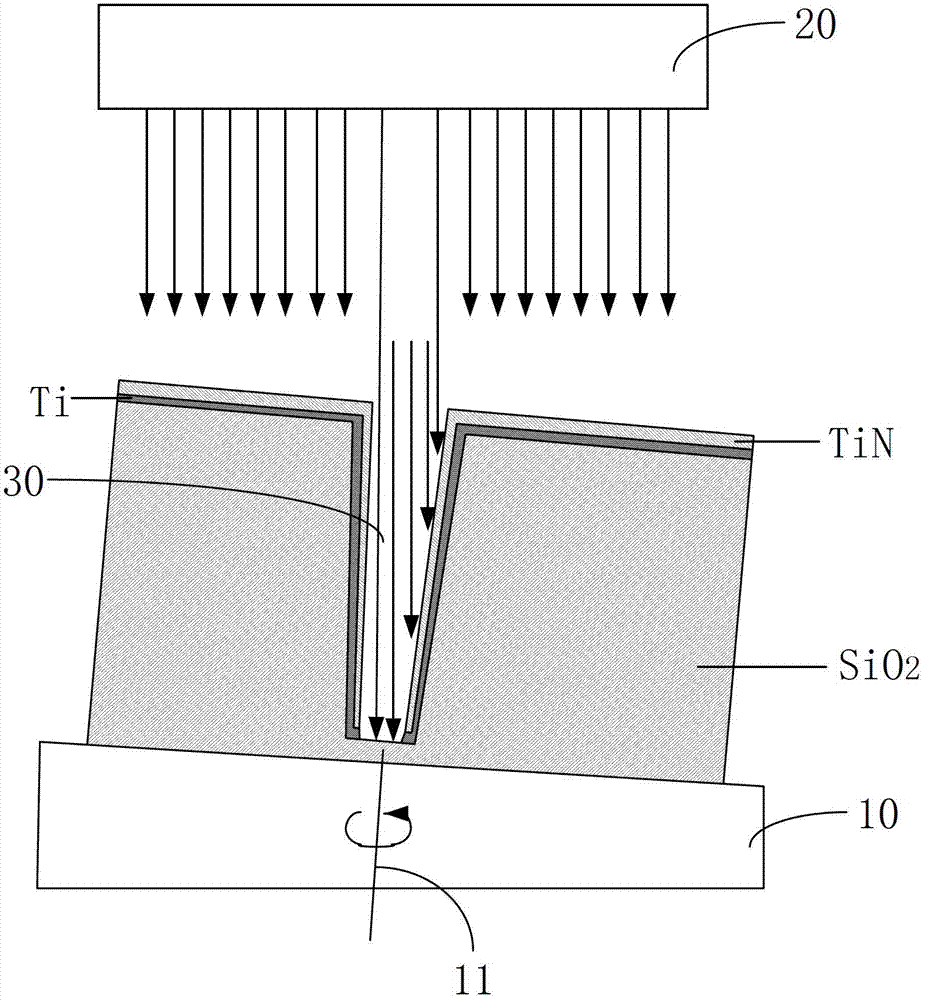

Titanium nitride chemical vapor deposition device

InactiveCN103194730AIncrease paddingQuality improvementChemical vapor deposition coatingTitanium nitrideChemical vapor deposition

The invention relates to a titanium nitride chemical vapor deposition device which comprises a base used for bearing a silicon wafer, and a spray head arranged at the upper end of the silicon wafer, wherein the included angle formed between the plane on which the upper surface of the base is arranged and the spraying direction of the spray head is 60-89 degrees; the titanium nitride chemical vapor deposition device also comprises a driving part which is connected with the base; and the driving part is used for driving the base to rotate around a rotating shaft which is vertical to the upper surface the base. The base is arranged in an inclined way, so that the side wall at the lower side of a tungsten through hole can be fully contacted with plasma, and the plasma can be treated; and furthermore, the base can be driven to rotate by the driving part, so that all the side walls of the tungsten through hole can be fully contacted with the plasma, so that the filling space of tungsten is enlarged, and the quality of the silicon wafer is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

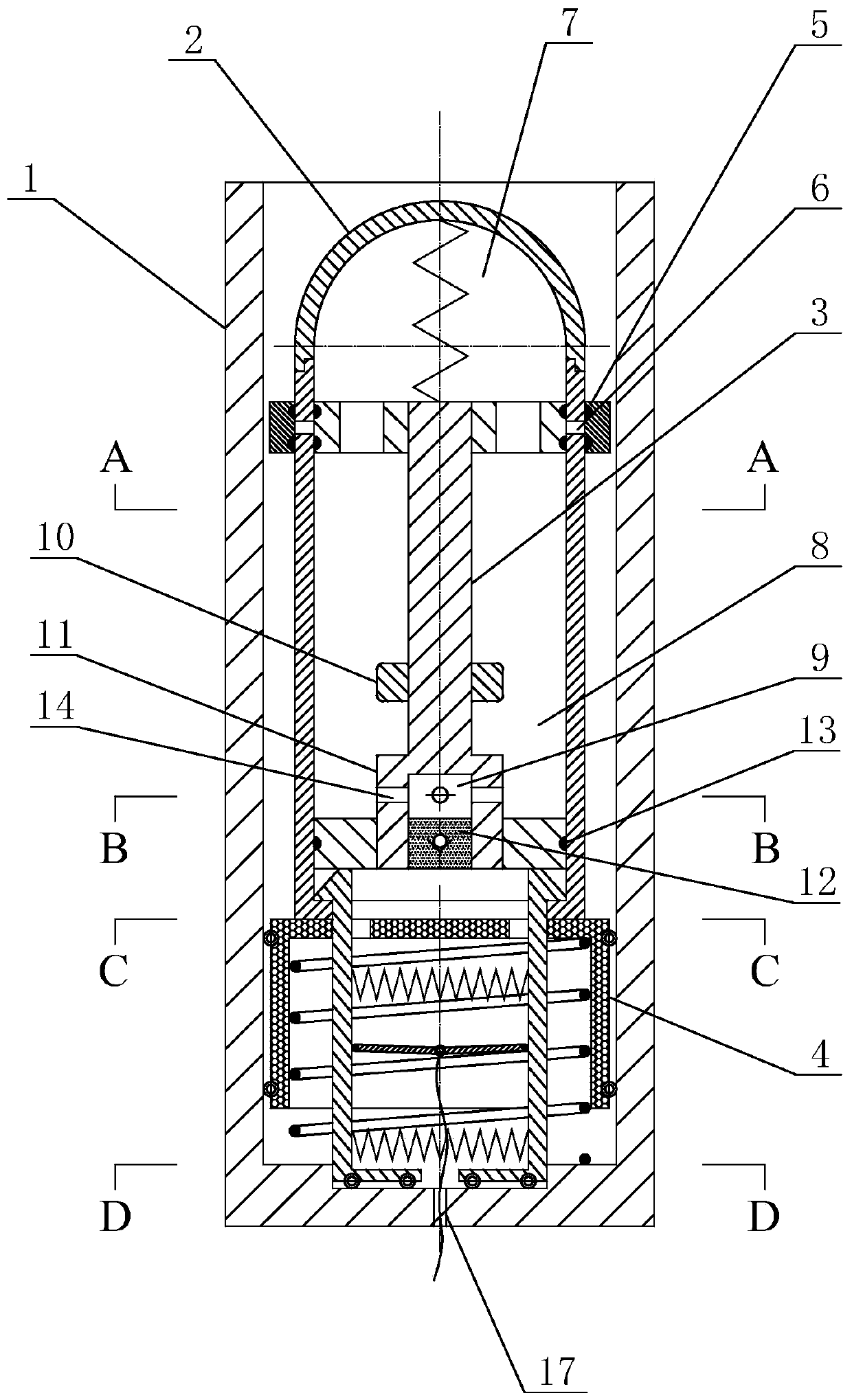

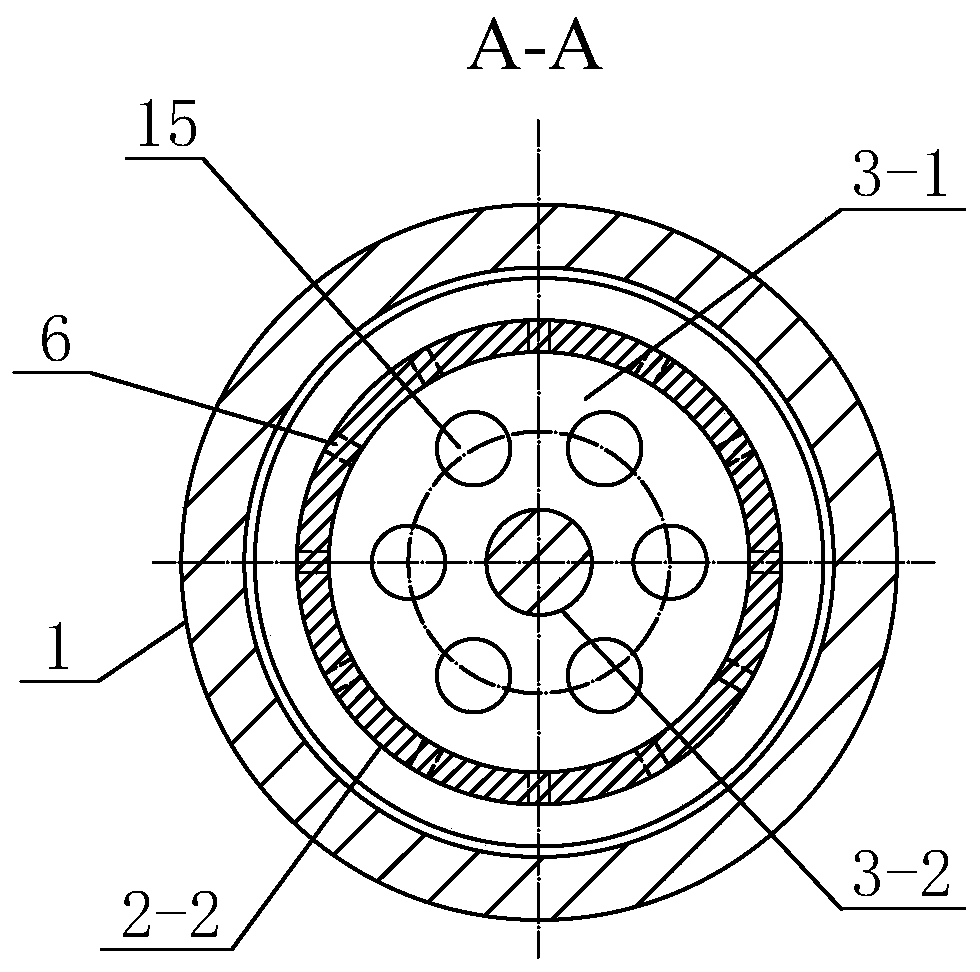

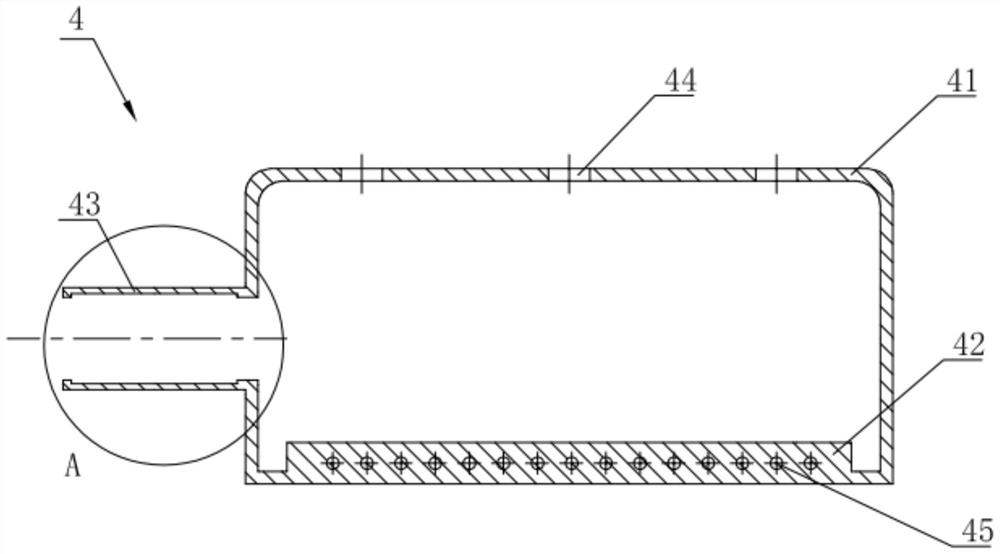

A large-load low-frequency vibration isolation device for ships and its installation method

ActiveCN110513421BImprove low frequency vibration isolation performanceGood vibration isolationFriction dampersNoise controlCylinder block

The invention relates to a marine high-load low-frequency vibration isolation device and an installation method thereof, comprising a cylinder body with one end open; a support frame is installed through the cylinder wall; a wire rope is installed at the end of the support frame inside the cylinder body; the wire rope is wound in a spiral manner It is wound between the support frame and the inner wall of the cylinder; the inside of the open end of the cylinder body is installed with a piston block that slides along it, and the piston block and the cylinder body together form a closed cavity, and the cavity is filled with shear thickening liquid; equipment on the top of the support frame The platform is used to install the equipment, the upper plate at the bottom of the support frame is located inside the cylinder body and used for winding the wire rope, the equipment platform and the upper plate are connected by a column, and the support frame is guided by the column to move up and down relative to the cylinder body; the invention is comprehensively applied The low-frequency shear energy dissipation characteristics of shear thickening fluid and the friction energy dissipation characteristics and load-bearing capacity of steel wire ropes enable the equipment to produce significant vibration isolation effects in the low-frequency vibration frequency range, especially for ships with large loads and low-speed equipment. Vibration and noise control.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Current collection body for battery

InactiveCN101425567BUniform mass distributionExtended service lifeSmall-sized cells cases/jacketsElectrode carriers/collectorsCapacitanceEngineering

The invention discloses a battery collector body. A sealing ring thereof is a rotating body; the bottom cover of the rotating body is provided with a raised structure protruding towards the sealing ring; and a deflation hole on the bottom cover is arranged in the raised structure. The raised structure is used for supporting the sealing ring when the sealing ring falls down due to a broken explosion-proof channel, thereby a broken opening communicated with the sealing ring and a deflation channel of the deflation hole are formed. Because the sealing ring is the rotating body, the mass distribution of the sealing ring is more uniform during the injection mold and processing, thereby the problem that the sealing ring is friable and easily broken in the prior art is effectively avoided, the service life is prolonged, and the reliability is improved. Because the deflation hole is arranged in the raised structure and is not on an identical plane with the bottom surface of the bottom cover, the tail end of a holddown spring is not easy to extend. In addition, because the thickness of the sealing ring is relatively lowered, the inside of the battery is ensured to have a larger space filledwith active substances, thereby the capacitance of the battery is obviously improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

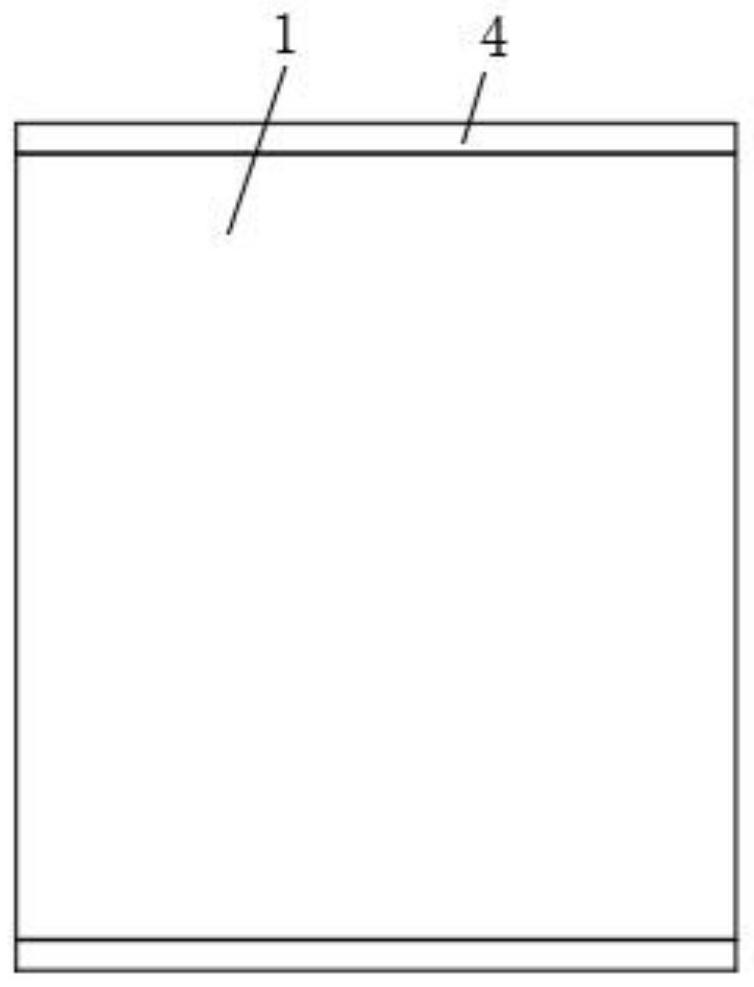

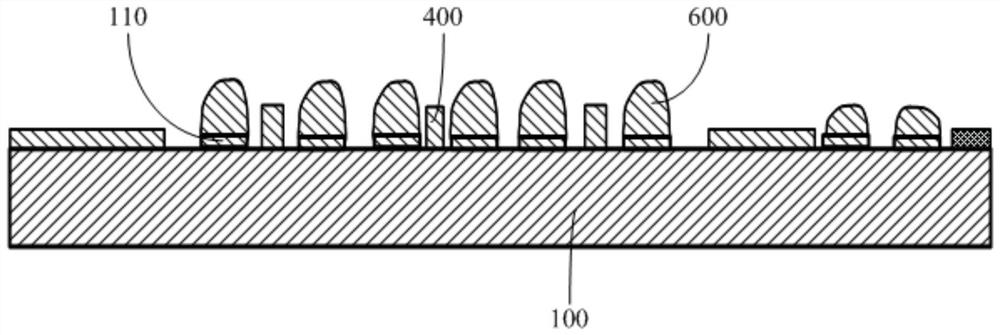

Adapter plate easy for SIP packaging bottom filling and manufacturing method thereof

ActiveCN111640730AIncrease heightGuaranteed fillingSemiconductor/solid-state device detailsSolid-state devicesSurface mountingEngineering

The invention relates to an adapter plate easy for SIP packaging bottom filling and a manufacturing method thereof, the adapter plate comprises copper column layers (1), the patterns of the copper column layers (1) correspond to the patterns of welding pads at the bottom of a subsequent mounting element, dielectric materials (2) are filled between the copper column layers (1), and the dielectric materials (2) are water-soluble materials. According to the adapter plate easy to fill the bottom of the SIP package and the manufacturing method of the adapter plate, the gap at the bottom of the surface mount device can be raised, so that the plastic package material is easier to fill.

Owner:JCET GROUP CO LTD

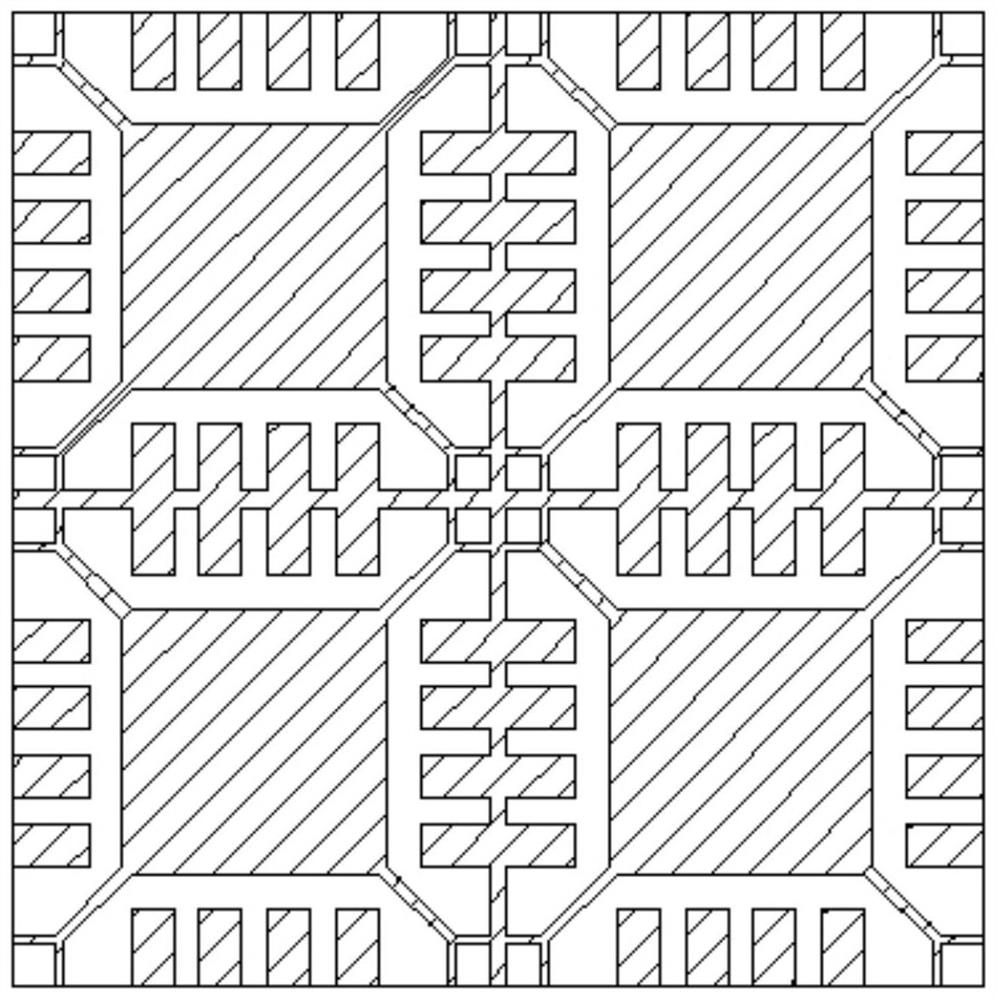

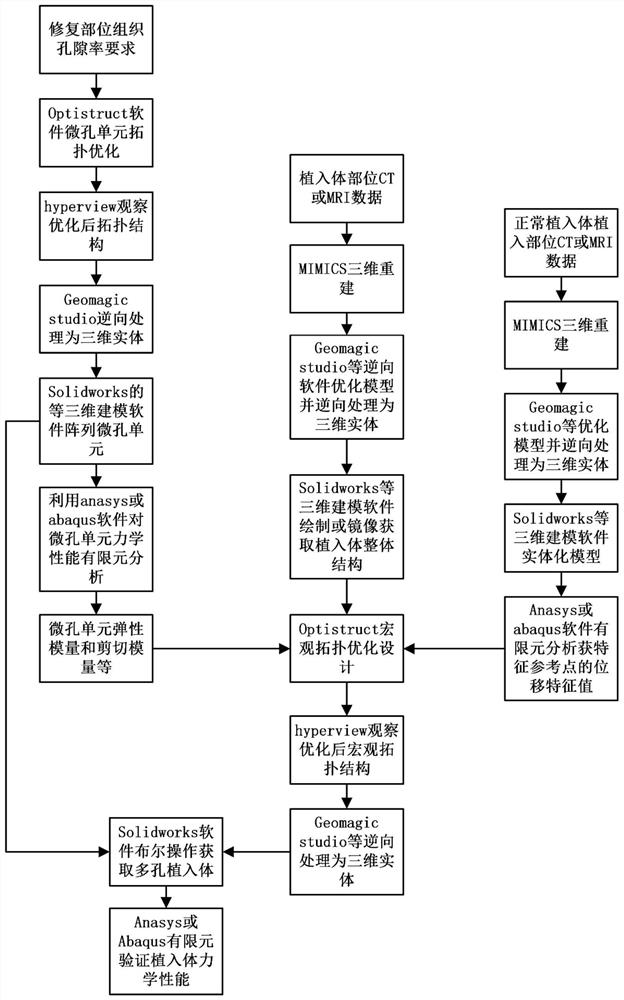

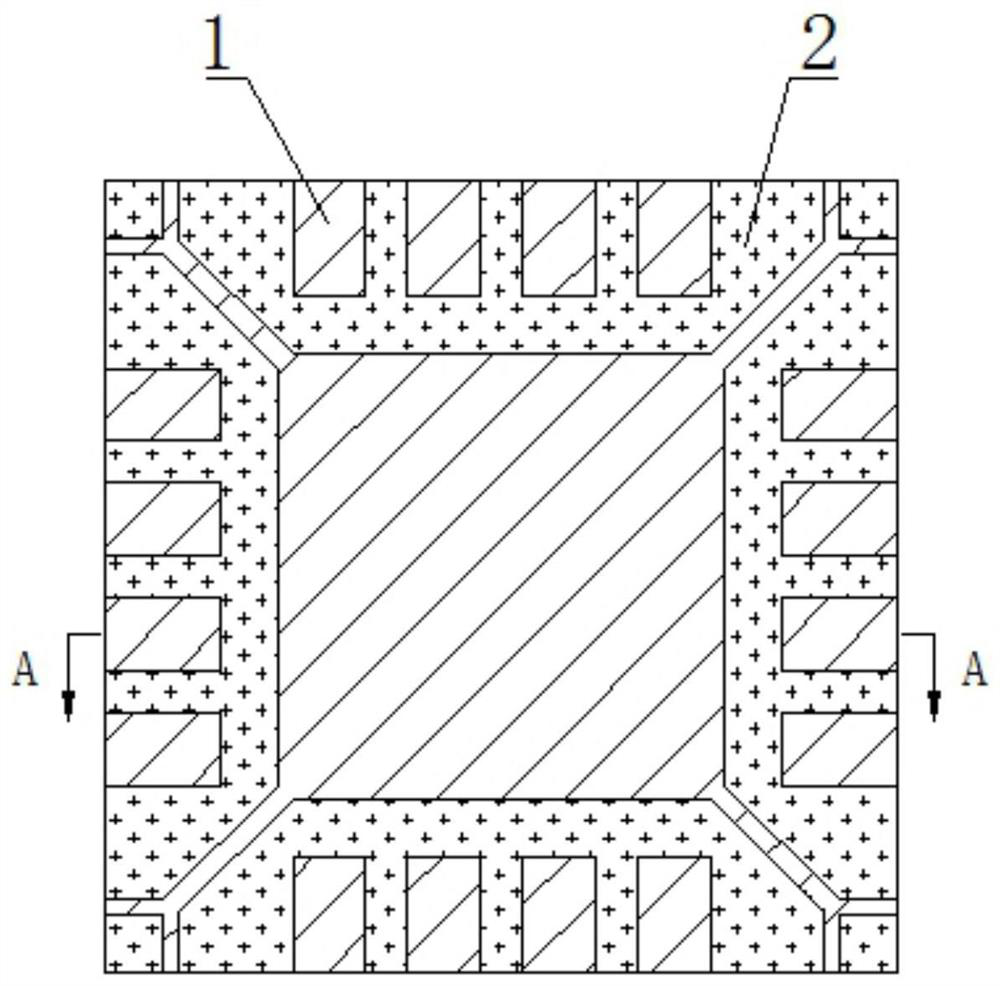

An Implant Design Method Combining Macroscopic and Microscopic Topology Optimization

ActiveCN109472096BReduce adverse effectsImprove performanceDesign optimisation/simulationSpecial data processing applicationsMacroscopic scaleDentistry

The invention discloses an implant design method combining macroscopic and microscopic topology optimization, which solves the problem that the porosity and shape of the implant cannot be effectively controlled in the prior art, and has the advantages of ensuring the microporous unit mechanics. Increase the porosity of the microporous unit while increasing the performance, improve the biological performance of the implant, and design the structure that best meets the mechanical requirements while reducing the amount of materials; the technical solution is: including the following steps: the microporous unit Topology optimization of microporous units, acquisition of mechanical parameters of micropore units, image acquisition and reverse processing, macroscopic mechanical analysis, topology optimization of macroscopic structures, and generation of implants.

Owner:SHANDONG UNIV

Adapter plate facilitating underfill of large-size element and manufacturing method thereof

PendingCN111640729AIncrease bottom heightIncrease paddingSemiconductor/solid-state device detailsSolid-state devicesSolubilityEngineering

The invention relates to an adapter plate facilitating underfill of a large-size element and a manufacturing method thereof. The adapter plate comprises a copper column layer (1), the pattern of the copper column layer (1) corresponds to the pattern of a welding pad at the bottom of a subsequent mounting element, the periphery of the copper column layer (1) is encapsulated with a dielectric material (2), the dielectric material (2) is made of a photosensitive material, and the solubility of the photosensitive material can change after the photosensitive material is illuminated. According to the adapter plate easy to fill the bottom of the large-size element and the manufacturing method thereof, the gap at the bottom of the surface mounting device can be raised, so that the plastic packagematerial is easier to fill.

Owner:JCET GROUP CO LTD

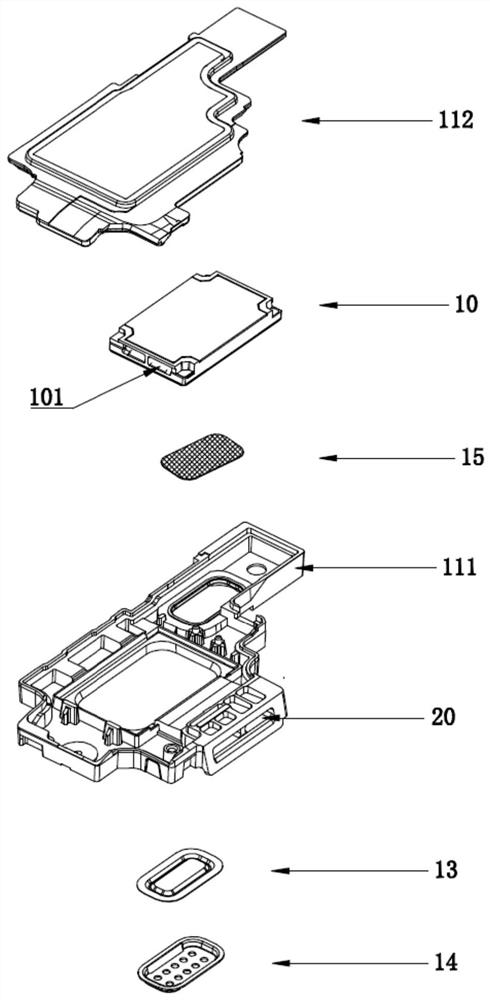

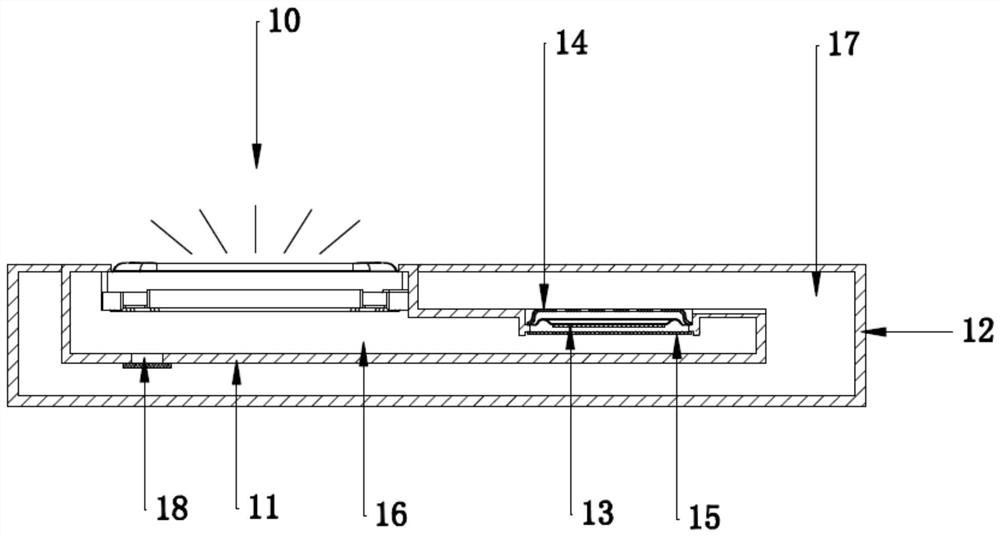

Acoustic and electronic equipment

ActiveCN110708642BAdjustable volumeIncrease volumeElectrical transducersLoudspeakersVibrating membraneAcoustics

Owner:GEER TECH CO LTD

Circuit board device and its manufacturing method, electronic equipment

ActiveCN111354705BAvoid voidsFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionPhysics

Owner:VIVO MOBILE COMM CO LTD

Oil-gas-free sealing protection system and protection method for external floating roof oil tank

The invention belongs to the technical field of petrochemical engineering, and particularly relates to an oil-gas-free sealing protection system and protection method for an external floating roof oil tank. According to the technical scheme, the oil-gas-free sealing protection system for the external floating roof oil tank involves a sealing bag arranged in a secondary sealing structure, wherein the sealing bag is located in a space defined by a primary sealing structure, a tank wall, the secondary sealing structure and a floating disc, the sealing bag is connected with an analysis control device through a pipeline, and the analysis control device is connected with an inert gas supply device through a pipeline and is also electrically connected with a control system. The invention provides the oil-gas-free sealing protection system and protection method for the external floating roof oil tank.

Owner:VITALONG FIRE SAFETY GRP

Current collection body for battery

InactiveCN101425566BUniform mass distributionExtended service lifeSmall-sized cells cases/jacketsElectrode carriers/collectorsCapacitanceMass distribution

The invention discloses a battery collector body. A sealing ring thereof is a rotating body; and the bottom cover of the rotating body is provided with a raised structure protruding towards the sealing ring simultaneously and is used for supporting the sealing ring when the sealing ring falls down due to a broken explosion-proof channel, thereby a broken opening communicating with the sealing ringand a deflation channel of a deflation hole on the bottom cover are formed. Because the sealing ring is the rotating body, the mass distribution of the sealing ring is more uniform during the injection mold and processing, thereby the problem that the sealing ring is easy to friable and broken in the prior art is effectively avoided, the service life is prolonged, and the reliability is improved.In addition, because the thickness of the sealing ring is relatively lower, the inside of the battery is ensured to have larger space filled with active substances, thereby the capacitance of the battery is obviously improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com