Adapter plate facilitating underfill of large-size element and manufacturing method thereof

An underfill and transfer board technology, used in semiconductor/solid-state device manufacturing, electrical components, semiconductor/solid-state device components, etc., can solve the problems of underfilling, product failure, and insufficient filling of plastic packaging materials, and increase the bottom Height, increase the filling space, and ensure the effect of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

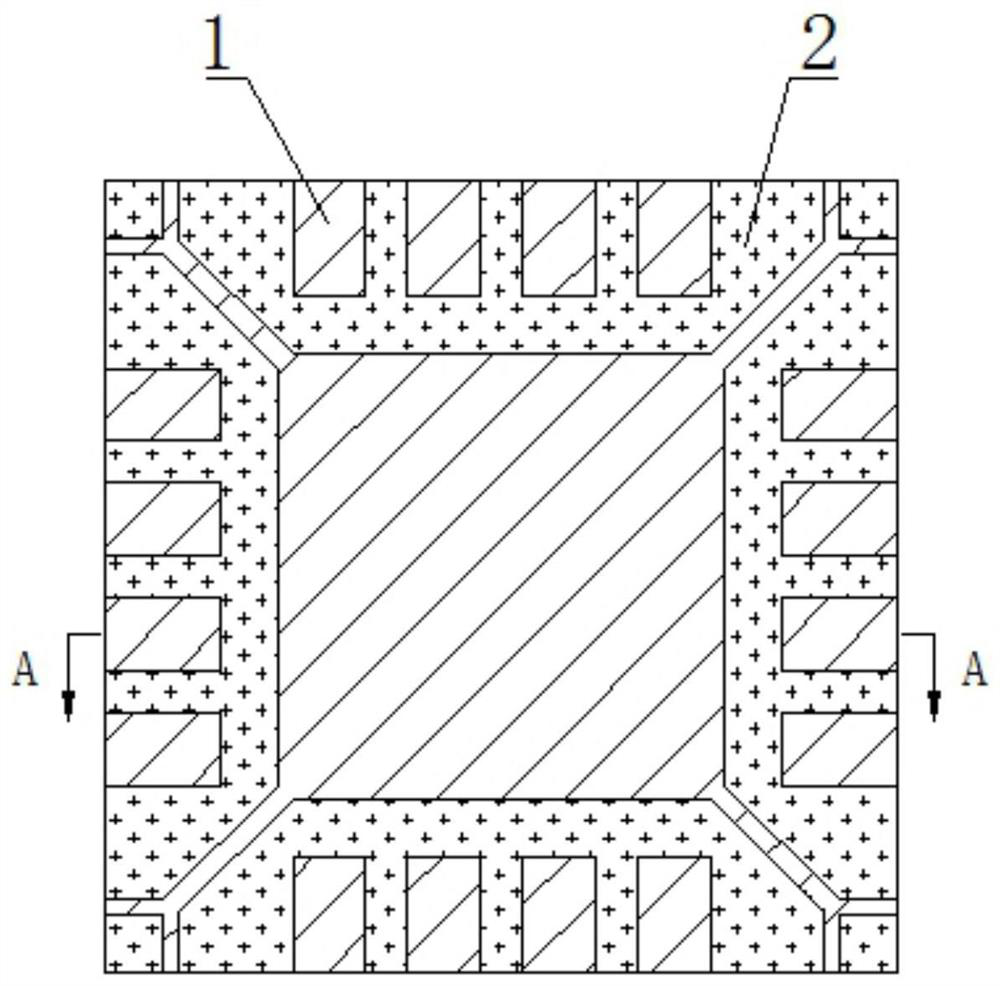

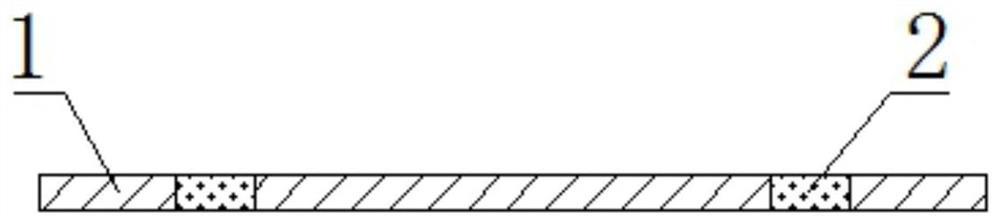

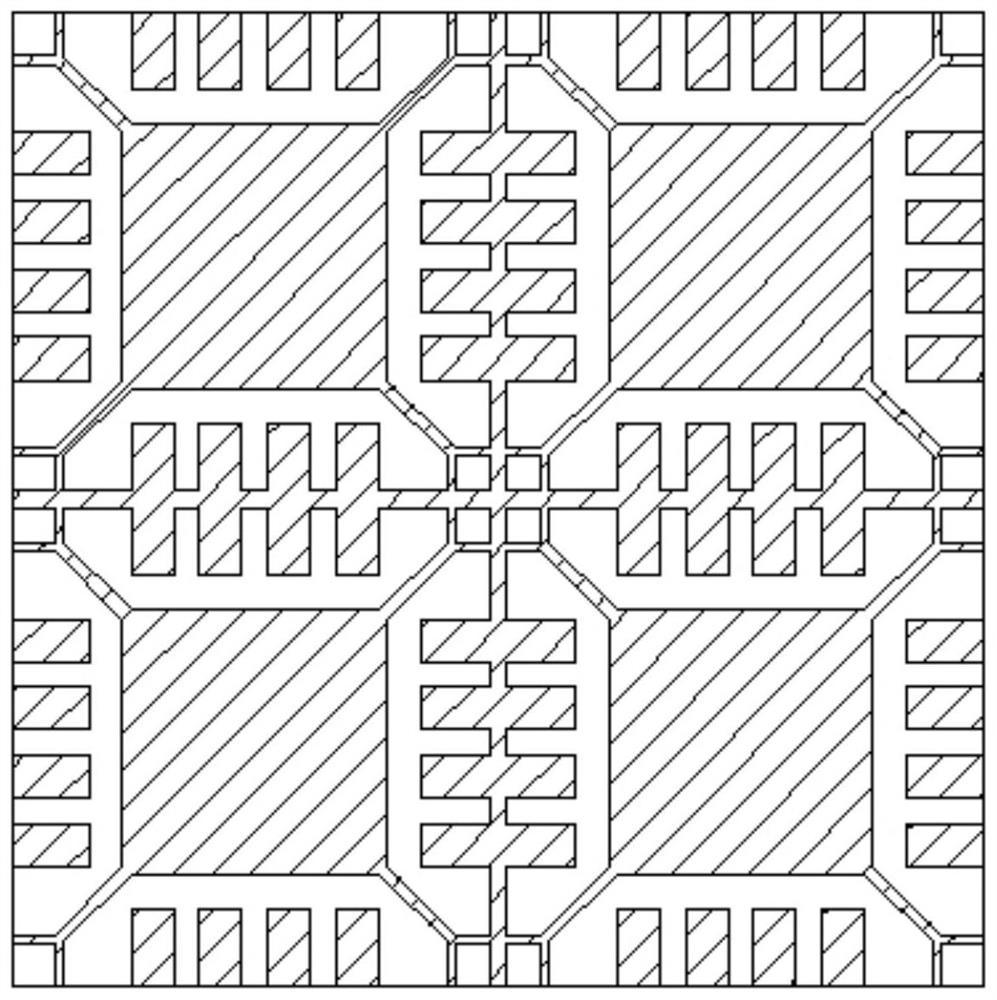

[0027] see figure 1 , figure 2 , the present invention relates to an adapter board that is easy to fill the bottom of large-sized components, which includes a copper column layer 1, the pattern of the copper column layer 1 corresponds to the pattern of the bottom pad of the mounted component, and the copper column layer 1 A dielectric material 2 is arranged between them, and the dielectric material 2 is a photosensitive material whose solubility will change after being illuminated.

[0028] The photosensitive material is a quinone azido compound material, which undergoes a photodecomposition reaction after being irradiated, and can change from oil solubility to water solubility.

[0029] The size of the adapter board is the same as the size of the mounted components.

[0030] Its manufacturing method comprises the following steps:

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com