Packaging box made of foamed plastic

A technology of foam plastics and foam boxes, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of damage and corrosion during transportation and handling, separation of box body and box cover, low utilization rate of foam boxes, etc., to achieve effective Facilitate transportation, increase use efficiency and service life, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

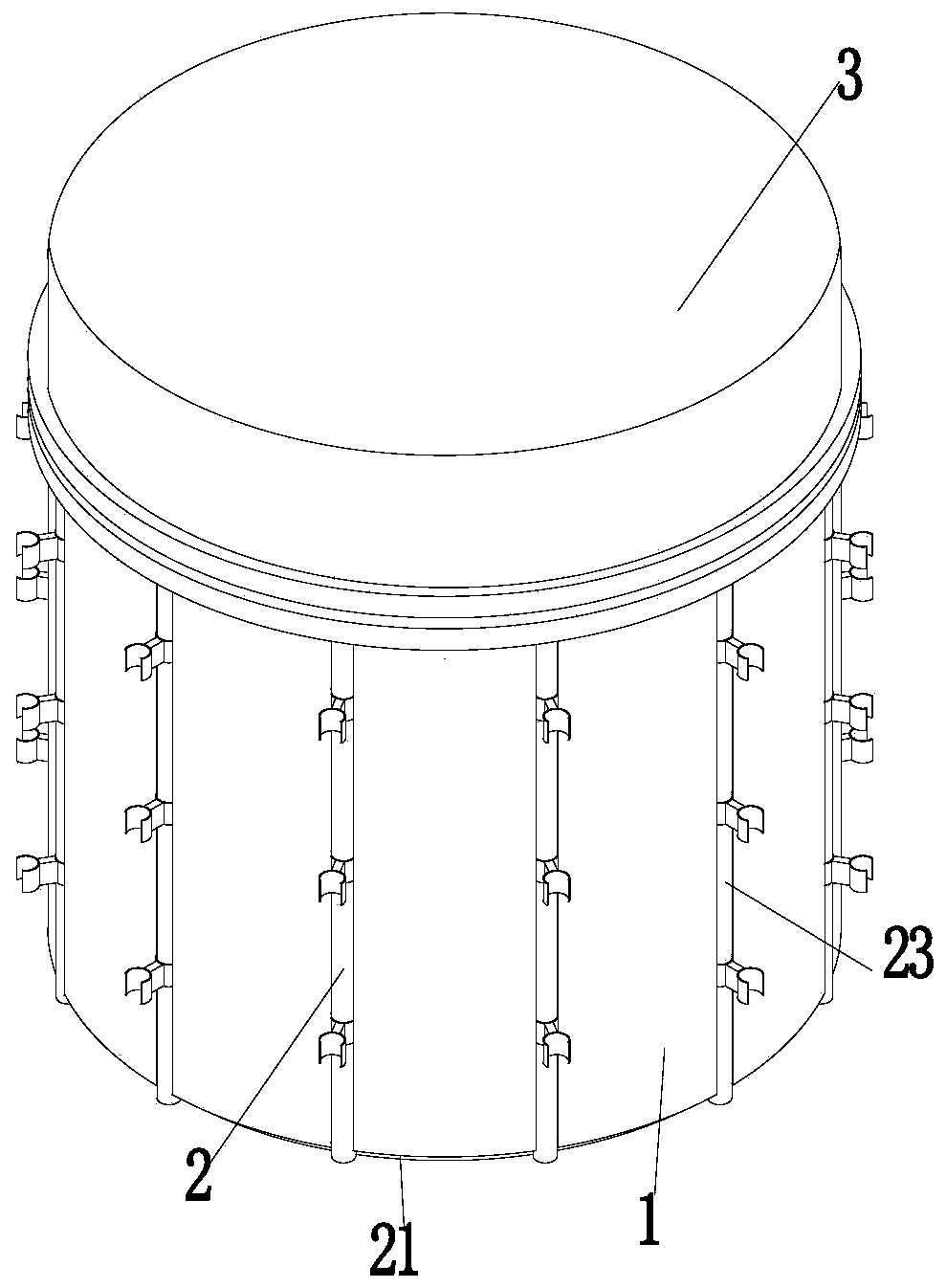

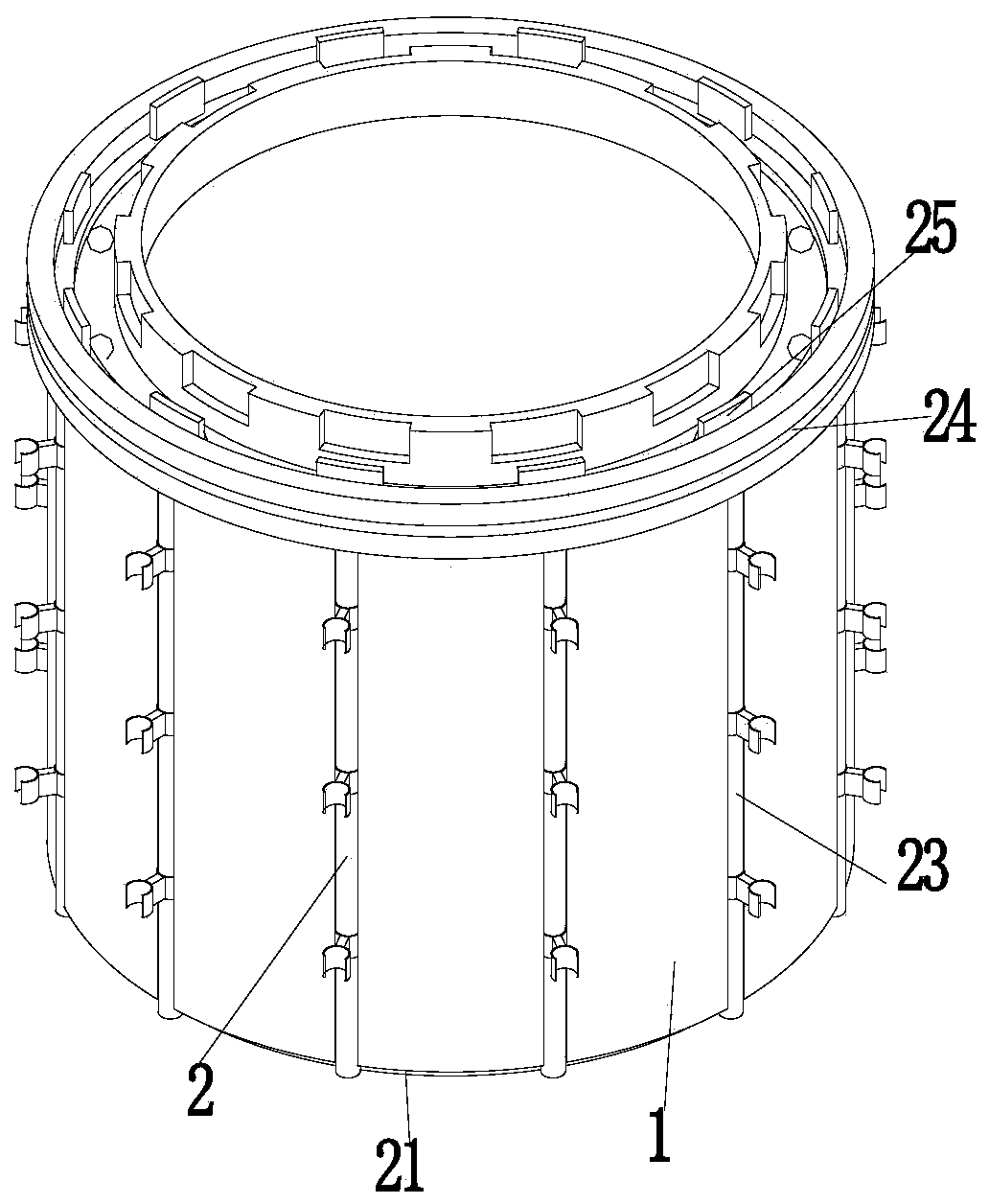

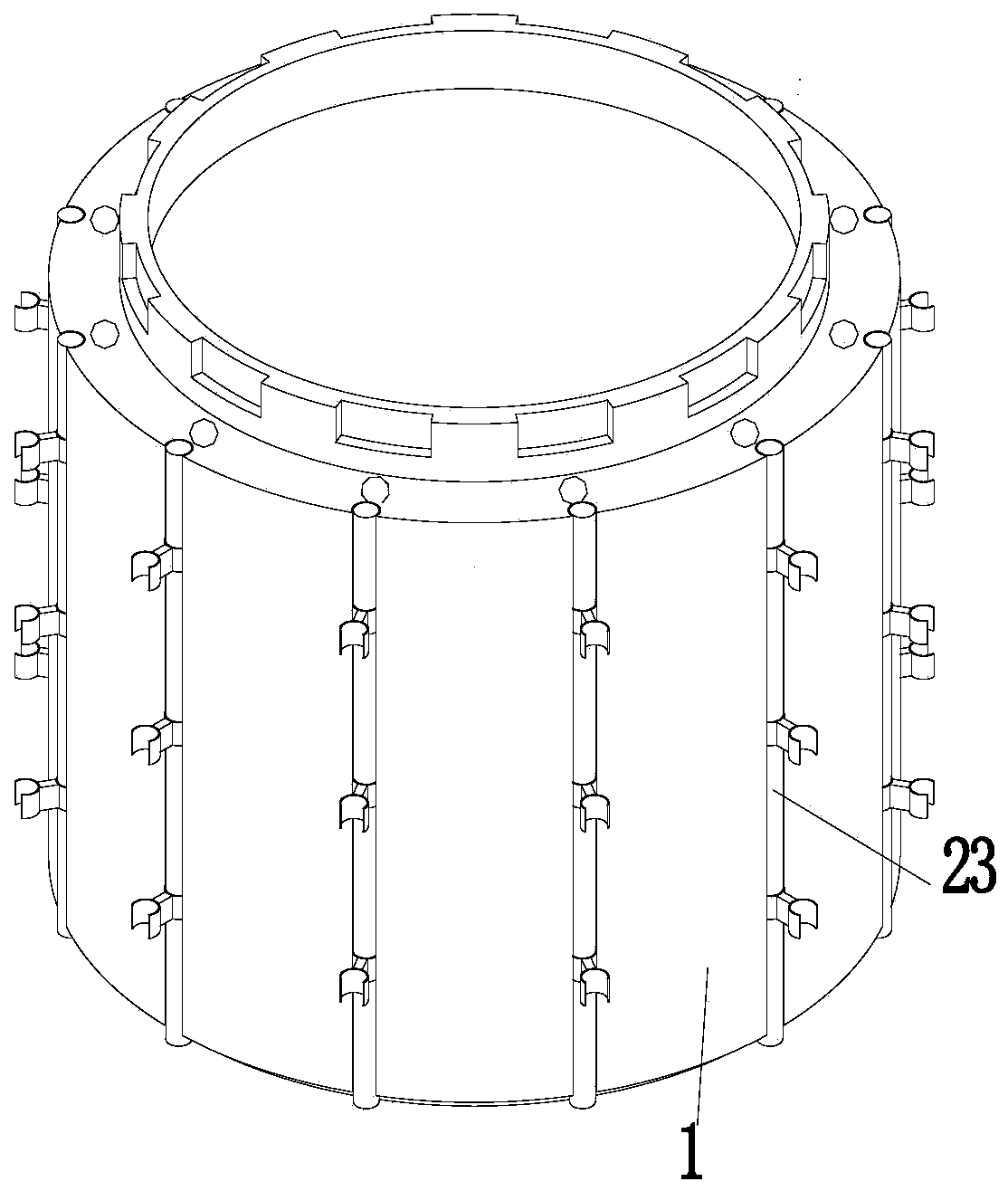

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0033] A foam plastic packaging box, comprising a foam box body 1, a plastic bracket 2 and a foam cover body 3, a plastic bracket 2 is installed on the outside of the foam box body 1, and a foam cover body 3 is installed on the upper end of the foam box body 1; wherein:

[0034] The foam box body 1 is a circular box body, and the outer side of the foam box body 1 is evenly provided with arc-shaped grooves along the circumferential direction. The lower end of the foam box body 1 is provided with a large annular groove and a small annular groove. The end face is evenly provided with arc-shaped protrusions along the circumferential direction, and the upper side of the foam box body 1 is fixedly provided with an annular plate, and the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com