Centrifugal pump

A centrifugal pump and pump stand technology, applied in the field of centrifugal pumps, can solve the problems of damage, the centrifugal pump is susceptible to moisture, and it is difficult to ensure that the centrifugal pump is installed in parallel with the horizontal plane, and achieves the effect of improving installation quality, improving use effect and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

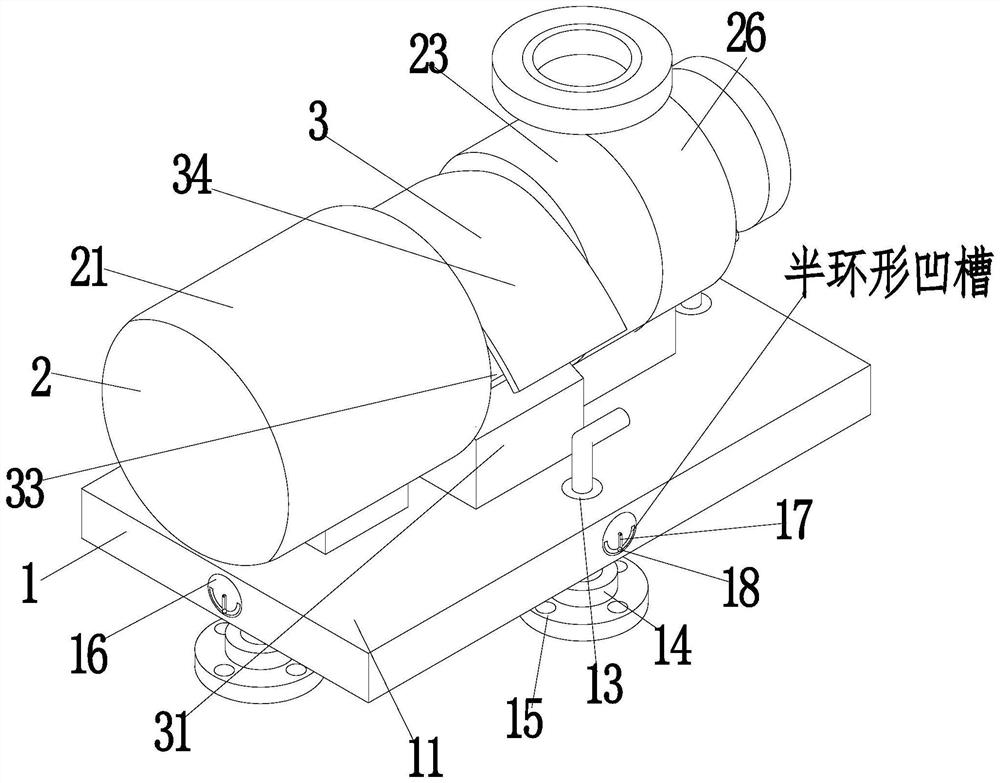

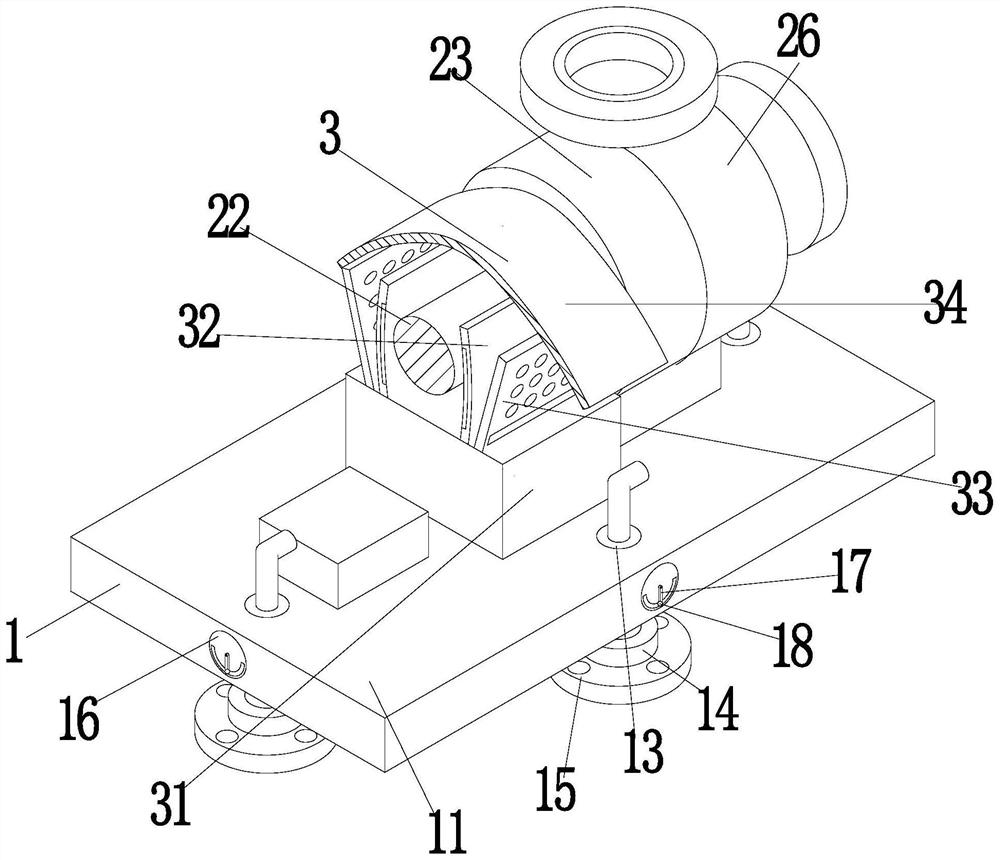

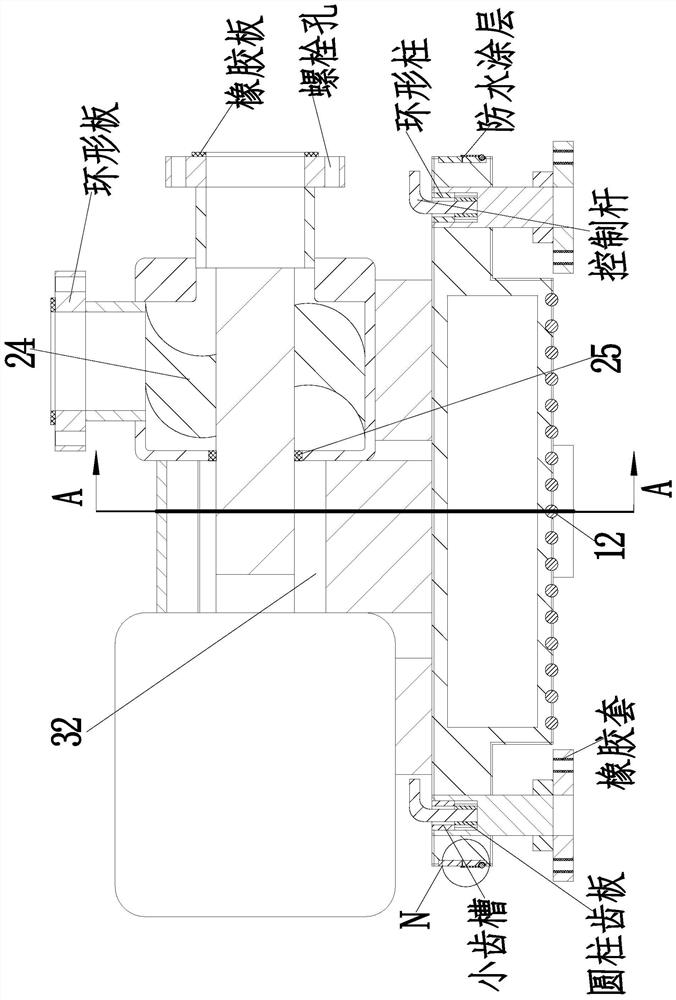

[0032] In order to make the technical means, the creation of the present invention, the purpose and energy is easy to understand, the following combinations Figure 1 to 8 Further, the invention is further illustrated.

[0033] A centrifugal pump comprising a base 1, a pump frame 2, and a housing 3, the base 1 is fixedly mounted having a pump frame 2, and the upper end surface of the base 1 is fixed to the outside of the pump frame 2; there is:

[0034] The base 1 includes an embedded panel 11, a ball 12, a screw column 13, a nut 14, a positioning plate 15, a circular feet 16, a straight rod 17 and a lead ball 18, and the lower end surface of the inverted parallelene plate 11 is uniform in sliding cooperation The rollers 12 are connected, and the inverted panel 11 is uniformly connected in a threaded connection. The threaded column 13 is connected in the lower outer end surface of the threaded connection. The nut is connected to the nut 14, the nut sheet 14 lower end surface fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com