Titanium nitride chemical vapor deposition device

A titanium nitride chemical and vapor deposition technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem that the side wall of the tungsten through hole cannot be treated by plasma, so as to improve the quality, Expand the effect of filling the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

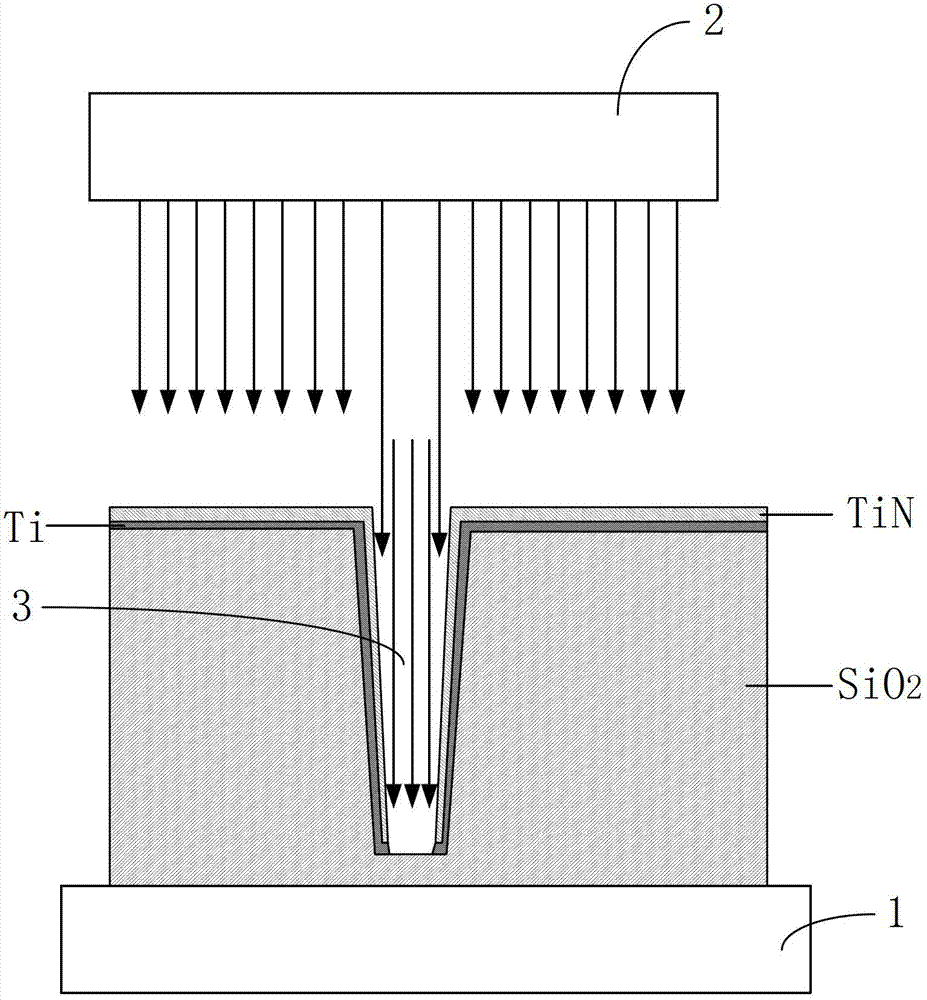

Image

Examples

Embodiment Construction

[0014] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

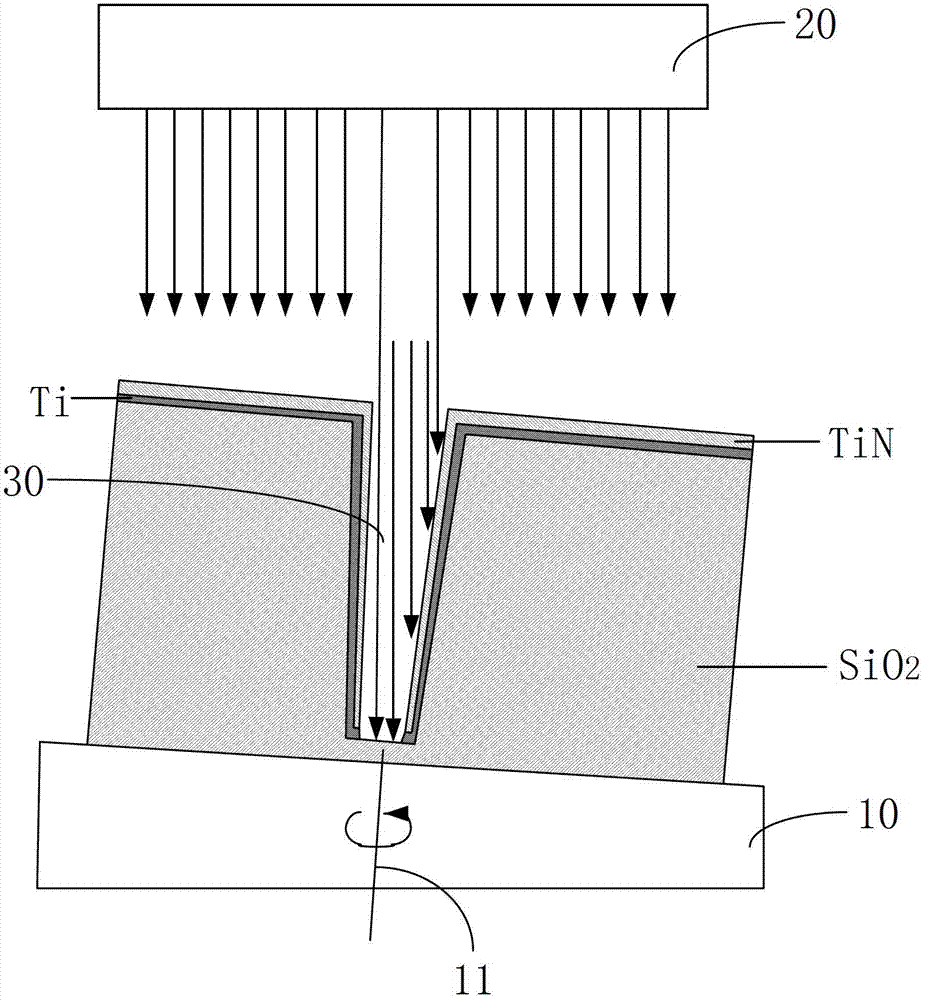

[0015] Titanium nitride chemical vapor deposition equipment provided by the invention, such as figure 2 As shown, it includes a base 10 for carrying a silicon wafer and a shower head 20 arranged on the upper end of the silicon wafer. Specifically, the bottom layer of the silicon wafer in this embodiment is SiO2, then a layer of Ti is deposited, and finally tetradimethyl Aminopeptide (TDMAT) is used as the initial compound to form a layer of TiN, and the silicon wafer contains tungsten through holes 30, nitrogen and hydrogen gas injected from the shower head 20 are injected into the tungsten through holes 30 to perform plasma on the TiN deal with. The included angle between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com