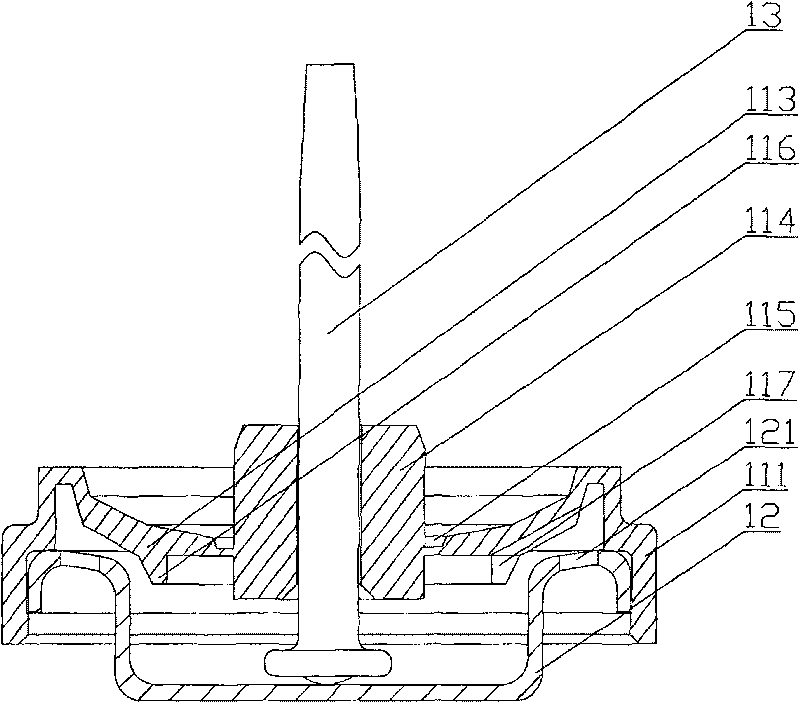

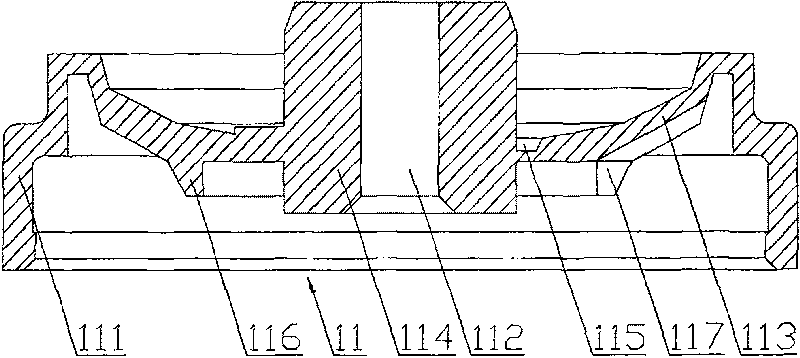

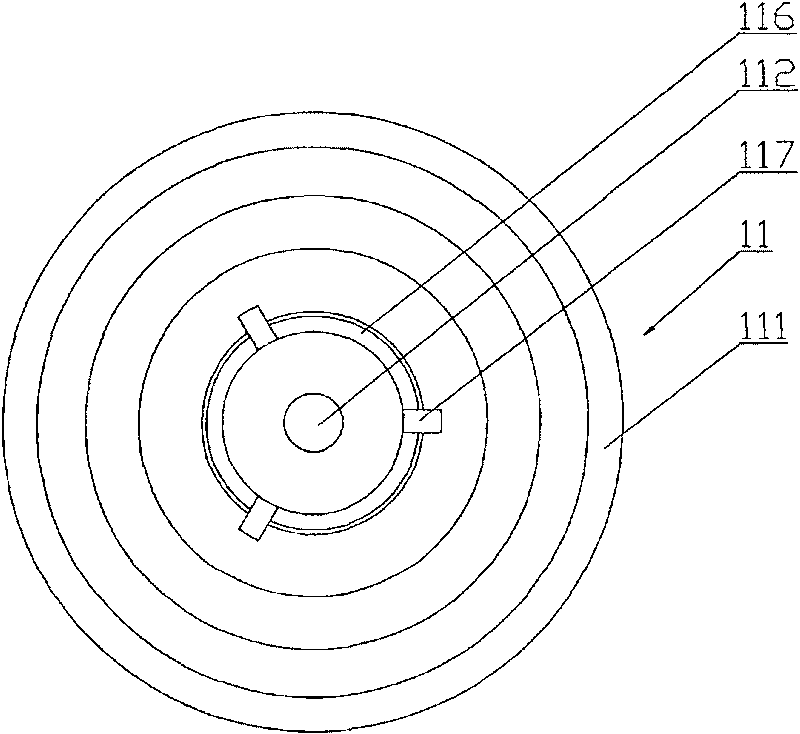

Current collection body for battery

A technology of battery collection and conductor nails, which is applied in the direction of electrode carriers/current collectors, battery components, circuits, etc., can solve the problems of uneven density of sealing rings, poor reliability, and reduced battery reliability, etc., and achieve large active material filling Space, reduced thickness, and improved capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058] Compared with the above-mentioned first embodiment, the second embodiment of the bottom cover provided by the present invention changes the specific shape of the protruding structure.

[0059] In the second specific implementation manner, the protruding structure may specifically be a bar-shaped boss 225 arranged along the radial direction of the bottom cover 22 . The bar-shaped protrusion 225 can also be formed by stamping, and has a top surface extending radially along the bottom cover 22 . The position of the strip-shaped boss 225 should be properly selected to ensure that the top surface of the strip-shaped boss 225 can support it when the main plane 213 of the sealing ring 21 falls due to the rupture of the annular explosion-proof groove 215 .

[0060] Only one bar-shaped boss 225 may be provided. In order to further ensure the unimpeded flow of the air leakage channel, a plurality of bar-shaped bosses 225 may be provided. Preferably, the number of strip-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com