Adapter plate easy for SIP packaging bottom filling and manufacturing method thereof

A technology of underfill and transfer board, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc., can solve the problems of insufficient filling, underfill, product failure, etc., to increase the filling space , Increase the height and ensure the effect of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

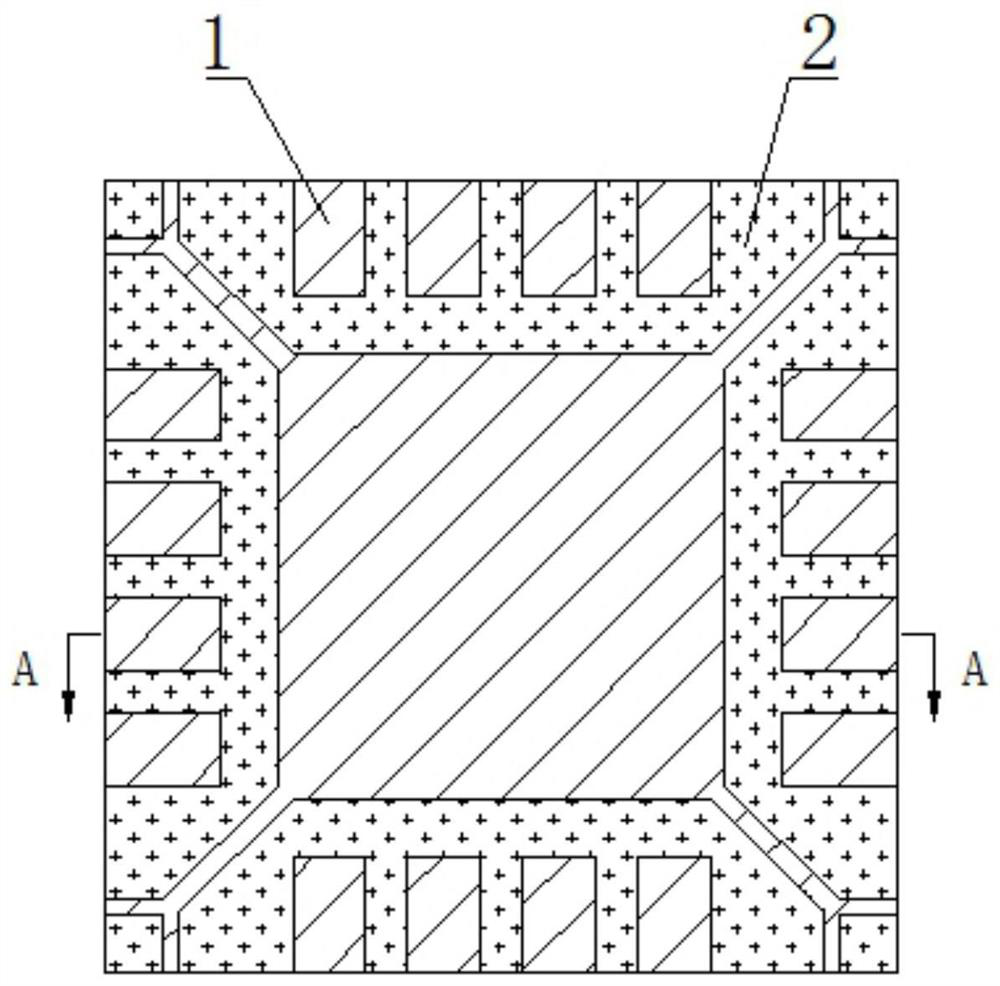

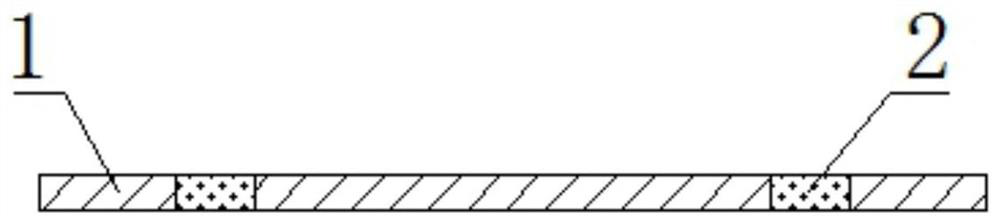

[0027] see figure 1 , figure 2 , the present invention relates to a kind of adapter board that is easy to fill the bottom of SIP package, it includes copper column layer 1, and the pattern of described copper column layer 1 is corresponding to the pattern of soldering pad at the bottom of mounting component, and between the copper column layers 1 Filling and setting a medium material 2, the medium material 2 adopts a water-soluble material;

[0028] The water-soluble material has low-temperature curing characteristics, and after curing, it is solid at low temperature, and softens and is easily dissolved by water at high temperature;

[0029] The size of the adapter board is the same as the size of the mounted components.

[0030] Its manufacturing method comprises the following steps:

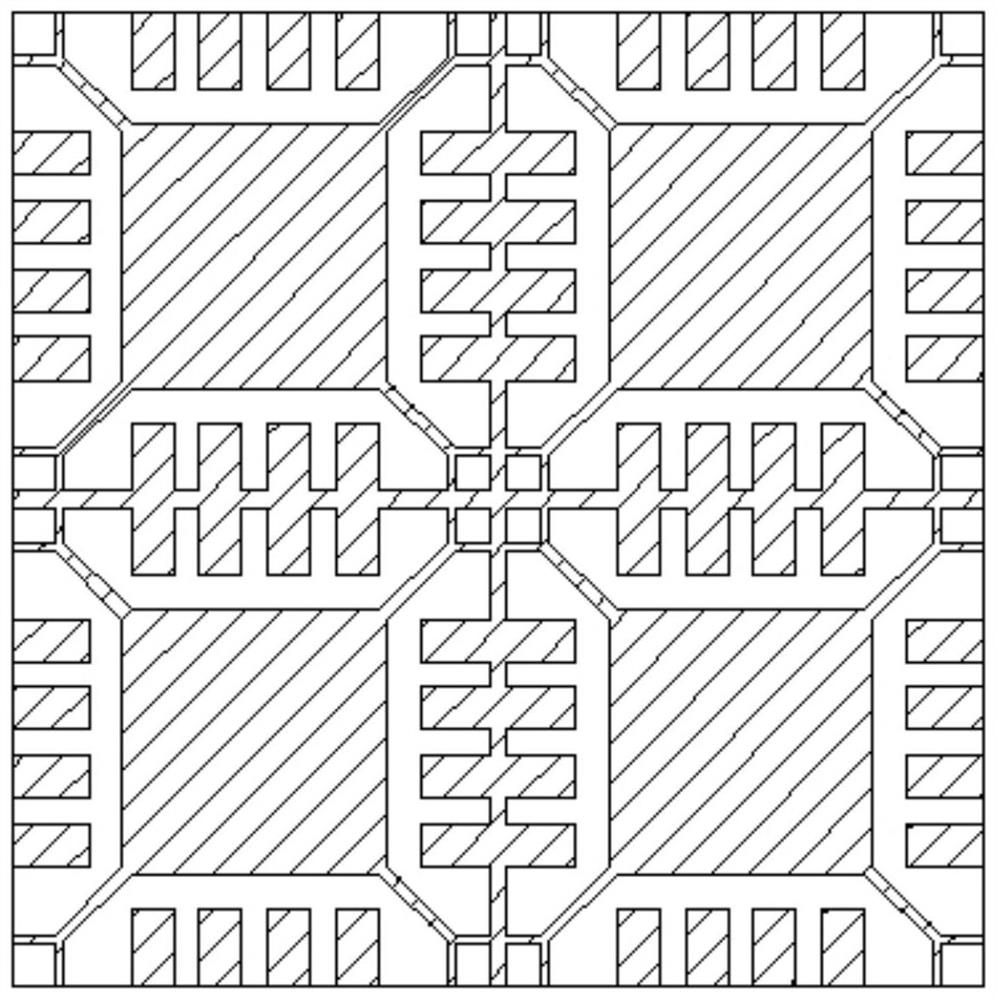

[0031] Step 1, see image 3 , take a copper substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com