A large-load low-frequency vibration isolation device for ships and its installation method

A large-load, low-frequency technology, which is applied in the field of large-load low-frequency vibration isolation devices for ships, can solve the problems that it is difficult to meet the low-frequency vibration and noise control requirements of large-scale mechanical equipment, and the initial stiffness of the damping force is limited, so as to improve low-frequency vibration isolation performance and facilitate operation , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

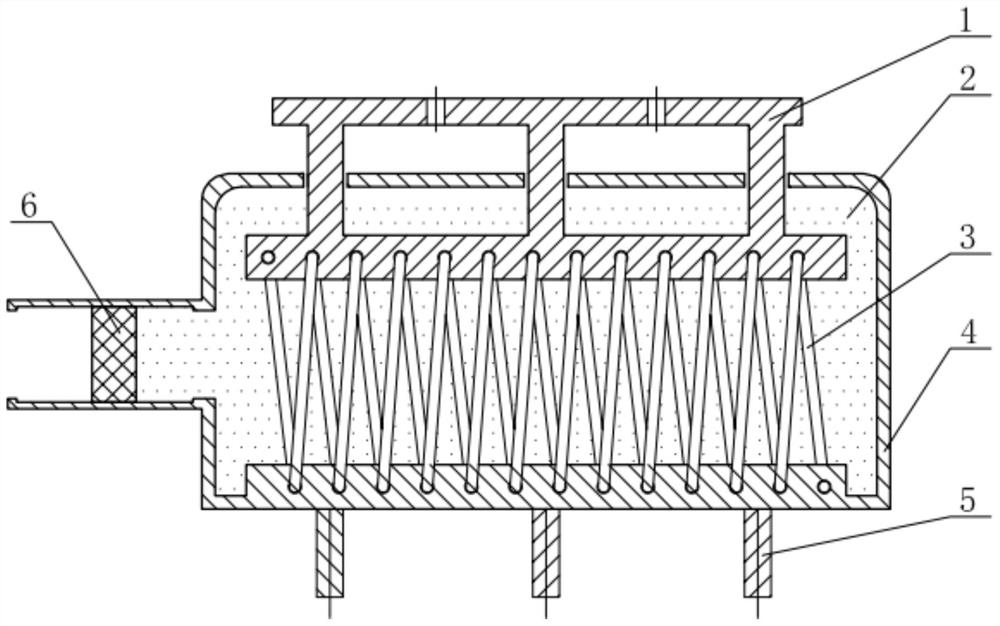

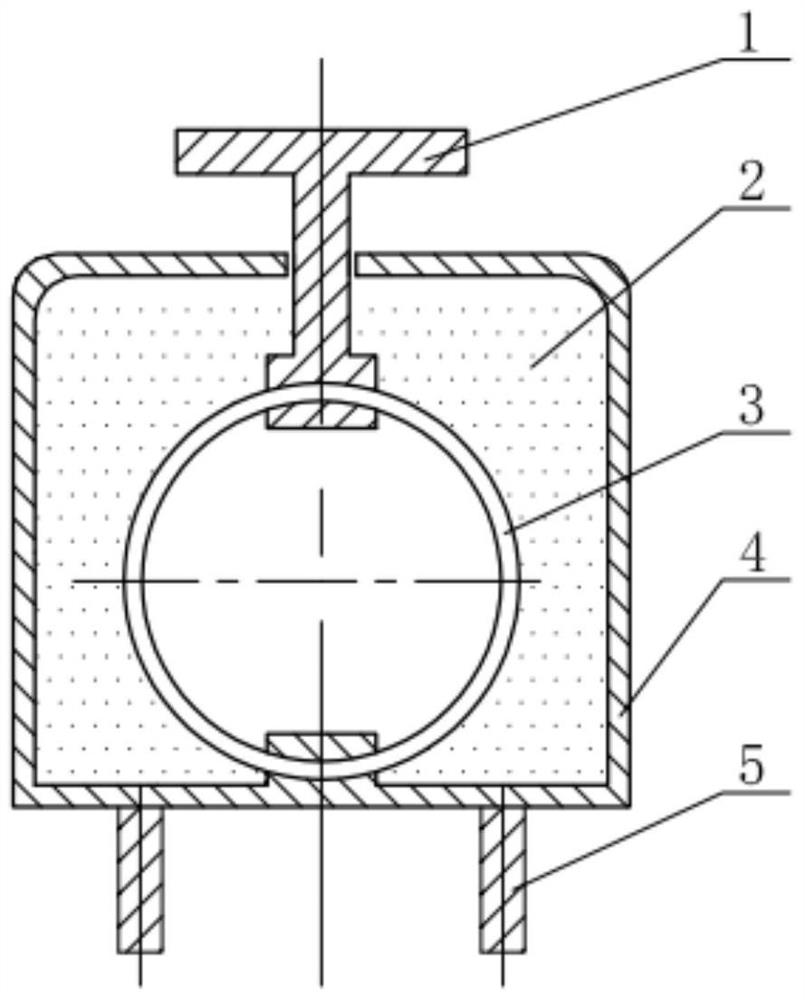

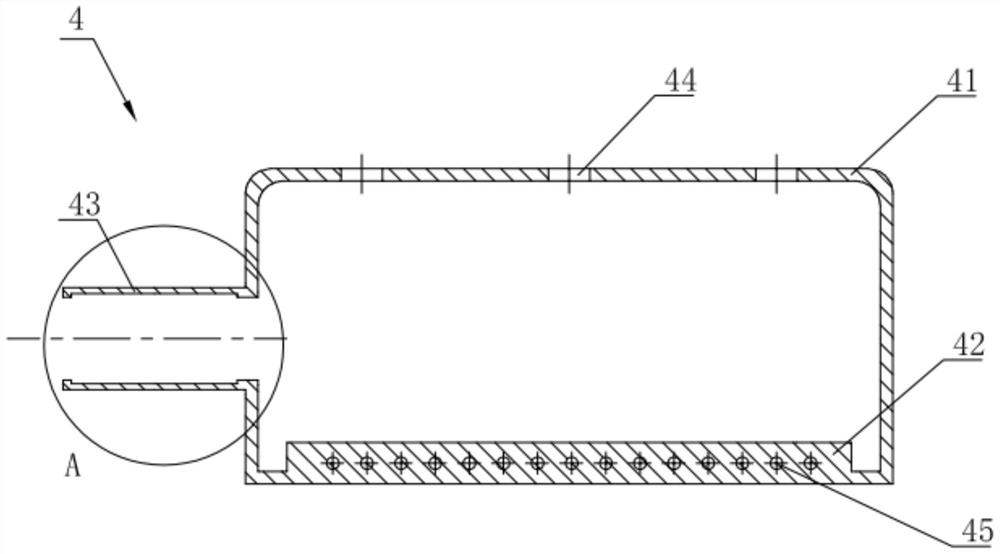

[0040] Such as figure 1 and figure 2 As shown, a marine large-load low-frequency vibration isolation device of this embodiment includes a cylinder 4 with an open end, a support frame 1 is installed through the cylinder wall of the cylinder 4, and the end of the support frame 1 located inside the cylinder 4 is installed. There is a steel wire rope 3, and the steel wire rope 3 is spirally wound between the support frame 1 and the inner wall of the cylinder body 4; a piston block 6 sliding along it is installed inside the open end of the cylinder body 4, and the piston block 6 and the cylinder body 4 jointly form a A closed cavity filled with a shear thickening fluid 2 .

[0041]Through the combined vibration isolation structure of "steel wire rope + shear thickening fluid (STF) + piston block", the structural load-bearing function and fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com