Current collection body for battery

A battery collector and conductor nail technology, applied in the direction of electrode carrier/current collector, small-sized battery/battery pack, battery box/jacket, etc., can solve the problems of reduced battery reliability, poor reliability, uneven density of sealing rings, etc. , to achieve the effect of increasing the capacitance, reducing the thickness, and filling the space with large active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The core of the invention is to provide a battery collector capable of prolonging the service life and reliability of the sealing ring while ensuring the safety and explosion-proof performance of the battery.

[0038] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

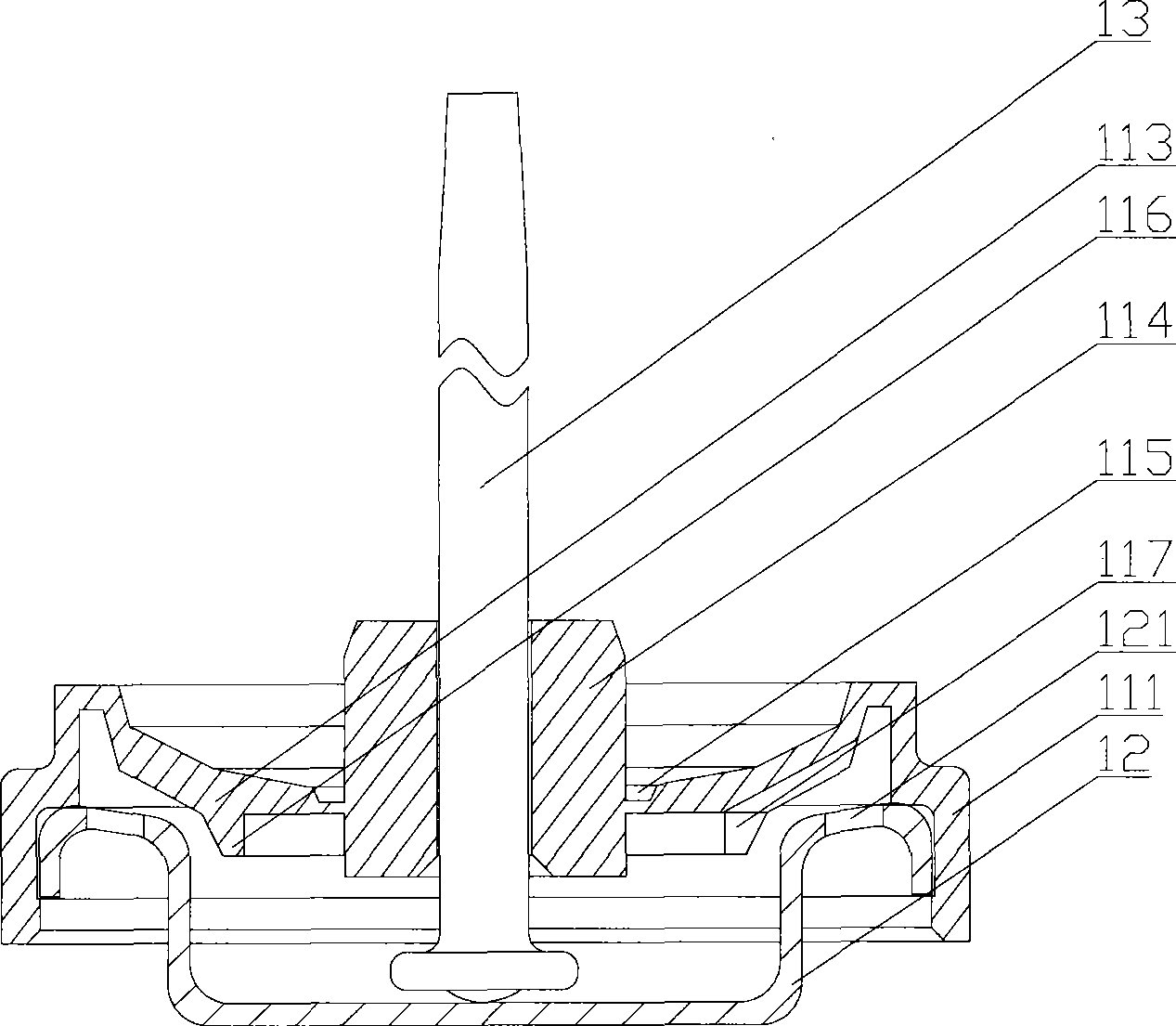

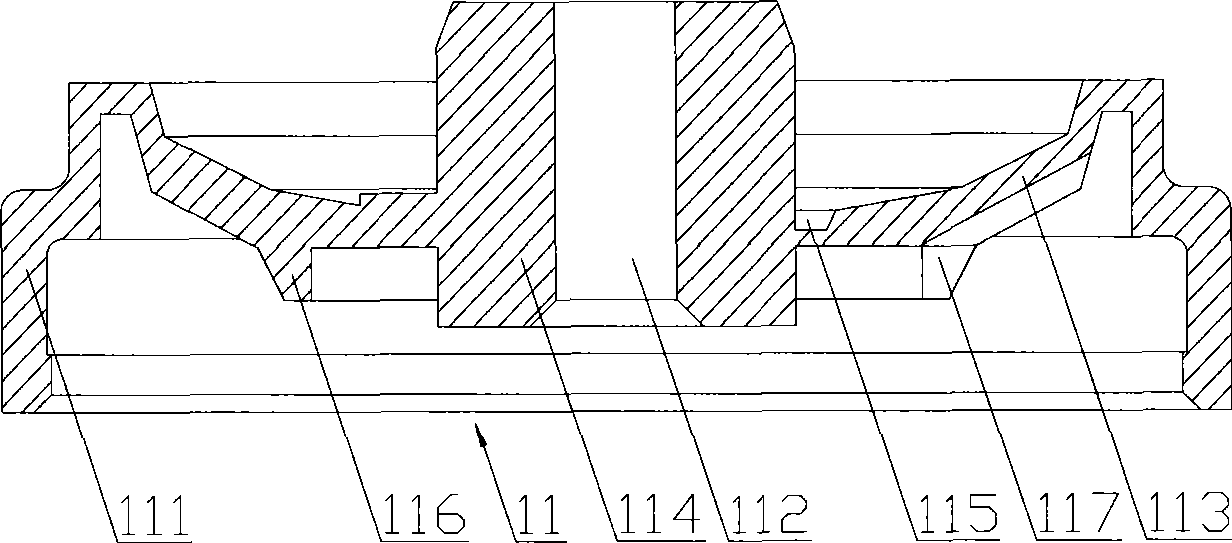

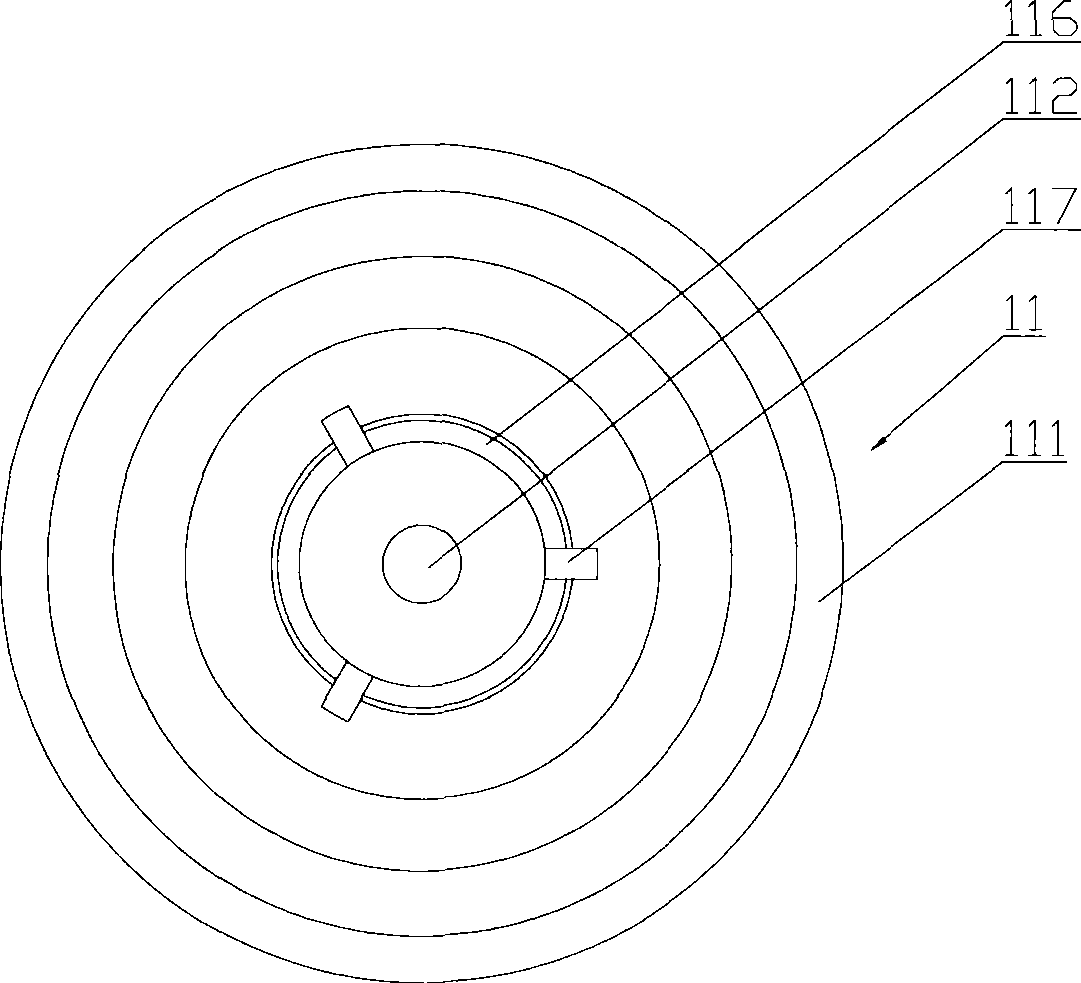

[0039] see Figure 4 and Figure 5 , Figure 4 It is a structural schematic diagram of a specific embodiment of the sealing ring provided by the present invention; Figure 5 for Figure 4 Bottom view of the seal shown.

[0040] In a specific implementation manner, the sealing ring 21 provided by the present invention can be made of nylon material, specifically, nylon 6, nylon 66 or nylon 610 can be selected.

[0041] The sealing ring 21 comprises a generally annular main plane 213 which is perpendicular to the longitudinal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com