Method and apparatus for controlling operation of dual mode hcci engines

a dual-mode hcci engine and control system technology, applied in the direction of electric control, machines/engines, output power, etc., can solve the problems of misfire condition, excessive peak pressure, poor efficiency and other issues, etc., to facilitate the transition between hcci-si combustion mode and promote efficient and stable hcci combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

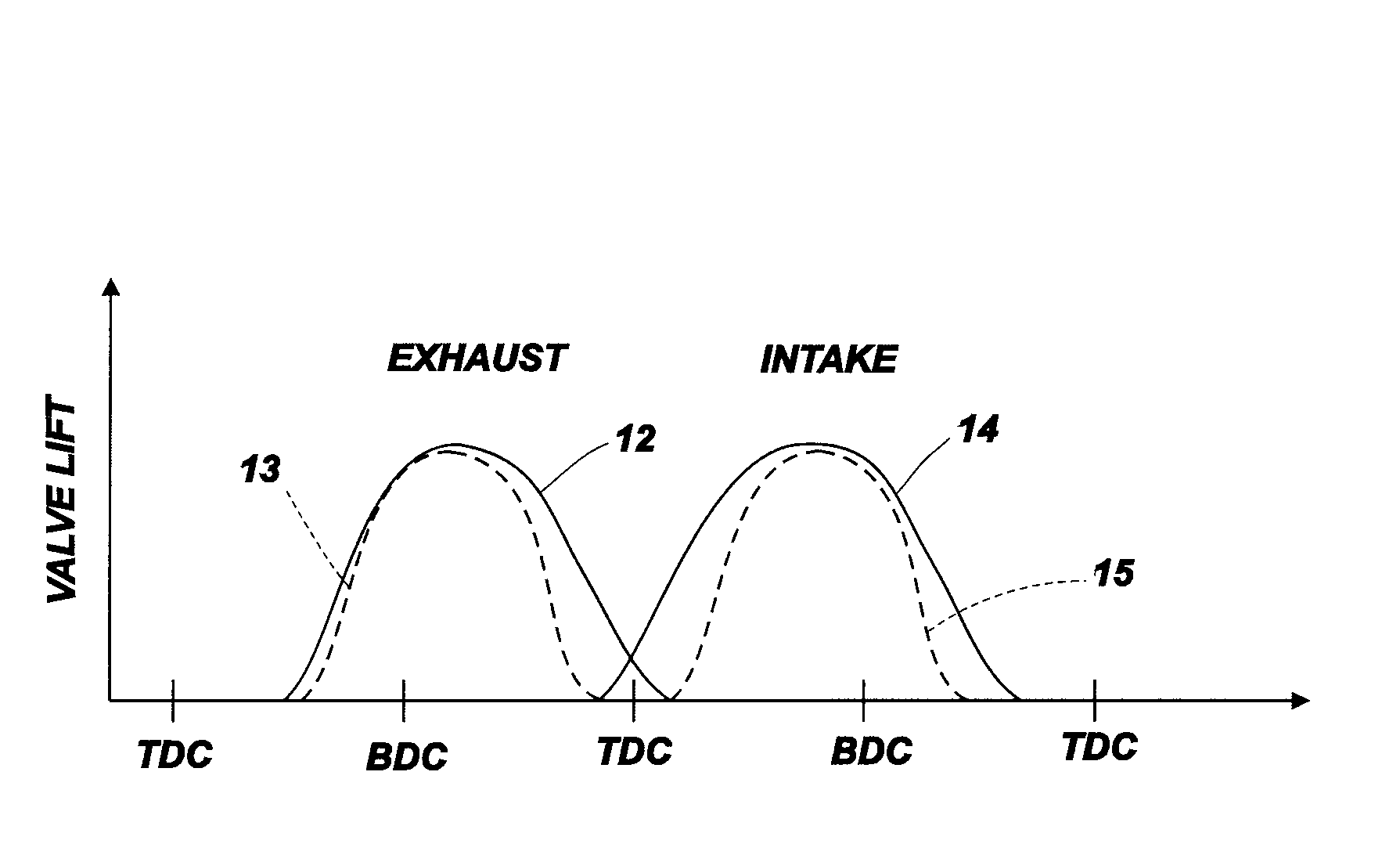

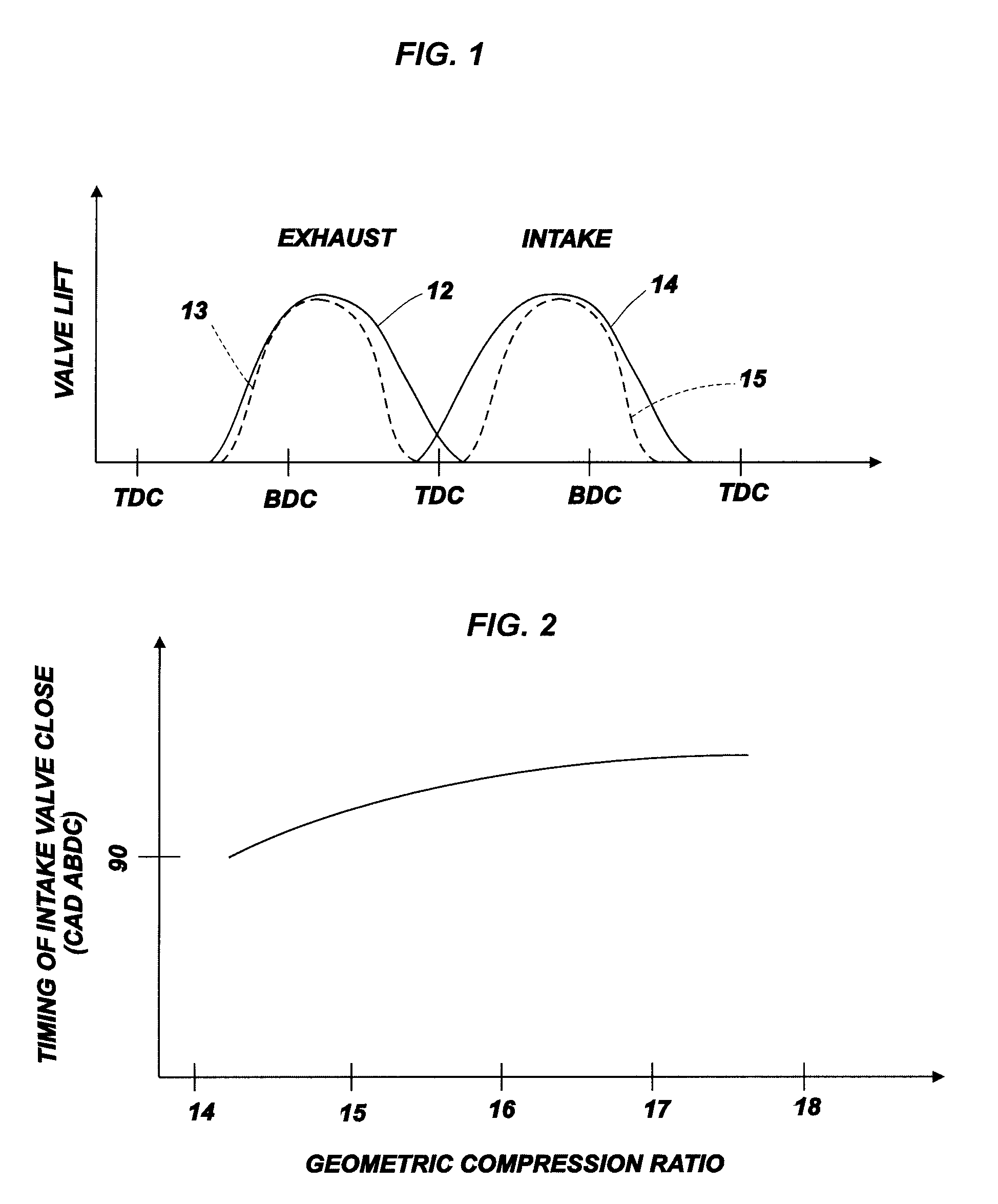

[0048] Referring to FIGS. 1-3, intake / exhaust system 10 is disclosed. For the embodiment of FIGS. 1-3, generally, there is described an HCCI-SI dual-mode engine system with a geometric compression ratio of approximately 15:1, which is higher than those of conventional SI engines. In order to operate an engine in both HCCI and SI modes, to achieve HCCI-SI combustion mode transition, and to operate an engine at high load (˜10 bar BMEP), the proposed engine system according to the present invention has the following features discussed herein in reference to FIGS. 1-3.

[0049] As illustrated in FIG. 1, there are disclosed proposed engine intake and exhaust valve timings and lifts according to the present invention. The valve lift profiles illustrated in FIG. 1 allow the use of cam profile switching as one of the major means to change the combustion mode between HCCI and SI by allowing the use of high engine geometric compression ratio. In the embodiments discussed herein, the cam profile ...

second embodiment

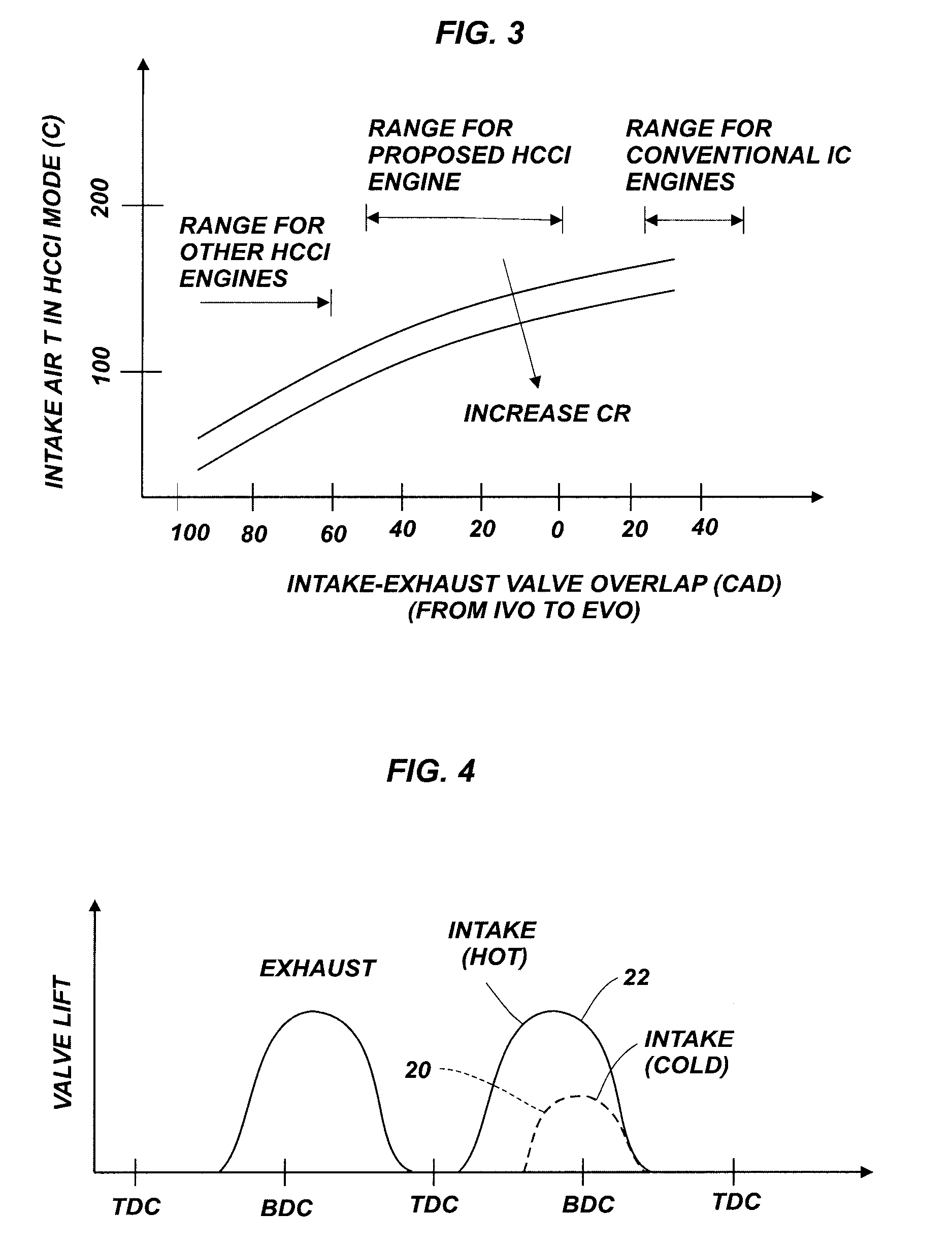

[0057] the present invention, which addresses heterogeneity of in-cylinder temperature, will be discussed in detail below in reference to FIGS. 4-7.

[0058] With regard to the second embodiment, in HCCI mode, an intake system can promote heterogeneity of the in-cylinder temperature distribution, hence reducing the overall combustion rate for a cylinder. During HCCI-SI combustion mode transition at engine speeds below 3000 rpm, an intake system can promptly change the air-fuel charge temperature, the residuals ratio, the intake pressure, as well as the effective compression ratio (intake valve closing time). In SI mode at high engine speeds up to 6000 rpm, an intake system can use all (two or more) intake valves per cylinder to achieve high volumetric efficiency, and can operate with boosted intake pressure. For the present invention, it is also desirable to switch the combustion mode in different cylinders at different times to achieve a smooth transition.

[0059] Based upon the aforem...

third embodiment

[0065] the present invention, which provides for further improvement in control of the combustion mode transition, will be discussed in detail below in reference to FIGS. 8-10.

[0066] Referring to FIG. 8(a), in order to improve the control of the combustion mode transition process, the third embodiment of the present invention uses two cam profile switching devices 35, 37 per cylinder for both cold and hot intake valves 24, 26, respectively, and a single cam profile switching device 23 for exhaust valves 27. For example, whereas the second embodiment for FIG. 5(a) uses a single cam profile switching device 25 for cold intake valve 24, the third embodiment of FIG. 8(a) uses two cam profile switching devices 35, 37 per cylinder for cold and hot intake valves, 24, 26, respectively. One advantage of using two cam profile switching devices is that the change of the throttle angle may be decreased without jeopardizing engine performance.

[0067] Specifically, lift curves 43, 44 for cold int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com