High-intensity active carbon sedimentation basin and sedimentation process

A technology of activated carbon and sedimentation tank, used in sedimentation separation, sedimentation tank, water/sludge/sewage treatment, etc., can solve the problems of odor, limited removal of chromatic organic matter, low turbidity of effluent, and small footprint. , to achieve the effect of good effluent quality, strong removal capacity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

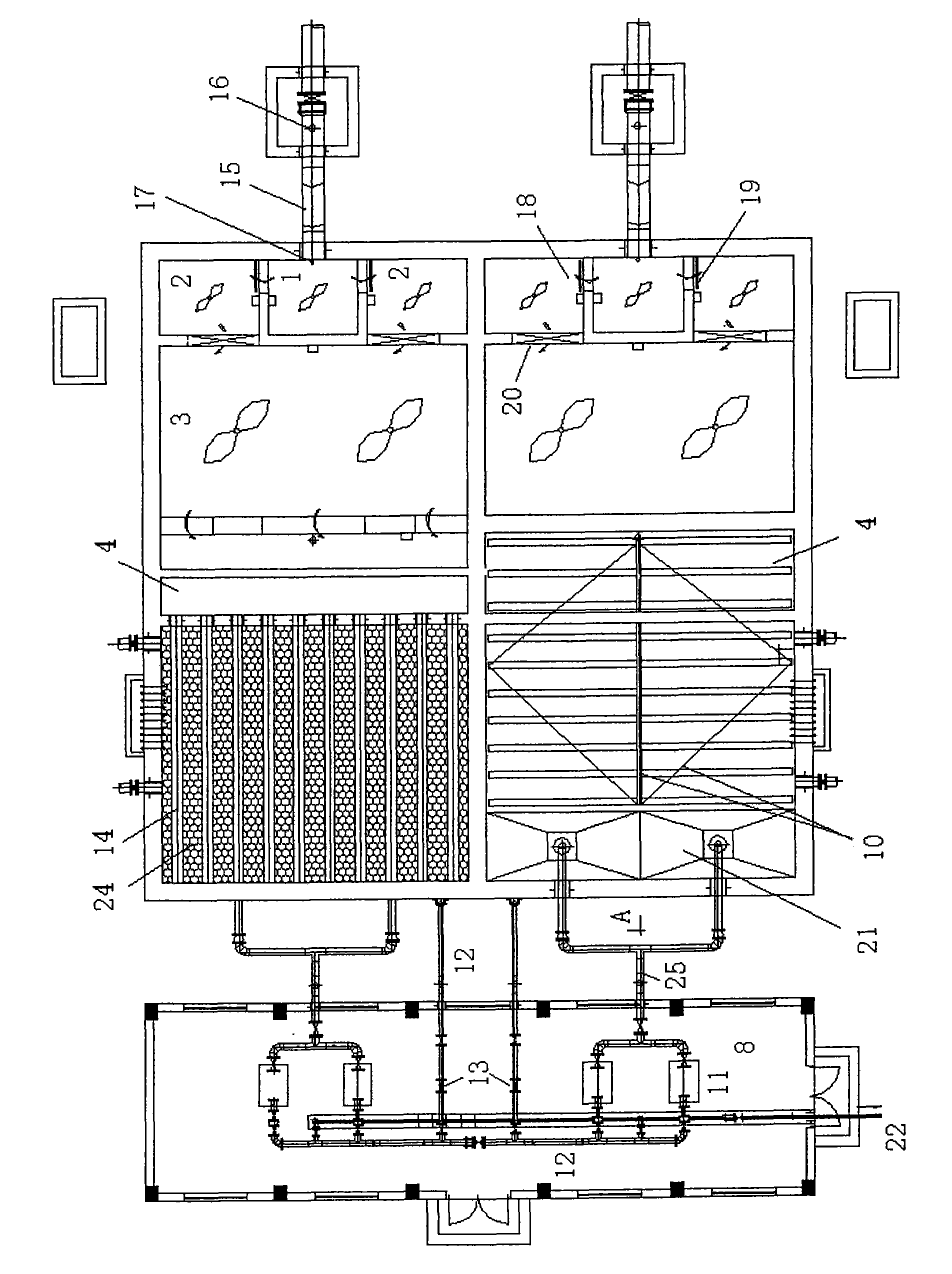

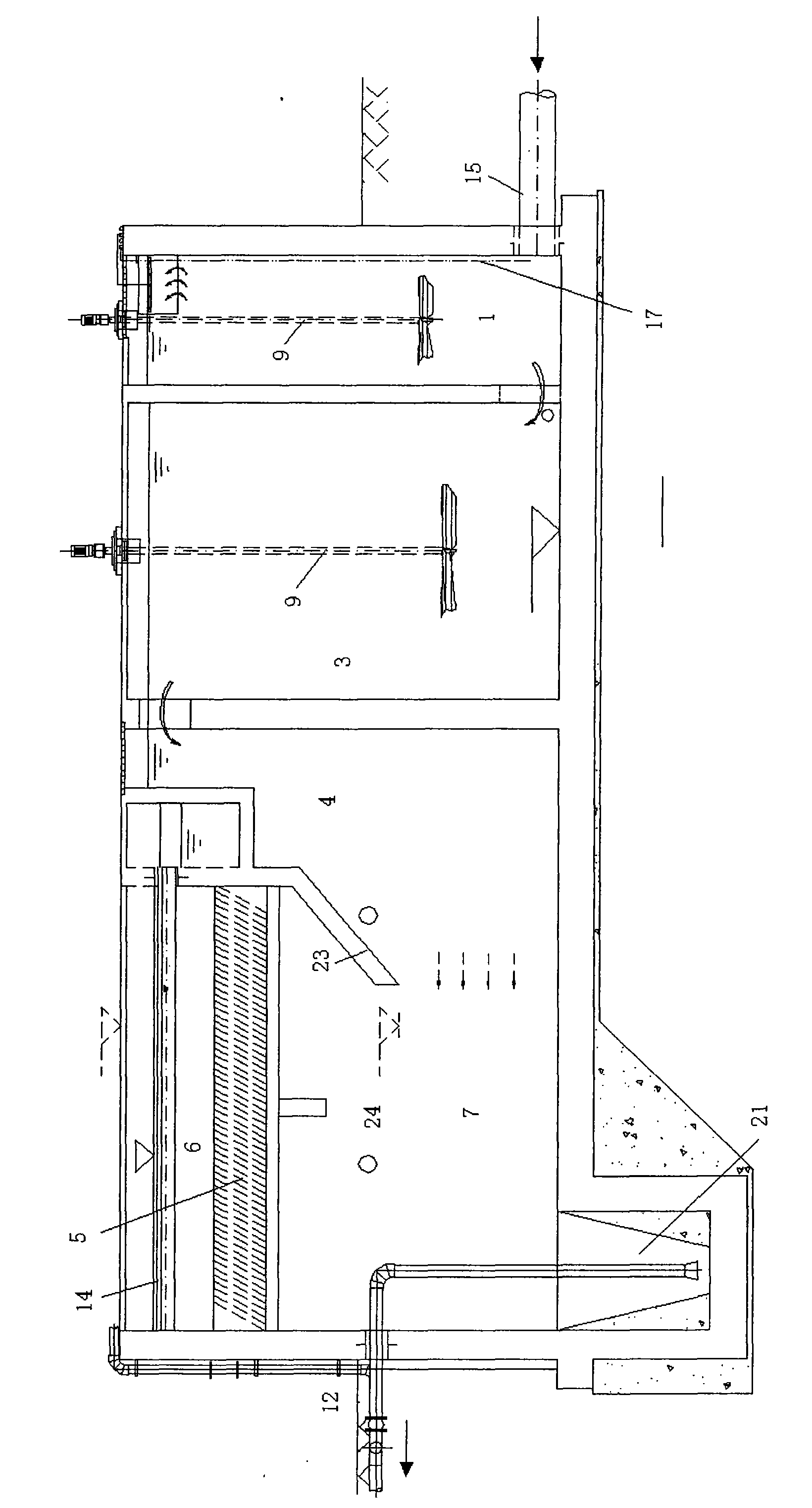

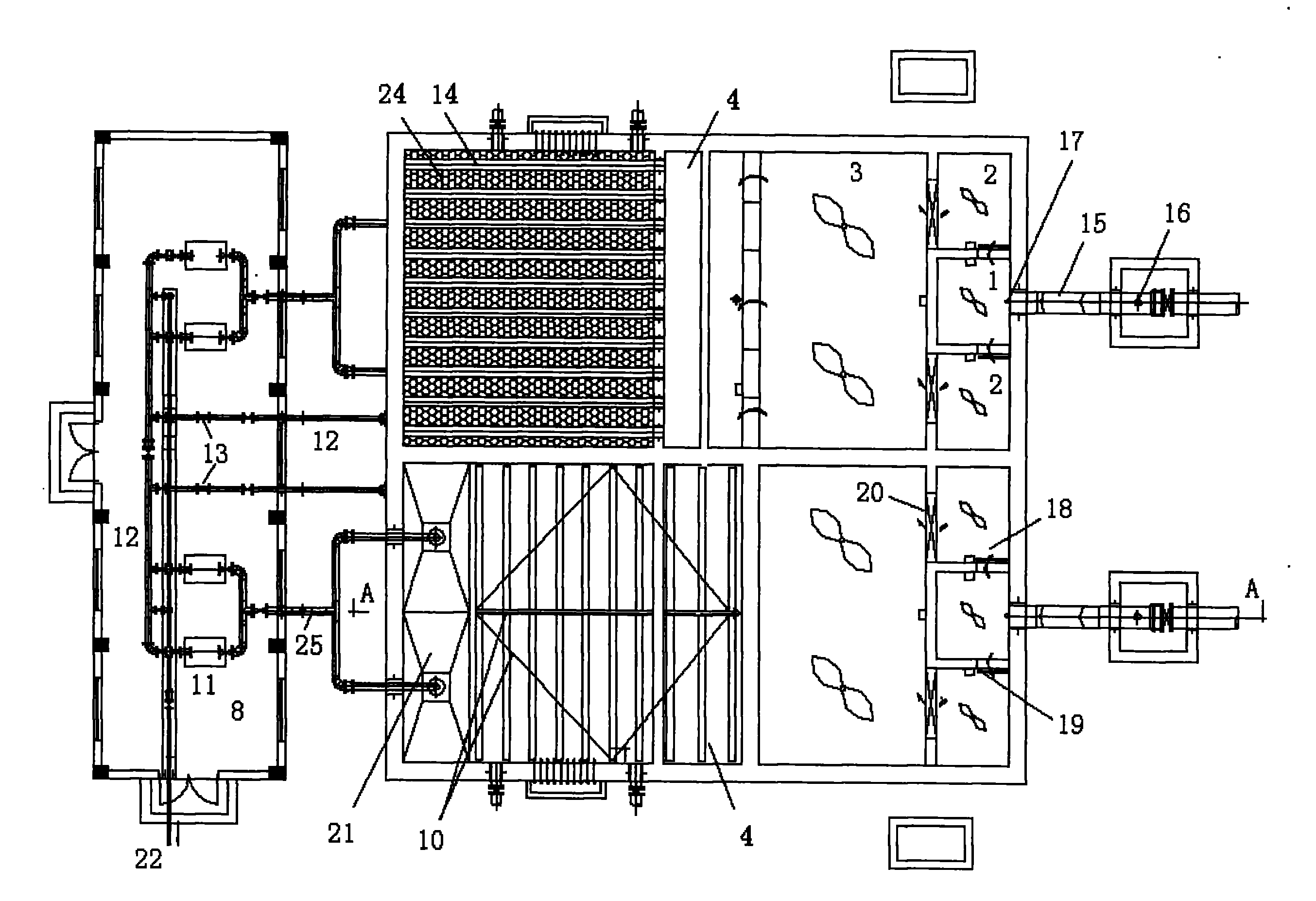

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] A high-density activated carbon sedimentation tank, including a water inlet pipe, is characterized in that the water inlet pipe 15 is connected to the mixing tank 1, the mixing tank 1 is connected to the first-level flocculation tank 2 arranged on both sides of the mixing tank, and the first-level flocculation tank 2 is connected to the second-level flocculation tank. The adsorption pool 3 is connected, the secondary flocculation adsorption pool 3 is connected with the sedimentation area 24 through the variable speed adsorption push flow area 4, and the connection between the variable speed adsorption push flow pool 4 and the sedimentation area 24 is provided with an inclined wall 23, and the bottom of the inclined wall 23 is connected to the bottom plate of the pool. There is a flow passage between them, and the variable speed adsorption push flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com