Circulation fluidized bed swirl-direct flow composite fluidizing device

A circulating fluidized bed and chemical device technology, applied in chemical instruments and methods, chemical/physical processes, separation methods, etc., can solve problems such as high internal circulation ratio, long residence time, airflow deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

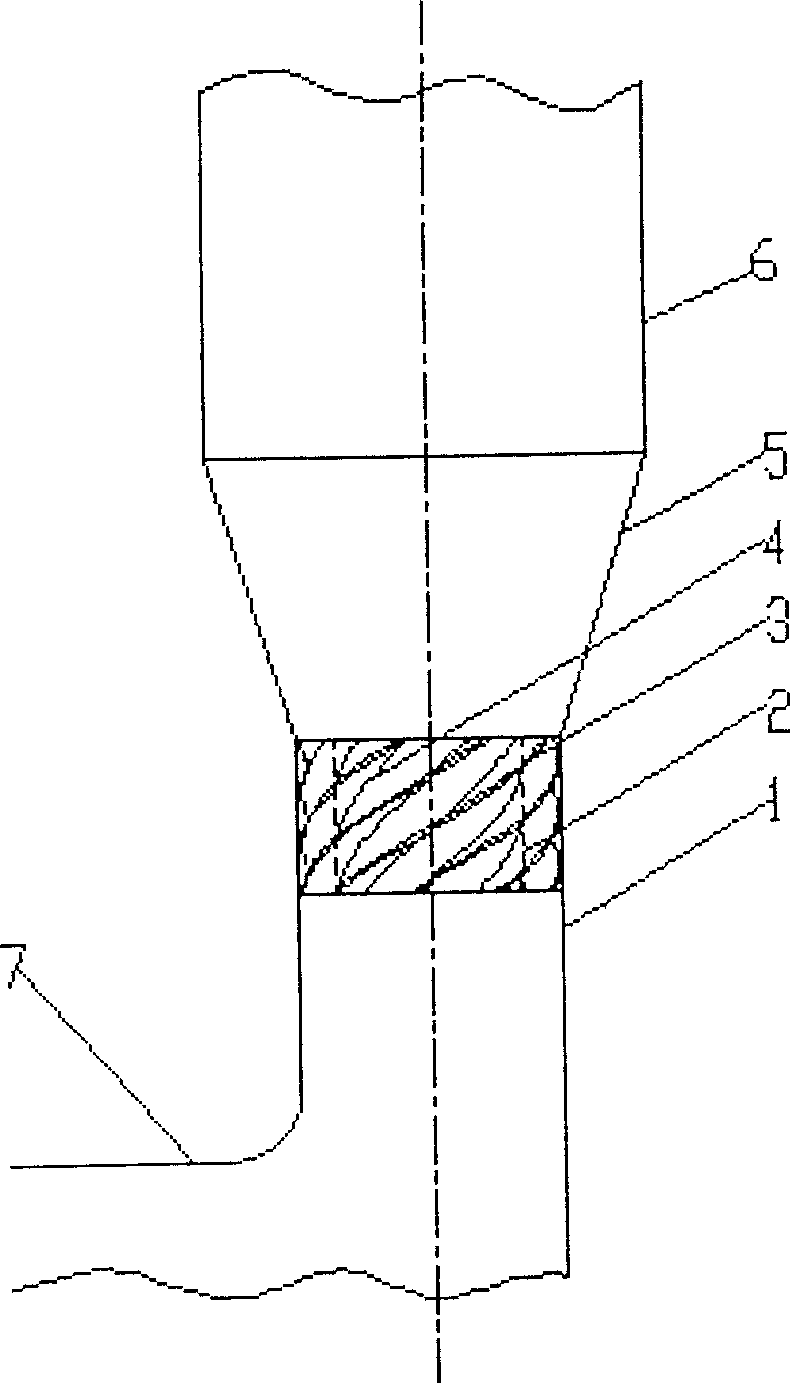

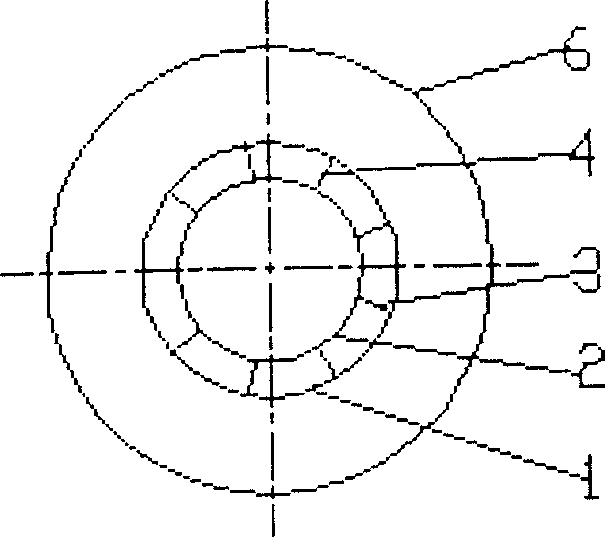

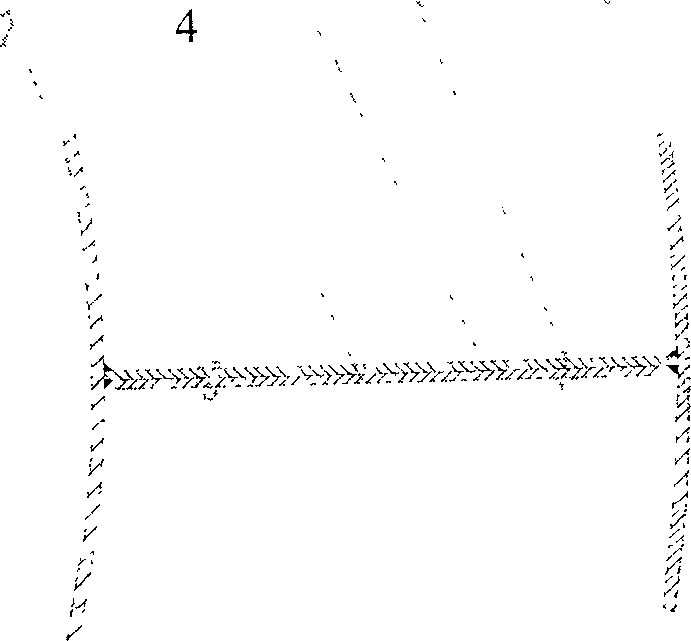

[0016] Example 1: For medium- or low-temperature circulating fluidized bed semi-dry flue gas desulfurization, the flue gas flows in horizontally through the inlet flue 7, rotates 90 degrees and then flows vertically upward through the venturi tube throat 1 and gradual expansion Section 5, enters the desulfurization tower. The inner sleeve 2 is installed in the Venturi tube throat 1, which is coaxial with the Venturi tube throat 1, and has a circular cross-section, whose cross-sectional area accounts for 60% of the Venturi tube throat 1, and the wall surface and the Venturi tube throat The walls of 1 are parallel, and the flue gas flowing in it is DC fluidization; between the inner sleeve 2 and the Venturi throat 1 is the swirl fluidization device 3, and the cross-sectional area of the swirl fluidization device 3 occupies the venturi throat 40% of the cross-sectional area of the pipe 1, the swirl fluidization device 3 is composed of 9 rotating blades 4, and the swirl fluidi...

Embodiment 2

[0017] Embodiment 2: The lower end of the inner sleeve 2 is located in the Venturi tube throat 1, and the upper end is located at half the height of the Venturi tube expansion section 5, and the cross-sectional area accounts for 70% of the cross-sectional area of the Venturi tube expansion section 5 at the same height. , the wall surface of the inner sleeve 2 is parallel to the wall surface of the Venturi expanding section 5 and the Venturi tube throat 1 . The swirling fluidization device 3 is located between the expanding section 5 of the Venturi tube and the inner sleeve, the upper end of the swirling fluidizing device 3 is flush with the upper end of the inner sleeve 2, and the cross-sectional area of the upper end occupies the same height as the venturi tube expanding 30% of the cross-sectional area of the section 5, the height of the swirling fluidization device 3 is 30% of the height of the expanding section 5 of the Venturi tube, and there are 6 rotating blades 4 w...

Embodiment 3

[0018] Embodiment 3: The lower end of the inner sleeve 2 is located in the Venturi throat 1, and the upper end is located in the lower part of the desulfurization tower cylinder 6, and the cross-sectional area of the inner sleeve 2 in the desulfurization tower cylinder 6 accounts for 10% of the desulfurization tower cylinder 6. 30% of the cross-sectional area, the wall surface of the inner sleeve 2 is parallel to the wall surfaces of the desulfurization tower body 6, the Venturi tube gradual expansion section 5, and the Venturi tube throat 1 respectively. The swirl fluidization device 3 is located between the desulfurization tower body 6 and the inner sleeve 2 , the upper end is flush with the upper end of the inner sleeve 2 , and the lower end is located at the inlet of the desulfurization tower body 6 . The cross-sectional area of the swirl fluidization device 3 accounts for 70% of the cross-sectional area of the desulfurization tower cylinder 6, and there are 15 rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com