Patents

Literature

71 results about "Channel geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Channel geometry and characteristics of stream flow are inherently related. Changes in the geometry of the channel can impact stream velocity and discharge. Figure 18.12 Cross-sectional area. The cross-sectional area of the stream is determined by multiplying channel depth by channel width along a transverse section of the stream.

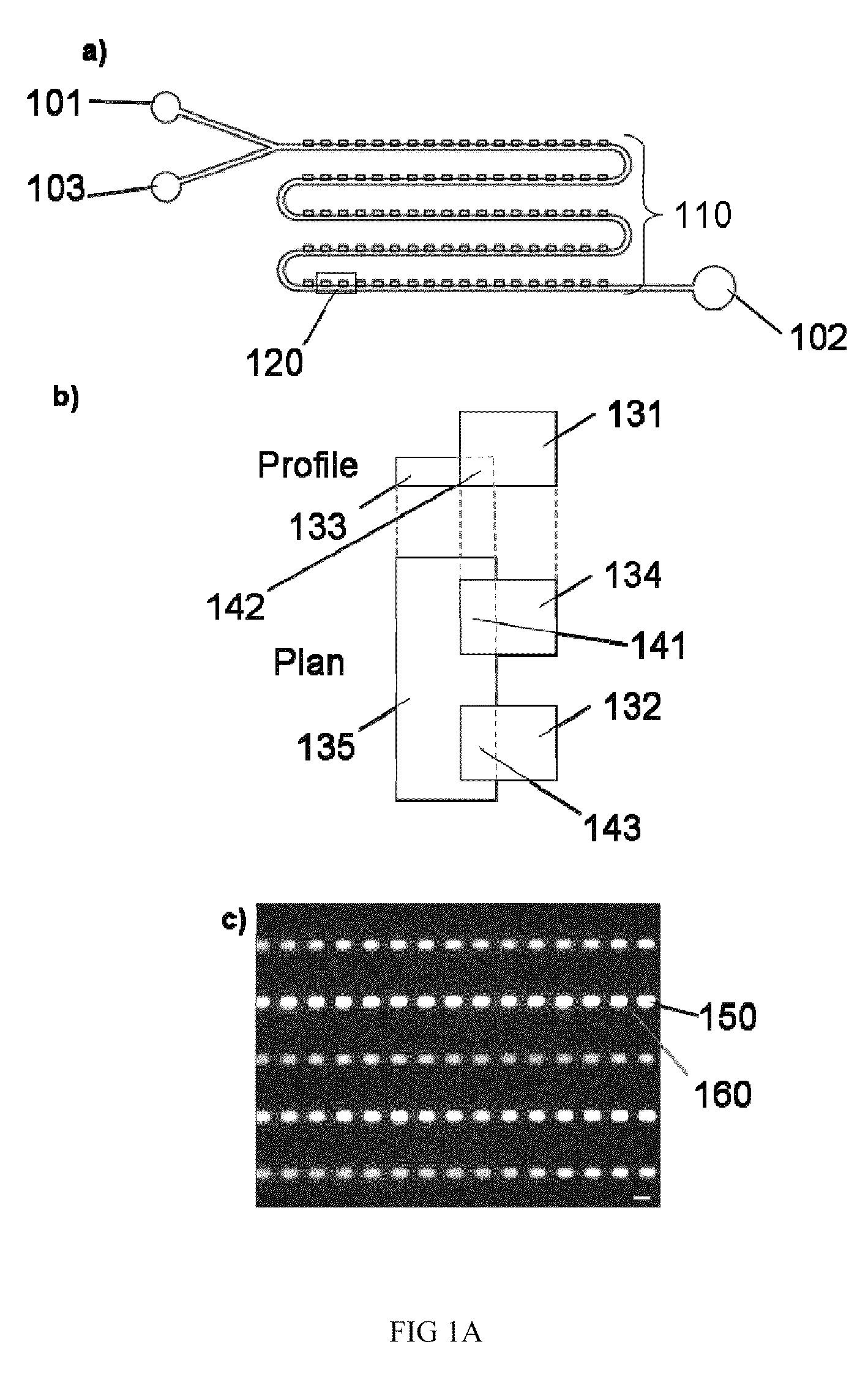

Method and apparatus for the discretization and manipulation of sample volumes

ActiveUS20100041046A1Easy to useEasy to implementBioreactor/fermenter combinationsBiological substance pretreatmentsChannel geometryAssay

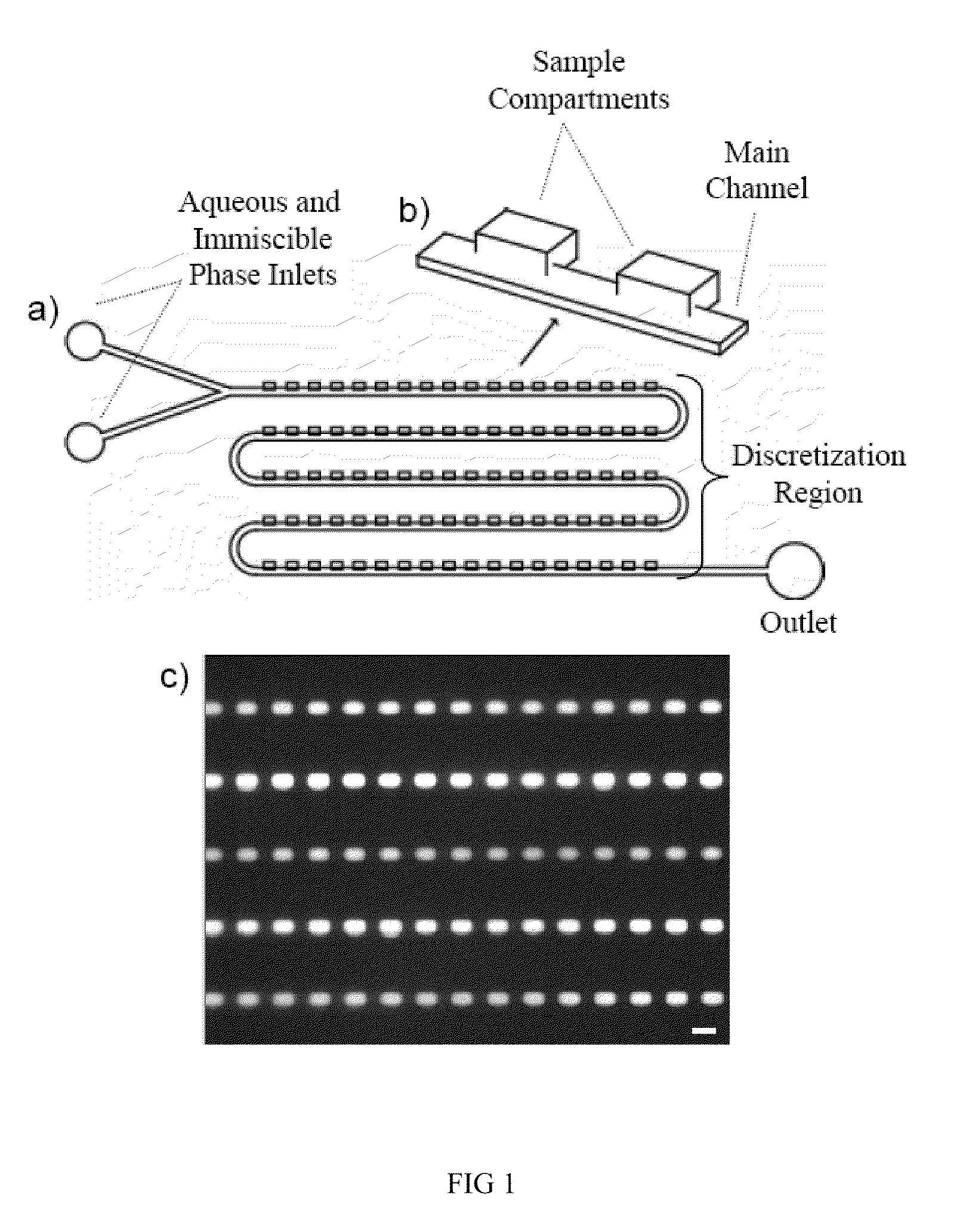

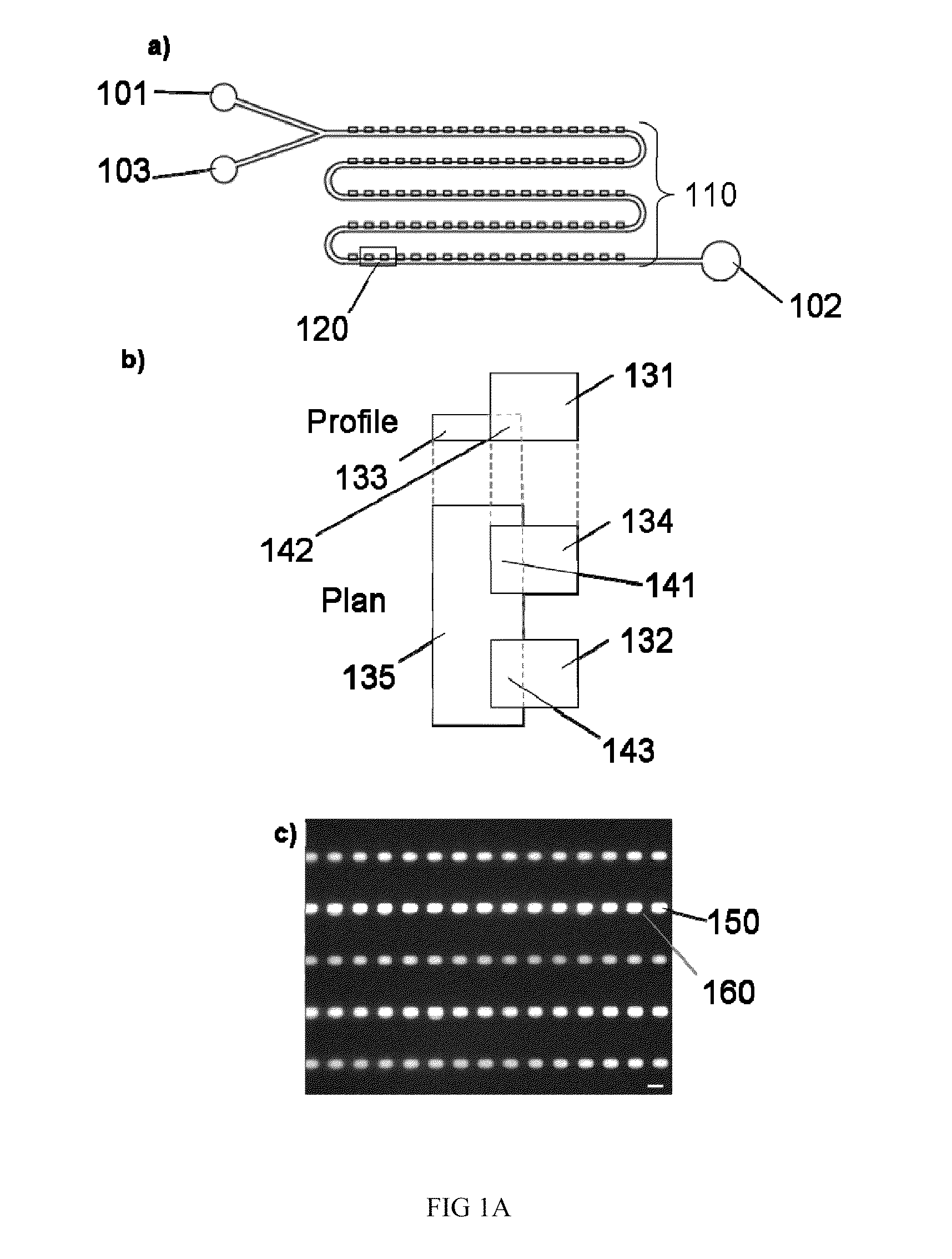

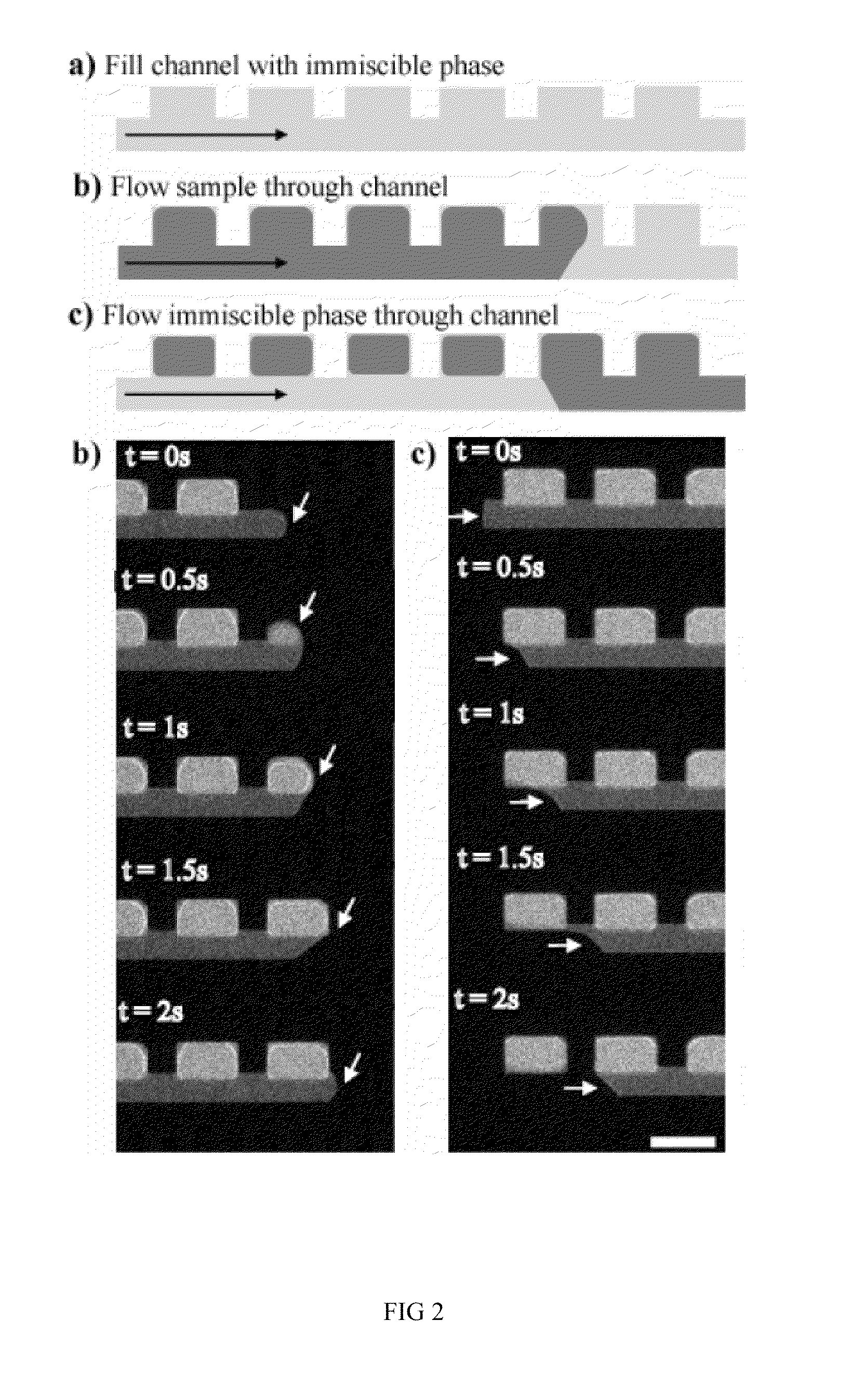

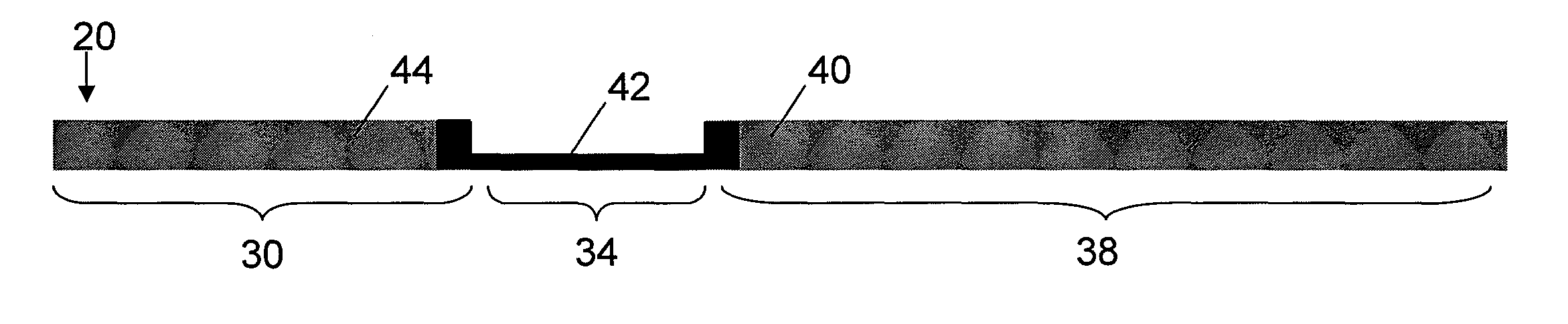

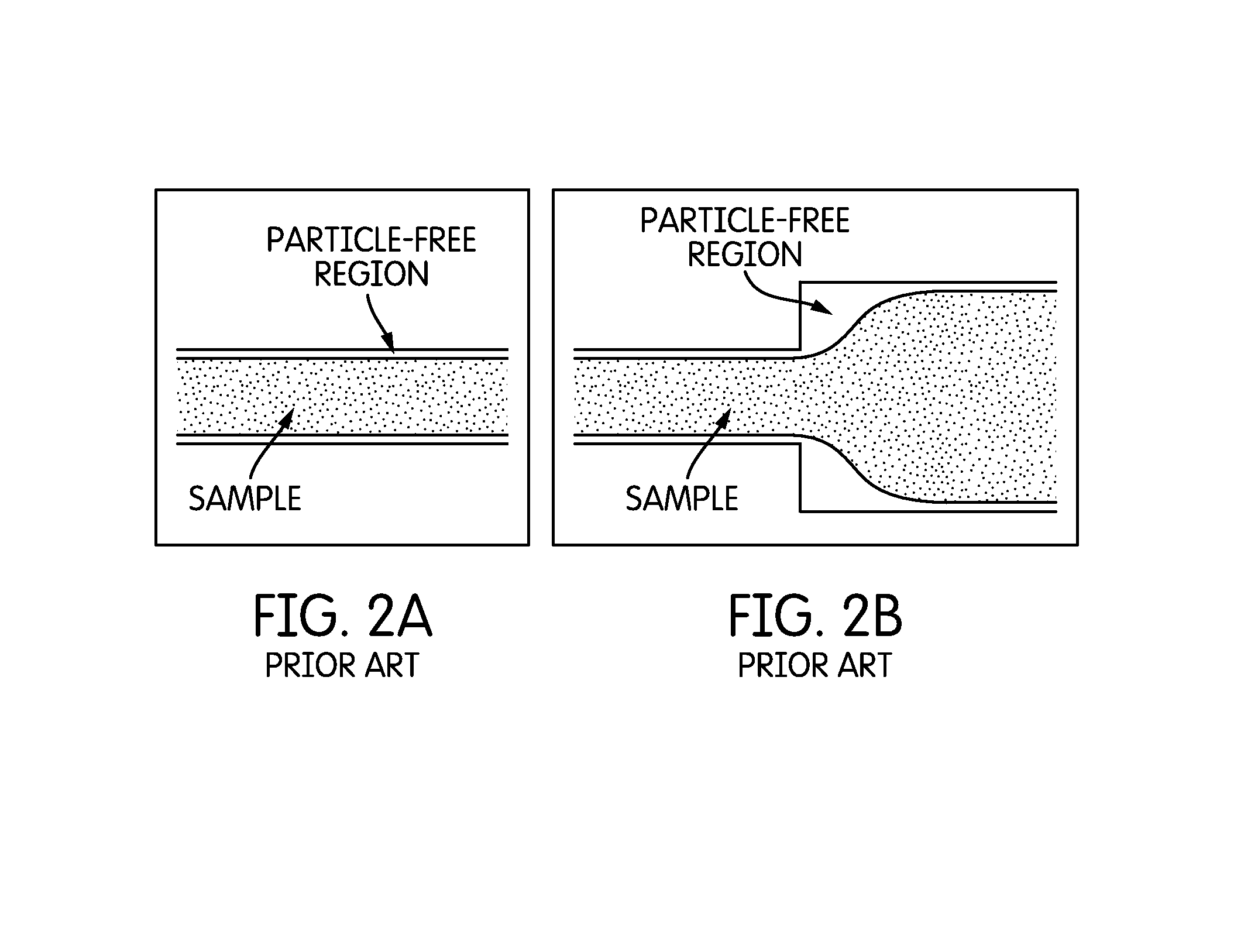

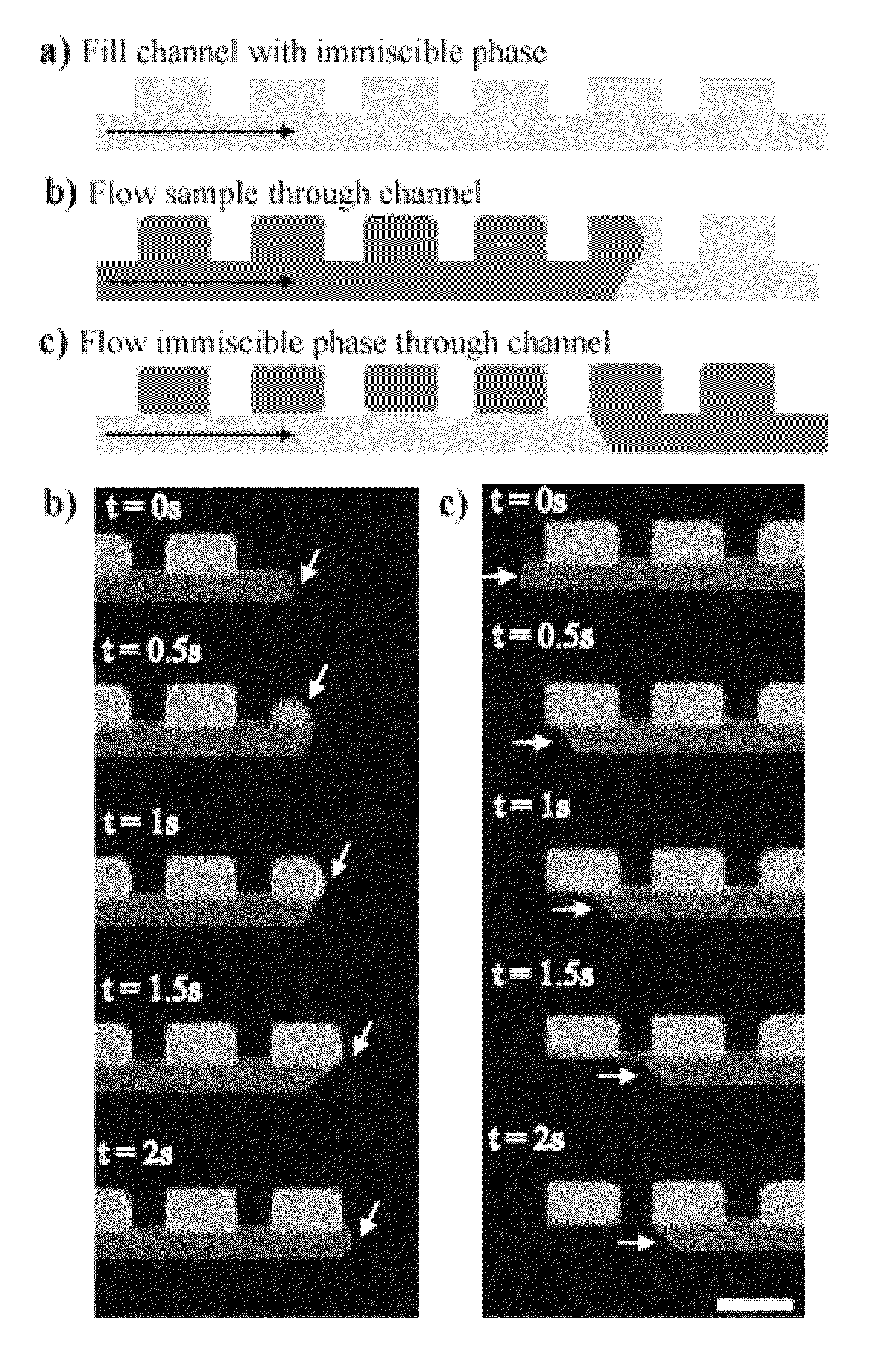

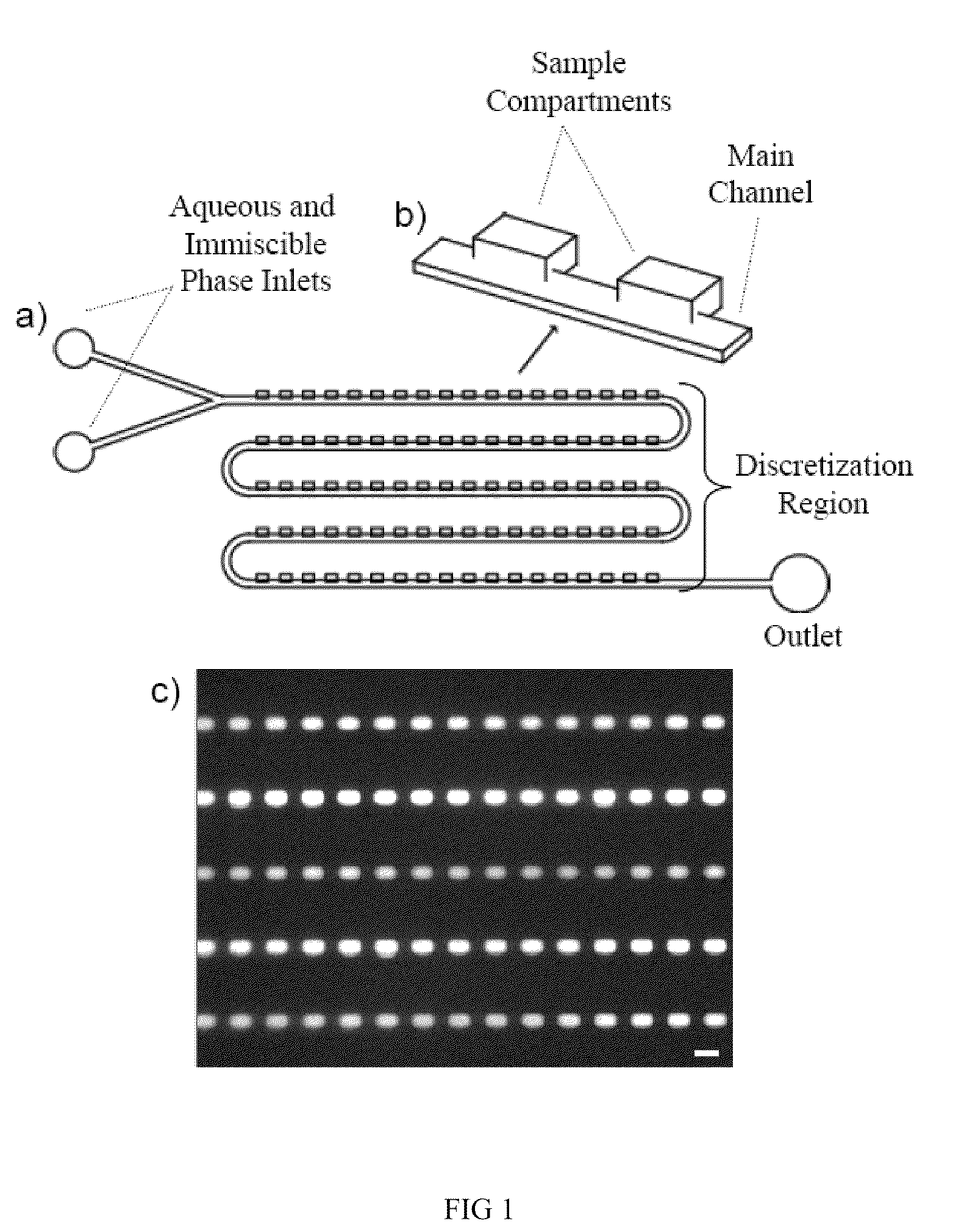

Embodiments of the present invention relate to methods and apparatuses for the discretization and manipulation of sample volumes that is simple, robust, and versatile. It is a fluidic device that partitions a sample by exploiting the interplay between fluidic forces, interfacial tension, channel geometry, and the final stability of the formed droplet and / or discretized volume. These compartmentalized volumes allow for isolation of samples and partitioning into a localized array that can subsequently be manipulated and analyzed. The isolation of the discretized volumes along with the device's inherent portability render our invention versatile for use in many areas, including but not limited to PCR, digital PCR, biological assays for diagnostics and prognostics, cancer diagnosis and prognosis, high throughput screening, single molecule and single cell reactions or assays, the study crystallization and other statistical processes, protein crystallization, drug screening, environmental testing, and the coupling to a wide range of analytical detection techniques for biomedical assays and measurements. The minimal fluid interconnects and simple flow geometry makes the device easy to use and implement, economical to fabricate and operate, and robust in its operations.

Owner:UNIV OF WASHINGTON

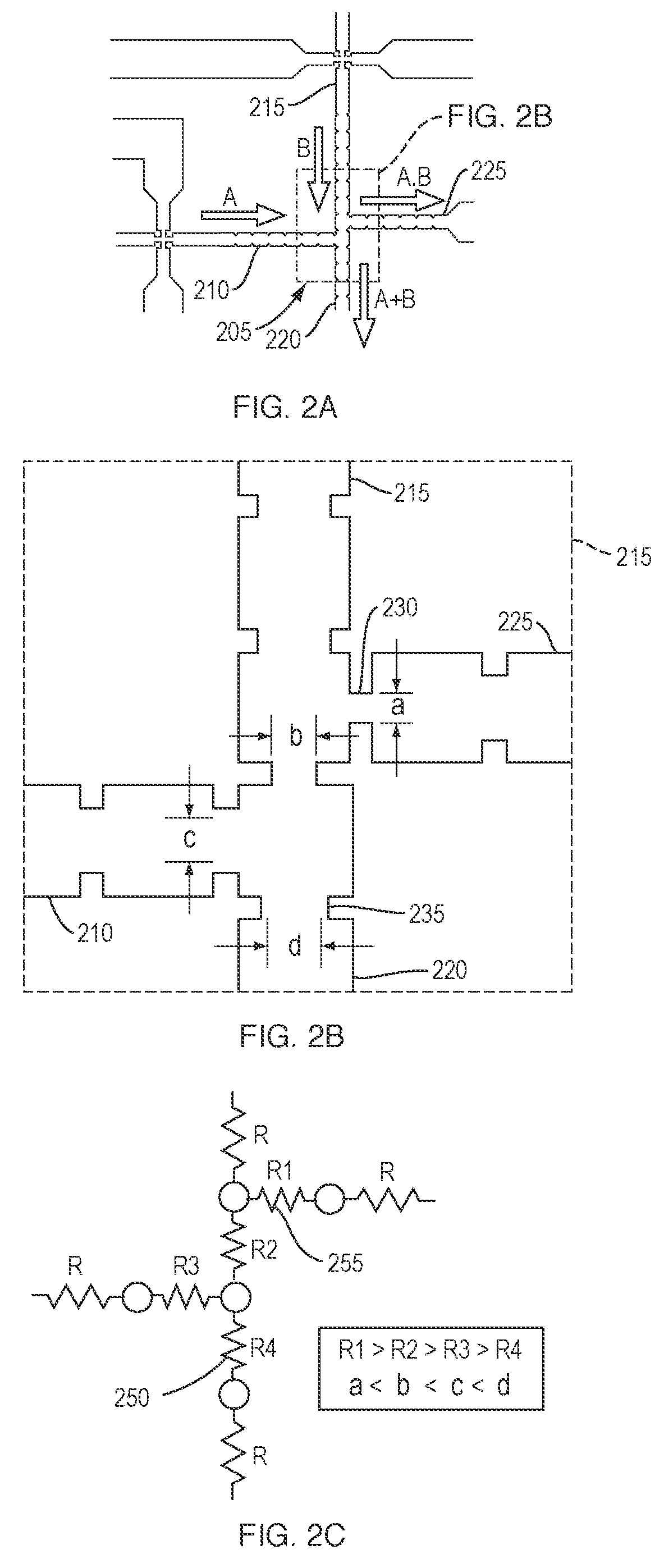

Flow control in microfluidic systems

ActiveUS8222049B2Reduce flow rateIncrease the cross-sectional areaBioreactor/fermenter combinationsBiological substance pretreatmentsChannel geometryFluid viscosity

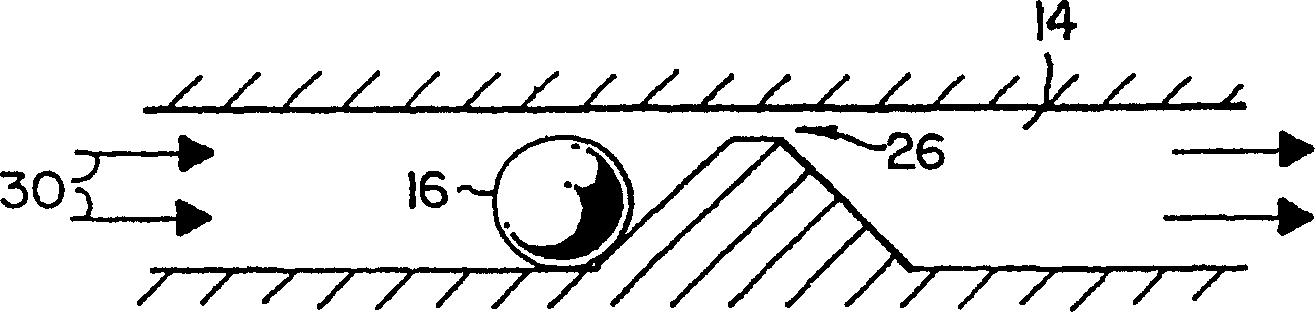

Microfluidic systems and methods including those that provide control of fluid flow are provided. Such systems and methods can be used, for example, to control pressure-driven flow based on the influence of channel geometry and the viscosity of one or more fluids inside the system. One method includes flowing a plug of a low viscosity fluid and a plug of a high viscosity fluid in a channel including a flow constriction region and a non-constriction region. In one embodiment, the low viscosity fluid flows at a first flow rate in the channel and the flow rate is not substantially affected by the flow constriction region. When the high viscosity fluid flows from the non-constriction region to the flow constriction region, the flow rates of the fluids decrease substantially, since the flow rates, in some systems, are influenced by the highest viscosity fluid flowing in the smallest cross-sectional area of the system (e.g., the flow constriction region). This causes the fluids to flow at the same flow rate at which the high viscosity fluid flows in the flow constriction region. Accordingly, by designing microfluidic systems with flow constriction regions positioned at particular locations and by choosing appropriate viscosities of fluids, a fluid can be made to speed up or slow down at different locations within the system without the use of valves and / or without external control.

Owner:OPKO DIAGNOSTICS

Microfluidic devices incorporating improved channel geometries

The present invention generally provides microfluidic devices which incorporate improved channel and reservoir geometries, as well as methods of using these devices in the analysis, preparation, or other manipulation of fluid borne materials, to achieve higher throughputs of such materials through these devices, with lower cost, material and / or space requirements.

Owner:CAPLIPER LIFE SCI INC

Flow control in microfluidic systems

ActiveUS20090266421A1Reduce flow rateIncrease the cross-sectional areaBioreactor/fermenter combinationsBiological substance pretreatmentsChannel geometryFluid viscosity

Microfluidic systems and methods including those that provide control of fluid flow are provided. Such systems and methods can be used, for example, to control pressure-driven flow based on the influence of channel geometry and the viscosity of one or more fluids inside the system. One method includes flowing a plug of a low viscosity fluid and a plug of a high viscosity fluid in a channel including a flow constriction region and a non-constriction region. In one embodiment, the low viscosity fluid flows at a first flow rate in the channel and the flow rate is not substantially affected by the flow constriction region. When the high viscosity fluid flows from the non-constriction region to the flow constriction region, the flow rates of the fluids decrease substantially, since the flow rates, in some systems, are influenced by the highest viscosity fluid flowing in the smallest cross-sectional area of the system (e.g., the flow constriction region). This causes the fluids to flow at the same flow rate at which the high viscosity fluid flows in the flow constriction region. Accordingly, by designing microfluidic systems with flow constriction regions positioned at particular locations and by choosing appropriate viscosities of fluids, a fluid can be made to speed up or slow down at different locations within the system without the use of valves and / or without external control.

Owner:OPKO DIAGNOSTICS

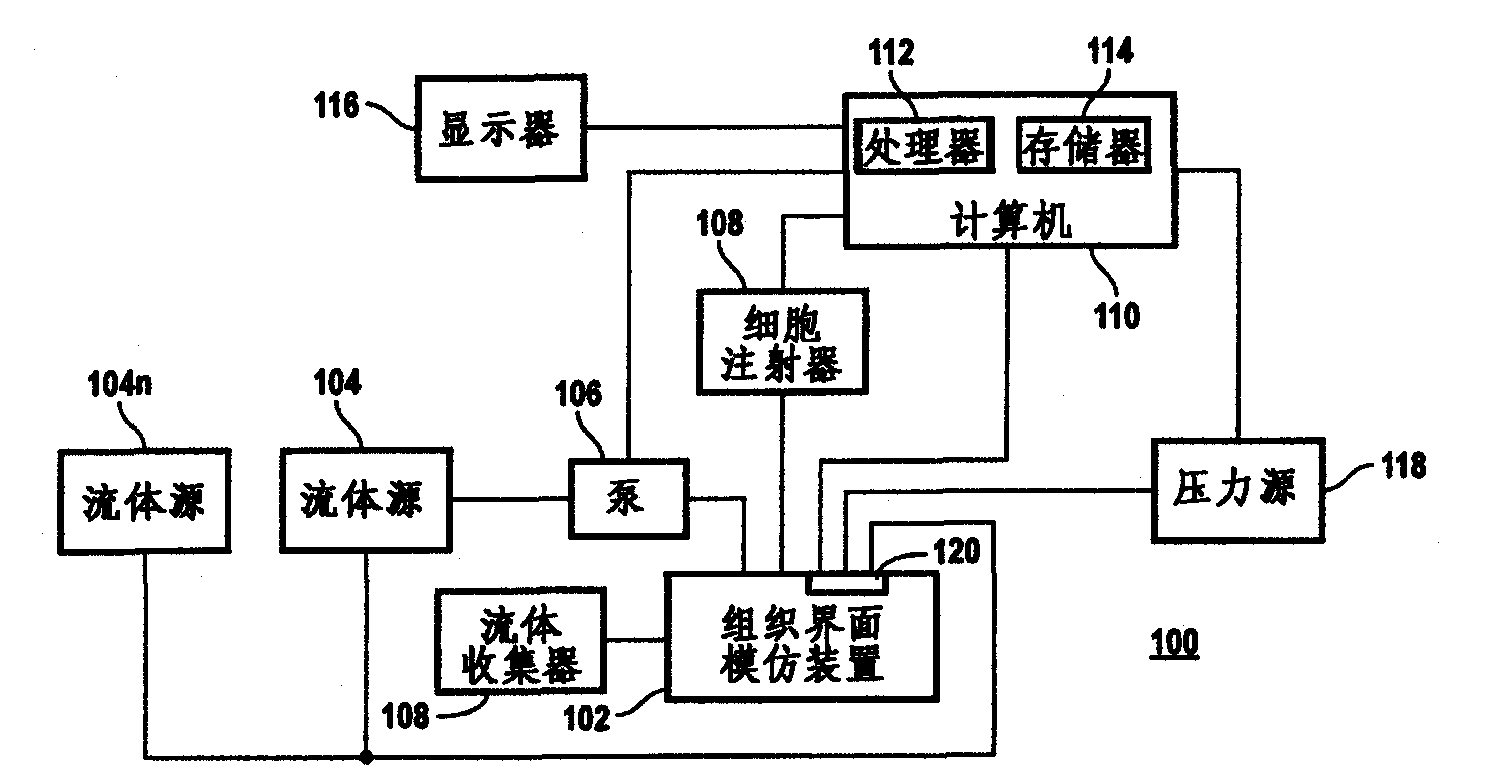

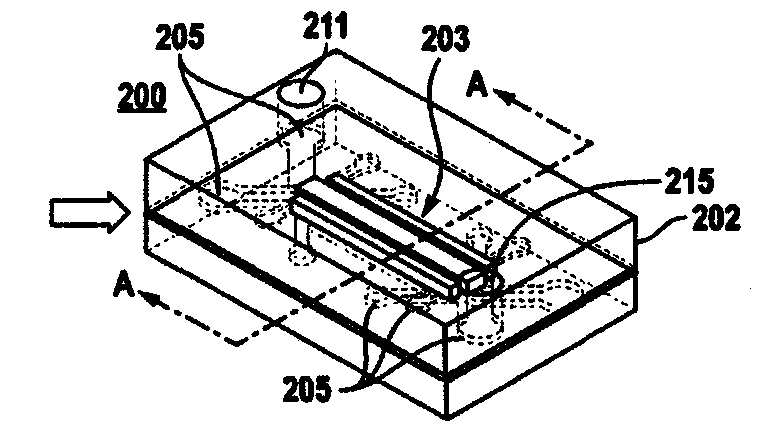

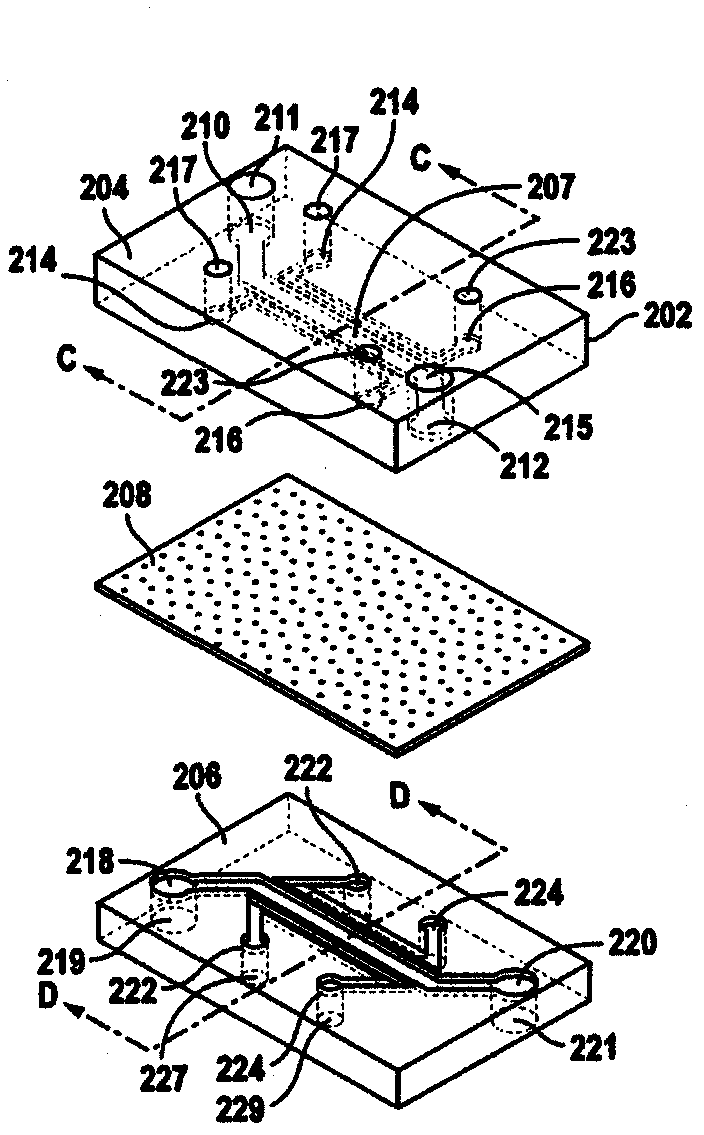

Organ mimic device with microchannels and methods of use and manufacturing thereof

The present invention discloses a system and a method including a body having a central microchannel separated by one or more porous membranes. The membranes are configured to divide the central microchannel into a two or more parallel central microchannels, wherein one or more first fluids are applied through the first central microchannel and one or more second fluids are applied through the second or more central microchannels. The surfaces of each porous membrane can be coated with cell adhesive molecules to support the attachment of cells and promote their organization into tissues on the upper and lower surface of the membrane. The pores may be large enough to only permit exchange of gases and small chemicals, or to permit migration and transchannel passage of large proteins and whole living cells. Fluid pressure, flow and channel geometry also may be varied to apply a desired mechanical force to one or both tissue layers.

Owner:CHILDRENS MEDICAL CENT CORP

Microfluidic devices incorporating improved channel geometries

The present invention generally provides microfluidic devices which incorporate improved channel and reservoir geometries, as well as methods of using these devices in the analysis, preparation, or other manipulation of fluid borne materials, to achieve higher throughputs of such materials through these devices, with lower cost, material and / or space requirements.

Owner:CALIPER TECH

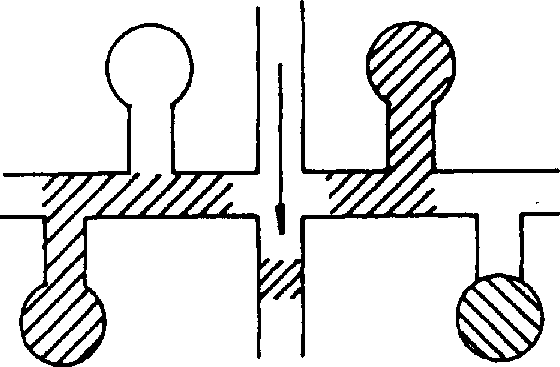

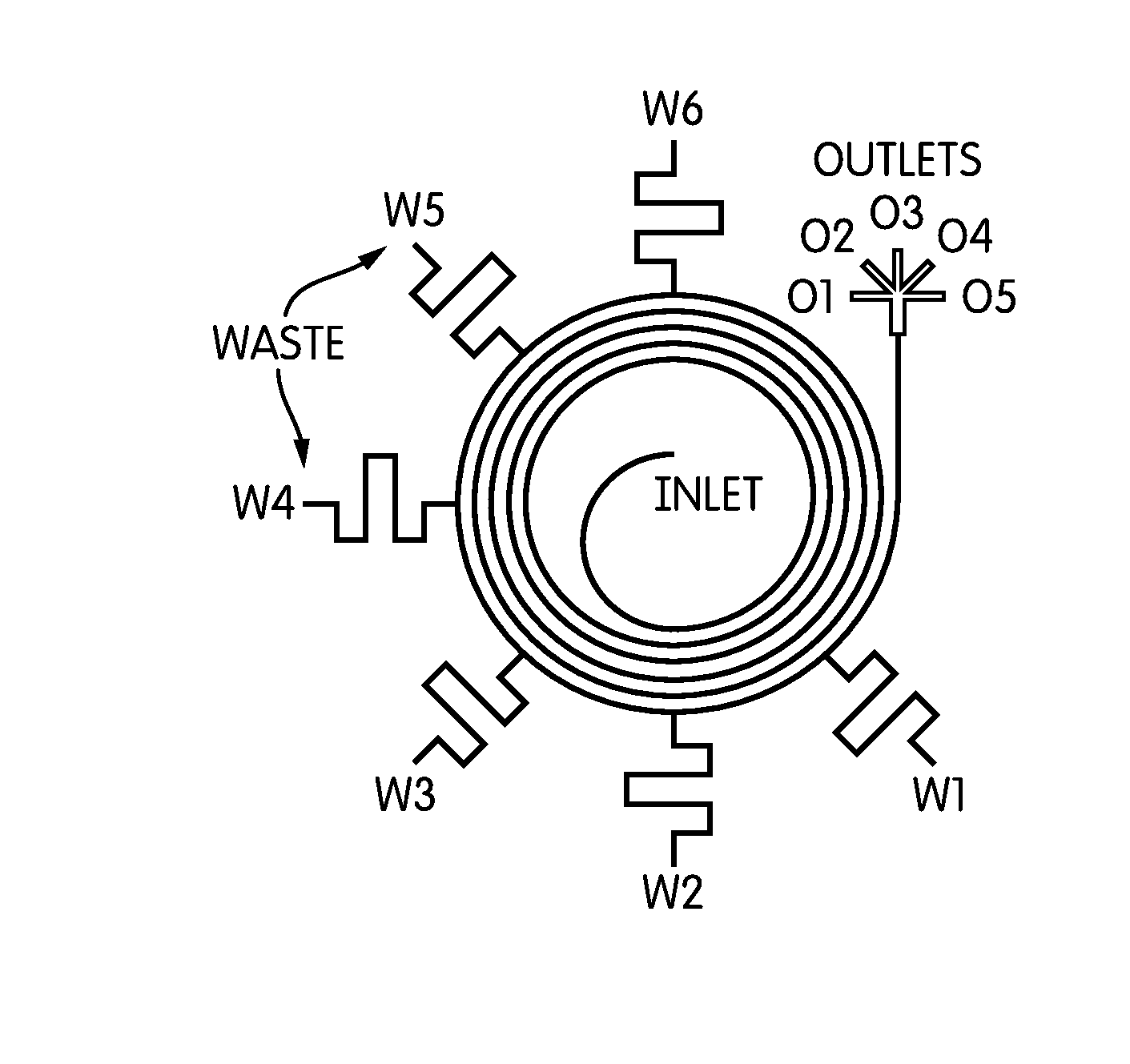

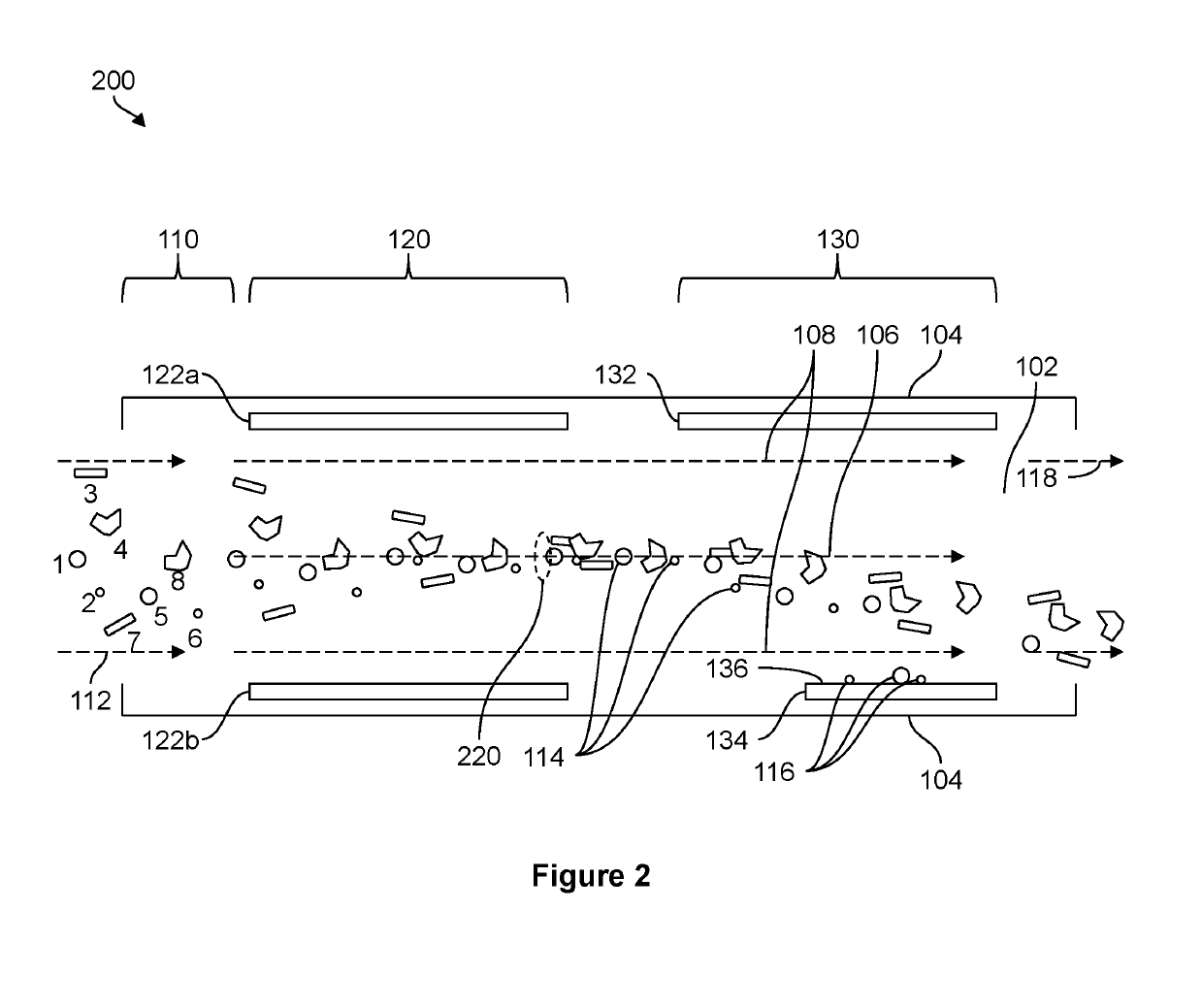

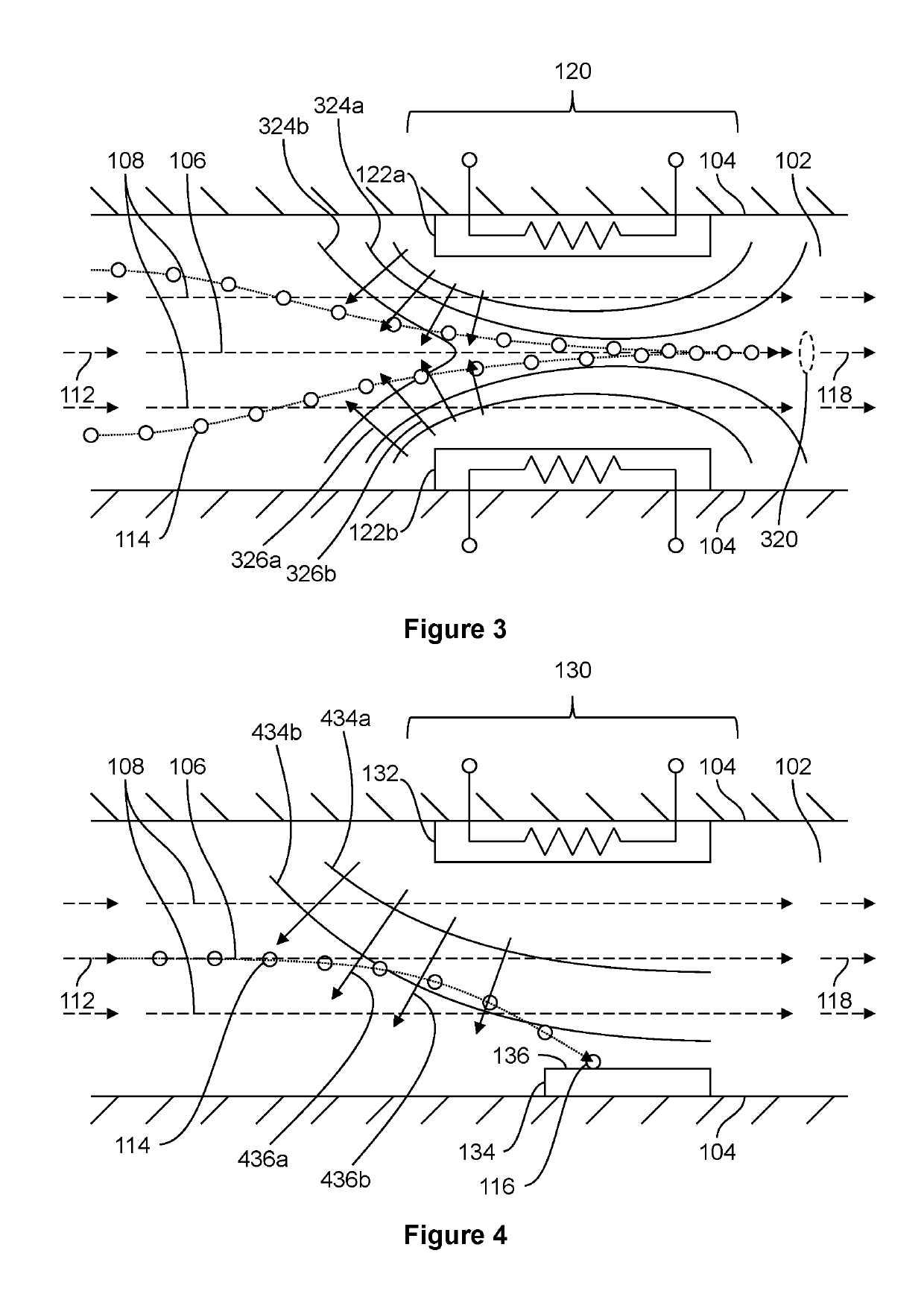

Particle separation and concentration using spiral inertial filtration

ActiveUS20140093867A1Increase particle concentrationLower the volumeMicrobiological testing/measurementPreparing sample for investigationChannel geometryFiltration

A spiral inertial filtration device is capable of high-throughput (1 mL / min), high-purity particle separation while concentrating recovered target particles by more than an order of magnitude. Large fractions of sample fluid are removed from a microchannel without disruption of concentrated particle streams by taking advantage of particle focusing in inertial spiral microfluidics, which is achieved by balancing inertial lift forces and Dean drag forces. To enable the calculation of channel geometries in the device for specific concentration factors, an equivalent circuit model was developed and experimentally validated. Large particle concentration factors were achieved by maintaining either average fluid velocity or Dean number throughout the entire length of the channel during the incremental removal of sample fluid. Also provided is the ability to simultaneously separate more than one particle from the same sample.

Owner:UNIV OF MARYLAND

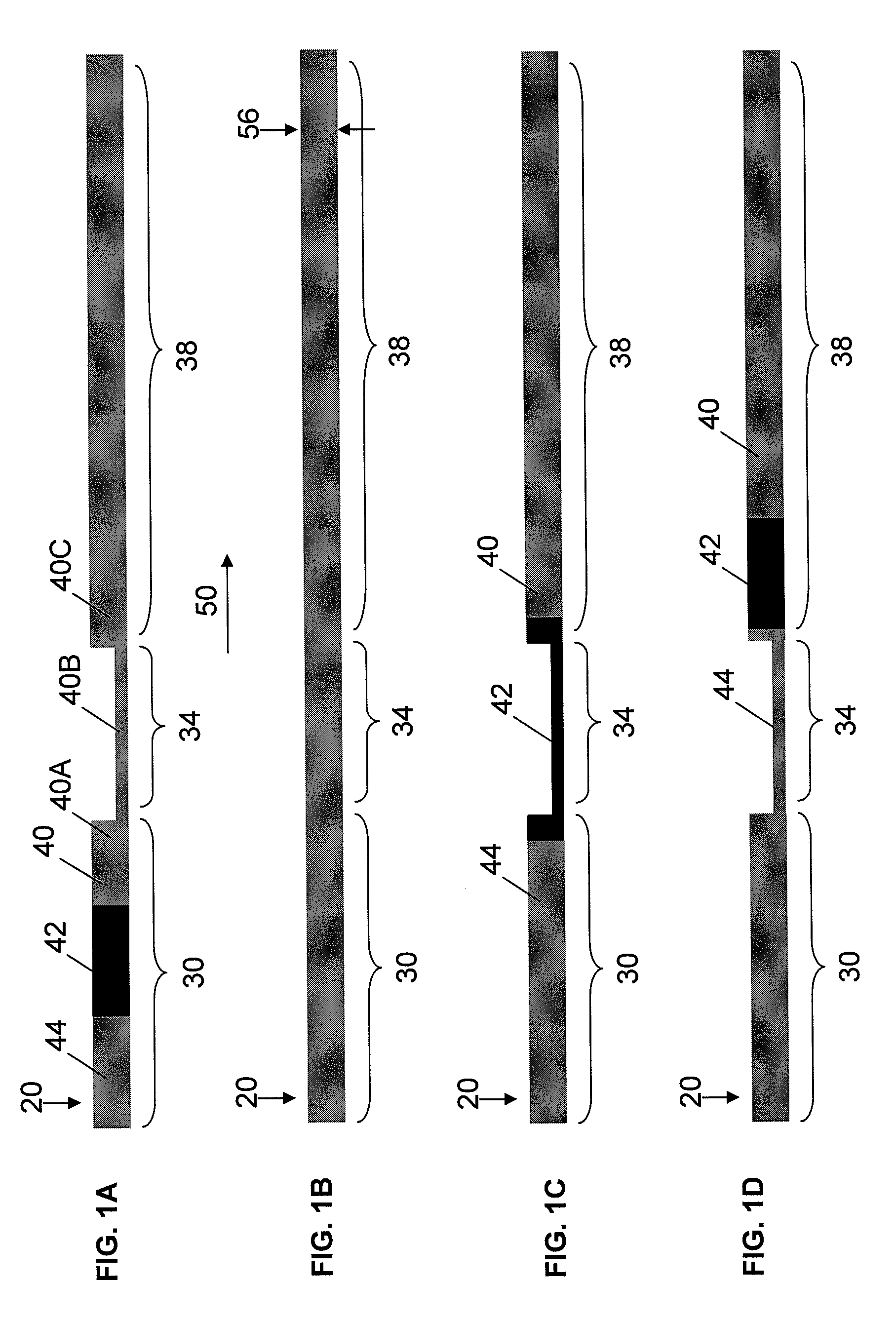

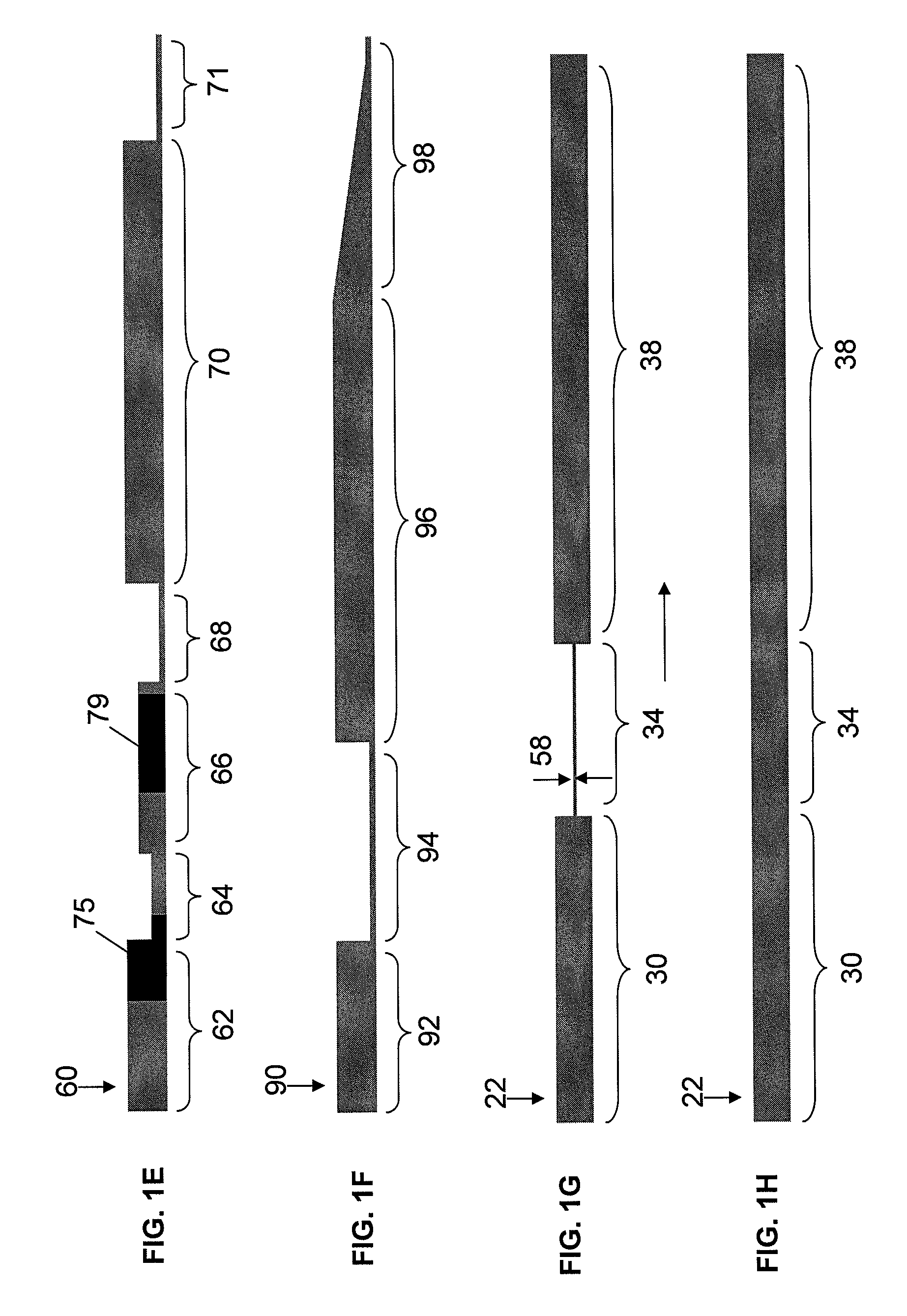

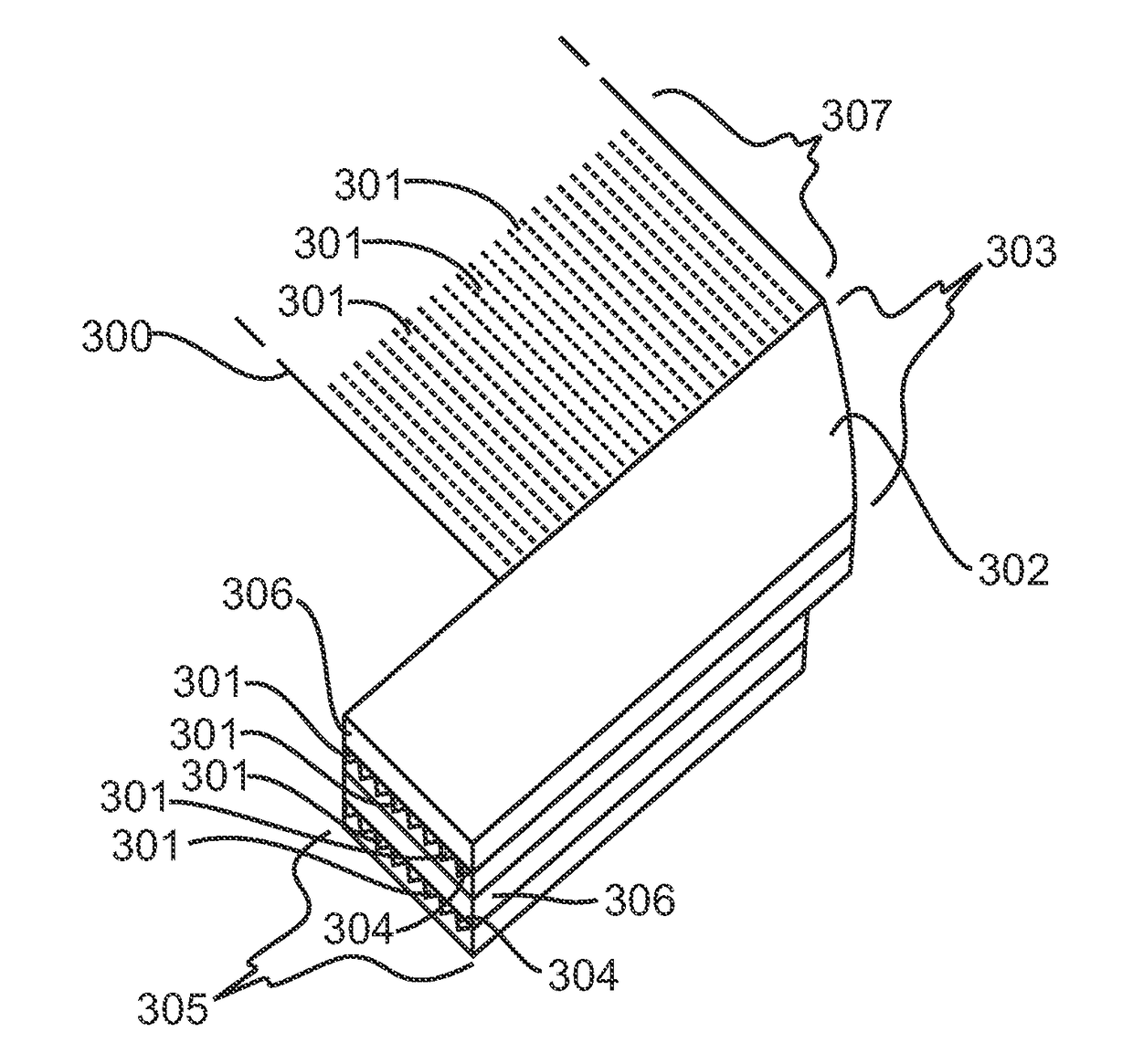

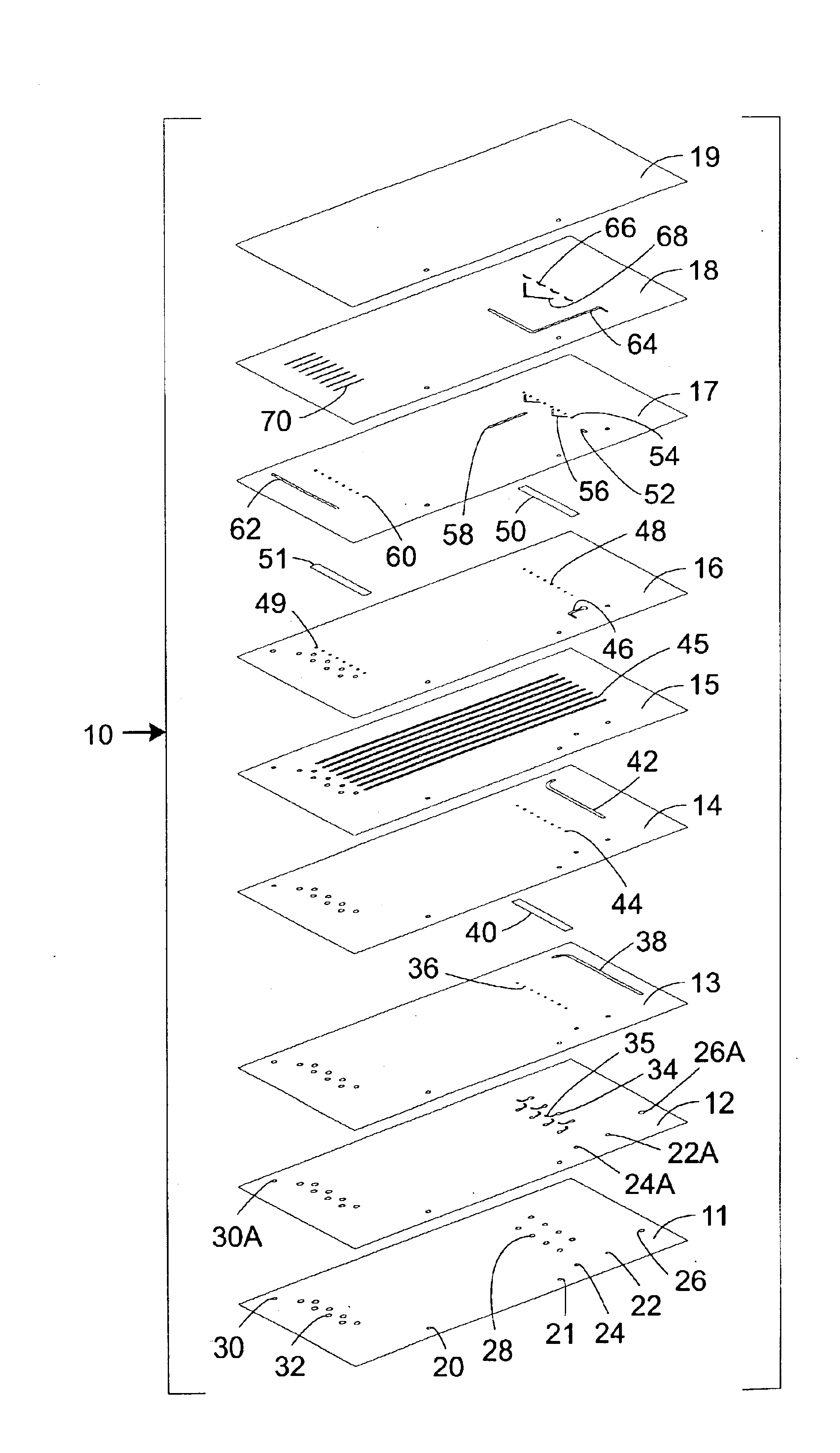

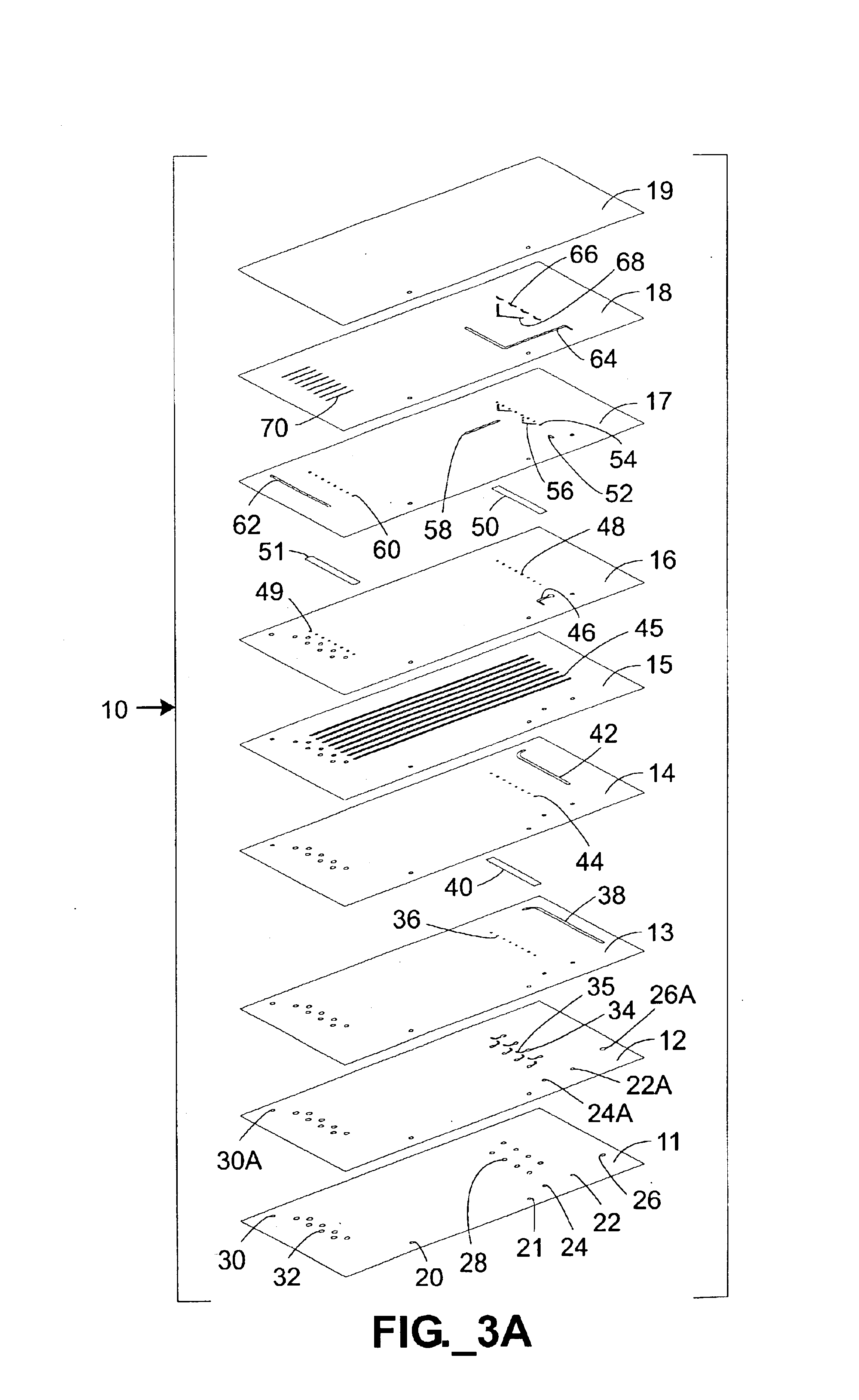

Fluid transfer systems, devices, components, and methods of manufacture

In one embodiment, a fluid transfer system comprises one or more fluid transfer components and one or more fluid input couplers or fluid output couplers. In one embodiment, the fluid transfer system delivers fluid to an active region, receives fluid from an active region, or passes a fluid through an active region using a fluid transfer component. In another embodiment, the fluid transfer component comprises film-based fluid channels converted from a first spatial arrangement geometry to a second spatial arrangement geometry different from the first spatial arrangement geometry. In another embodiment, the fluid transfer component comprises at least one of a fluid input coupler and fluid output coupler comprising a fluid channel geometry converter comprising re-arranged extended segments of a film comprising the active region fluid channels.

Owner:COLEMAN ZANE

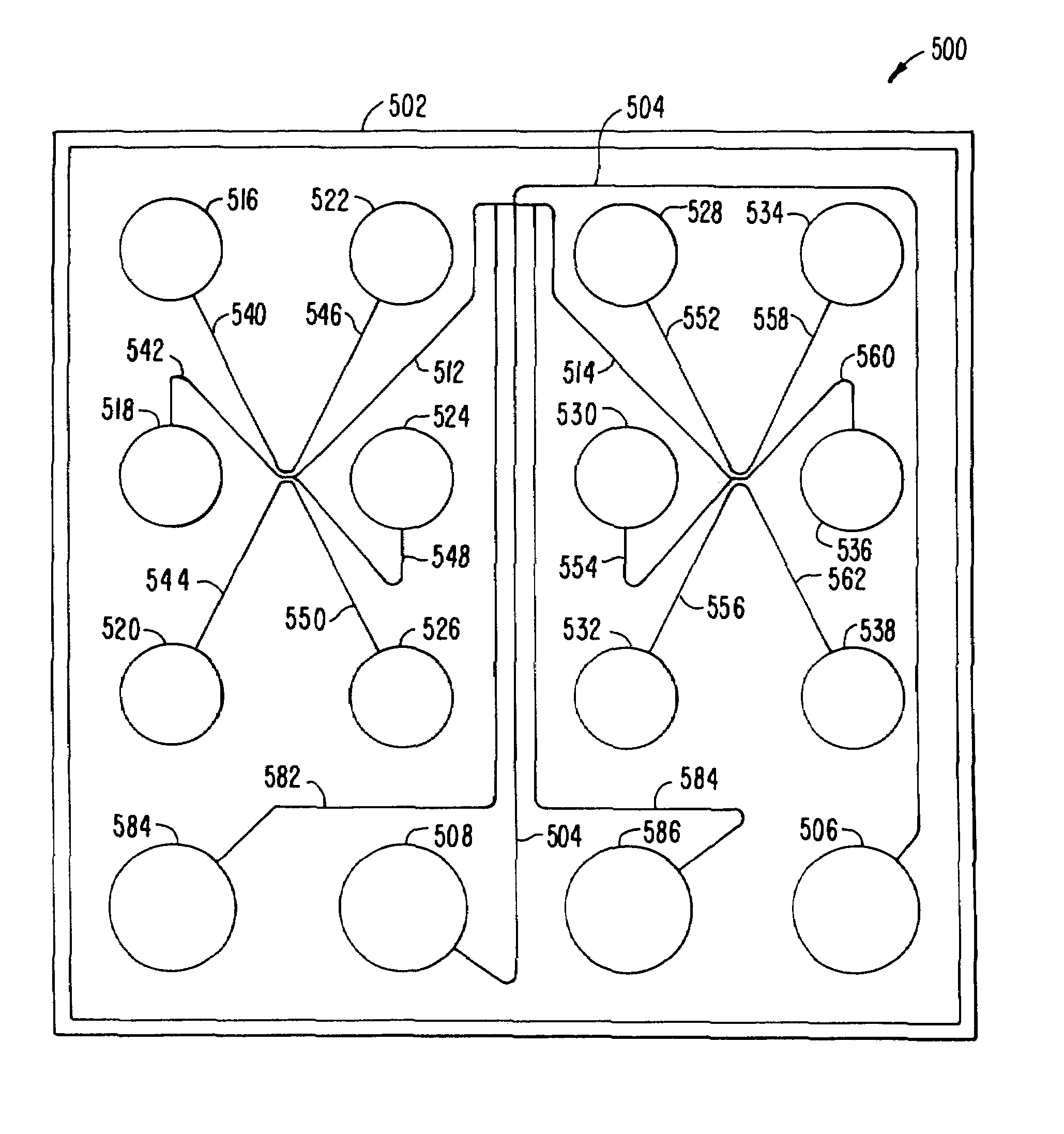

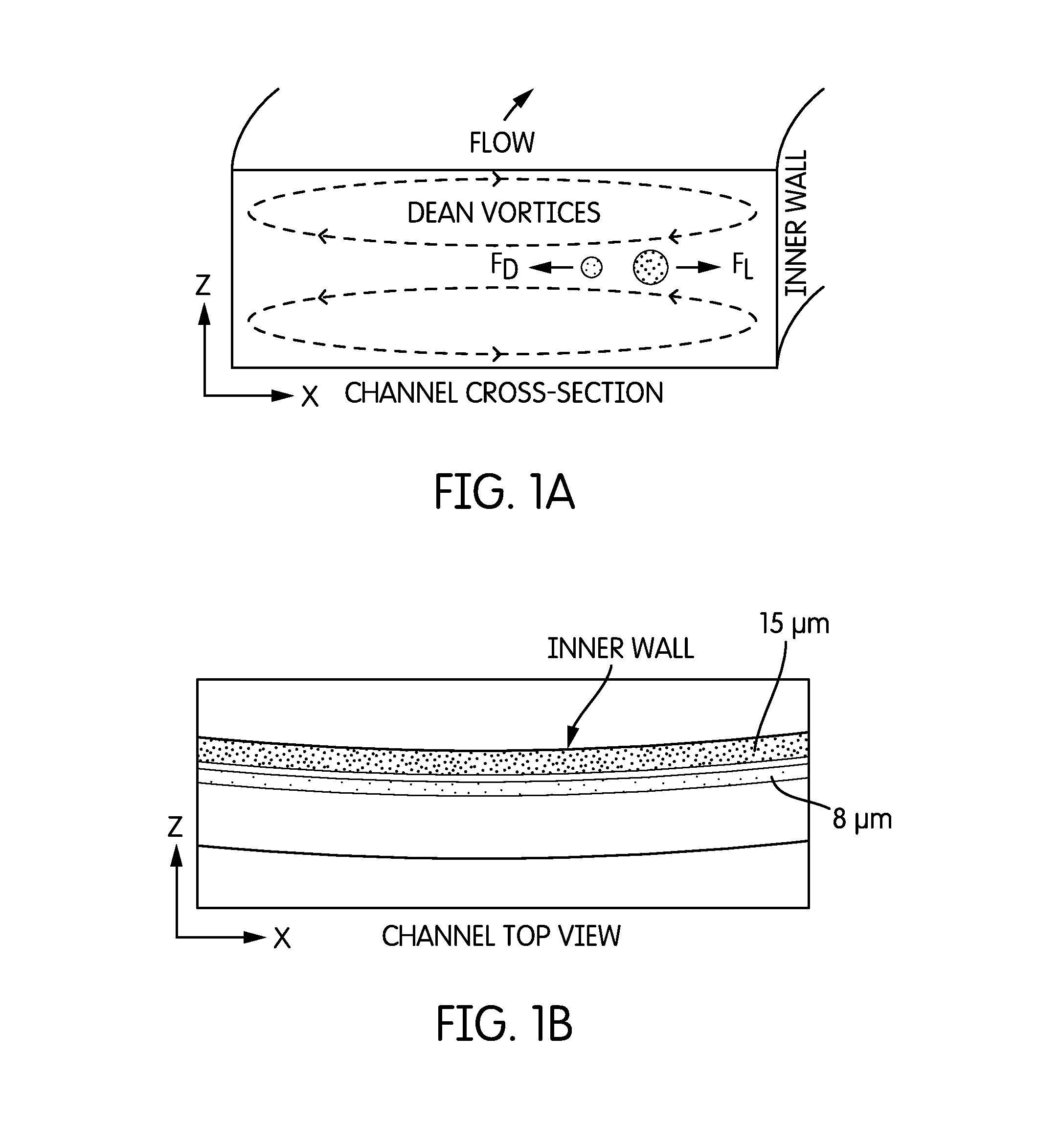

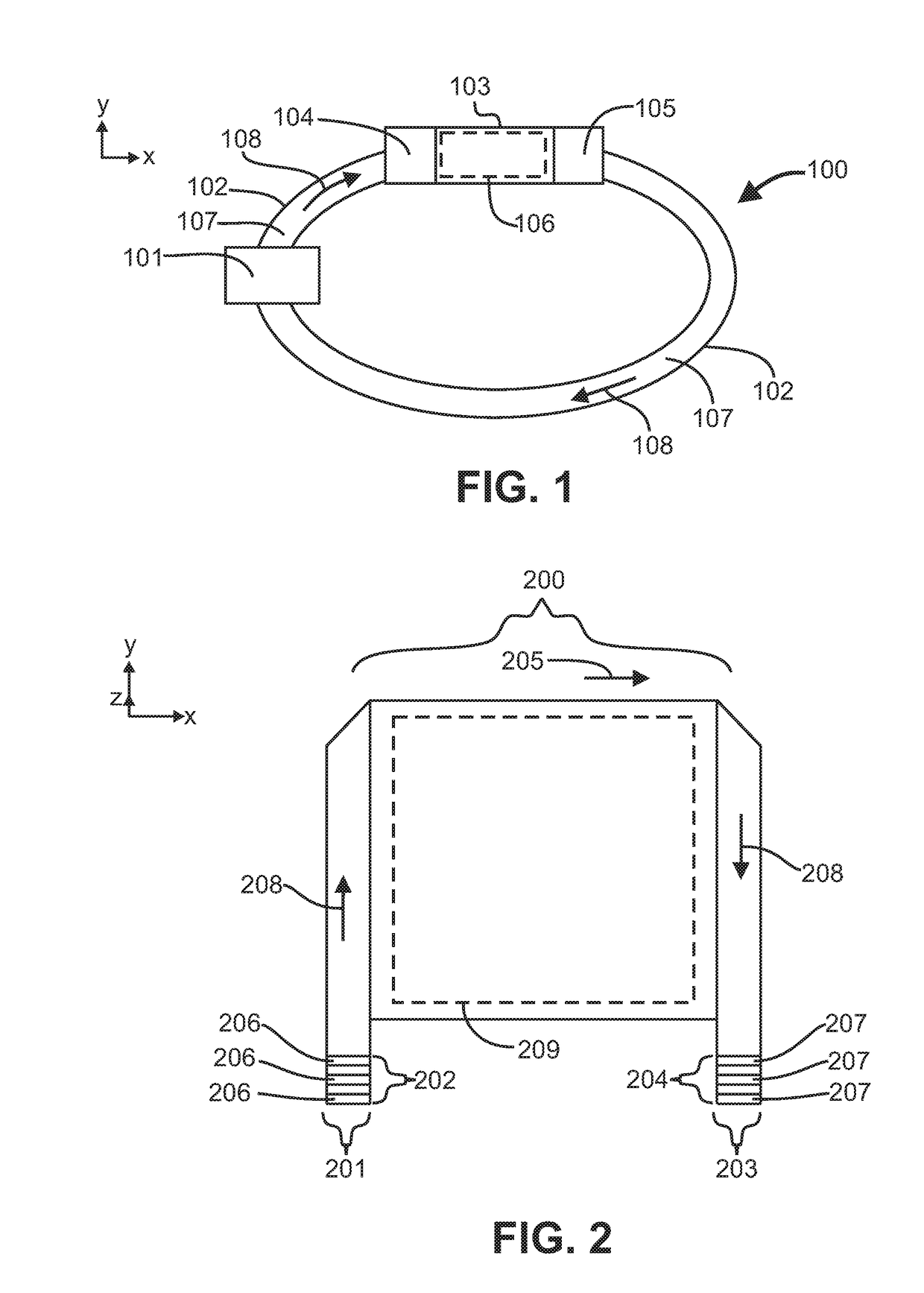

Microfluidic multi-splitter

A splitter for multi-layer microfluidic devices is provided. The splitter includes multiple forked channels defined in two or more device layers. The forked channels communicate fluidically at overlap regions. The overlap regions, in combination with symmetrical channel geometries balance the fluidic impedance in the system and promote even splitting.

Owner:AGILENT TECH INC

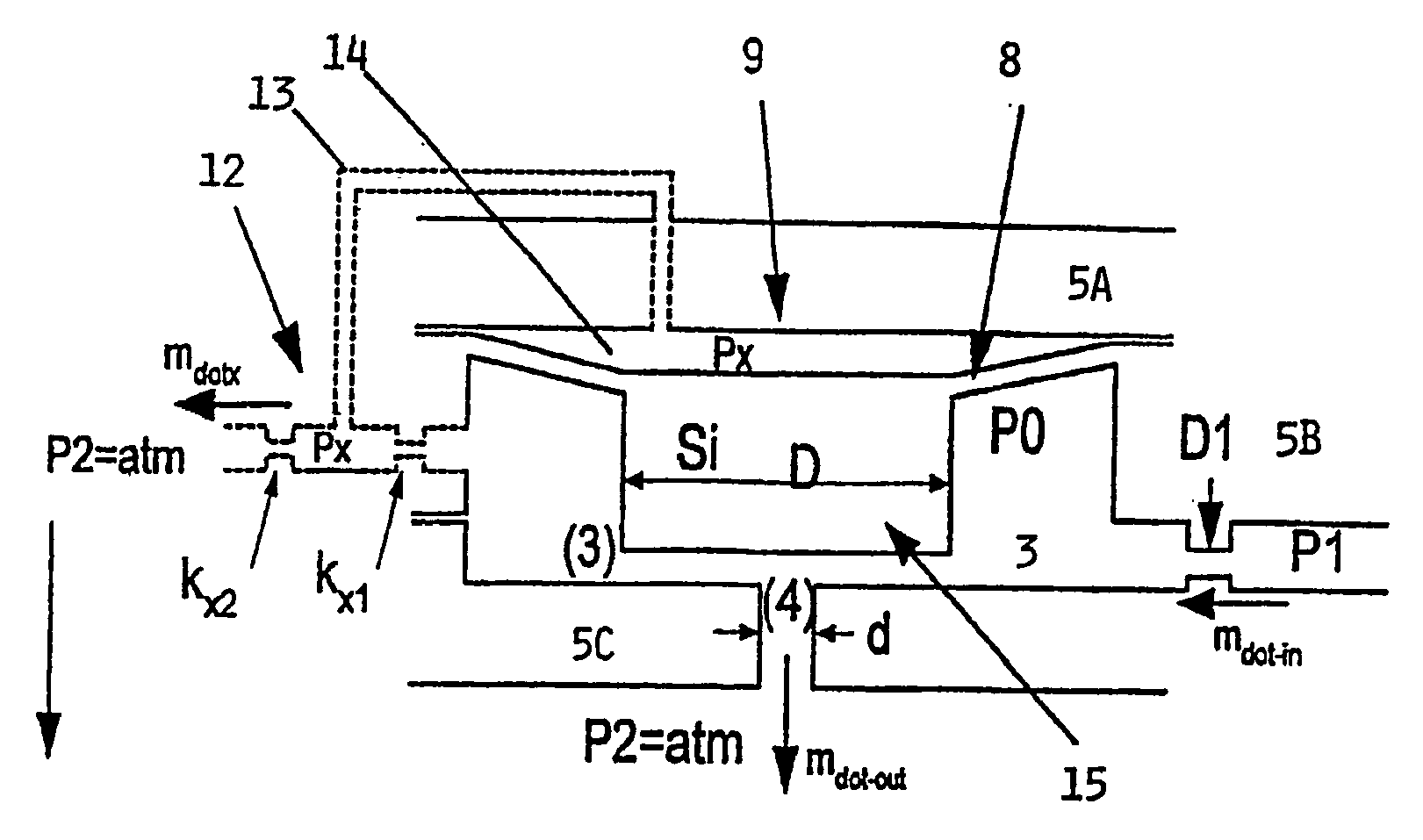

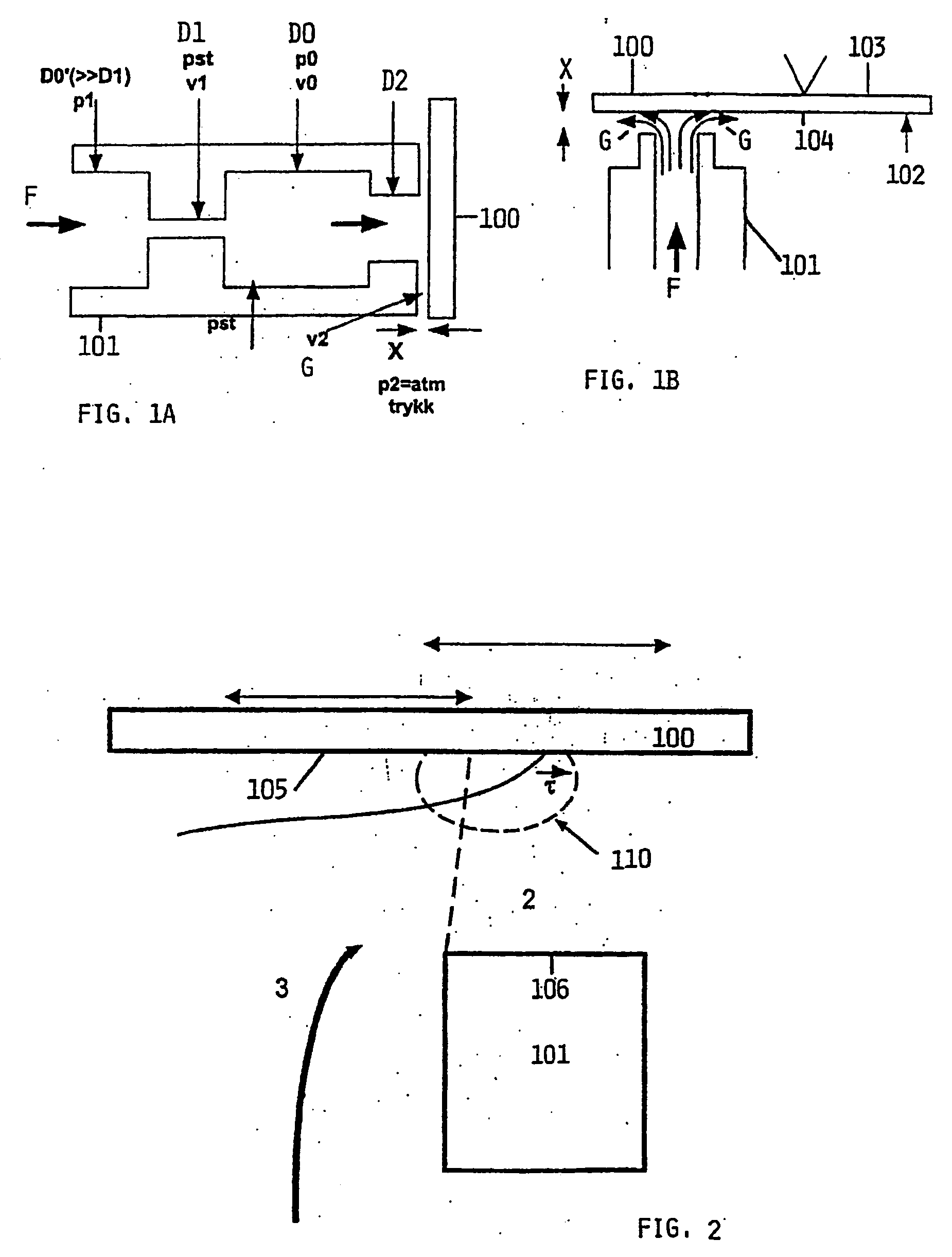

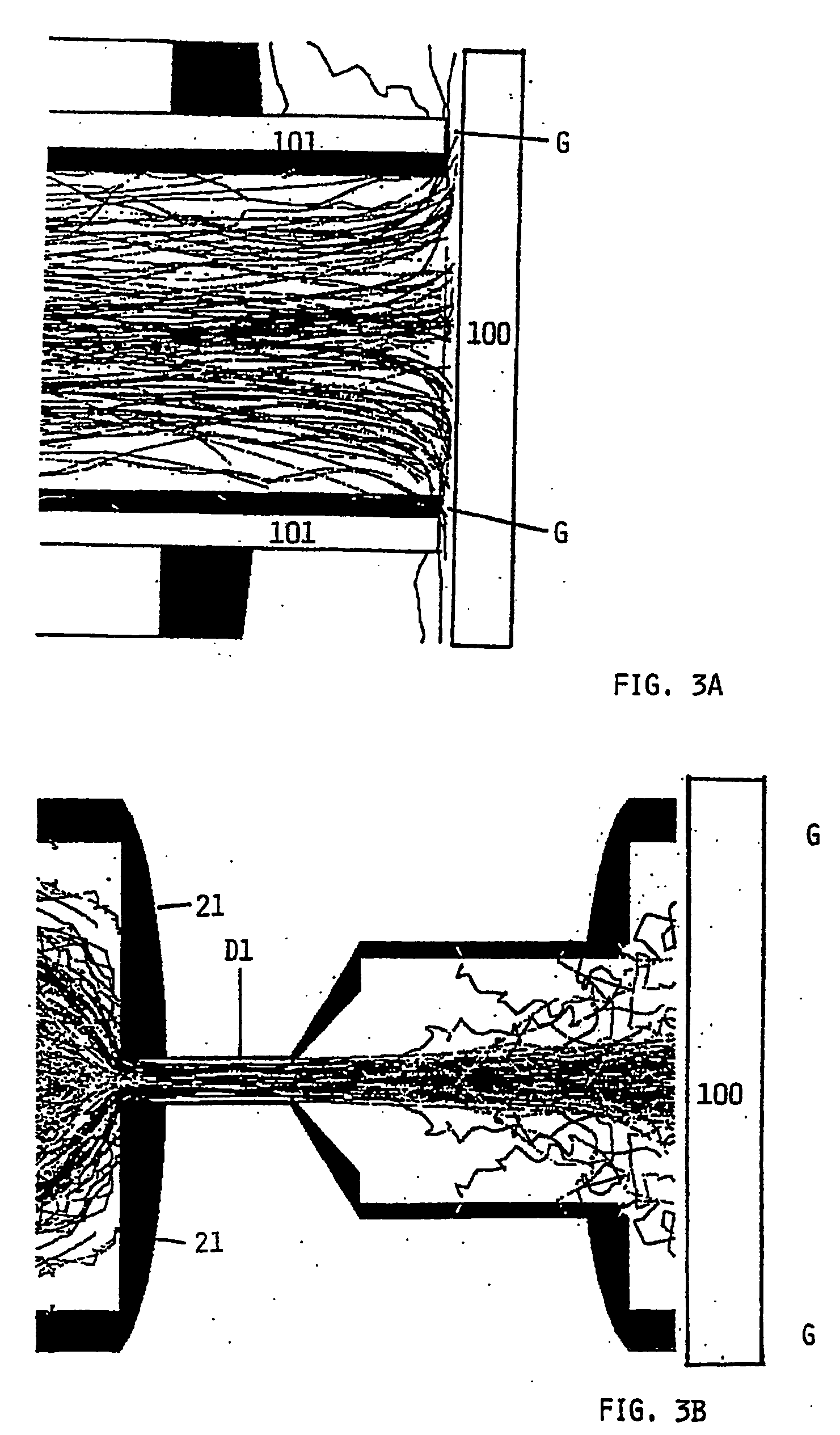

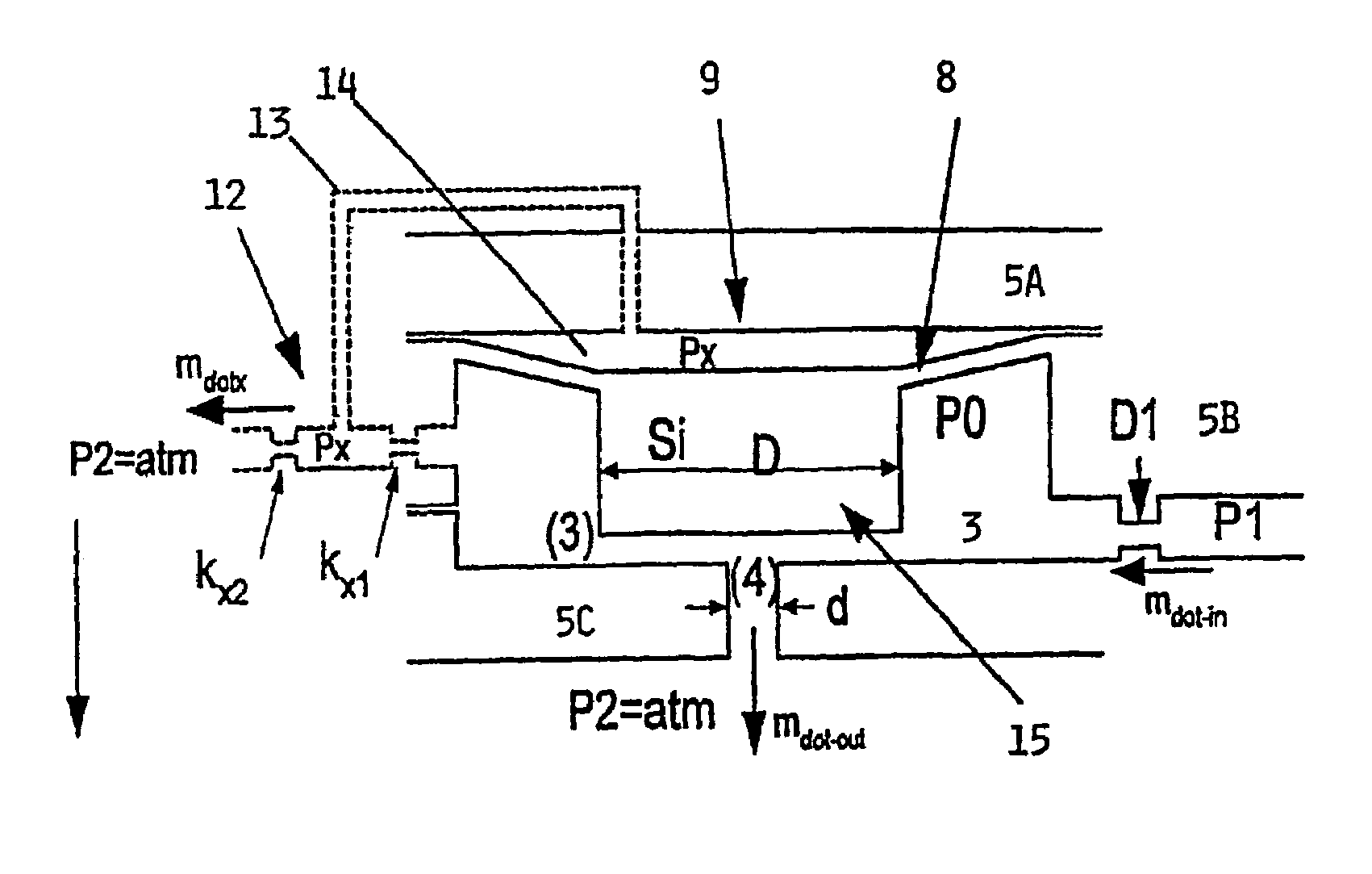

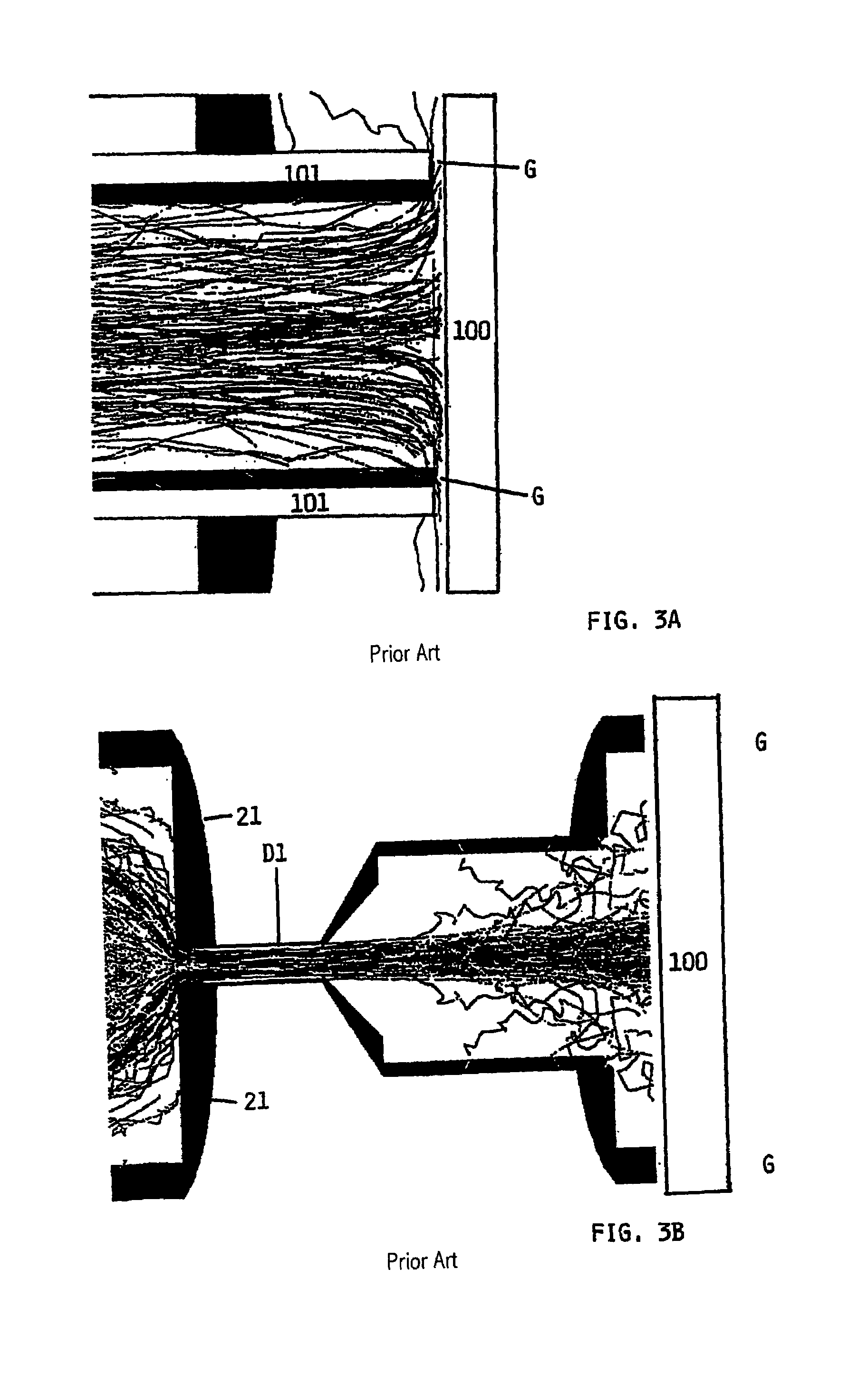

Mems pilot valve

InactiveUS20050257835A1Improve toleranceProlong lifePipe supportsOperating means/releasing devices for valvesChannel geometryEngineering

A valve including a fluid inlet and a fluid outlet coupled by a fluid channel, all of which are defined by walls and structures produced by micromachining of glass and / or silicon. An actuator can be set to at least two different positions in order to vary the flow cross section of the fluid channel. The geometries of the fluid inlet, outlet and channel are adapted for preventing the flow from changing its direction so sharply that a significant portion of contaminating droplets and or particles in the flow hit the walls of structures, as given in any arrangement according to or between the following two extremes: i) flow outlet is perpendicular to the flow inlet and the outlet dimension is larger than a critical dimension, Lcrit estimated according to a given formula and / or as simulated in a Computational Fluid Dynamics tool, and ii) flow outlet and flow channel is generally parallel to flow inlet giving a substantially unidirectional flow pattern.

Owner:ABB RES LTD

Method and apparatus for the discretization and manipulation of sample volumes

ActiveUS9180453B2Easy to useEasy to implementBioreactor/fermenter combinationsHeating or cooling apparatusChannel geometryHigh-Throughput Screening Methods

Embodiments of the present invention relate to methods and apparatuses for the discretization and manipulation of sample volumes that is simple, robust, and versatile. It is a fluidic device that partitions a sample by exploiting the interplay between fluidic forces, interfacial tension, channel geometry, and the final stability of the formed droplet and / or discretized volume. These compartmentalized volumes allow for isolation of samples and partitioning into a localized array that can subsequently be manipulated and analyzed. The isolation of the discretized volumes along with the device's inherent portability render our invention versatile for use in many areas, including but not limited to PCR, digital PCR, biological assays for diagnostics and prognostics, cancer diagnosis and prognosis, high throughput screening, single molecule and single cell reactions or assays, the study crystallization and other statistical processes, protein crystallization, drug screening, environmental testing, and the coupling to a wide range of analytical detection techniques for biomedical assays and measurements. The minimal fluid interconnects and simple flow geometry makes the device easy to use and implement, economical to fabricate and operate, and robust in its operations.

Owner:UNIV OF WASHINGTON

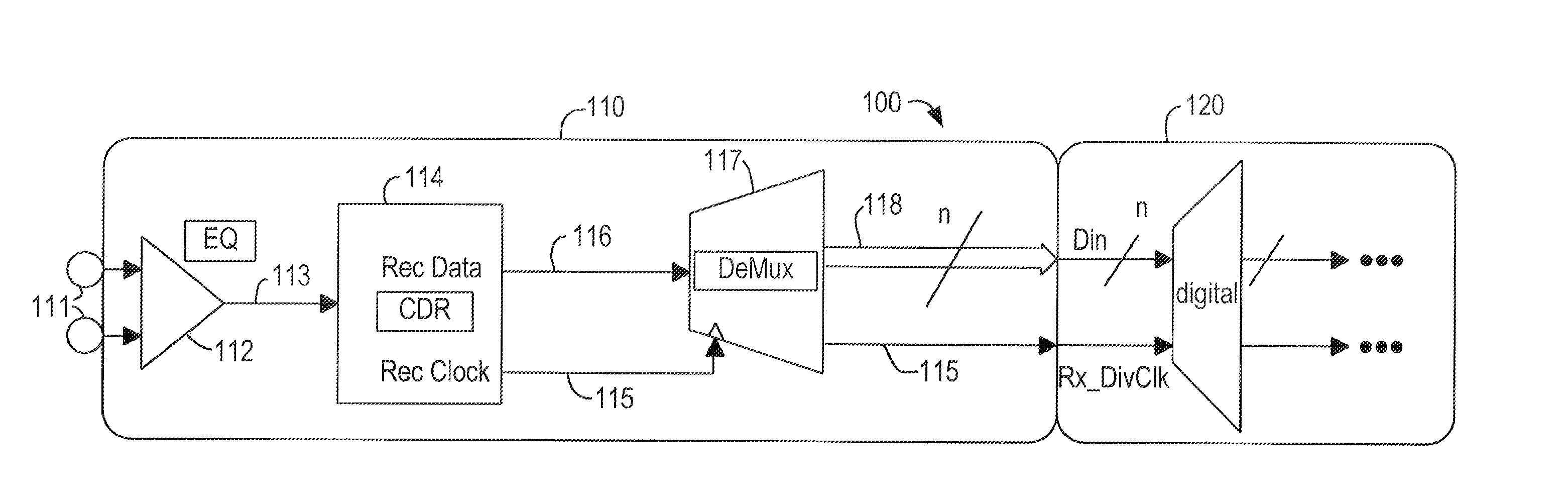

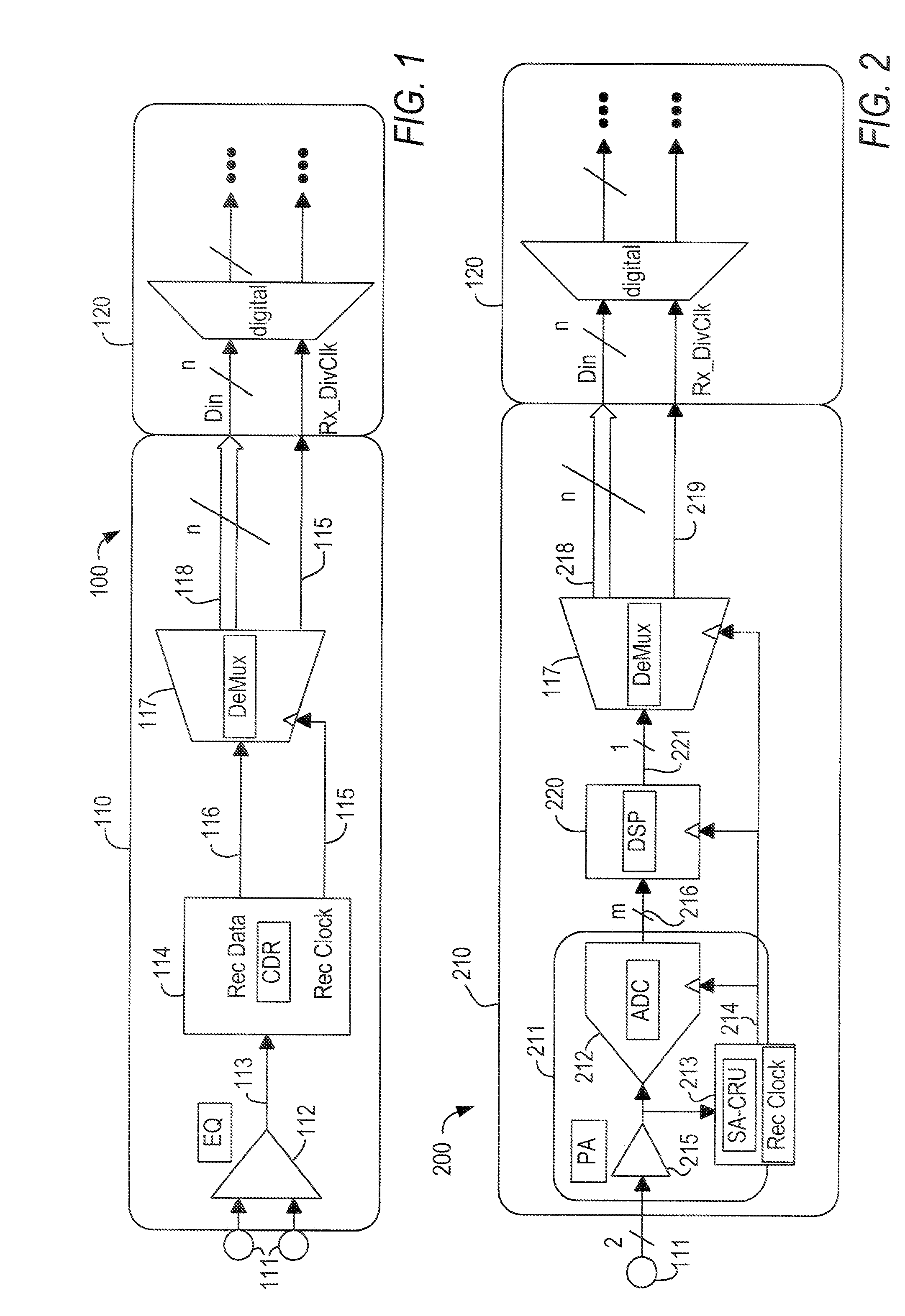

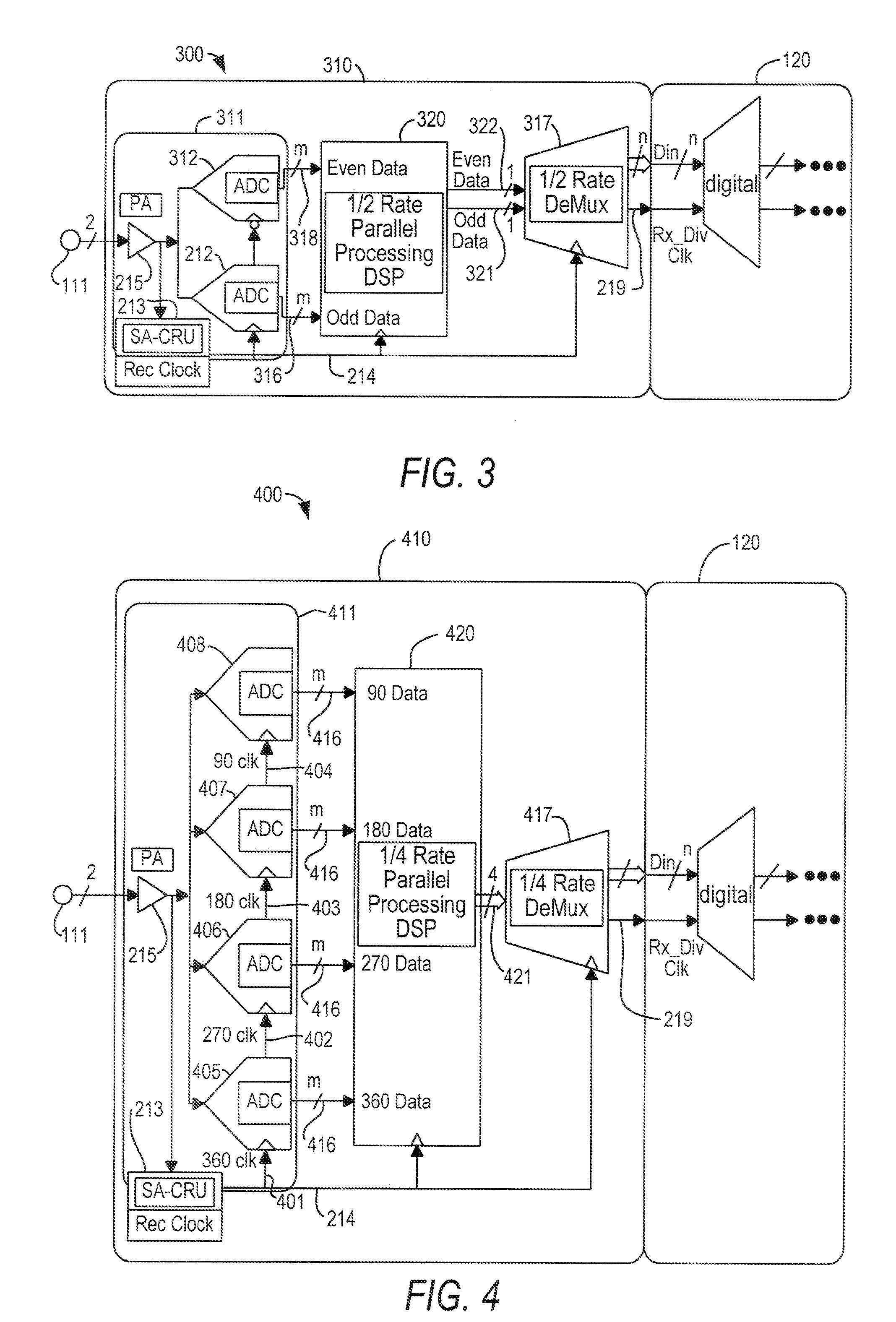

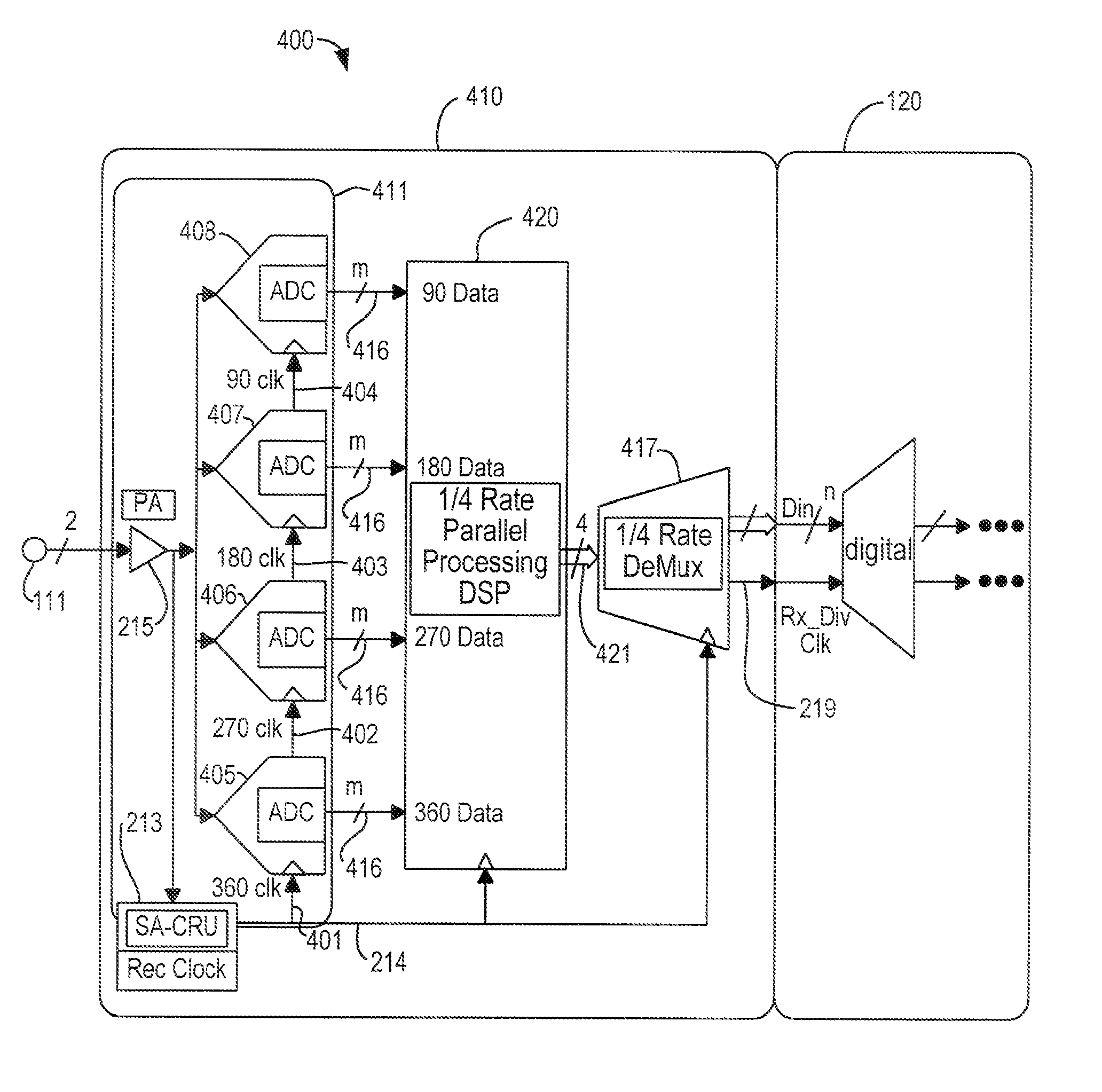

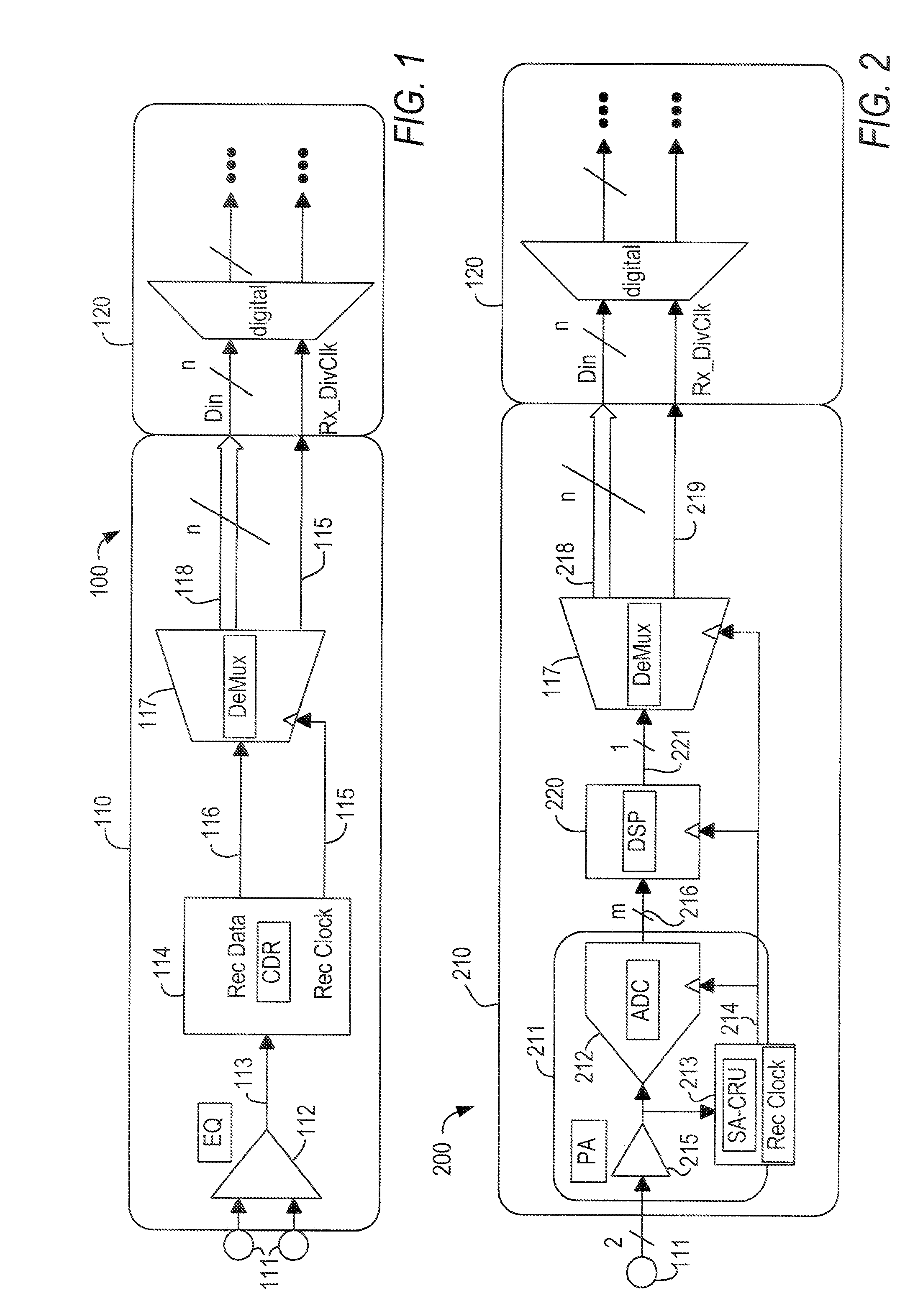

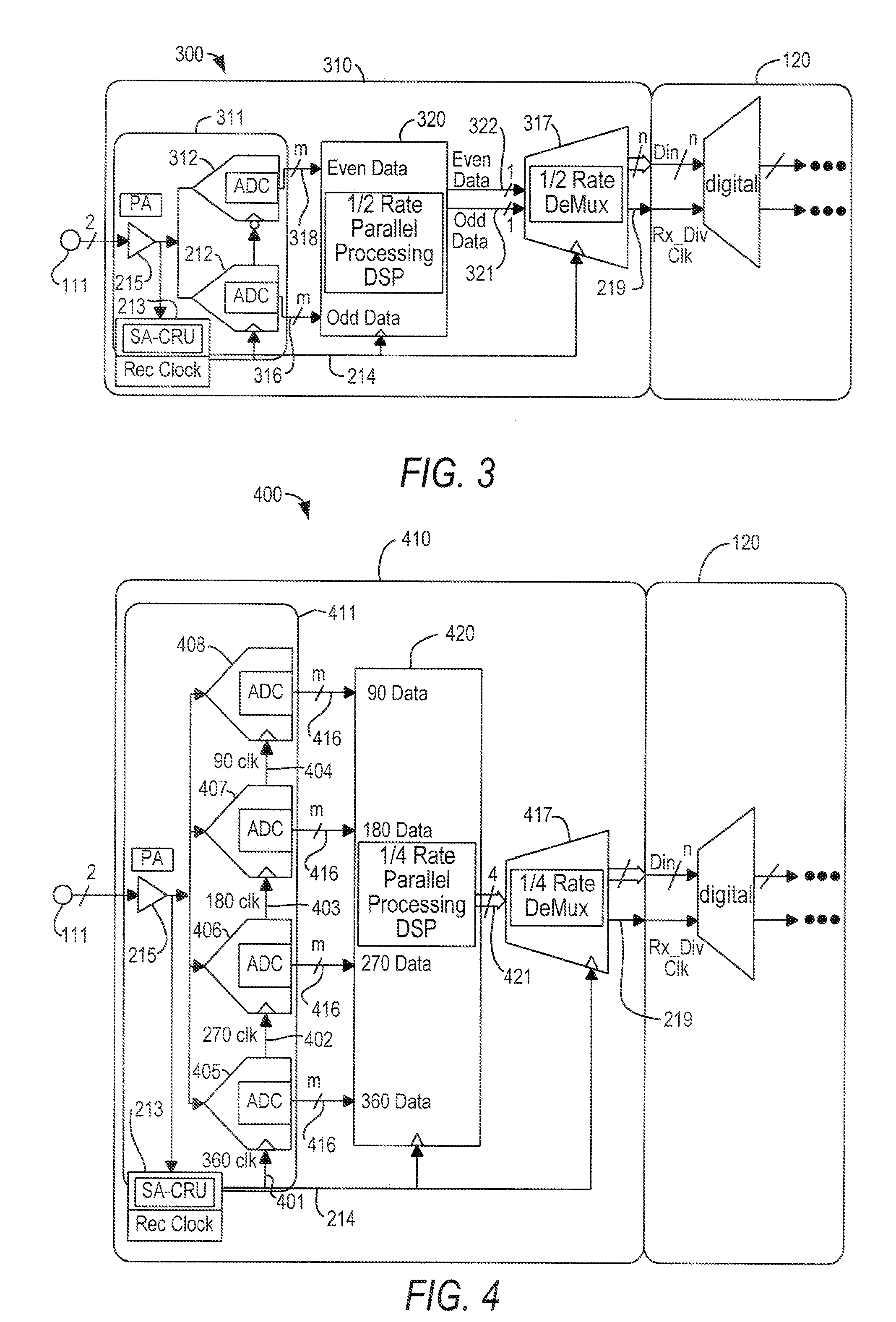

Digital equalizer for high-speed serial communications

InactiveUS20090279597A1Multiple-port networksDelay line applicationsDigital signal processingChannel geometry

Incoming data at a high-speed serial receiver is digitized and then digital signal processing (DSP) techniques may be used to perform digital equalization. Such digital techniques may be used to correct various data anomalies. In particular, in a multi-channel system, where crosstalk may be of concern, knowledge of the characteristics of the other channels, or even the data on those channels, may allow crosstalk to be subtracted out. Knowledge of data channel geometries, particularly in the context of backplane transmissions, may allow echoes and reflections caused by connectors to be subtracted out. As data rates increase, fractional rate processing can be employed. For example, the analog-to-digital conversion can be performed at half-rate and then two DSPs can be used in parallel to maintain throughput at the higher initial clock rate. At even higher rates, quadrature techniques can allow analog-to-digital conversion at quarter-rate, with four DSPs used in parallel.

Owner:ALTERA CORP

Mems pilot valve

InactiveUS7124773B2Improve toleranceProlong lifePipe supportsOperating means/releasing devices for valvesChannel geometryEngineering

A valve including a fluid inlet and a fluid outlet coupled by a fluid channel, all of which are defined by walls and structures produced by micromachining of glass and / or silicon. An actuator can be set to at least two different positions in order to vary the flow cross section of the fluid channel. The geometries of the fluid inlet, outlet and channel are adapted for preventing the flow from changing its direction so sharply that a significant portion of contaminating droplets and or particles in the flow hit the walls of structures, as given in any arrangement according to or between the following two extremes: i) flow outlet is perpendicular to the flow inlet and the outlet dimension is larger than a critical dimension, Lcrit estimated according to a given formula and / or as simulated in a Computational Fluid Dynamics tool, and ii) flow outlet and flow channel is generally parallel to flow inlet giving a substantially unidirectional flow pattern.

Owner:ABB RES LTD

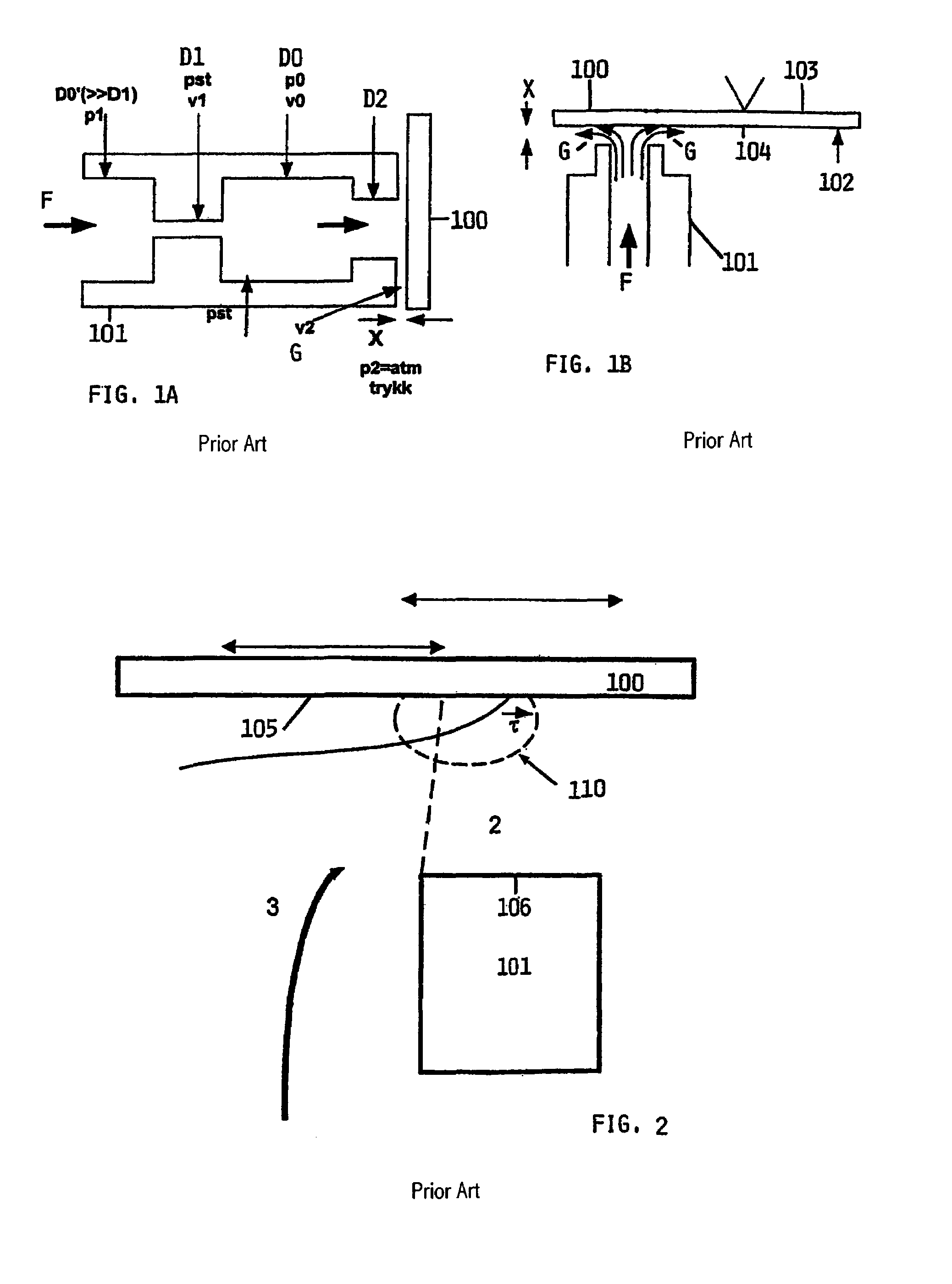

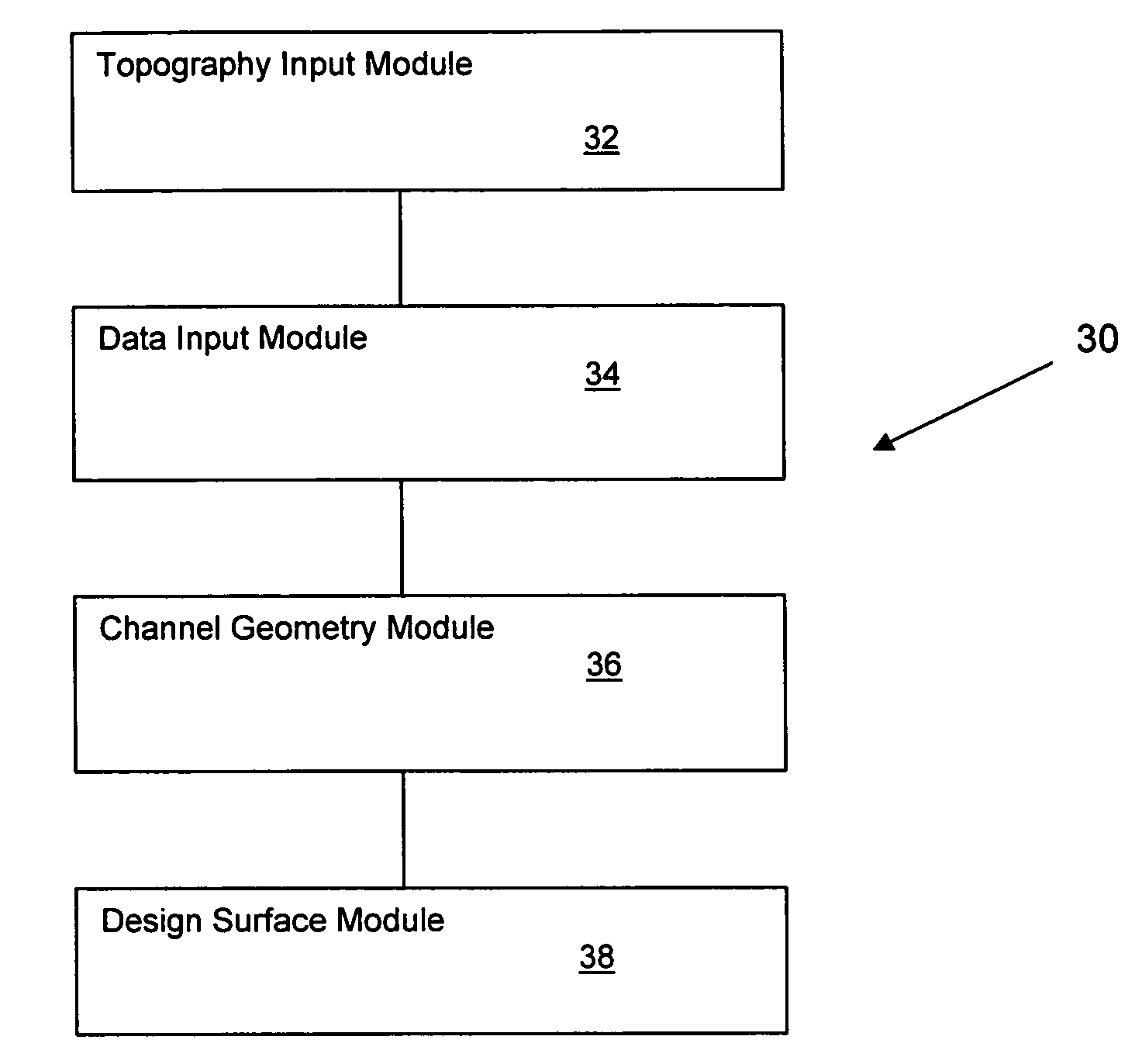

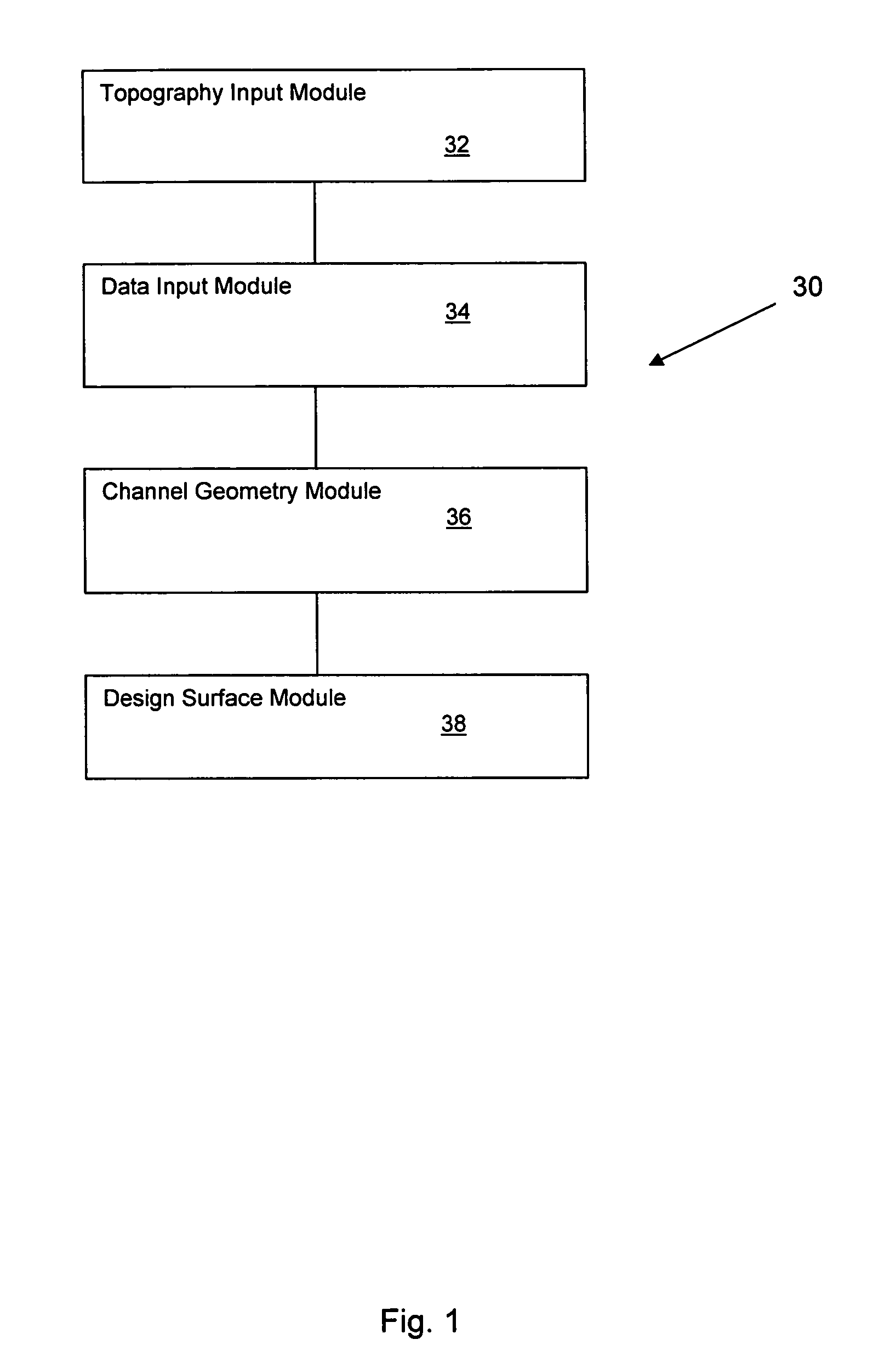

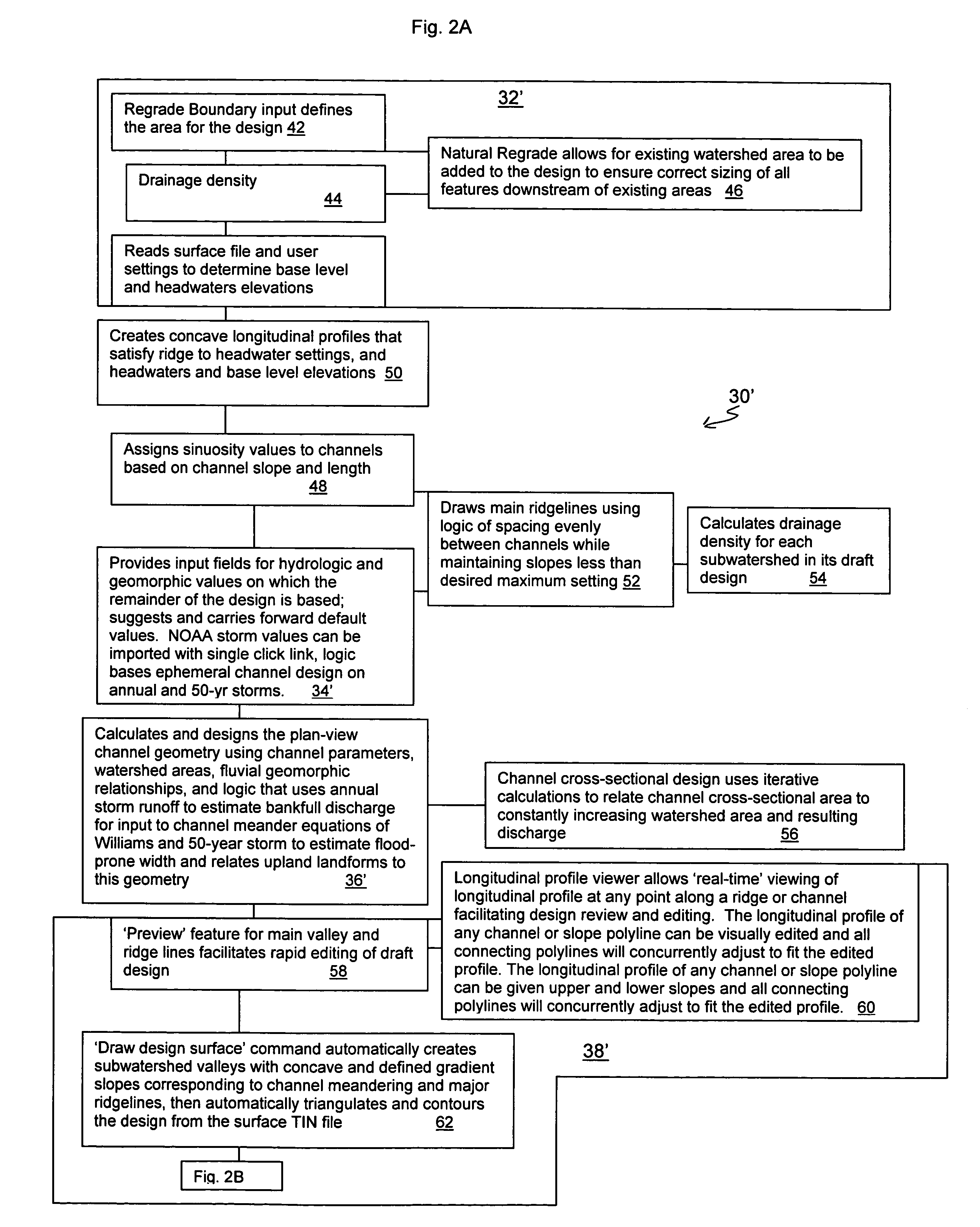

Fluvial geomorphic landscape design computer software

Owner:CARLSON SOFTWARE

Digital equalizer for high-speed serial communications

InactiveUS8654898B2Multiple-port networksDelay line applicationsDigital signal processingChannel geometry

Incoming data at a high-speed serial receiver is digitized and then digital signal processing (DSP) techniques may be used to perform digital equalization. Such digital techniques may be used to correct various data anomalies. In particular, in a multi-channel system, where crosstalk may be of concern, knowledge of the characteristics of the other channels, or even the data on those channels, may allow crosstalk to be subtracted out. Knowledge of data channel geometries, particularly in the context of backplane transmissions, may allow echoes and reflections caused by connectors to be subtracted out. As data rates increase, fractional rate processing can be employed. For example, the analog-to-digital conversion can be performed at half-rate and then two DSPs can be used in parallel to maintain throughput at the higher initial clock rate. At even higher rates, quadrature techniques can allow analog-to-digital conversion at quarter-rate, with four DSPs used in parallel.

Owner:ALTERA CORP

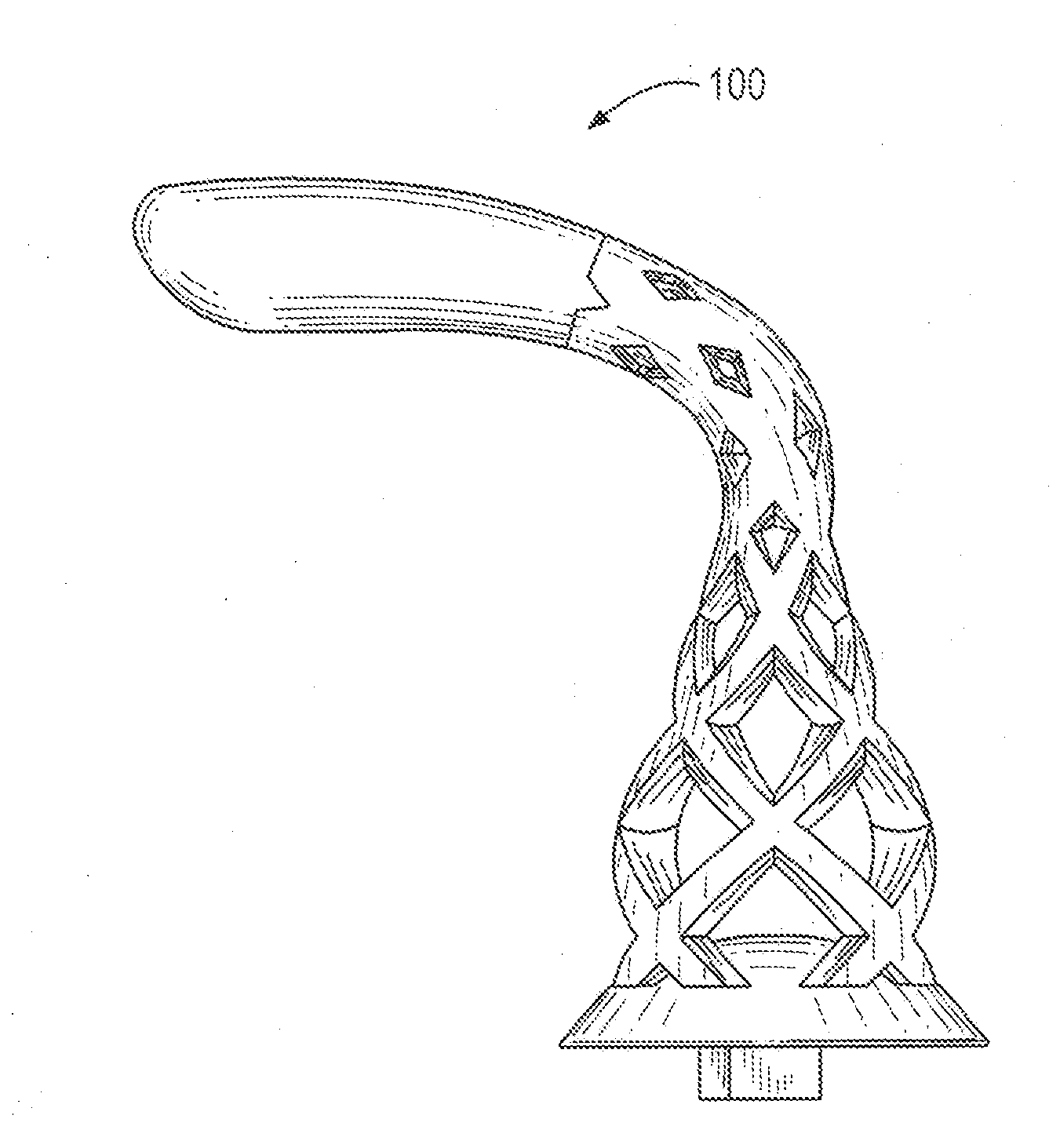

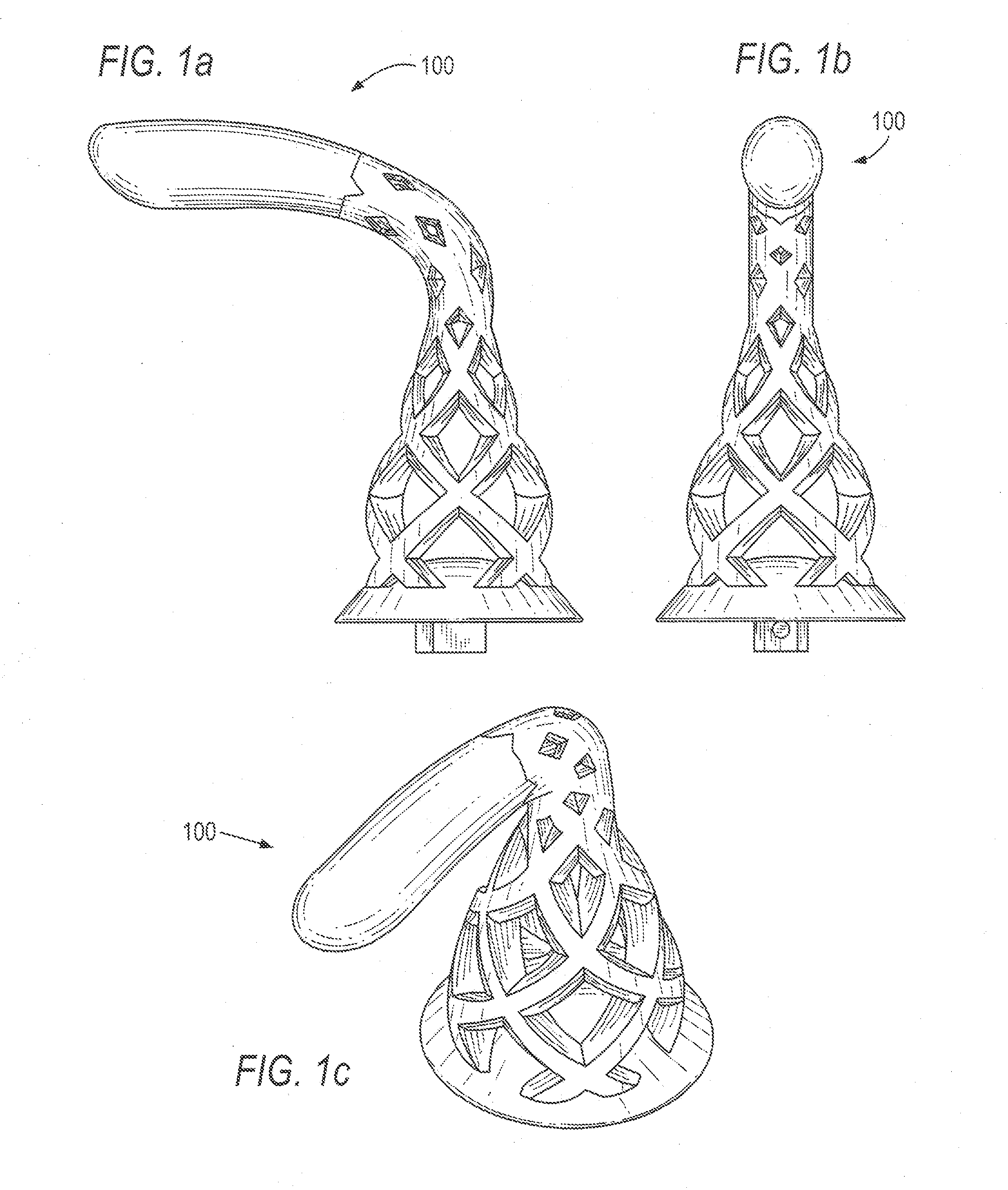

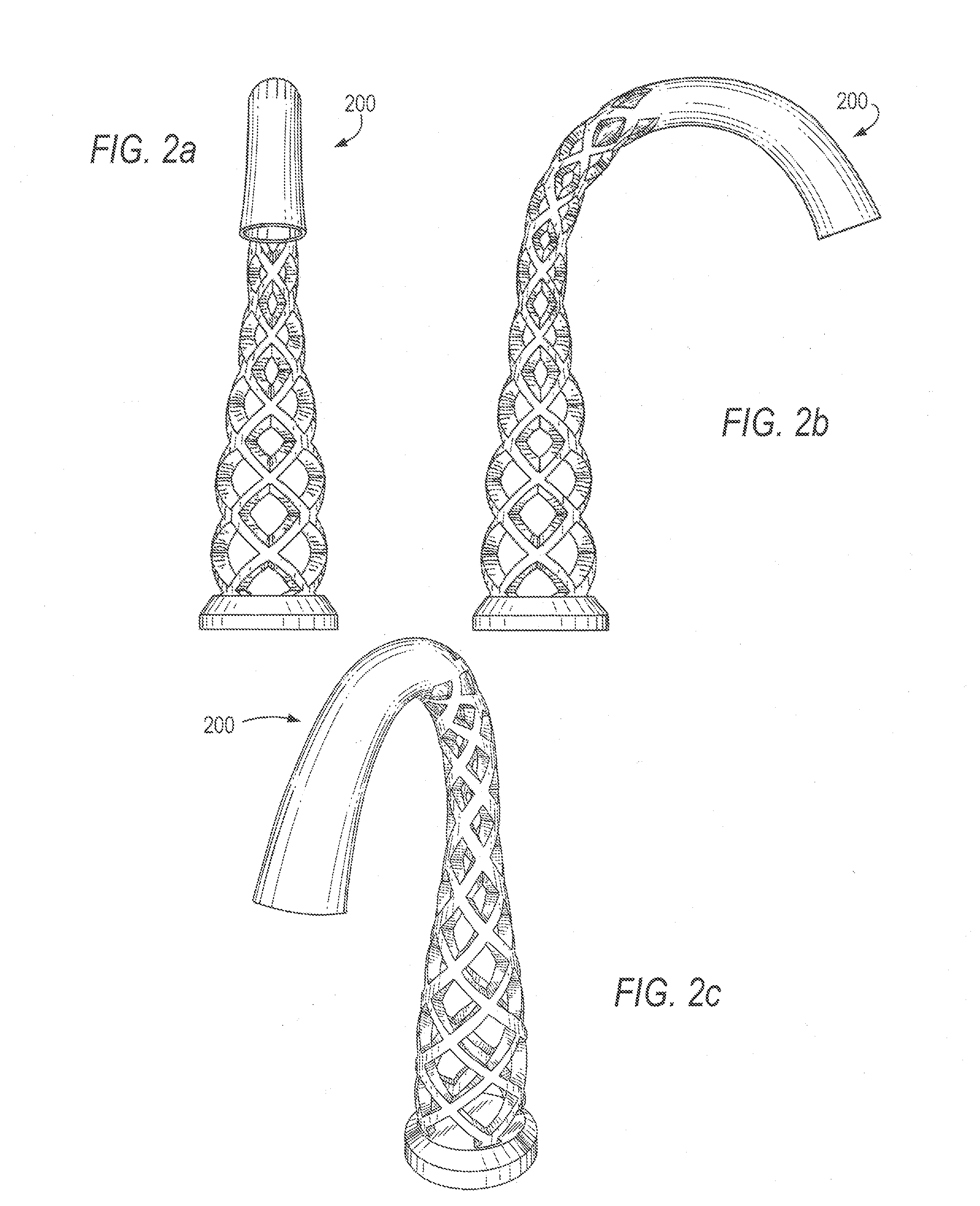

Multi-channel plumbing products

Novel plumbing products, including faucets, are fabricated, e.g., using metallic 3-dimensional or other 3-D printing techniques, to have complex geometries, such as multiple channels that may diverge and re-converge near the spout. The geometries of the various channels can resemble interwoven net-like patterns that define various shapes between the channels, such as a lattice-type faucet defining parallelograms, circles or ovals, or multiple channels defining ellipses or half ellipses as channels diverge and then re-converge. Other embodiments may have fewer channels that diverge at the base of a faucet and re-converge at some distance above, after defining various curved paths at some defined convex curvature. The plumbing fixtures may be formed from one or more of stainless steels, INCONEL, brass, bronze, polycarbonate, PVC, acrylics, rigid polyolefins, PET, carbon fiber, AES, or other plumbing fitting suitable corrosion resistant materials. In some embodiments, the handles of an exemplary faucet can include the same or a similar multiple channel configuration as the spout, providing an advantageously, aesthetically pleasing faucet system. In exemplary embodiments, faucet spouts and their handles are formed so as to couple to standard faucet underbodies, standard valve platforms, or standard threaded hose / waterway connections.

Owner:AS AMERICA

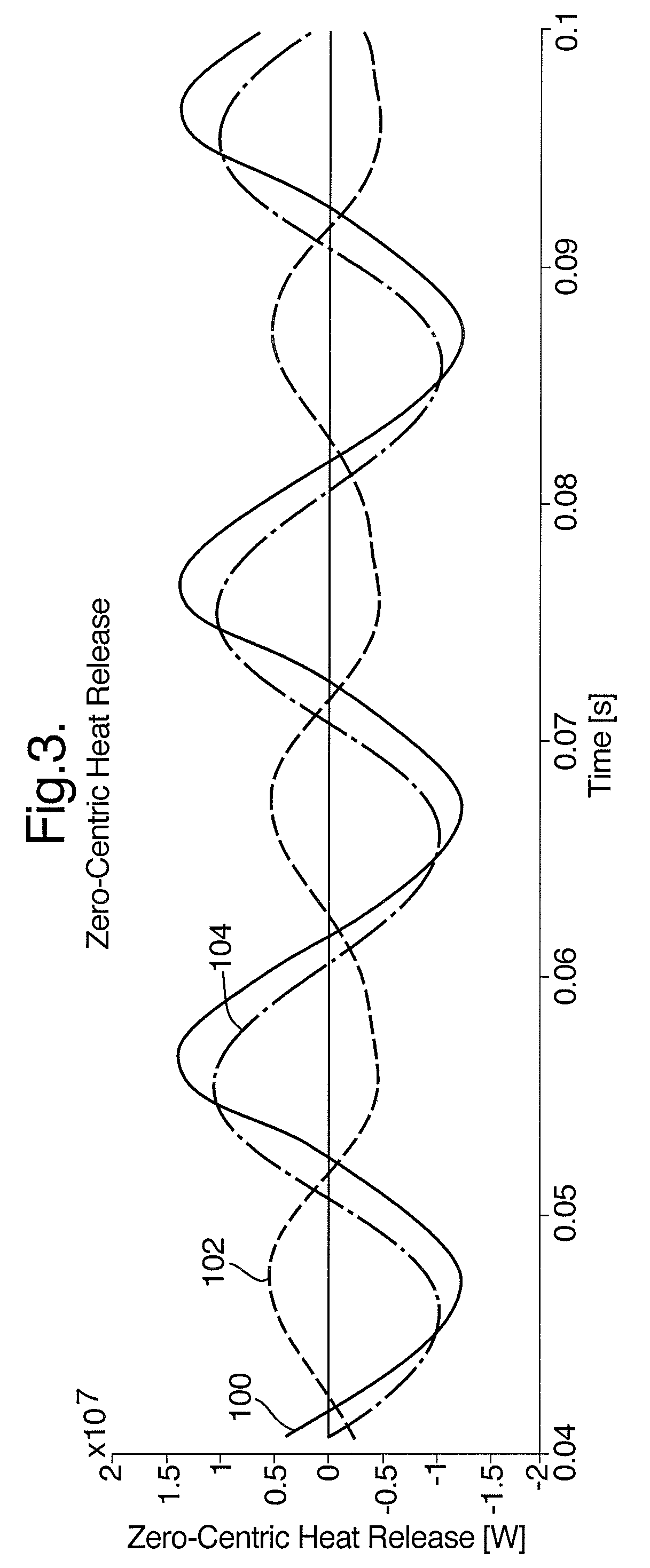

Combustion control for a gas turbine

InactiveUS20080118343A1Reduce the amplitudeMinimizing amplitudeContinuous combustion chamberWind motor controlCombustion systemChannel geometry

A method for controlling instability in a combustion system comprising a combustion chamber and a passage external of the combustion chamber which supplies a secondary non-combustible fluid to the combustor chamber. The passage external to the combustion chamber is arranged such that the phase of perturbations in the mass flow of the secondary non-combustible fluid in the passage acts to reduce the amplitude of unsteady instability in the combustor chamber. Furthermore, the geometry of the external passage may be actively adjusted to tune the system if the frequency of the unstable instability differs from that for which the combustor was originally designed to attenuate.

Owner:ROLLS ROYCE PLC

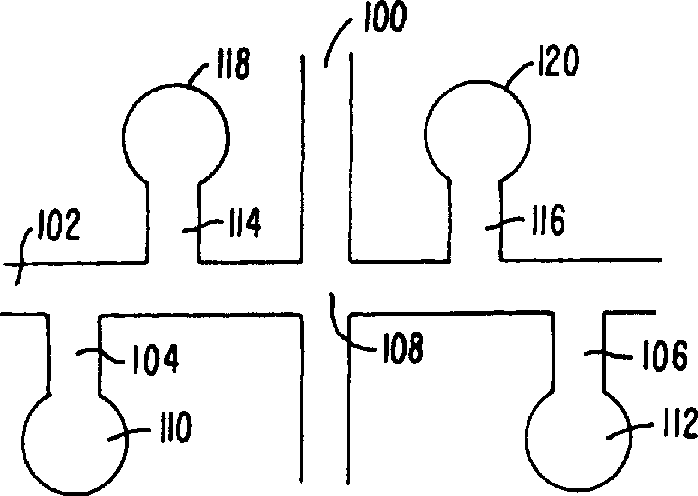

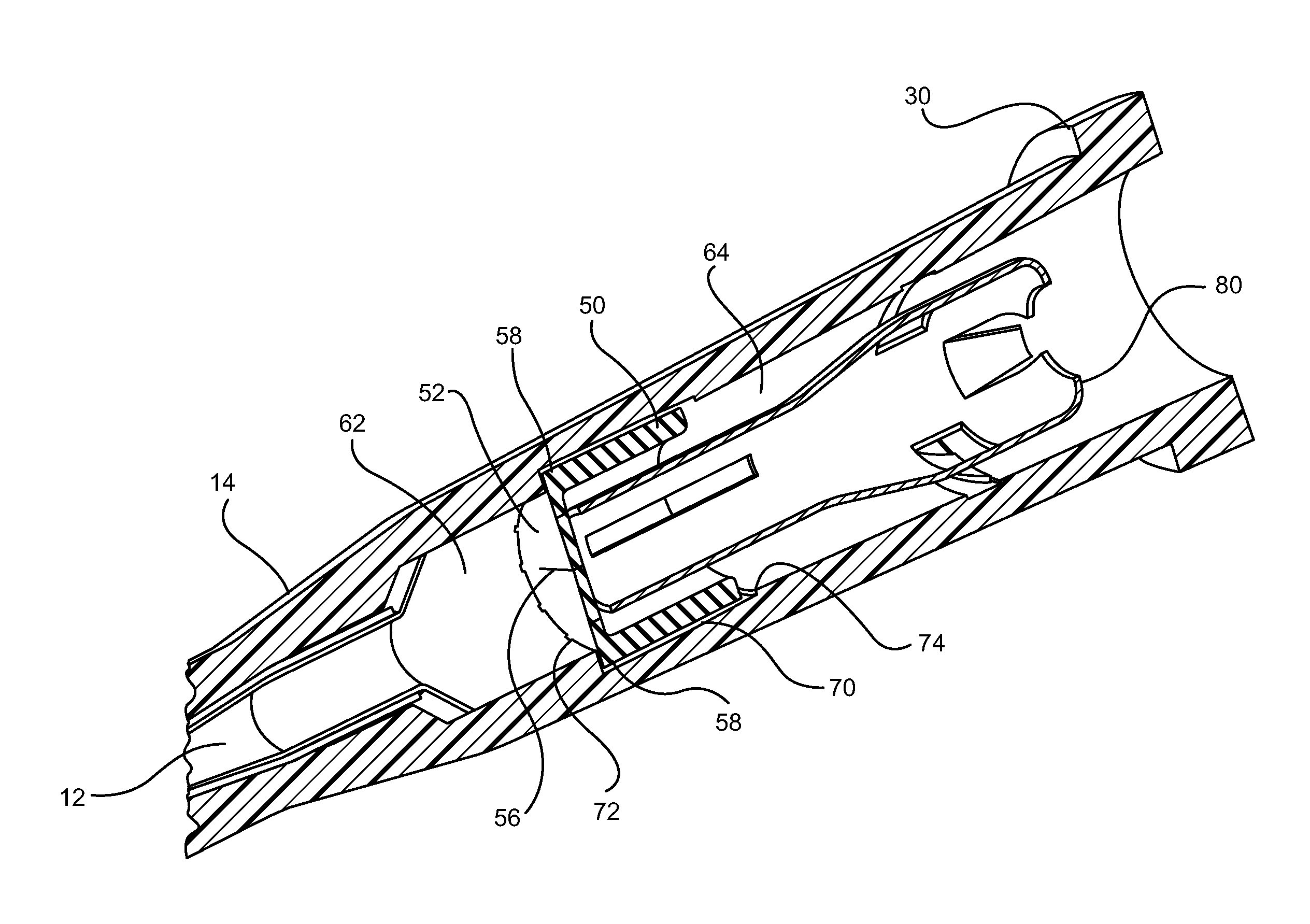

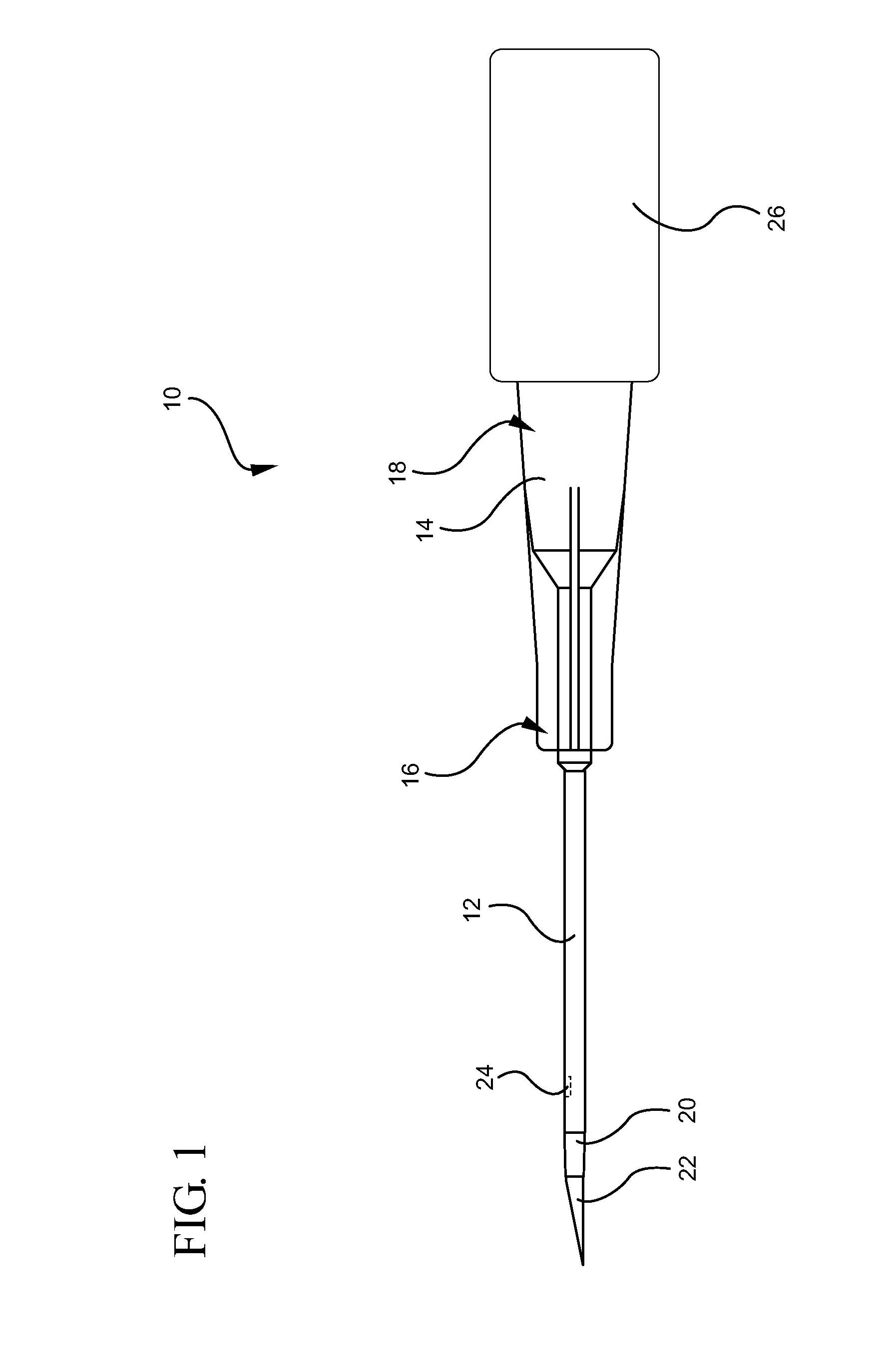

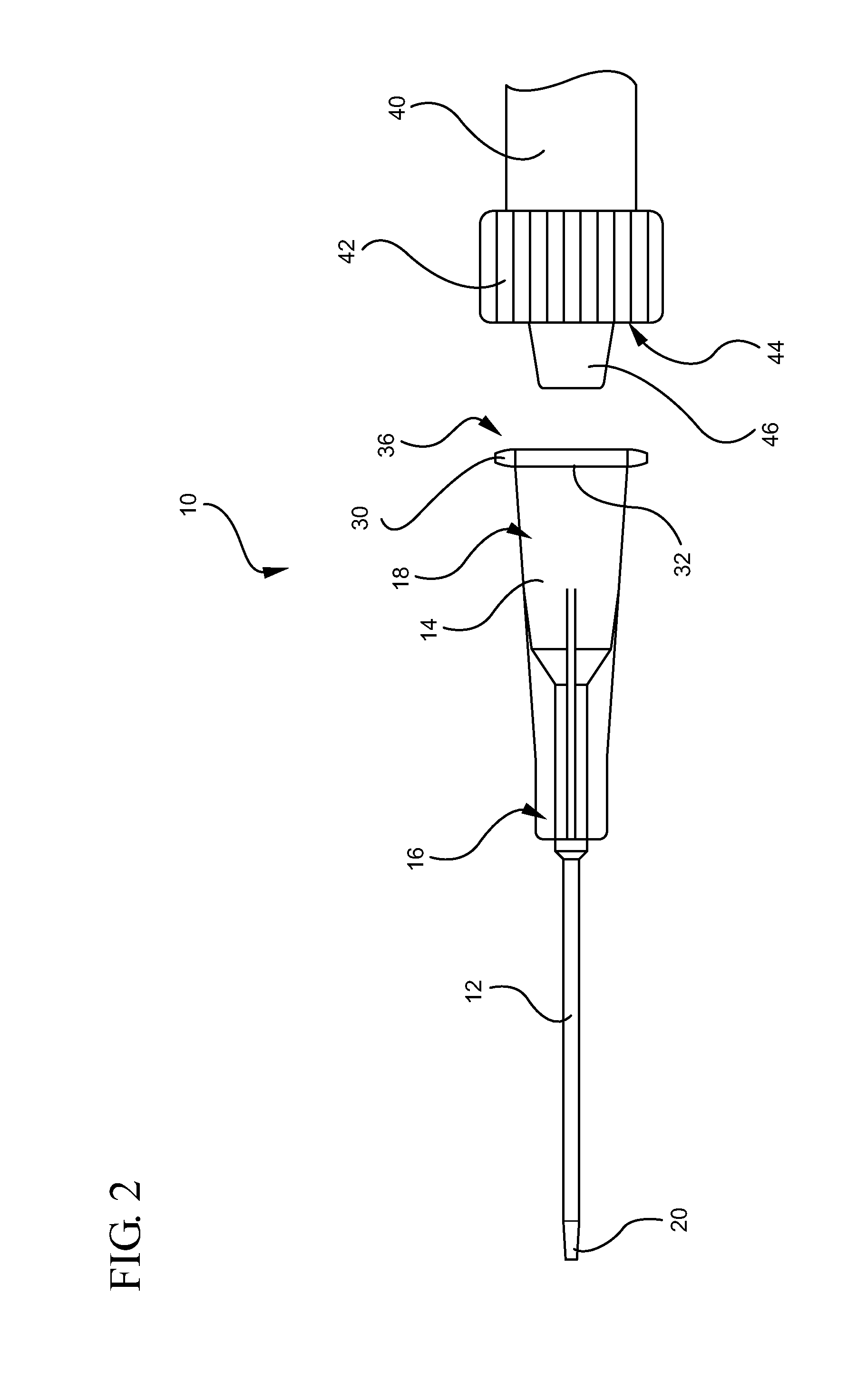

Systems and methods to compensate for compression forces in an intravascular device

ActiveUS20120232498A1Increase surface areaInfusion devicesMedical devicesChannel geometryEngineering

A system and method for providing vent channel geometries to compensate for compression forces experienced by a septum within an intravascular device.

Owner:BECTON DICKINSON & CO

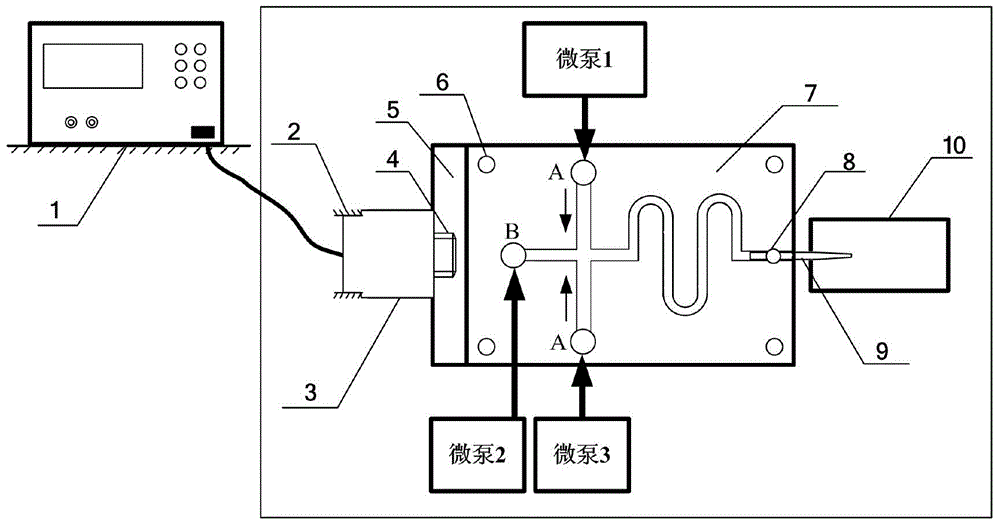

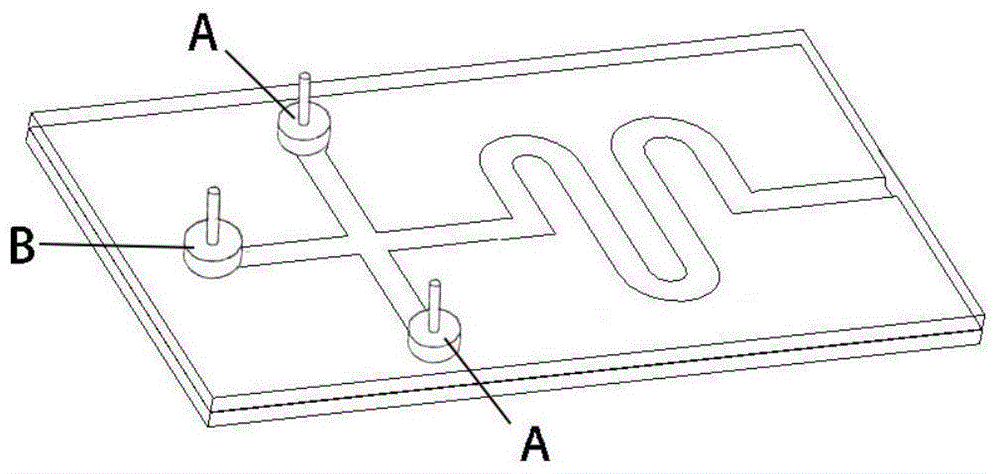

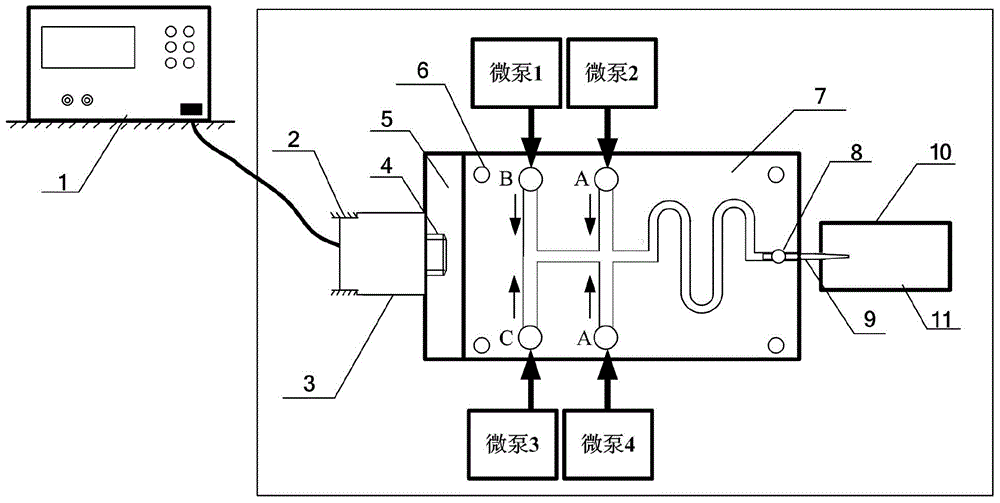

System and method for preparing microcapsules

InactiveCN104941541AUniform particle sizeImprove stabilityMicroballoon preparationMicrocapsule preparationChannel geometryInlet channel

The present invention provides a system and a method for preparing microcapsules, and relates to the technical field of materials. The system comprises a drive power supply, a piezoelectric ceramic, a bracket, a microfluidic chip, a micro pump, a micro spraying nozzle and a wall material reaction vessel. The method further comprises: injecting at least a solution to be prepared to the preparing system; emulsifying the injected solution to be prepared, such that the solution is in the micro-droplet form; and jetting the obtained solution having the micro-droplet form into the wall material solution so as to form the microcapsules through the reaction. According to the present invention, the microfluidic chip technology and the micro-jetting technology are firstly combined to carry out the metronomic microcapsule preparation, such that the mixing uniformity of the single component or multi-component solution and the capsule wall solution is enhanced, and the assurance is provided for the metronomic jetting of the microcapsules; and the microcapsule component configuration is flexible, wherein only the number of the inlet channels on the microfluidic chip and the channel geometry are changed so as to flexibly configure the number of the microcapsule components.

Owner:ANHUI UNIV OF SCI & TECH

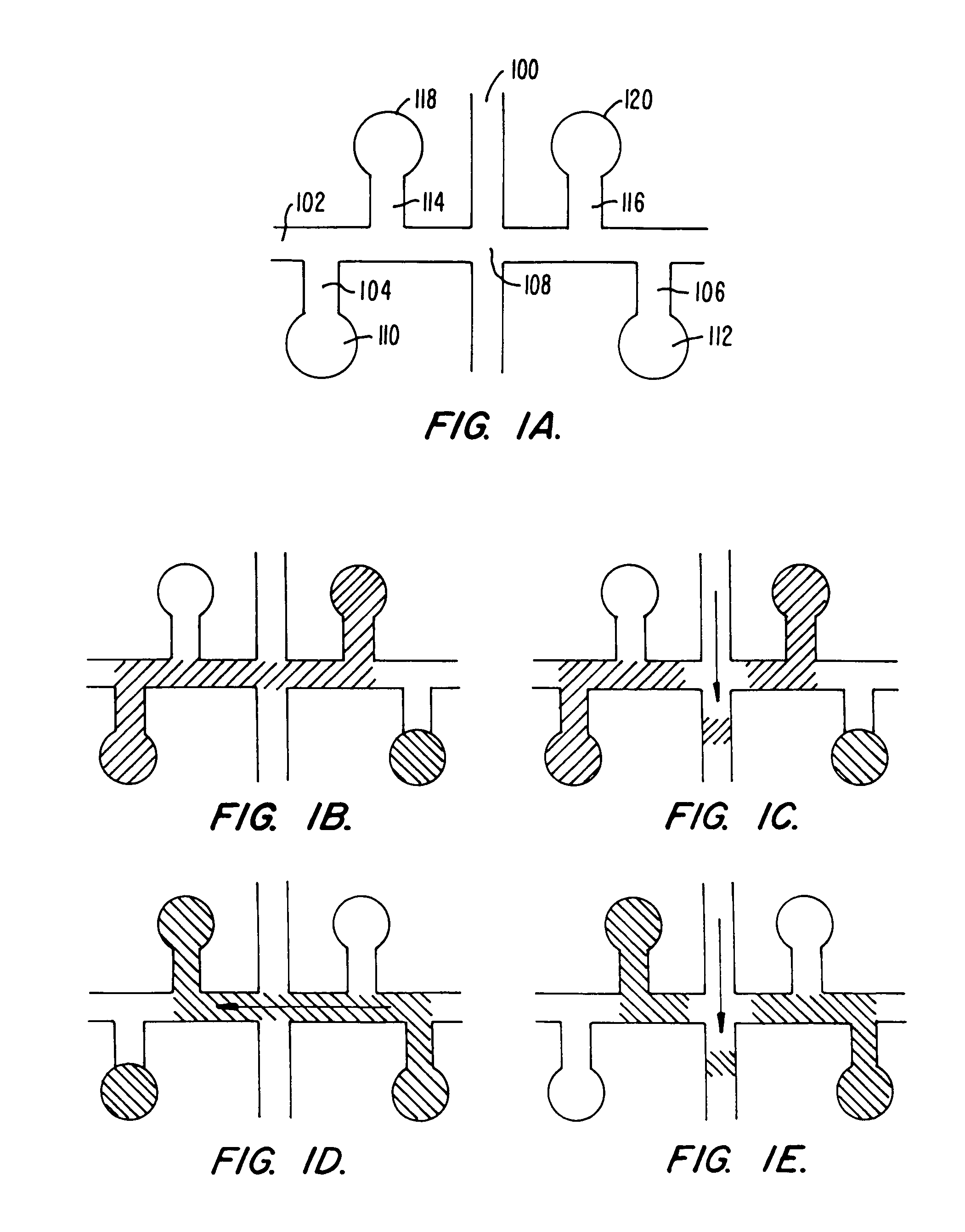

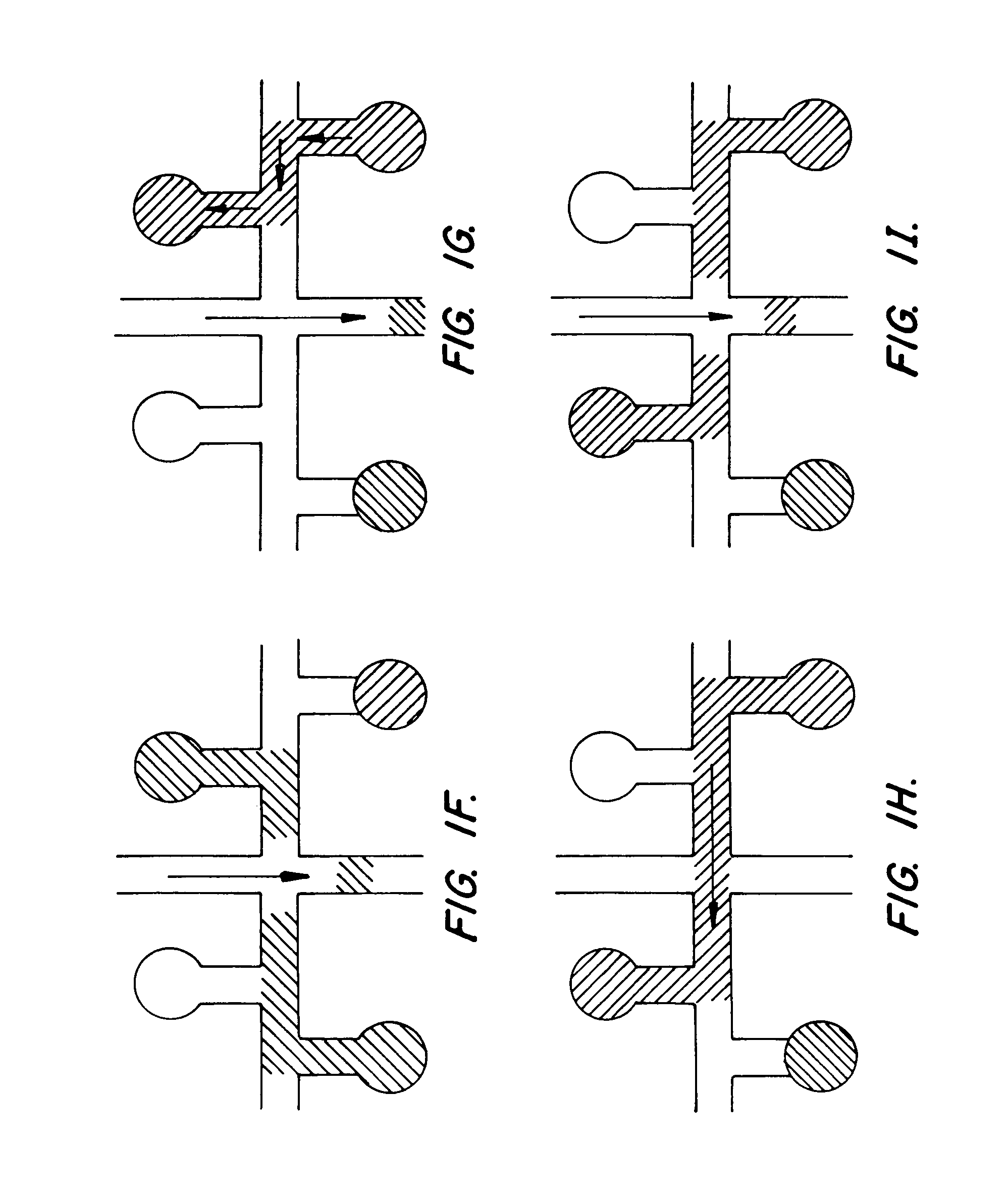

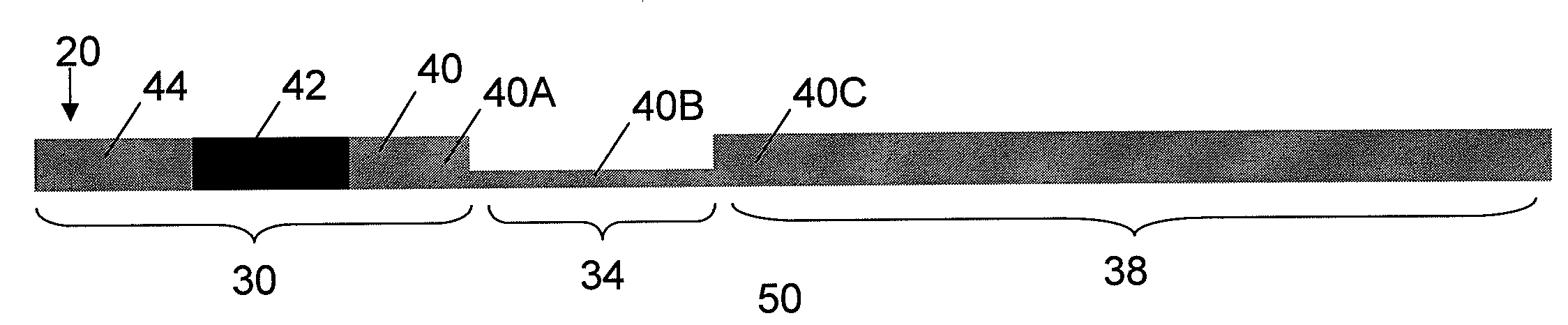

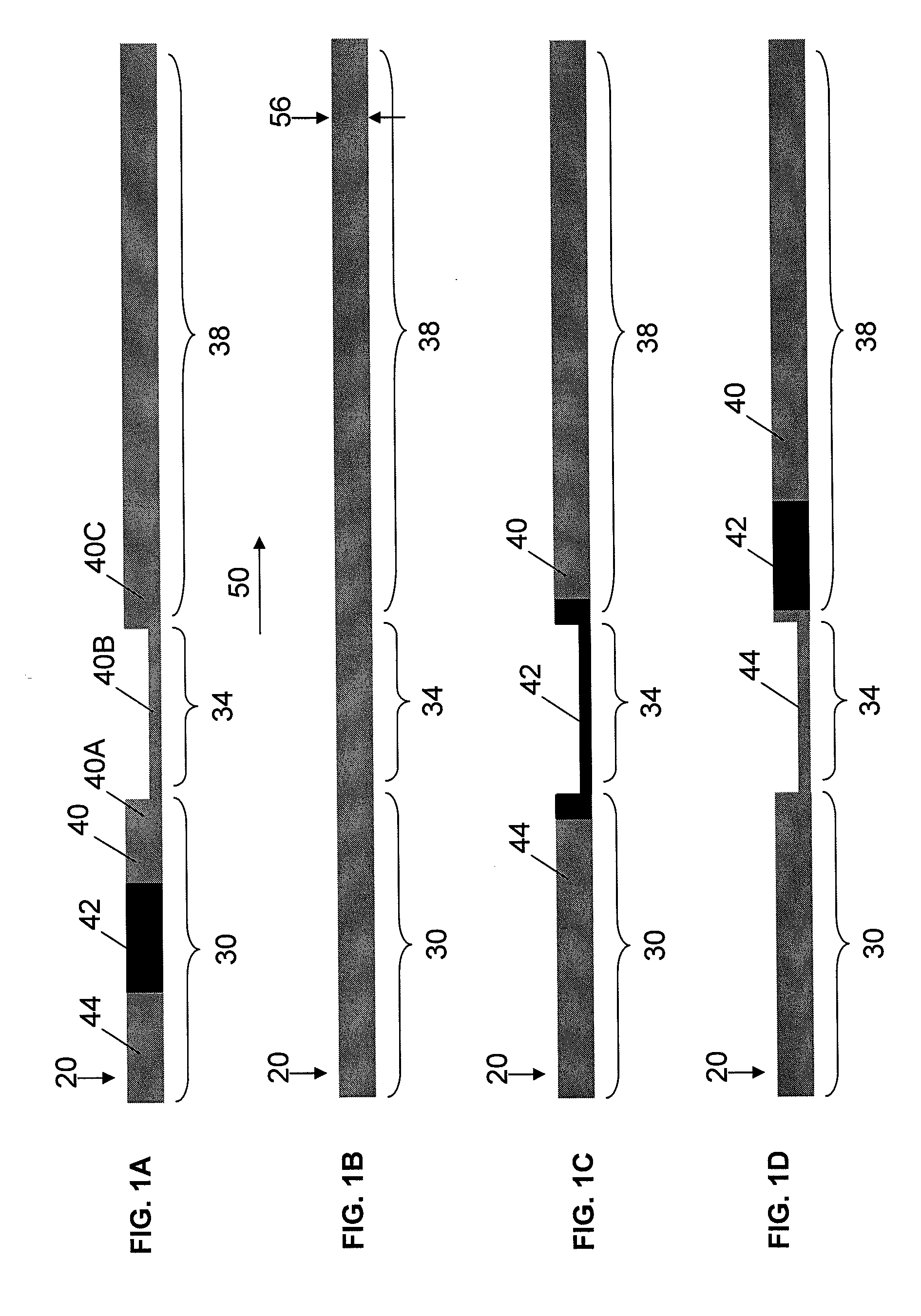

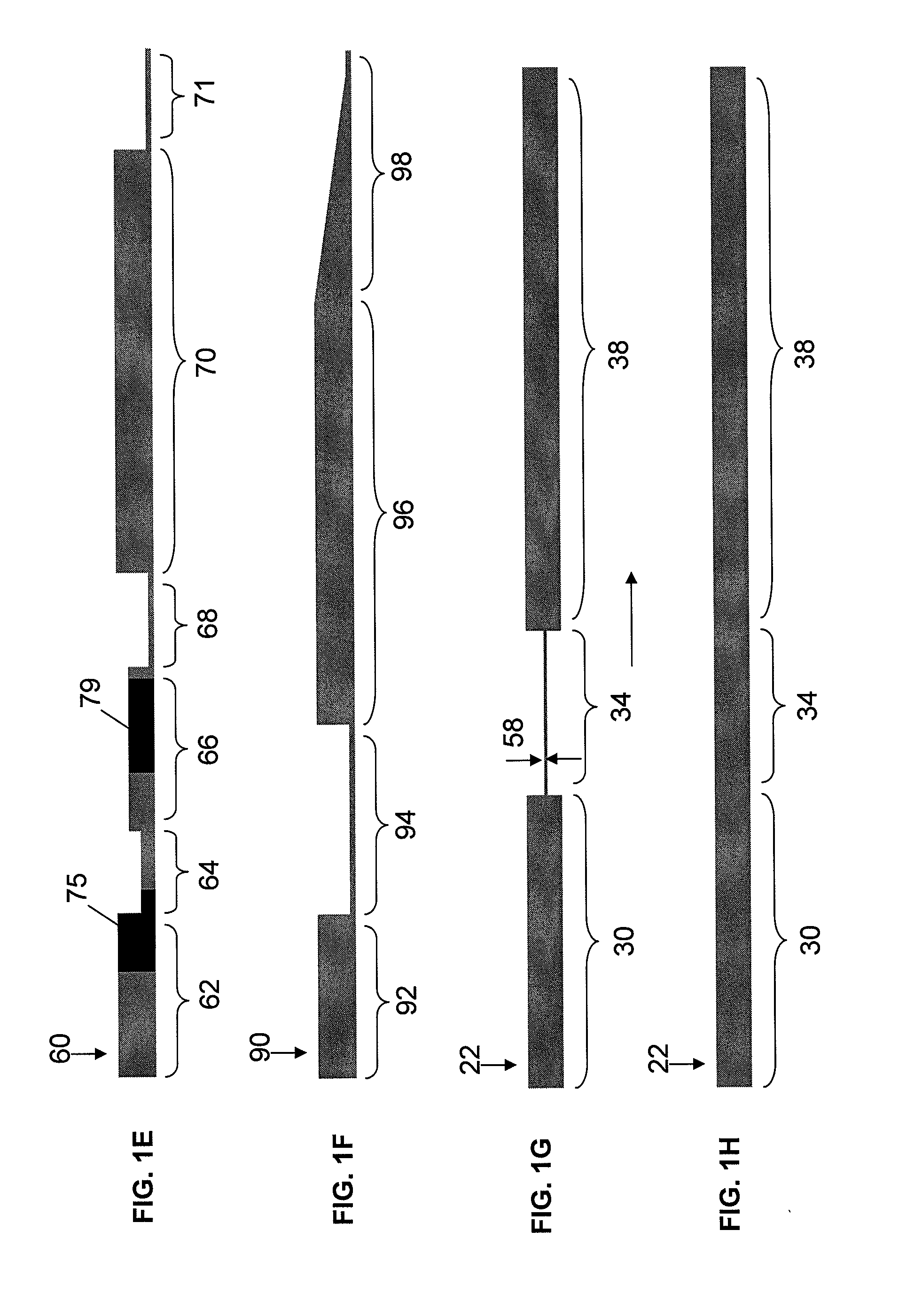

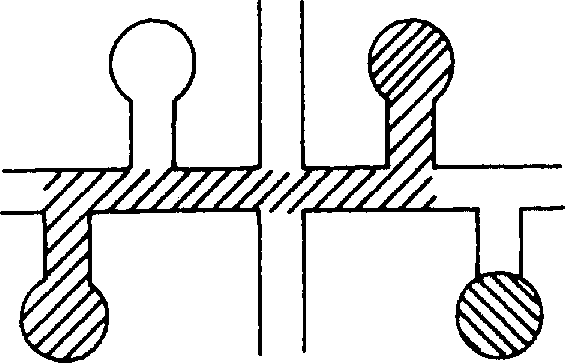

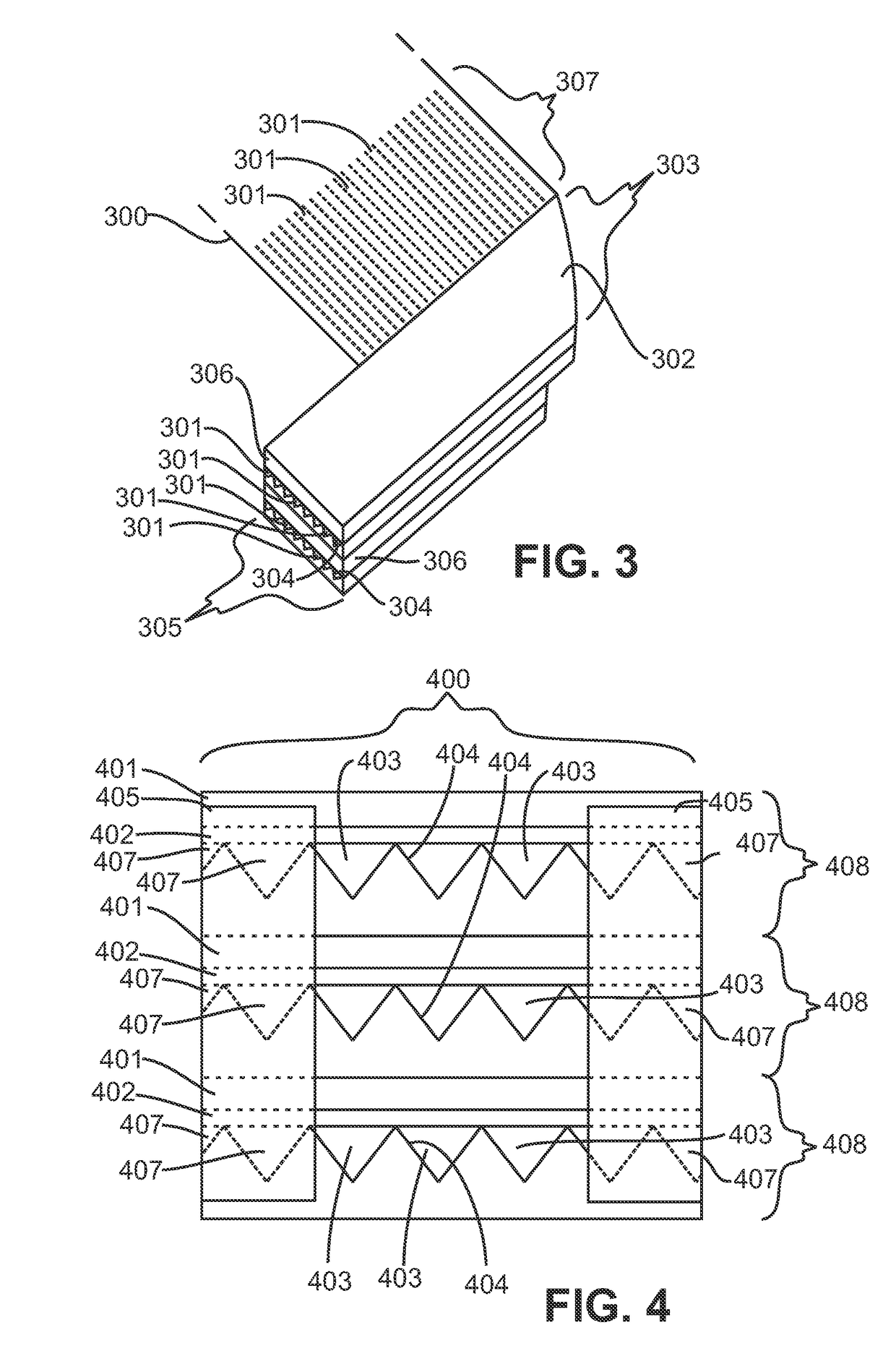

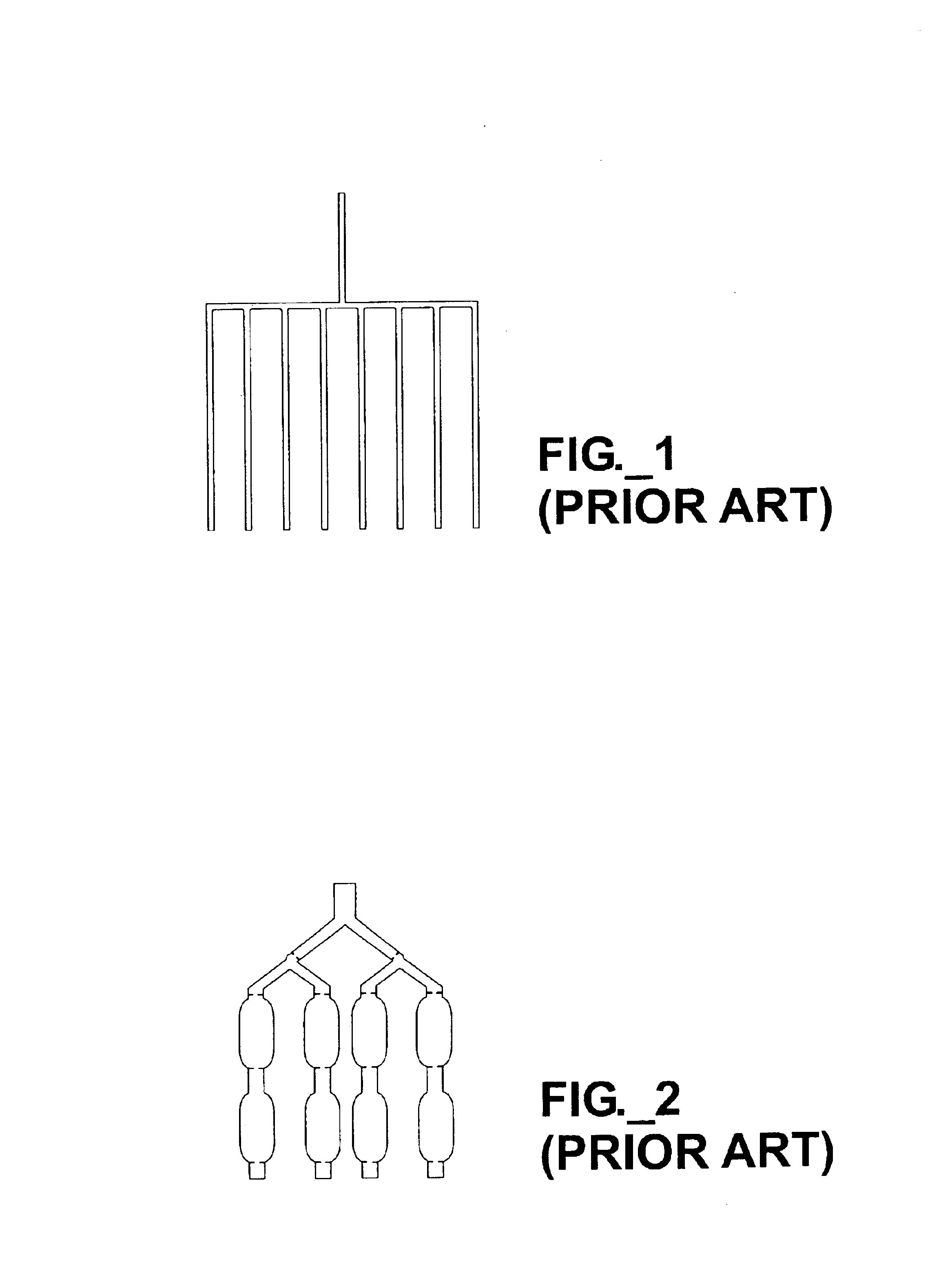

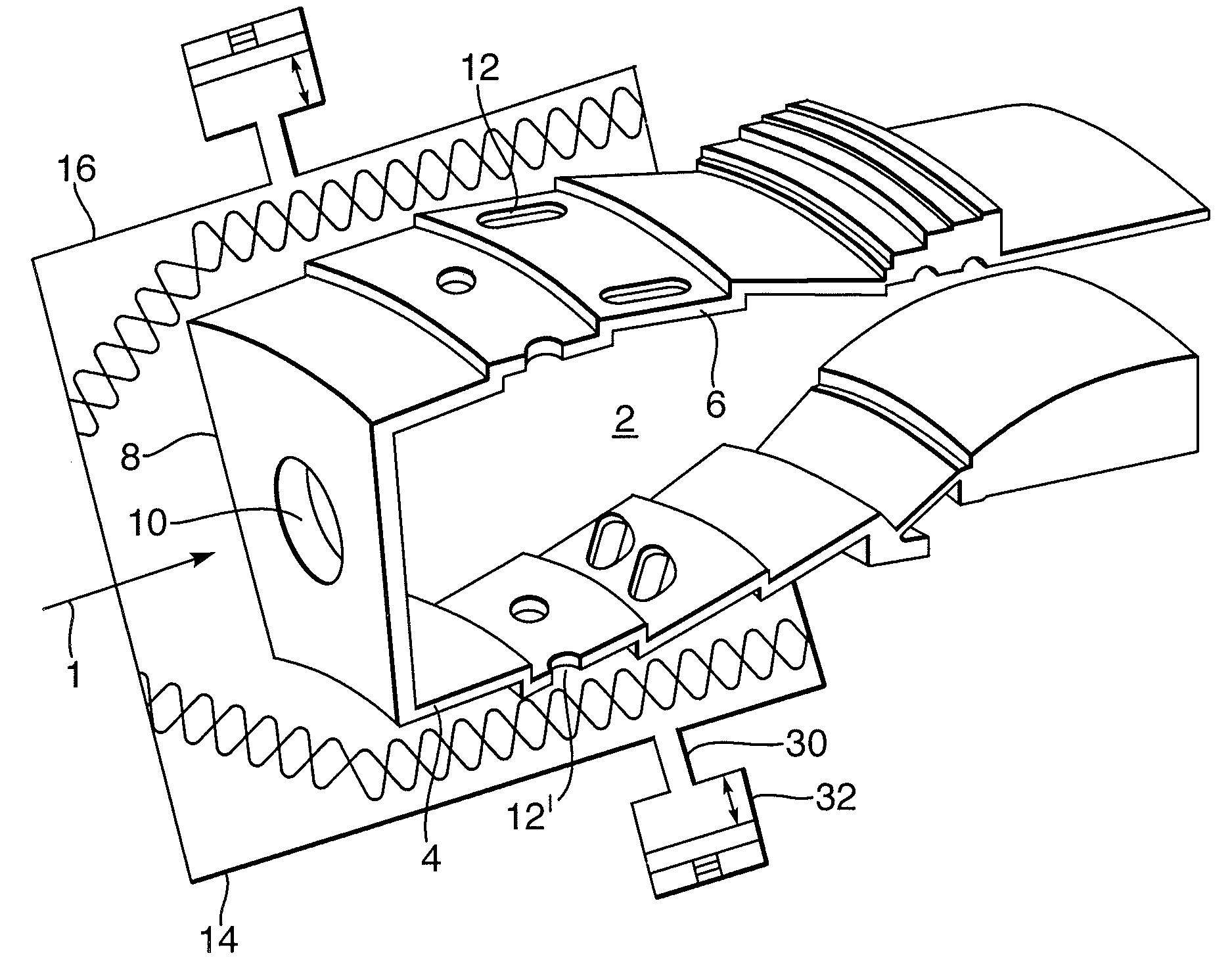

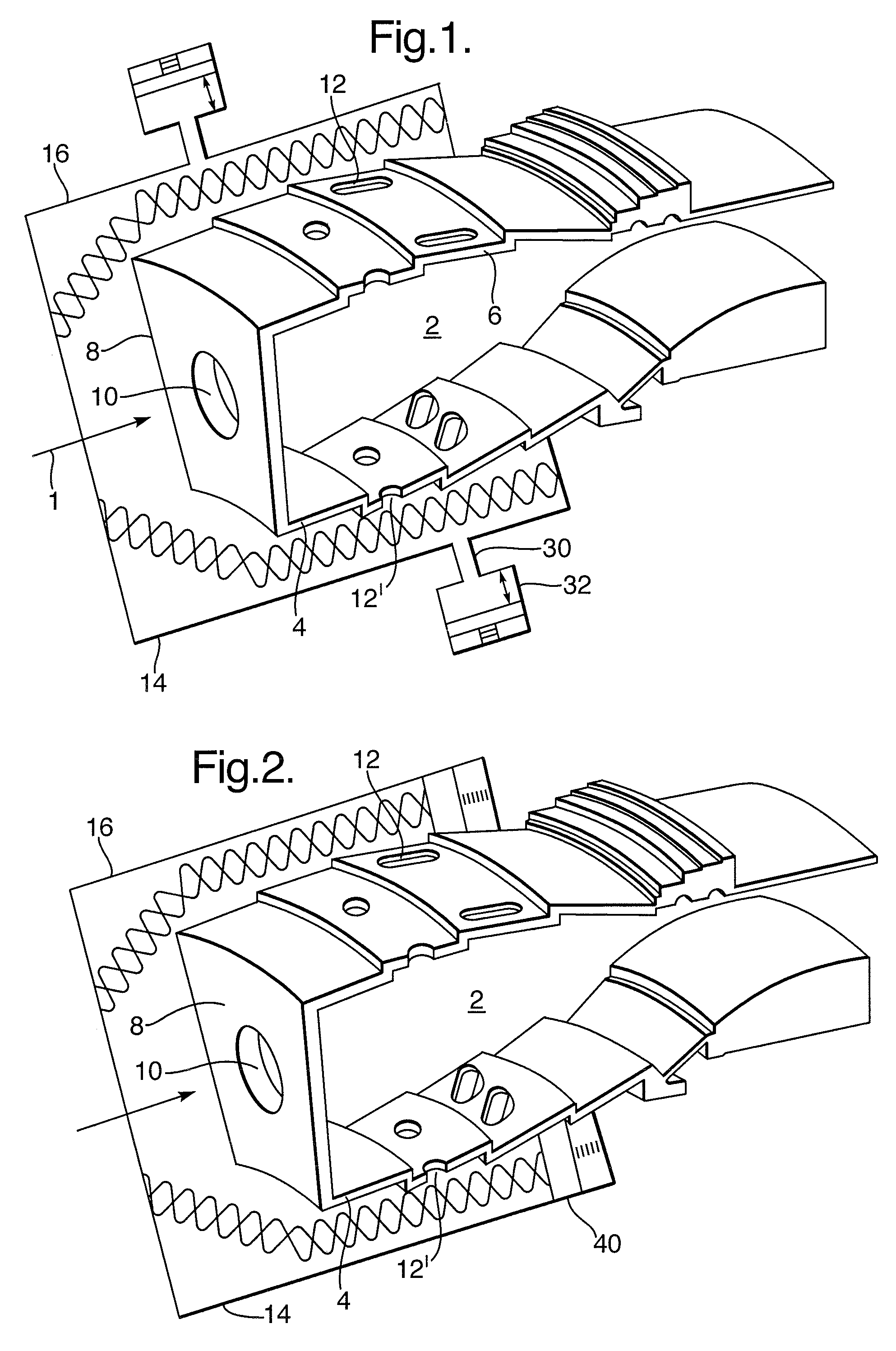

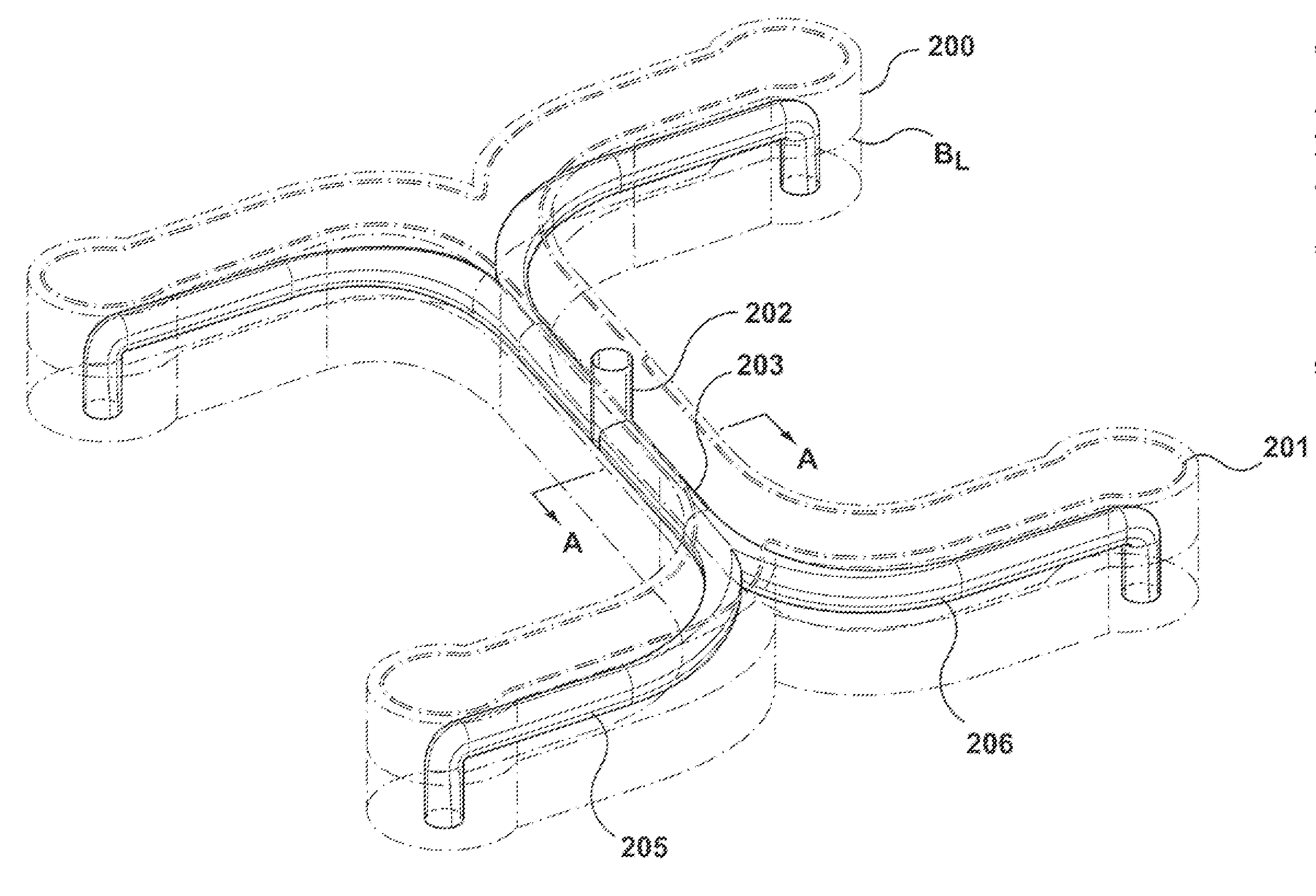

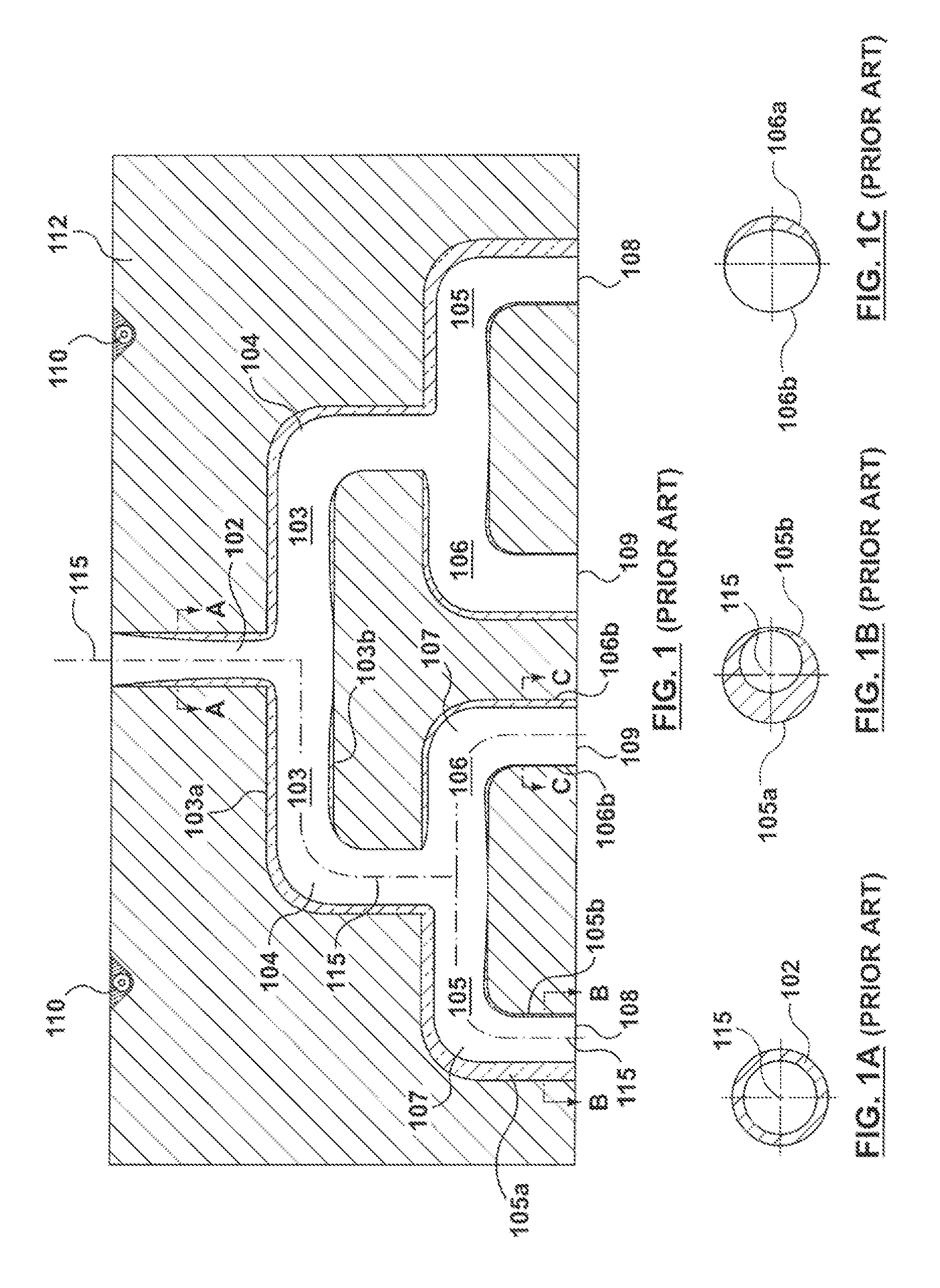

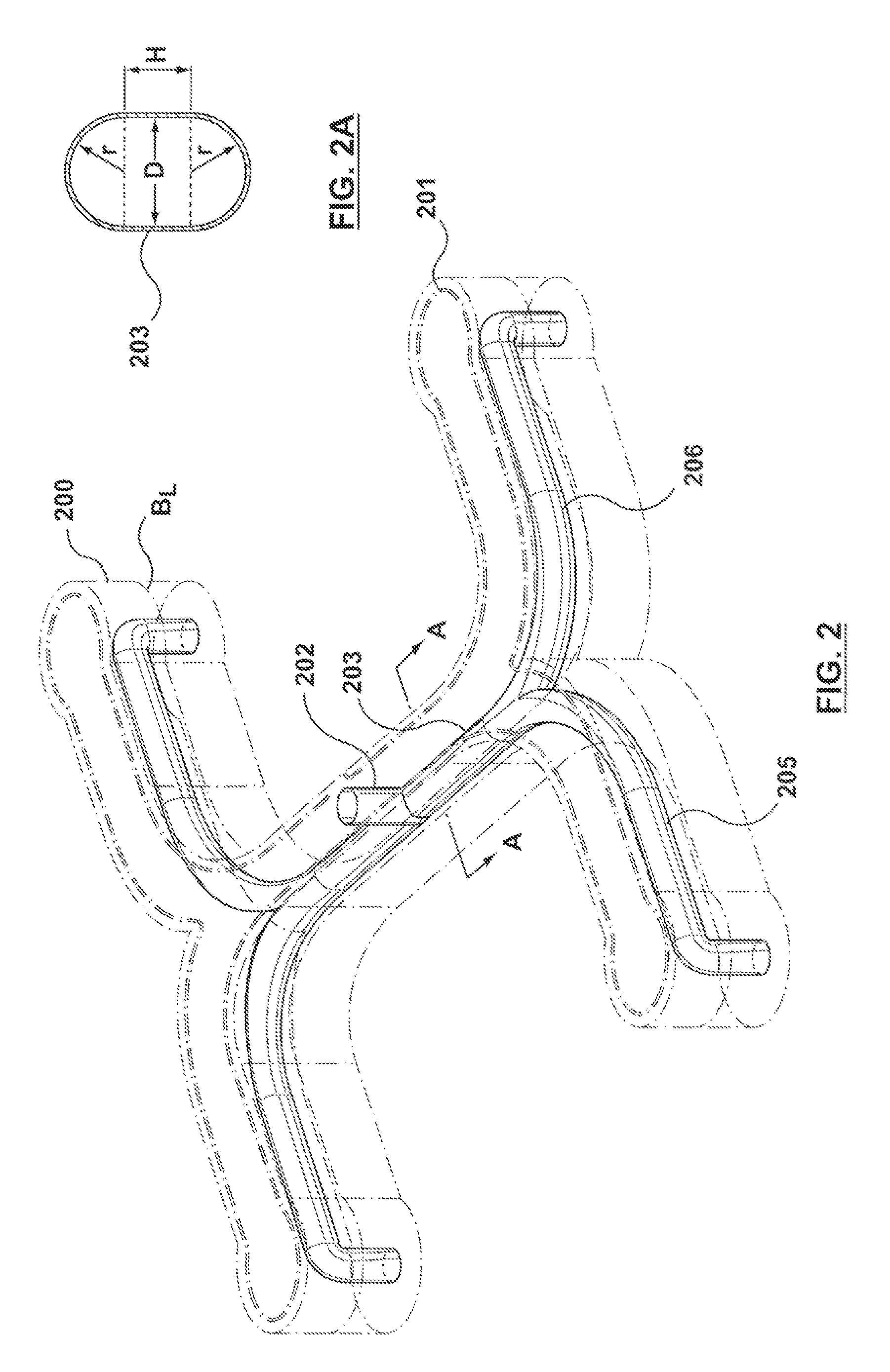

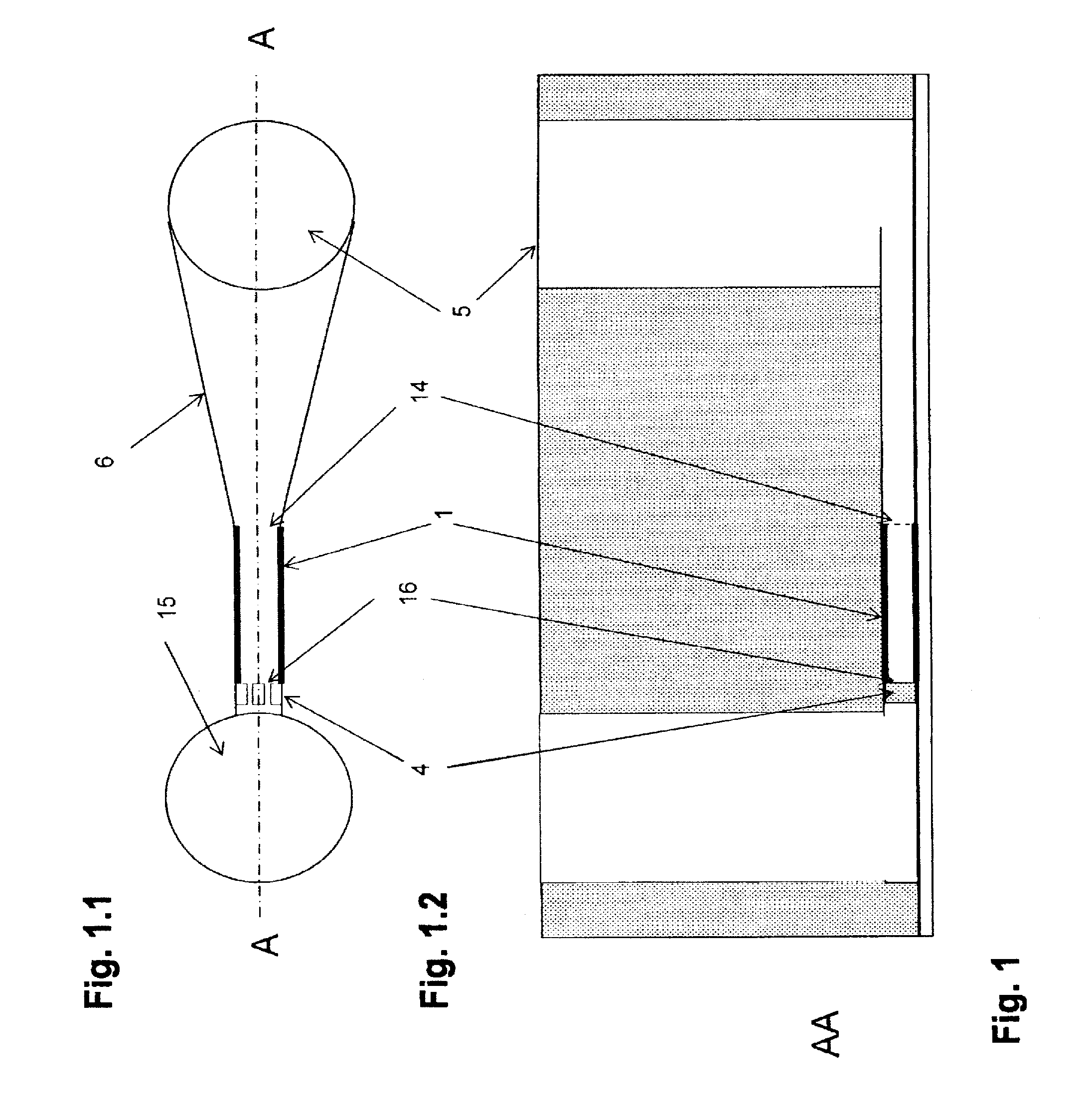

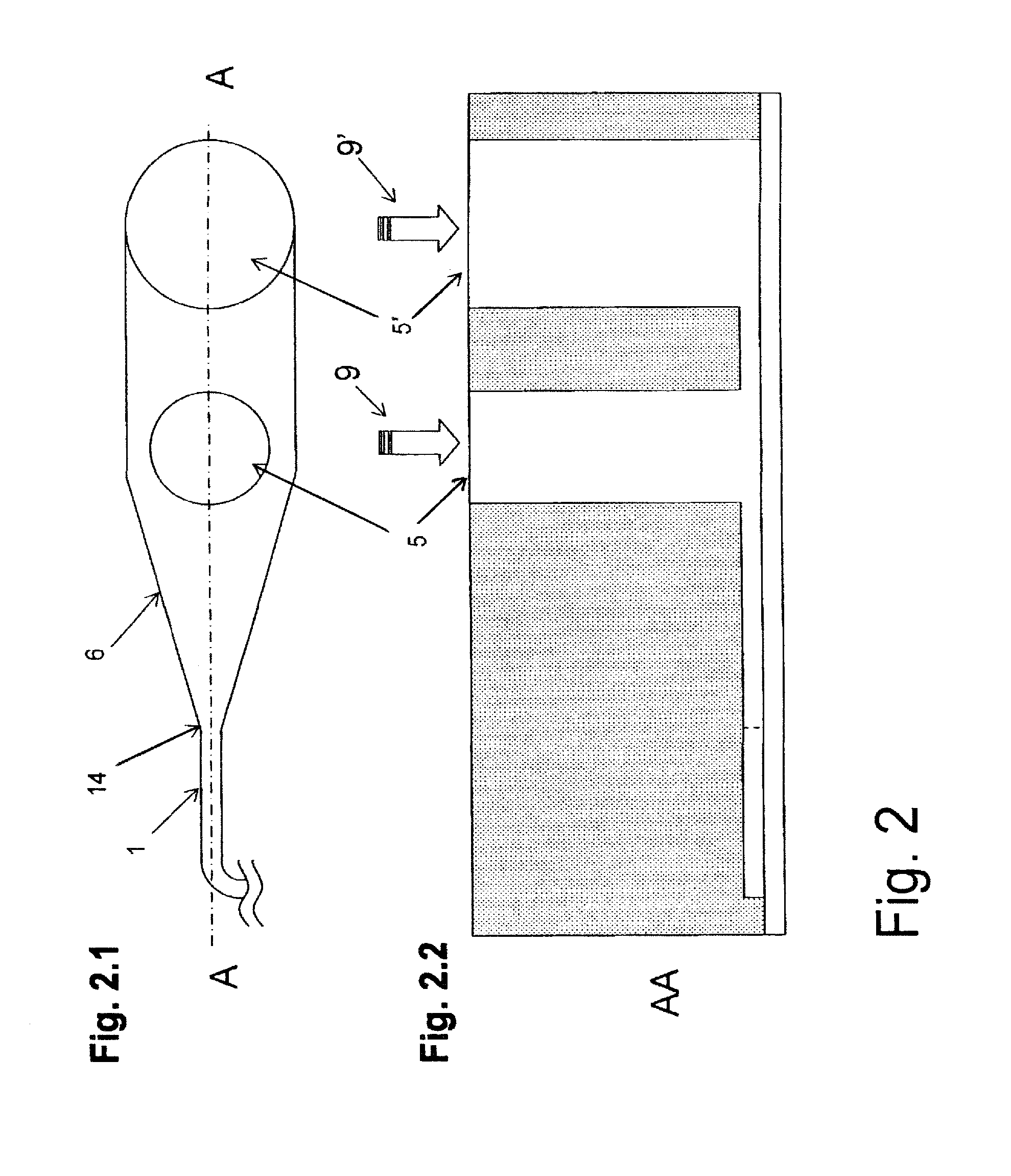

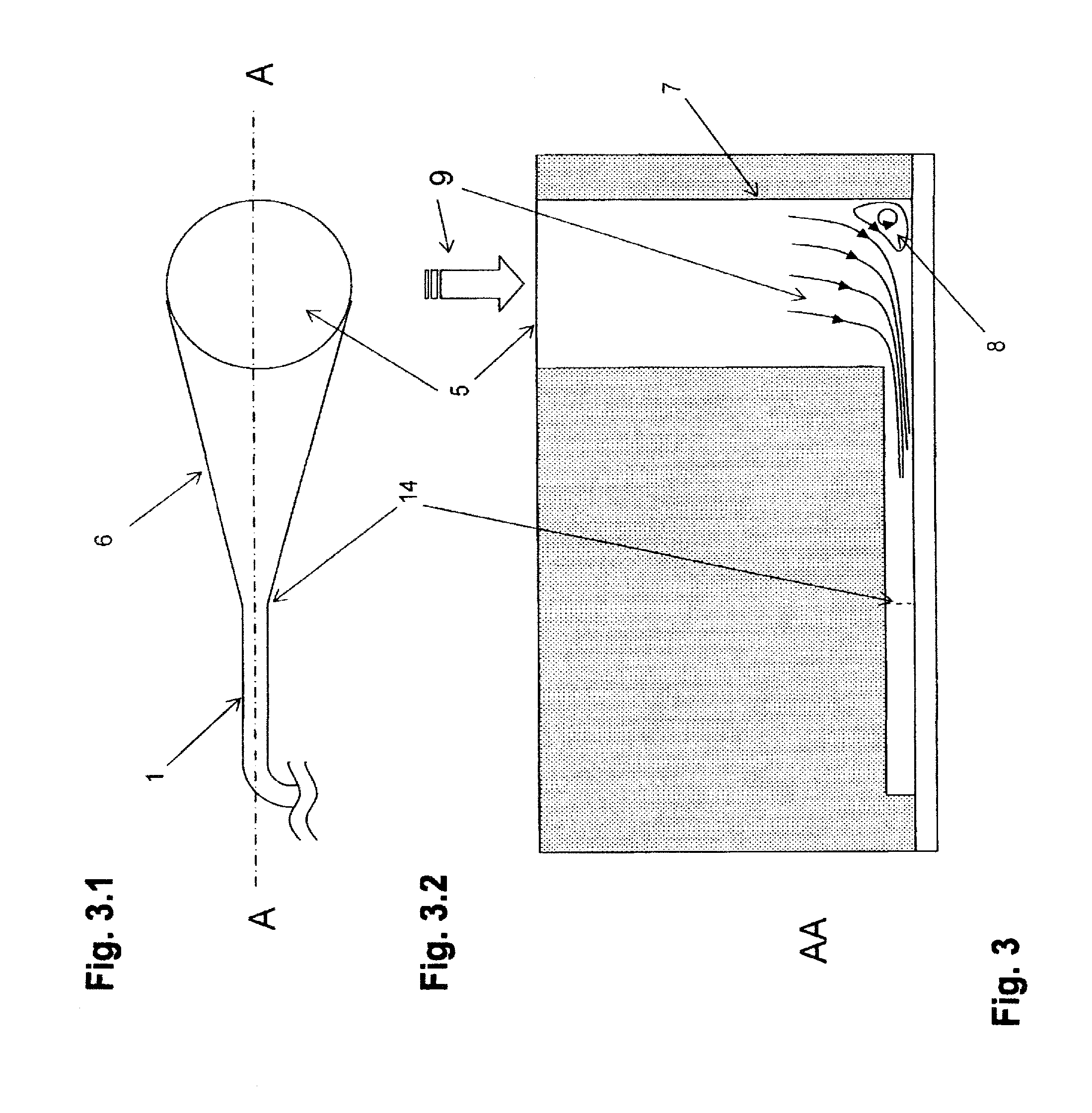

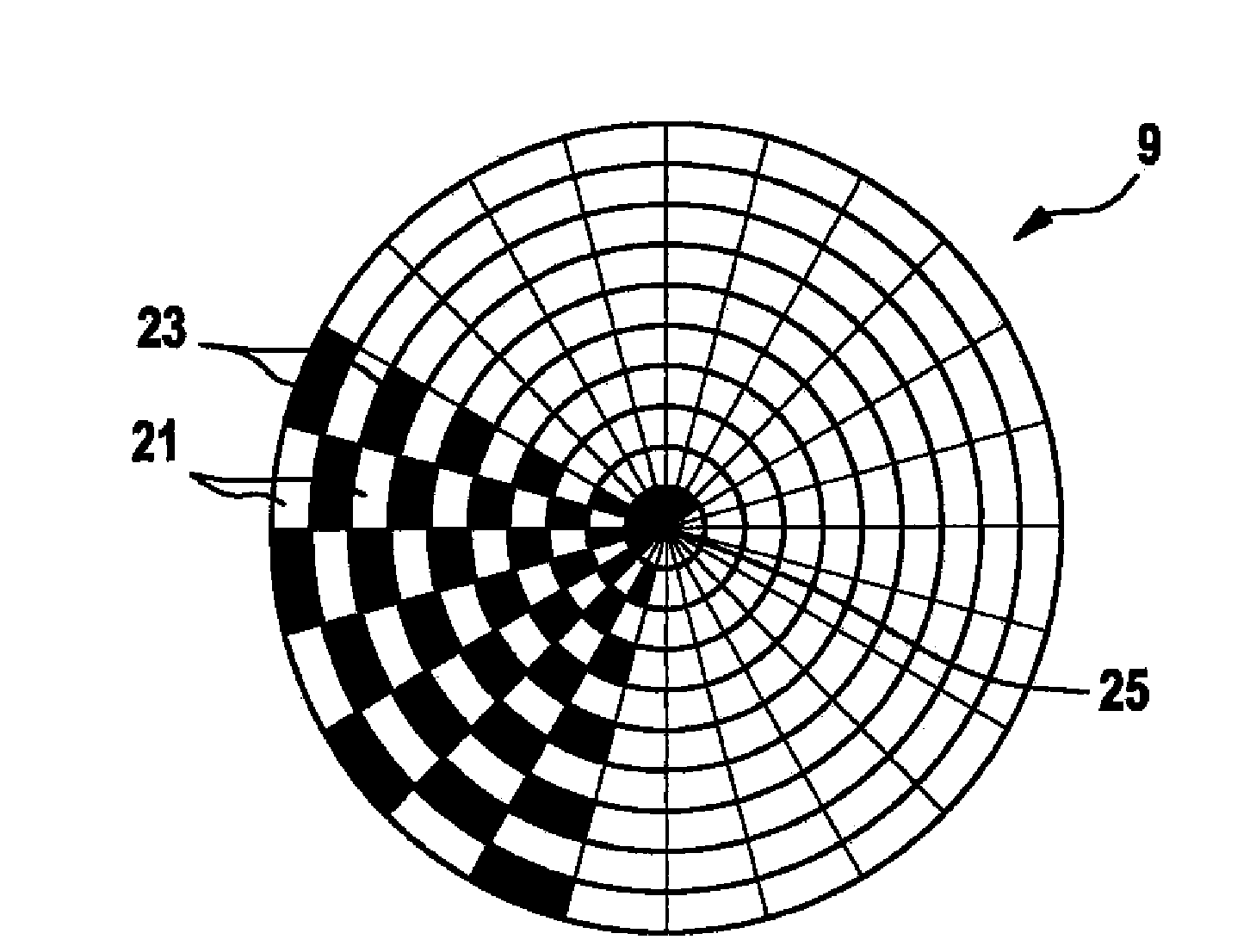

Melt Channel Geometries for an Injection Molding System

An injection molding system is disclosed that utilizes a melt channel wherein at least a portion of the melt channel has a noncircular cross-section for balancing shear in a melt stream of moldable material that flows therethrough. The noncircular cross-section of the melt channel portion may be, for e.g., capsule-shaped, extended egg-shaped, oval, teardrop-shaped, or peanut-shaped. A flow splitter is also disclosed that is positioned offset from a central axis of an upstream melt channel to protrude between inlets of respective downstream melt channels, where the upstream melt channel splits into the downstream melt channels, to thereby create a narrower inlet into one of the downstream melt channels and a wider inlet into the other of the downstream melt channels.

Owner:MOLD MASTERS 2007

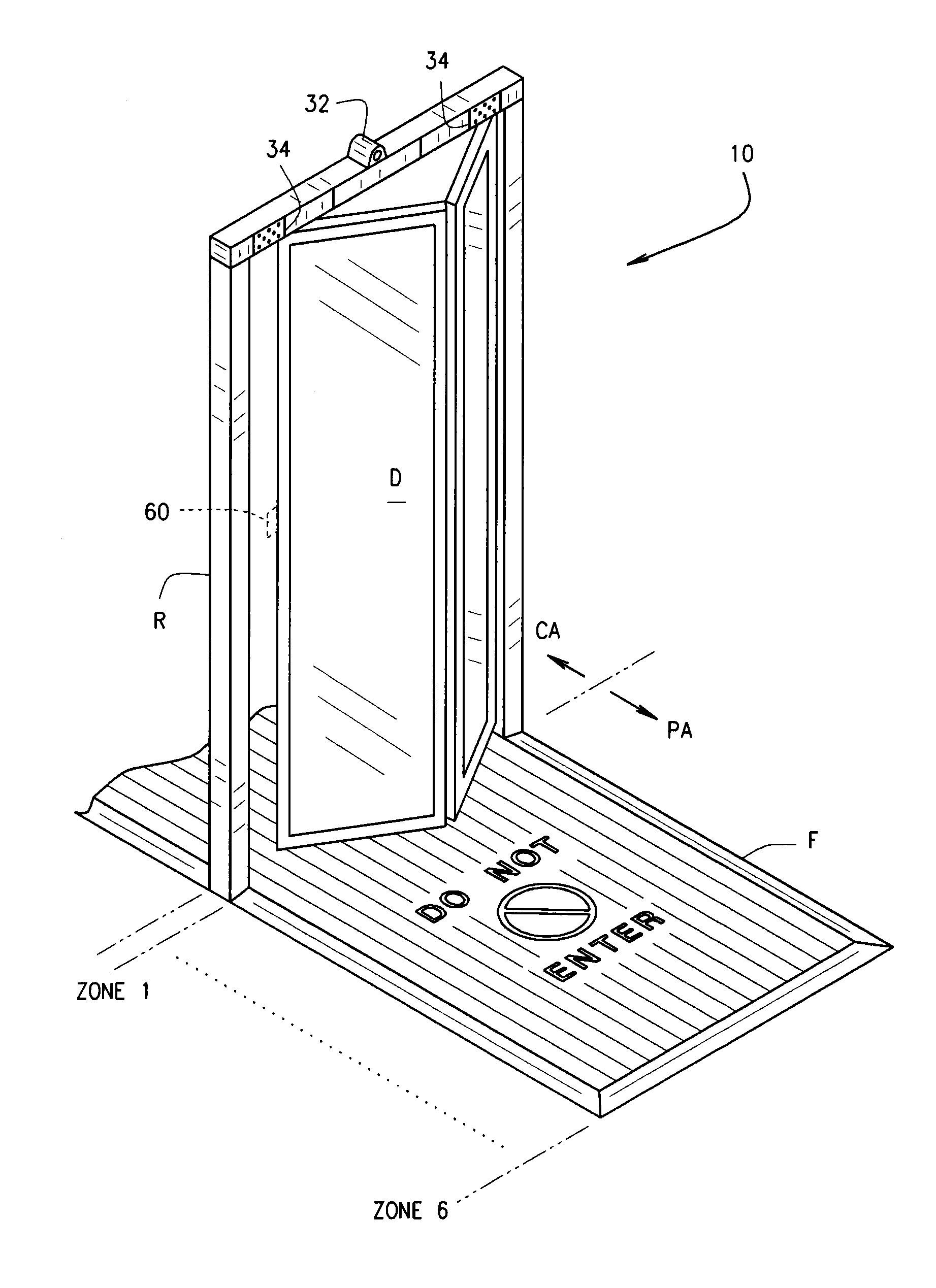

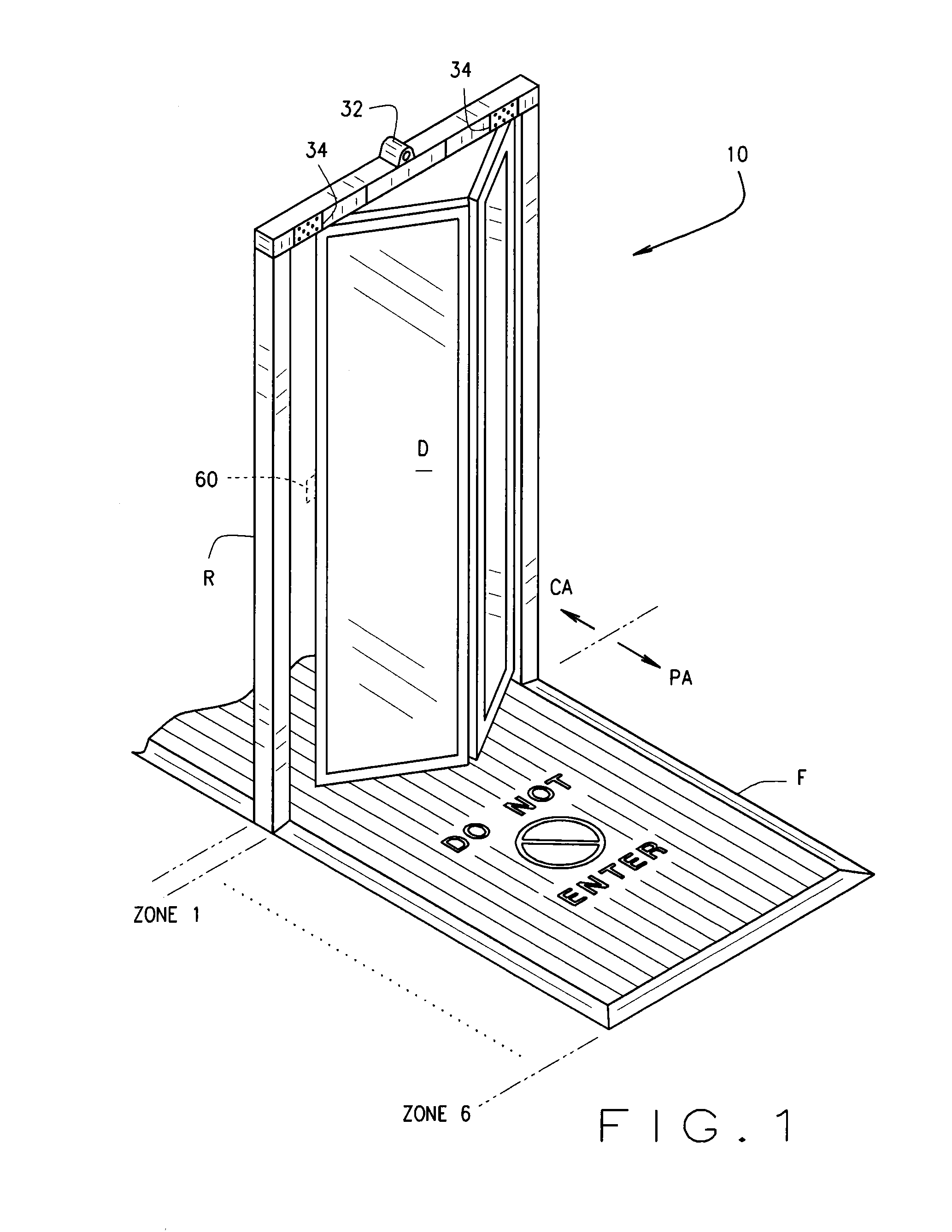

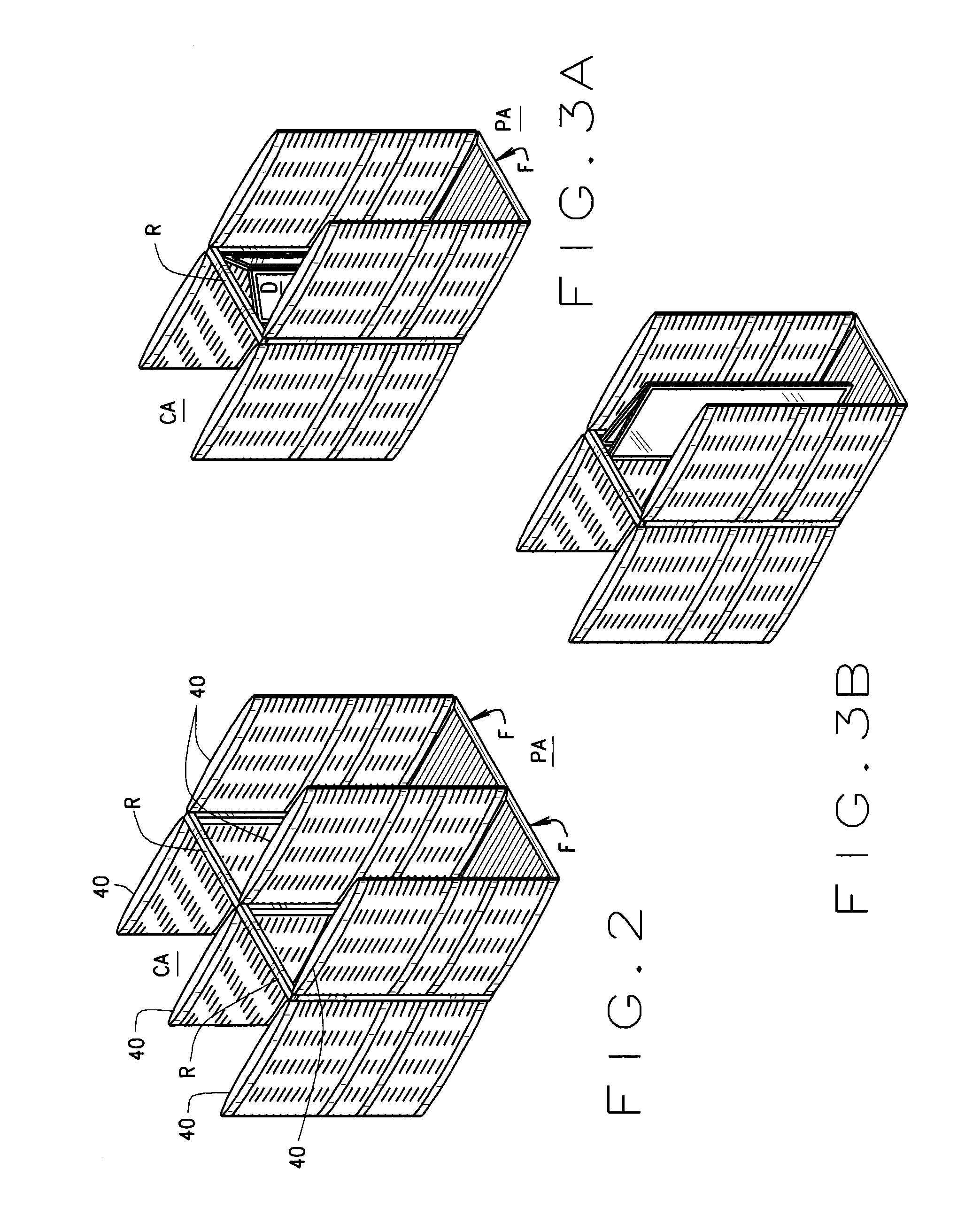

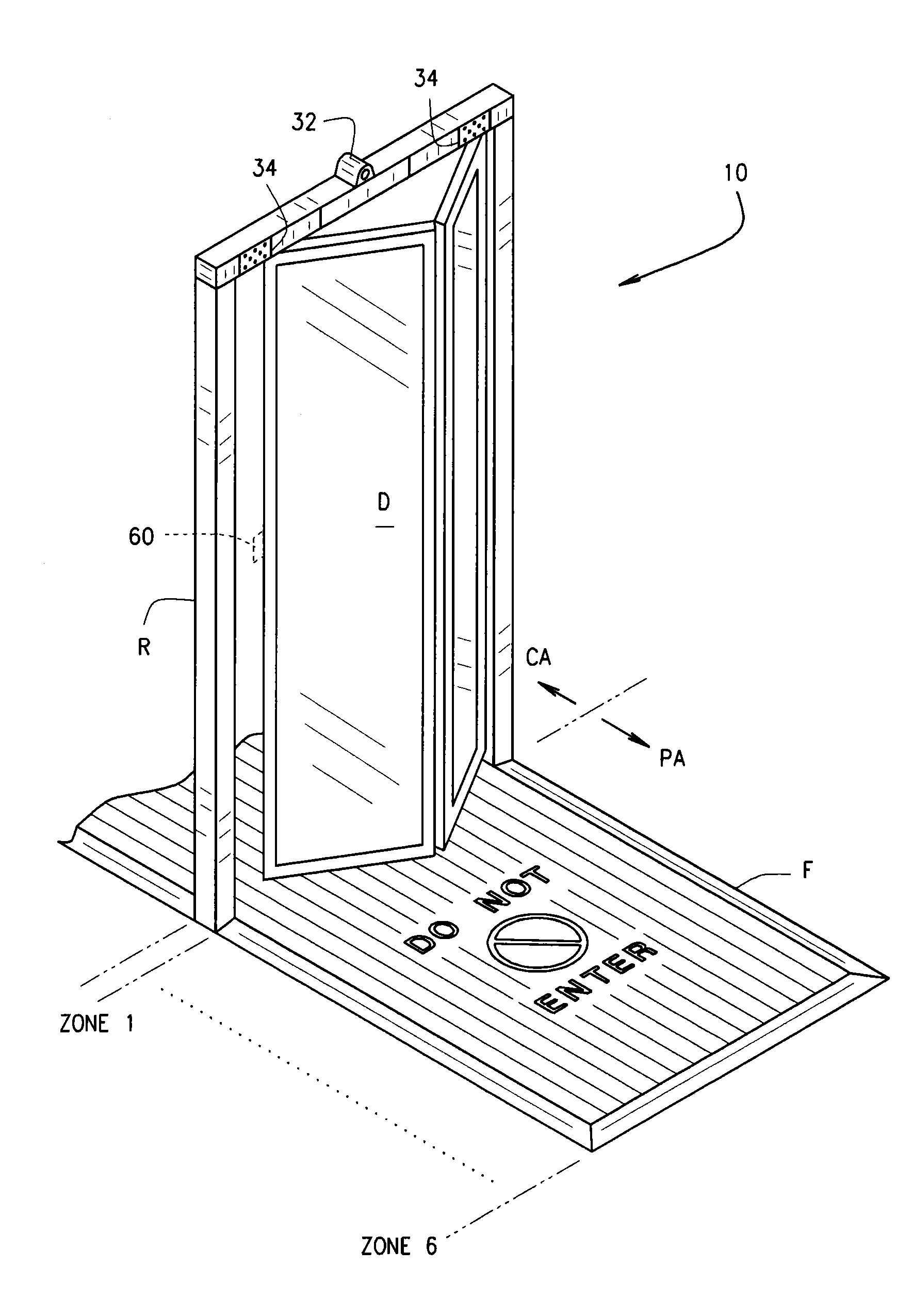

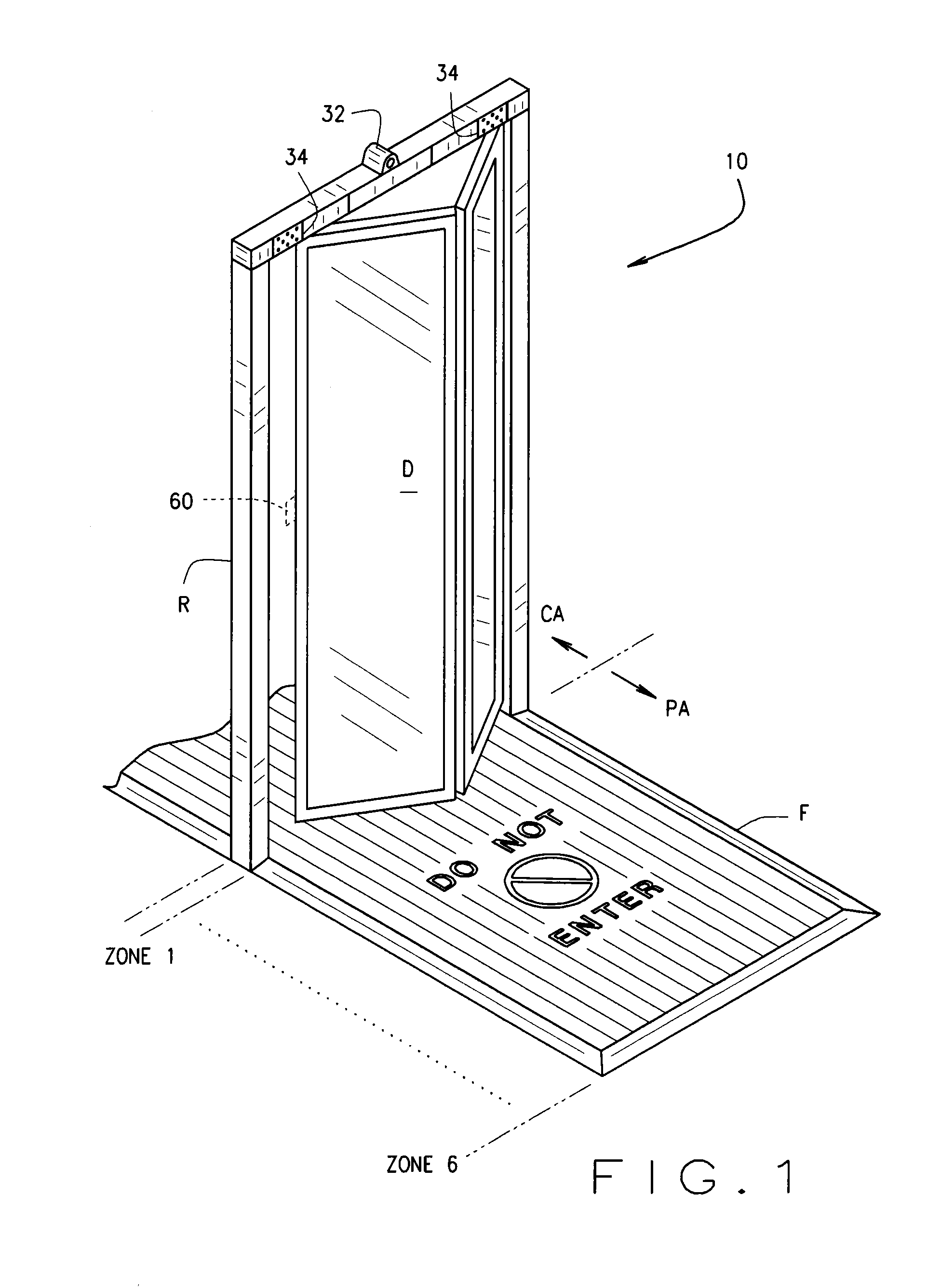

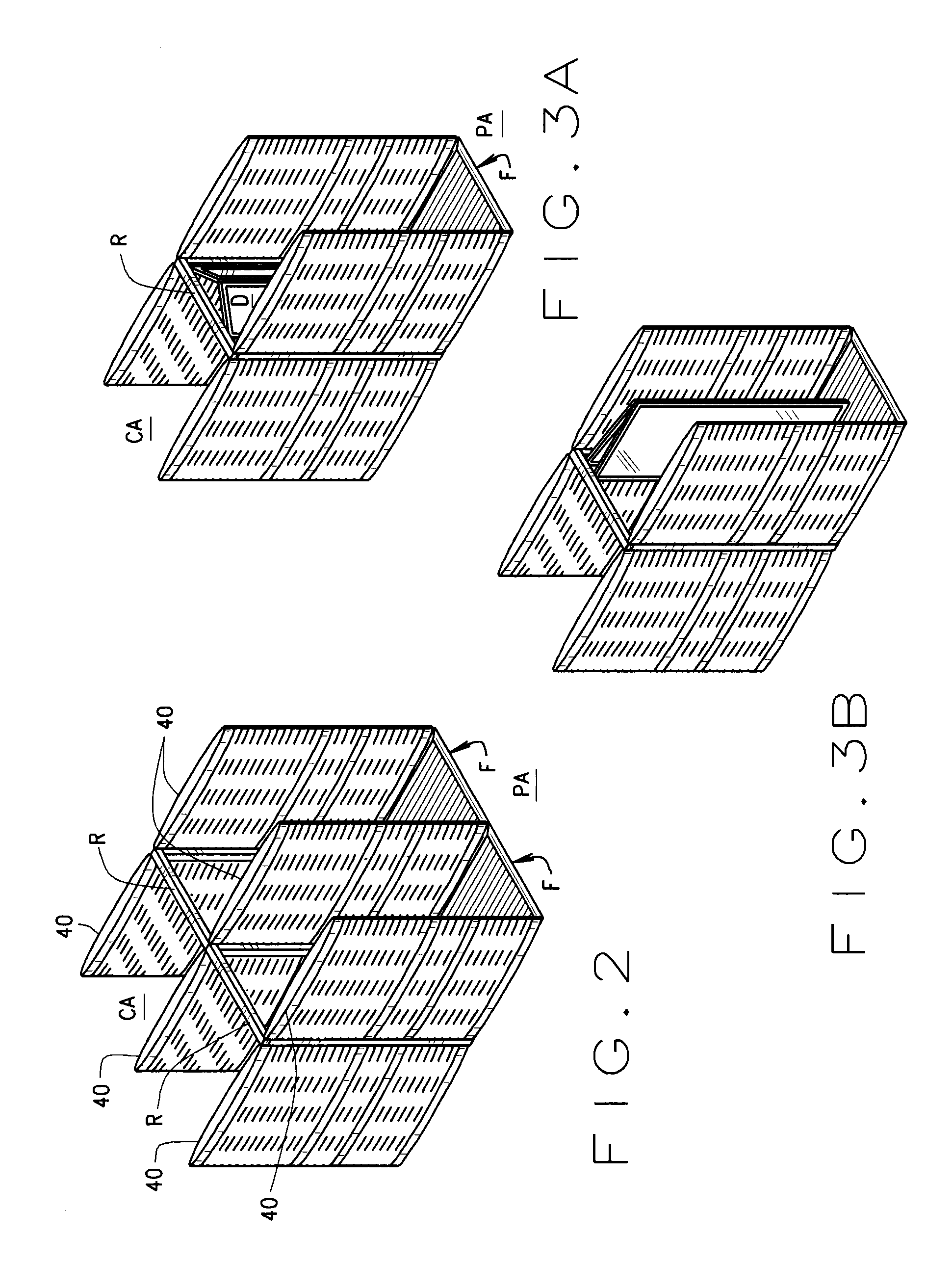

Exit Lane Monitoring System

InactiveUS20130021136A1Programme controlElectric signal transmission systemsChannel geometryMonitoring system

An exit lane monitoring system (10) detects wrong-way movement through a passage (P) between a secure area and a public area. Heel before toe sensors (12) are positioned on the floor of the passage and detect the foot pressure exerted by people moving through the passage from the secure area toward the public area and of persons moving the wrong way through the passage. Positioning of the sensors in the passage depends upon the geometry of the passage so sensors may be oriented in a non-geometric pattern if so dictated by the passage's geometry. A door (D) is selectively operated to block the passage and prevent persons moving the wrong way through it from entering the secure area. A control unit (16) is responsive to a sensor indication that someone is moving the wrong way to activate the door to block the passage and prevent movement into the secure area.

Owner:TEN4WARD

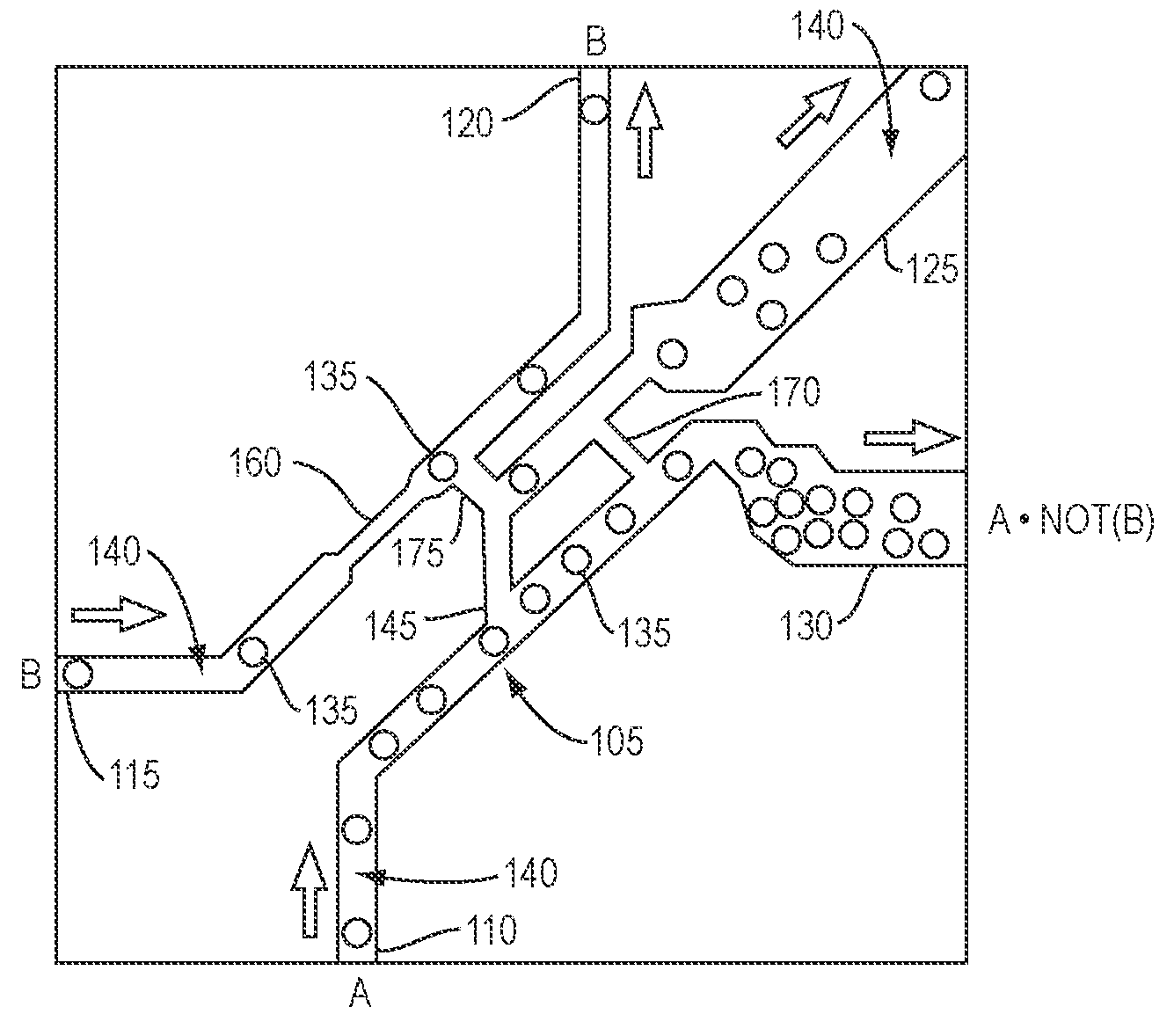

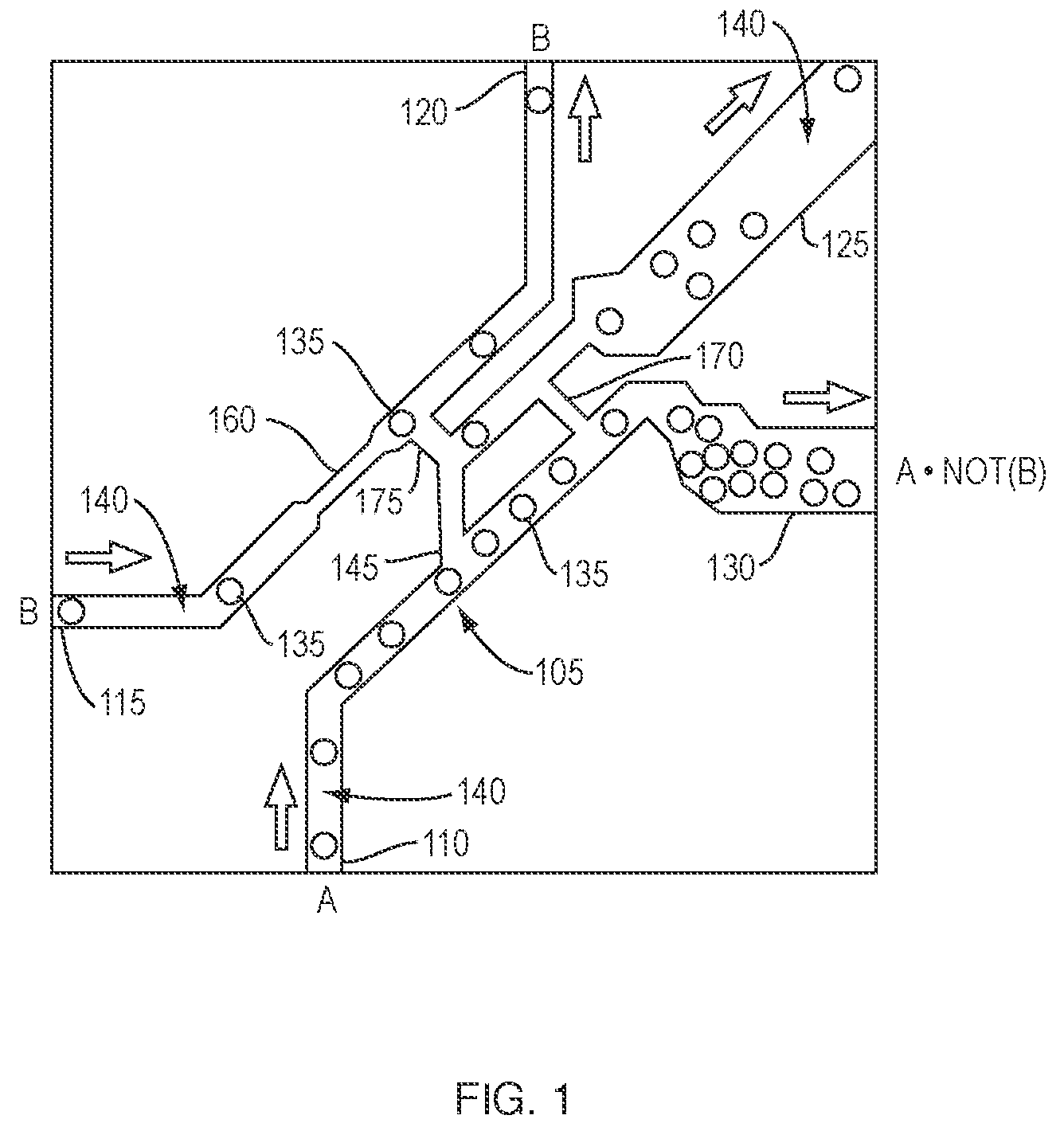

Microfluidic bubble logic devices

ActiveUS7918244B2Increase flow resistanceWell formedValve arrangementsSamplingChannel geometryChemical synthesis

Fluid-based no-moving part logic devices are constructed from complex sequences of micro- and nanofluidic channels, on-demand bubble / droplet modulators and generators for programming the devices, and micro- and nanofluidic droplet / bubble memory elements for storage and retrieval of biological or chemical elements. The input sequence of bubbles / droplets encodes information, with the output being another sequence of bubbles / droplets or on-chip chemical synthesis. For performing a set of reactions / tasks or process control, the modulators can be used to program the device by producing a precisely timed sequence of bubbles / droplets, resulting in a cascade of logic operations within the micro- or nanofluidic channel sequence, utilizing the generated droplets / bubbles as a control. The devices are based on the principle of minimum energy interfaces formed between the two fluid phases enclosed inside precise channel geometries. Various devices, including logic gates, non-volatile bistable memory, ring oscillators, bubble synchronizers, analysis chips, and printers have been designed.

Owner:MASSACHUSETTS INST OF TECH

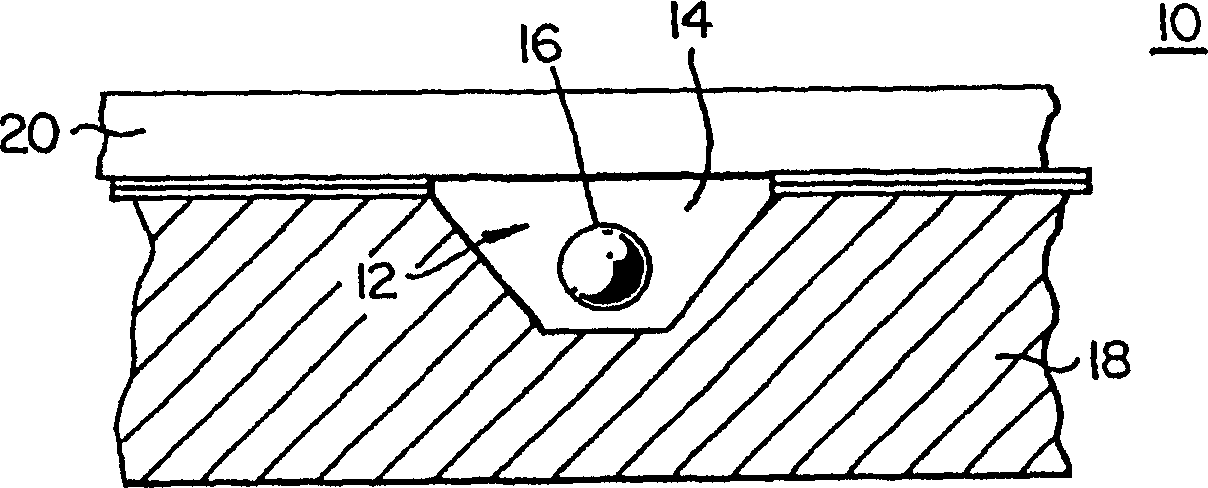

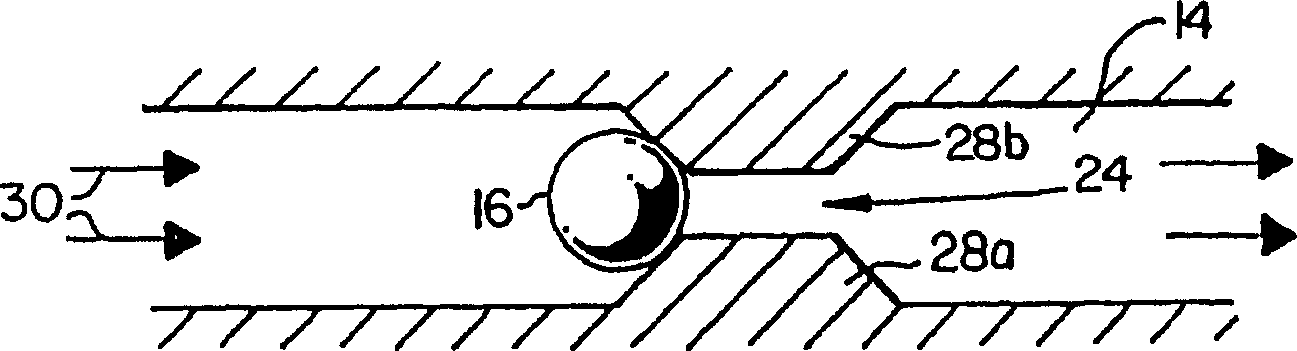

Microfluidic channel embryo and/or oocyte handling, analysis and biological evaluation

InactiveCN1441652AEliminate processingEasy to collectBioreactor/fermenter combinationsBiological substance pretreatmentsChannel geometrySurvivability

Microfluidic embryo scaled channels (14) for handling and positioning embryos provide the opportunity to evaluate and treat embryos in improved manners. Fluid flow is used to move and position embryos within microfluidic channels and channel geometrics may be used to place embryos at specific locations. Surface properties and compliance (deformation) properties of embryos are evaluated as a predictor of viability. The microfluidic channels provide the opportunity for fine controls of pressure to conduct various evalutions at forces slightly below which damage to embryos is known to occur. Measurement of the distance and / or which embryos roll in a same pressure gradient microfluidic channel provides information, with healthy embryos traveling slower or a shorter distance as they demonstrate more stiction to channel walls. Positioned at a constriction (14a, 14b, 24, 26), health embryos also appear to deform less than unhealthy embryos that are more readily pulled into a constriction. In addition, healthy embryos appear to resume their shape better. Fluid from microfluidic channels is easily collected downstream without altering the embryo environment, providing a better opportunity for chemical analysis of fluid chemical analysis than convention manual handling and sampling techniques. Zona pellucida removal of mammalian embryos is achieved as embryos are moved through flow to a precise location where lysing agent can be washed over the embryo to achieve zona removal. Cumulus removal is realized with a series of constrictions to cut cumulus followed by fluid flows to remove cut cumulus from the embryo.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

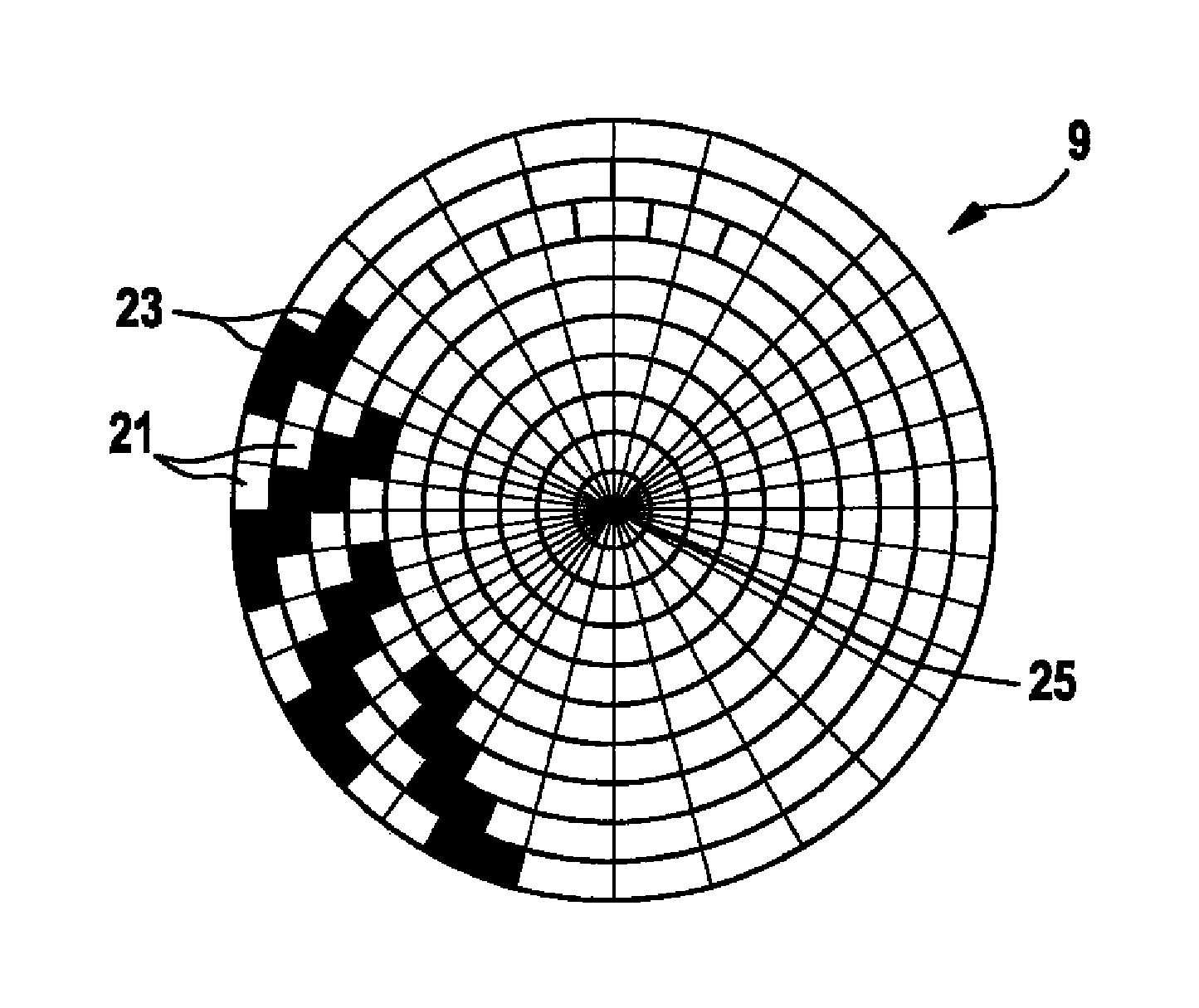

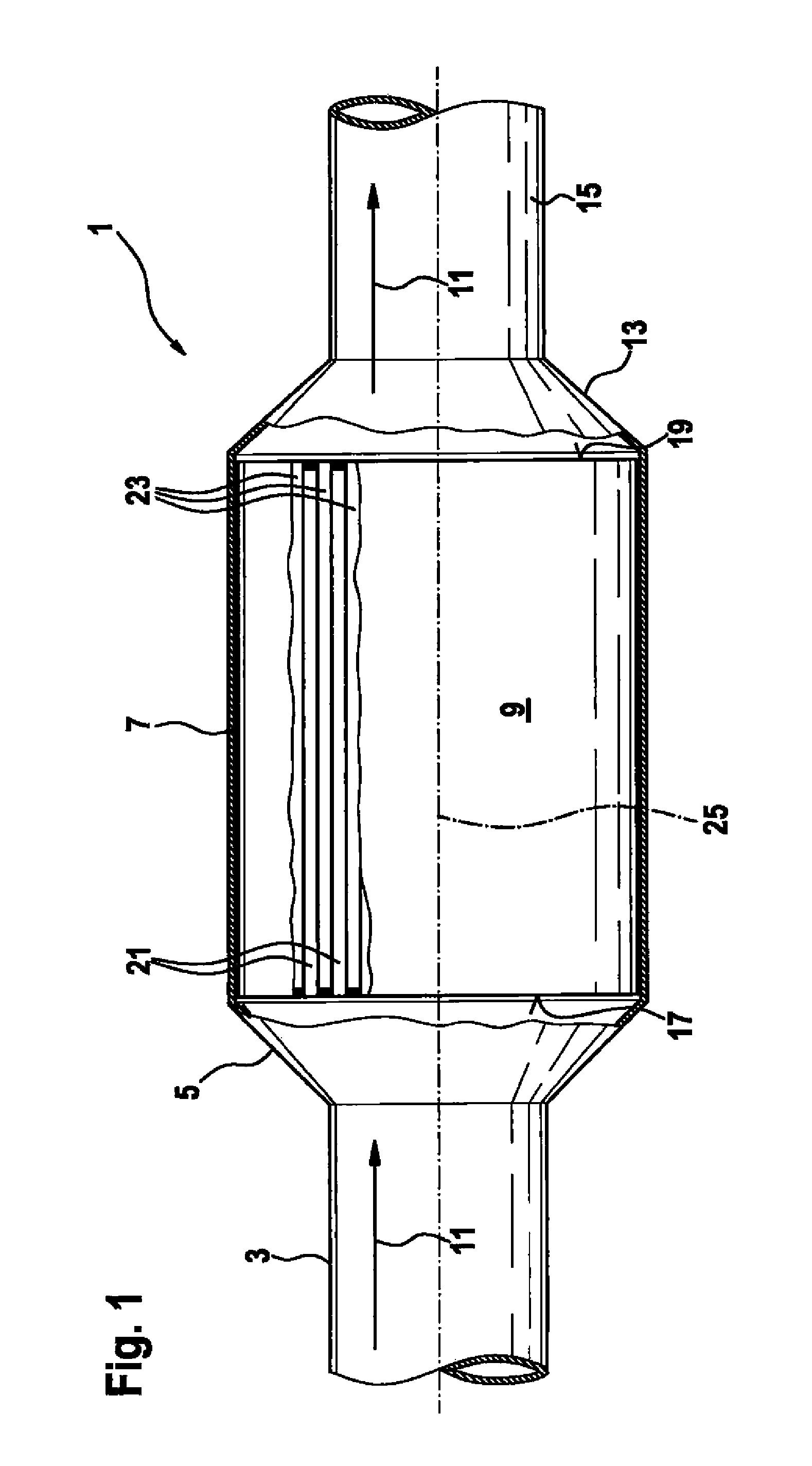

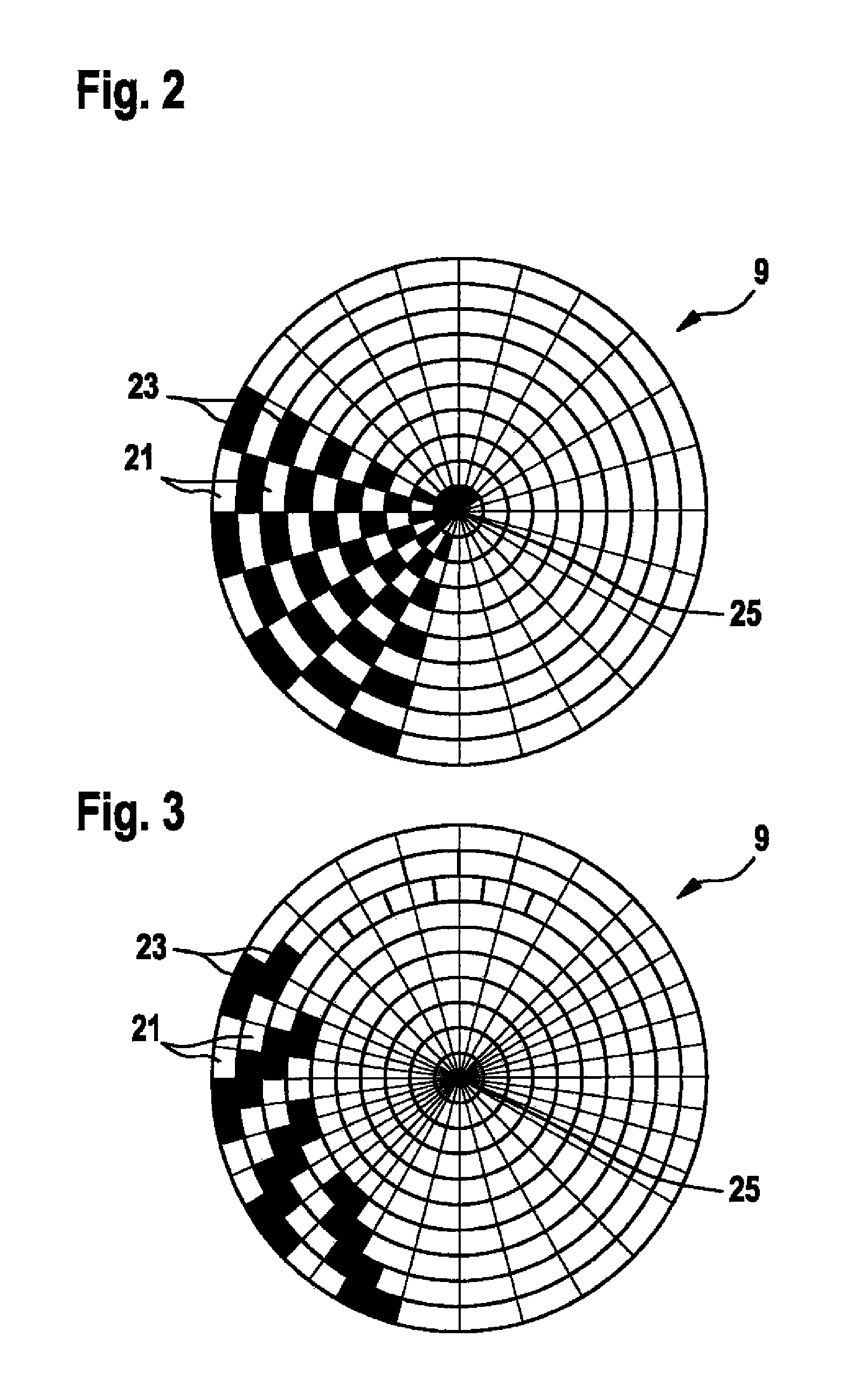

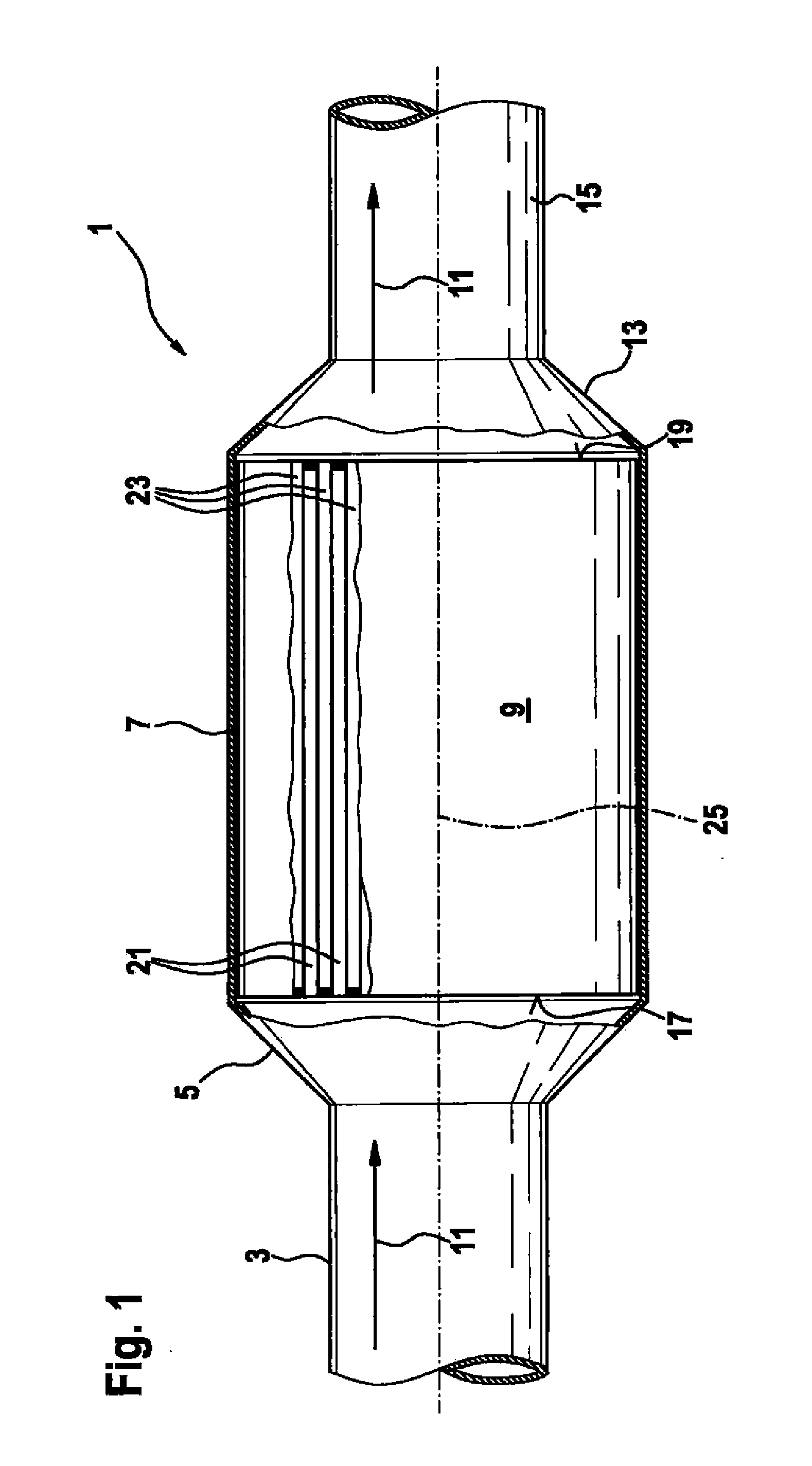

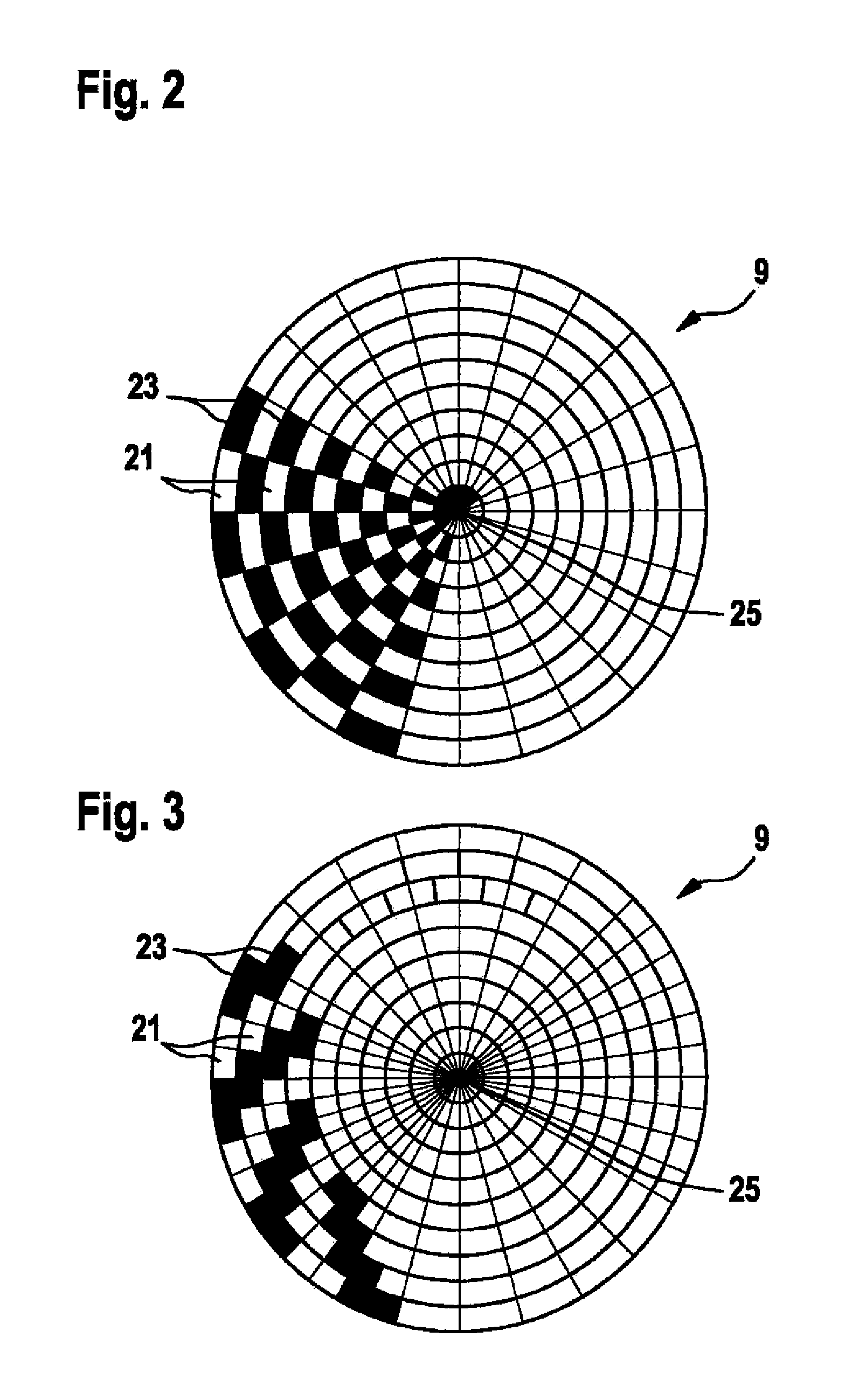

Filter element and soot filter having geometrically similar channels

InactiveUS8257460B2Extended service lifeEasy to operateCombination devicesInternal combustion piston enginesChannel geometryEngineering

A filter element and a soot filter are provided, in which resistance against thermal shocks is improved due to the channel geometry.

Owner:ROBERT BOSCH GMBH

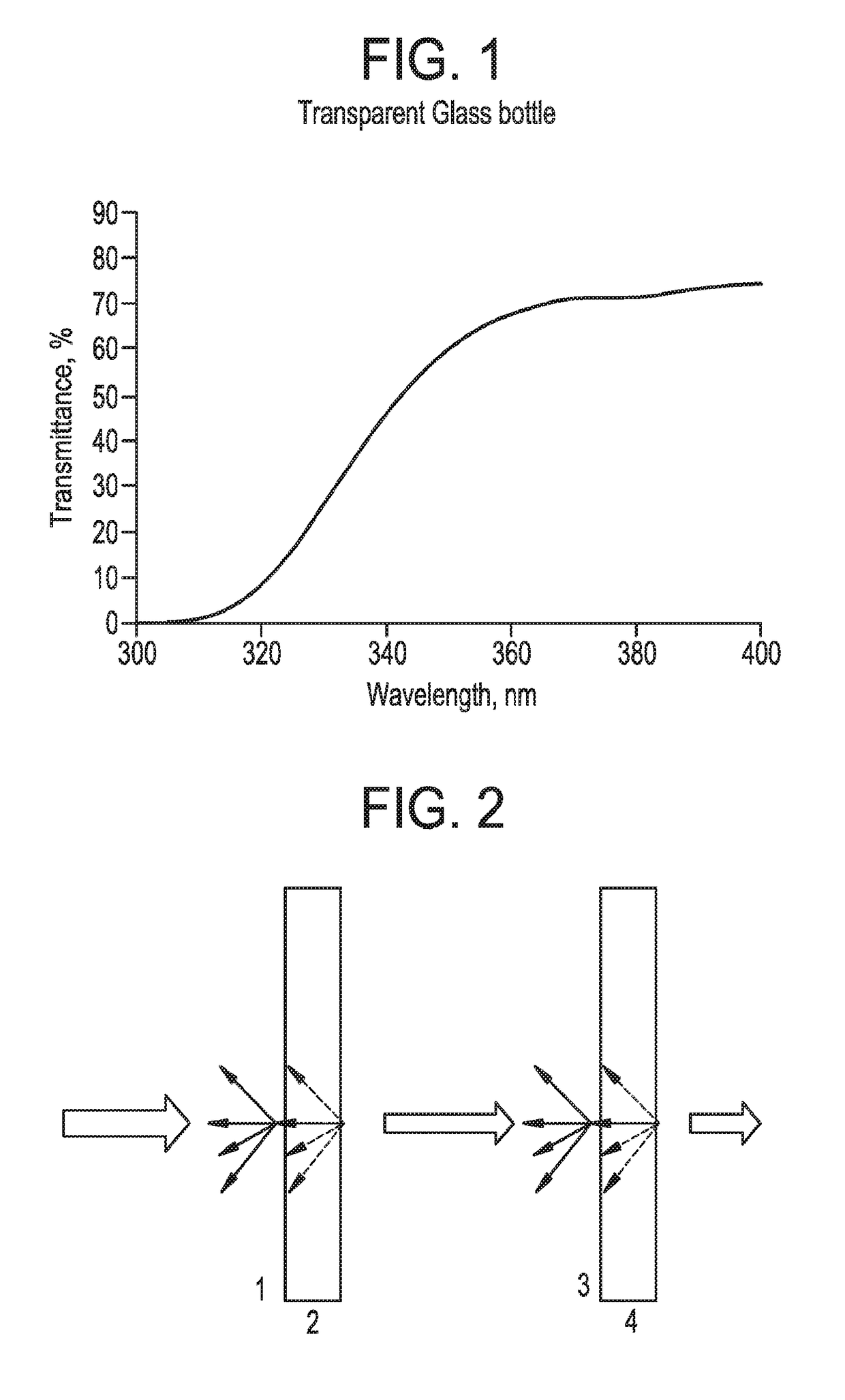

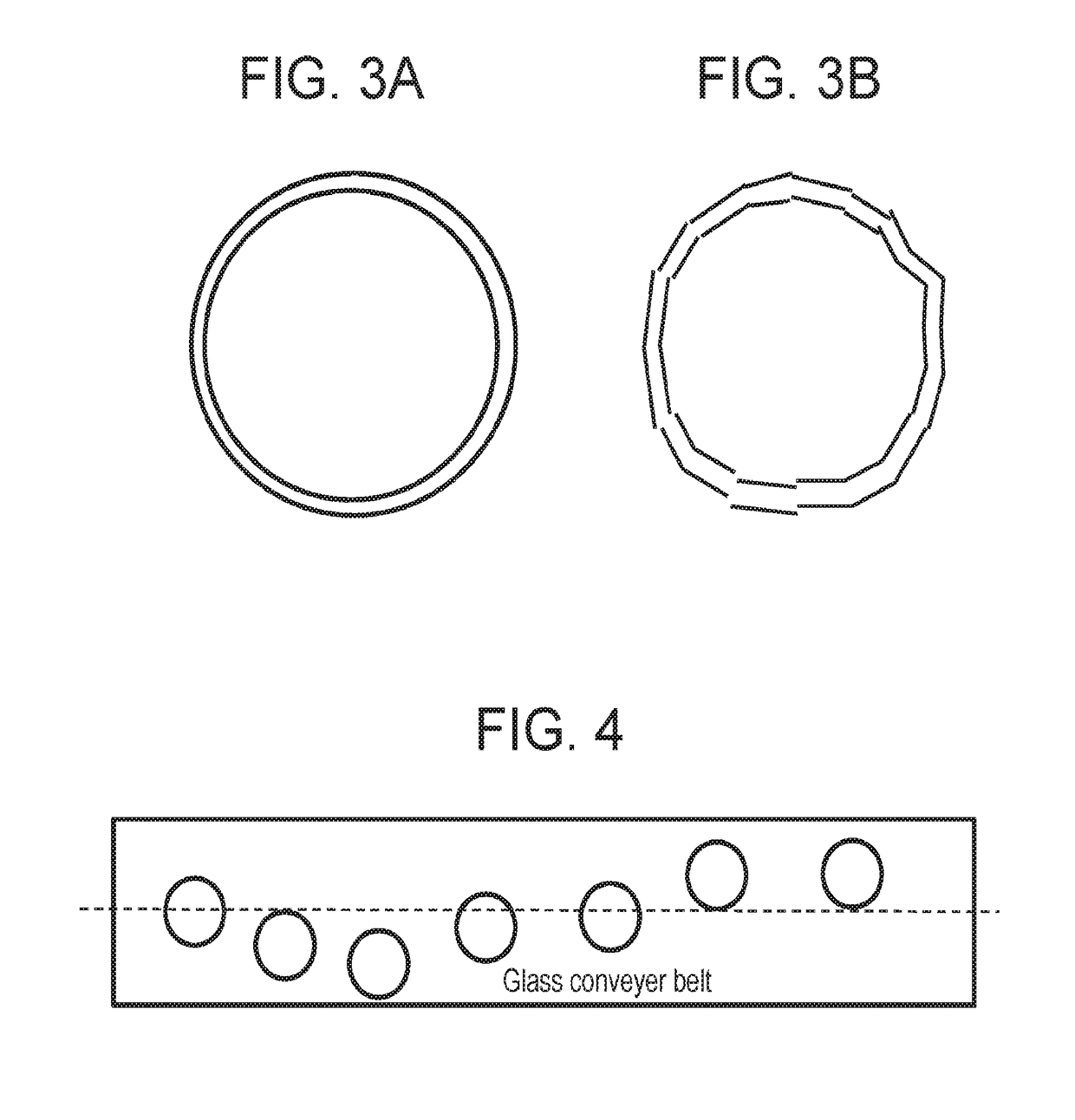

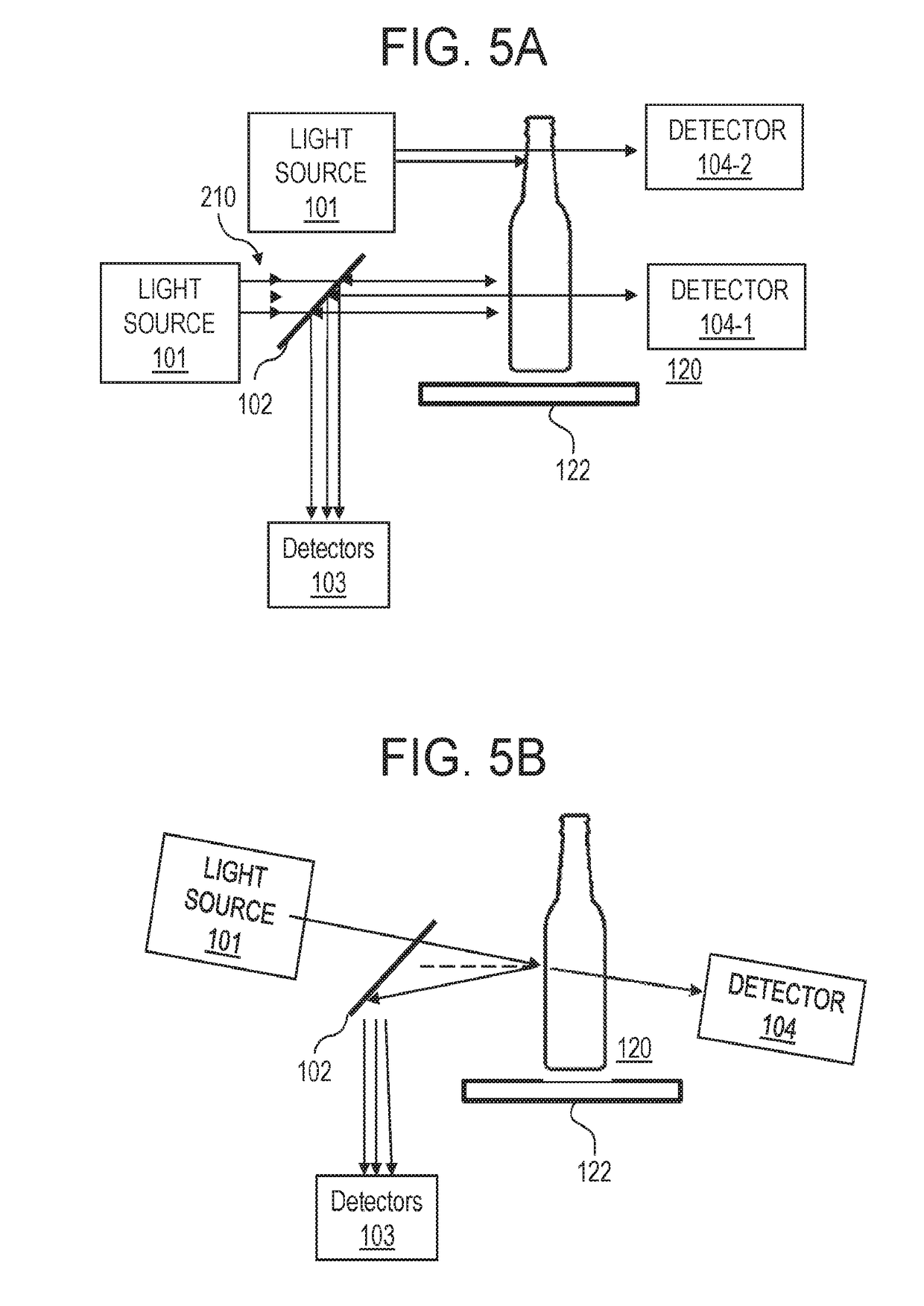

Object position independent method to measure the thickness of coatings deposited on curved objects moving at high rates

ActiveUS20190011251A1Accurate measurementAccurately identifying small change in coating thicknessColor/spectral properties measurementsUsing optical meansChannel geometryHigh rate

Methods and apparatus for measuring a thickness of a coating on an moving object are provided. Light is directed toward the object at a predetermined location on the object such that a portion of the light interacts with the object. A I D and / or 2D maximum intensities for at least one wavelength channel is captured that is produced by the portion of the light interacting with the object. A measured average intensity of the wavelength channel and / or intensities and their arithmetic derivatives of multi wavelength channel geometries is converted into I D (averaged) and / or 2D thickness values. Based on these values an acceptability of the coating is evaluated and thickness calculated.

Owner:ARKEMA INC

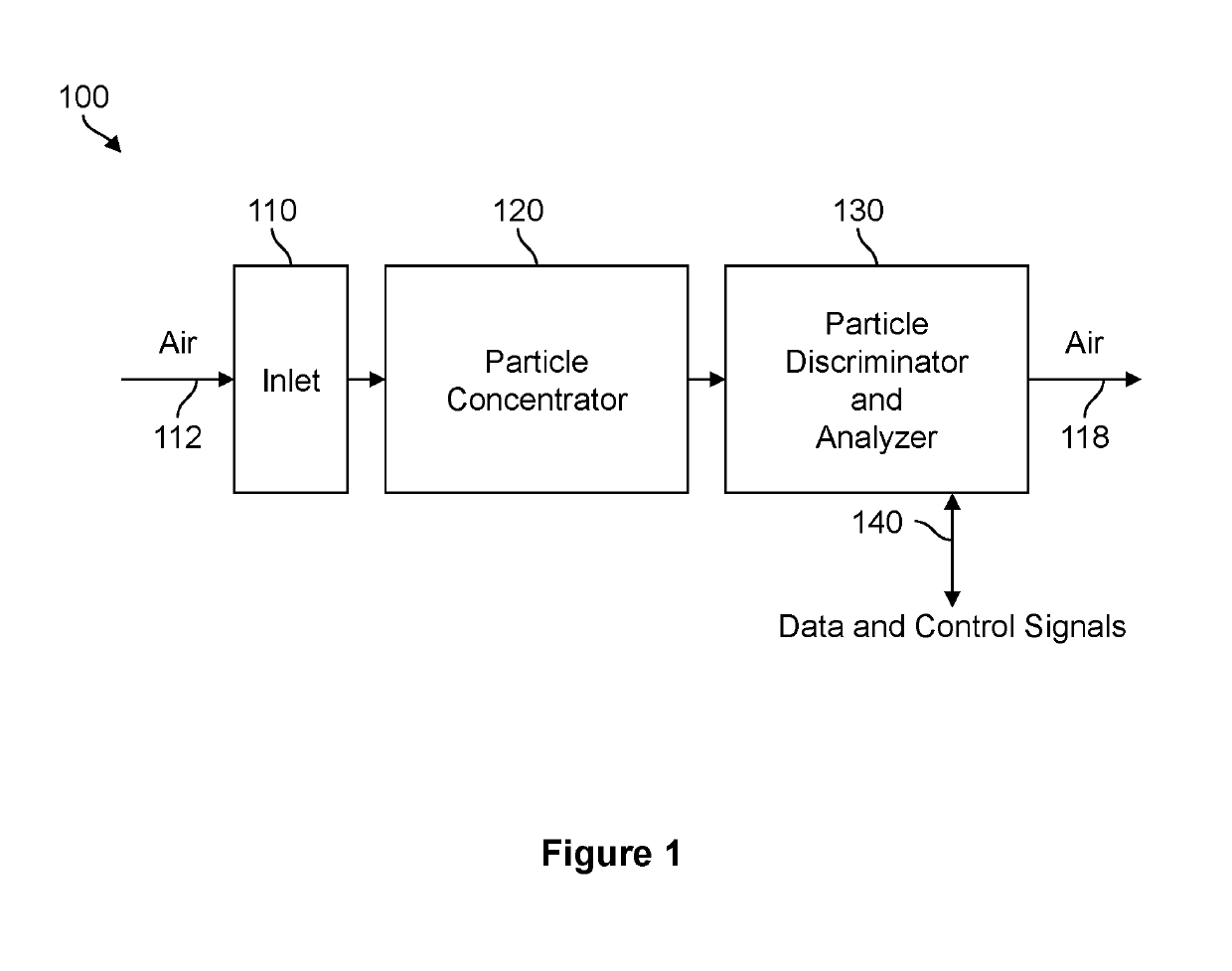

Thermophoretic particle detection system with variable channel geometry

ActiveUS20190145874A1High thermal gradientLarge thermophoretic forceCellsWithdrawing sample devicesDiscriminatorChannel geometry

A system for detecting and analyzing particles in an air stream includes an inlet, a particle concentrator and a particle discriminator having an air channel with a cross-sectional geometry that changes within at least one of the inlet, particle concentrator and particle discriminator. The system may have a sheath air stage including a port for providing sample air, at least one sheath air inlet port for providing sheath air, and a sheath air combining region. The system may include an airflow compression stage having a varying air channel that narrows as the air stream traverses the airflow compression stage to pre-concentrate particles within an interior region of the air stream. The system may include an airflow expansion stage having an air channel that widens to slow the airstream and particle velocities. A portion of the air channel height may be narrowed to allow a larger thermophoretic force to be generated.

Owner:AERODYNE MICROSYSTEMS INC

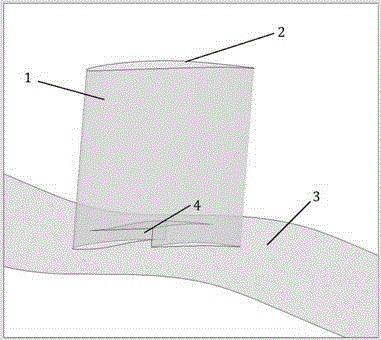

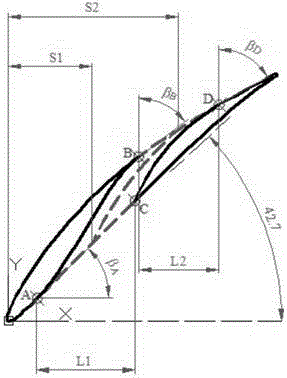

Gas compressor stator blade root slotting method based on optimization algorithm

ActiveCN105756719AGrooving geometry results of excellent leaf rootEngine manufacturePump componentsImpellerChannel geometry

The invention discloses a method for optimizing gas compressor stator blade root slotting channel geometry based on an optimization algorithm, and relates to the technical field of optimization algorithms and impeller mechanical flow control.The method aims at obtaining optimal blade root channel geometry through optimization calculation so that the angle area separation control effect of a force suction face can be optimal.By means of the gas compressor stator blade root slotting method based on the optimization algorithm, all design parameters of blade root channels can be subjected to coupling calculation and analysis, the optimal channel control effect is proposed based on an optimization calculation result, the coupling effect between the geometrical parameters of the channels can be comprehensively considered, and thus it is avoided that only changes of a single parameter or a few of parameters are calculated in flow optimization control.The optimization algorithm is a multi-target function optimization algorithm based on a non-domination ranking genetic algorithm, the S-shaped channels contracting to a force suction surface from a pressure surface are subjected to optimization calculation, the optimization parameters include inlet positions and outlet positions of the channels, lengths and channel heights, and a target function includes a blade grid total pressure loss coefficient, a static pressure raising coefficient and a blade grid channel blockage coefficient.The gas compressor stator blade root slotting method has the advantages that an optimization method and a blade grid flow control method are combined, channel geometry is optimized on the condition that the original blade grid blade shape is fixed, and thus the control effect is optimal.

Owner:BEIHANG UNIV

Exit lane monitoring system

InactiveUS8749344B2Kitchenware cleanersDigital data processing detailsChannel geometryMonitoring system

An exit lane monitoring system (10) detects wrong-way movement through a passage (P) between a secure area and a public area. Heel before toe sensors (12) are positioned on the floor of the passage and detect the foot pressure exerted by people moving through the passage from the secure area toward the public area and of persons moving the wrong way through the passage. Positioning of the sensors in the passage depends upon the geometry of the passage so sensors may be oriented in a non-geometric pattern if so dictated by the passage's geometry. A door (D) is selectively operated to block the passage and prevent persons moving the wrong way through it from entering the secure area. A control unit (16) is responsive to a sensor indication that someone is moving the wrong way to activate the door to block the passage and prevent movement into the secure area.

Owner:TEN4WARD

Assay device and method for performing biological assays

InactiveUS9040463B2Simple procedureEnhanced mass transferLibrary screeningLaboratory glasswaresChannel geometryEngineering

The invention provides a multiplexed assay device comprising a reaction chamber and several sets of encoded microcarriers 2 wherein the reaction chamber is a microchannel 1 and wherein the longitudinal movement of the microcarriers 2 is restricted and wherein the microcarriers 2 have a shape in relation to the geometry of the microchannel 1 such that at least two can stand side by side in the microchannel 1 without touching each other and without touching the perimeter of the microchannel 1 and are preferably observable in the reaction chamber. Moreover, the invention provides a method for performing multiplexed assay based on microcarriers 2 that improves mass transfer, simplifies the preparation and the execution of the assay and facilitates readout of biological reactions and identity of microcarriers 2.

Owner:MYCARTIS

Filter element and soot filter having geometrically similar channels

InactiveUS20100037573A1Extended service lifeEasy to operateCombination devicesAuxillary pretreatmentChannel geometryEngineering

A filter element and a soot filter are provided, in which resistance against thermal shocks is improved due to the channel geometry.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com