Gas compressor stator blade root slotting method based on optimization algorithm

A compressor and cotyledon technology, applied to components, stators, mechanical equipment, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

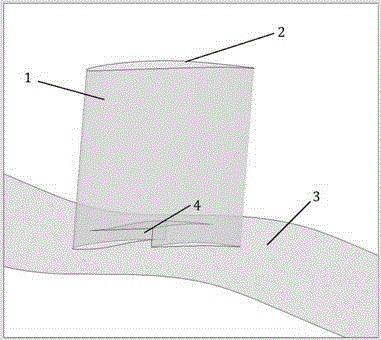

[0035] Such as figure 1 As shown, for a compressor stator cascade with slotted S-shaped blade roots, a tapered channel 4 is provided at the end wall 3 of the cascade root from the pressure surface 1 to the suction surface 2 of the cascade.

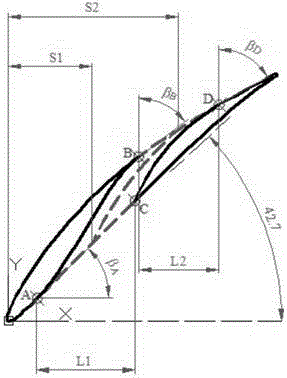

[0036] Such as figure 2 As shown, according to the flow field of the NACA prototype stator cascade, the slot geometry of the reference point is initially determined by the 4° angle of attack separation.

[0037] Combined with the actual geometry of the channel, the parameter ranges and reference values of the channel are shown in the table below:

[0038]

Minimum value (mm)

Reference value (mm)

Max(mm)

S1

Channel inlet position

25

40

60

S2

Channel exit position

40

60

80

L1

Channel inlet length

15

35

55

L2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com