Powder activated coke adsorption desulfurization device and method for adsorbing and desulfurizing flue gas by utilizing powder activated coke adsorption desulfurization device

A technology of adsorption desulfurization and desulfurization equipment, which is applied in the field of flue gas desulfurization, and can solve the problems of low adsorption efficiency and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

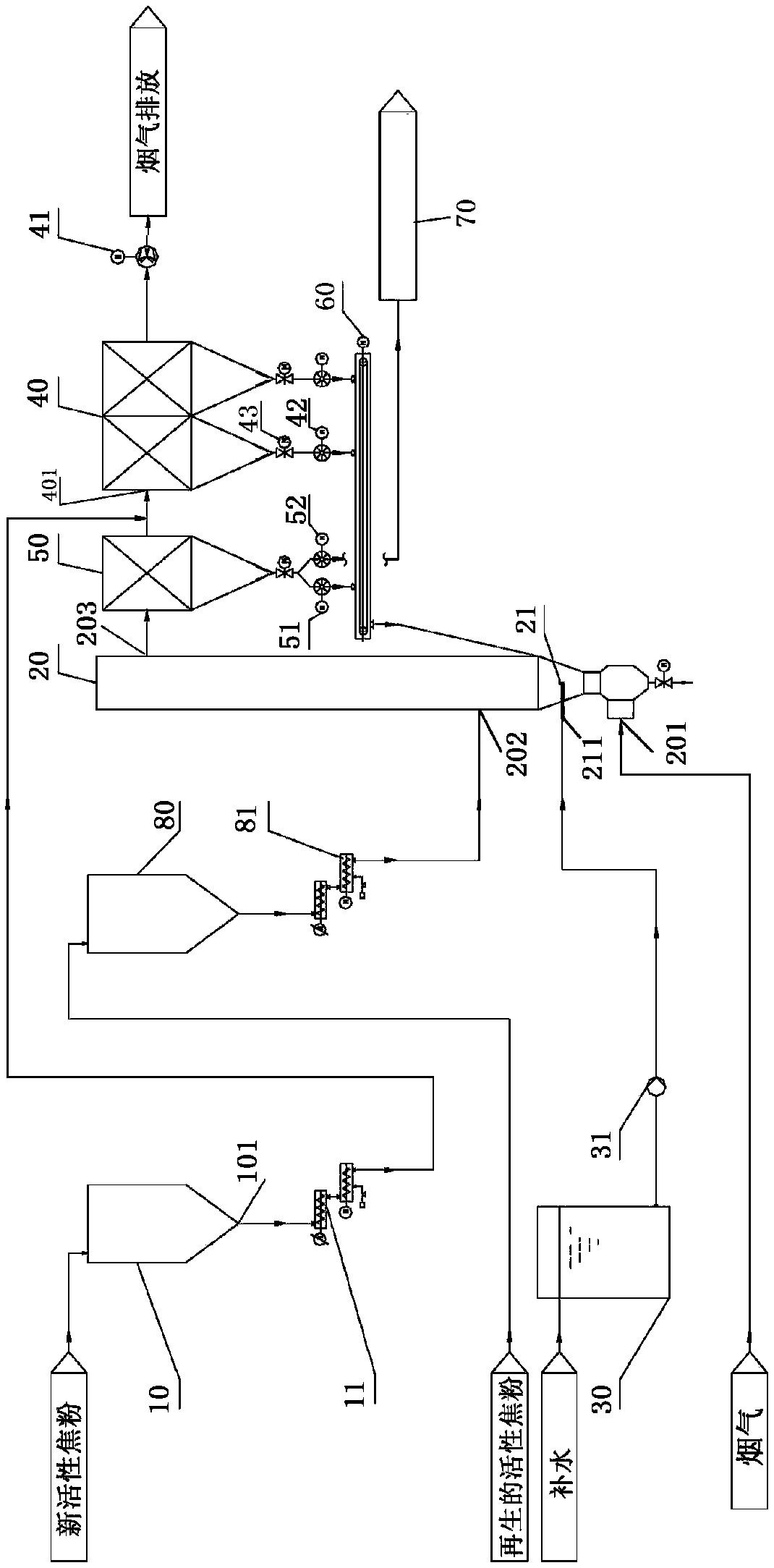

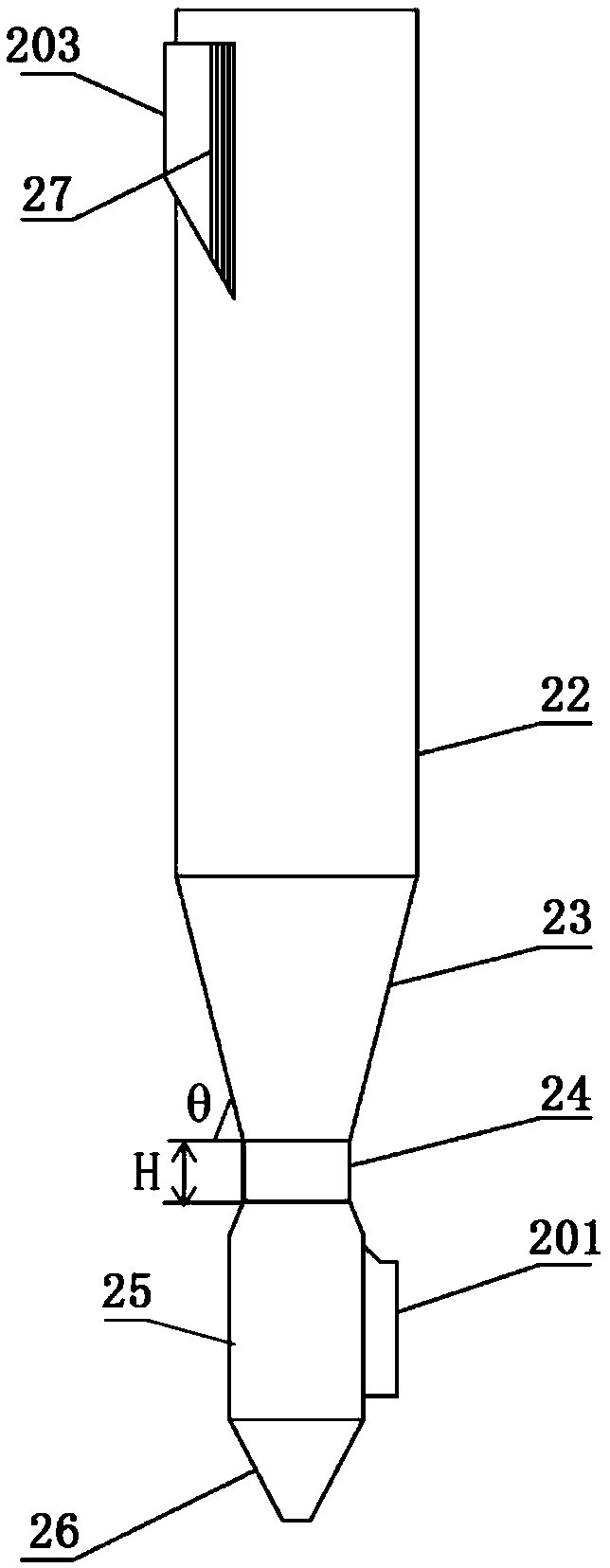

[0070] use figure 1 with 2 The shown powder activated coke adsorption desulfurization device performs adsorption desulfurization treatment on sulfur-containing flue gas, in which the diffusion angle of the fluidized bed desulfurization device 20 is 60°C, the length of the reduced diameter section 24 is 2m, and the particle size of the powdery active coke is 100 μm .

[0071] The treatment process is as follows: the above-mentioned sulfur-containing flue gas is passed into the fluidized bed desulfurization device 20 for adsorption and desulfurization to obtain desulfurized flue gas. The flow velocity of the section 24 is 50m / s, the flow velocity of the straight section 22 is 4.5m / s, and the residence time of the flue gas in the fluidized bed desulfurization device 20 is 6s.

[0072] After treatment, the desulfurization rate of sulfur-containing flue gas is 99.3%.

Embodiment 2

[0074] The difference from Example 1 is that during the desulfurization process, the temperature in the fluidized bed desulfurization device is 80° C., and the bed pressure of activated coke is 2500 Pa. The desulfurization rate of sulfur-containing flue gas is 98.9%.

Embodiment 3

[0076] The difference from Example 1 is that during the desulfurization process, the temperature in the fluidized bed desulfurization device is 105° C., and the bed pressure of activated coke is 1200 Pa. The desulfurization rate of sulfur-containing flue gas is 97.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com